Modification method of large-scale crane ship

A crane ship, large-scale technology, applied in the direction of ship hull, hull deck, ship construction, etc., can solve the problems of a large amount of capital, slow effect, long construction period, etc., to achieve large economic benefits, time and cost savings, and rapid deployment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

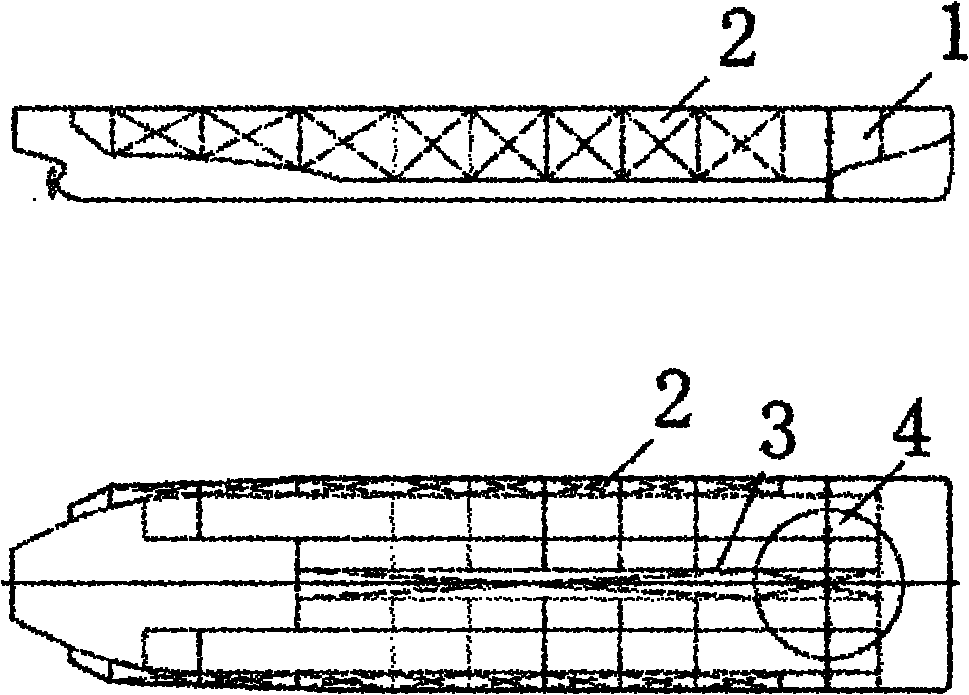

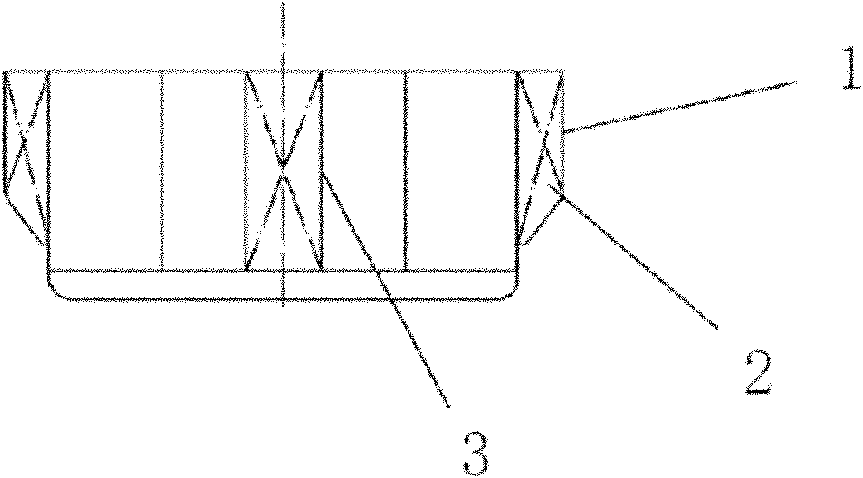

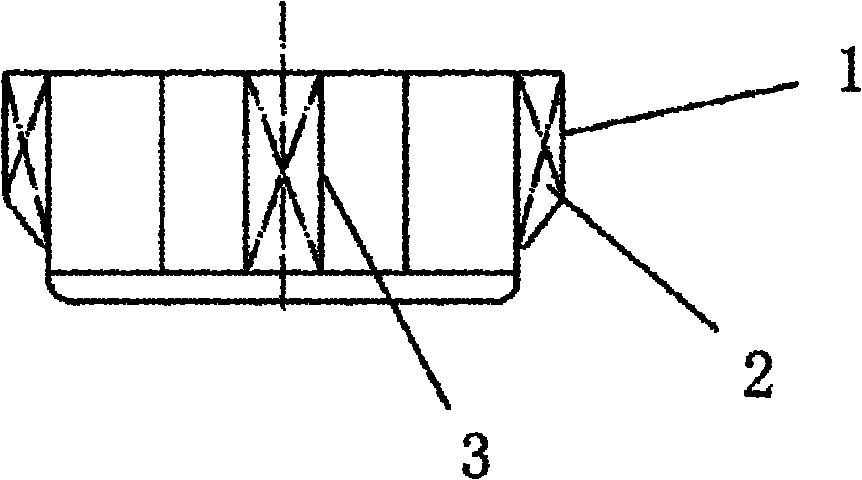

[0023] Such as figure 1 As shown, this embodiment includes the following steps:

[0024] The first step is to cut off the bow of the oil tanker to be transformed, add a modified bow that meets the lifting operation and speed requirements, and fix the crane base and anti-collision bulkhead on the transformed bow.

[0025] The modified bow is a multi-layer platform deck structure used as the basis for the rotatable support of the crane base, and is equipped with a fore peak tank, a bow pump room, a chain locker room and a side thruster room.

[0026] The anti-collision bulkhead is a watertight bulkhead, and the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com