Special-purpose needled felt for complex condition coal fired power plants and preparation method thereof

A technology for coal-fired power plants and complex working conditions, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of difficult manufacturing process, high price, difficult production and wide application, and improve the dust interception rate , low cost, and increased adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

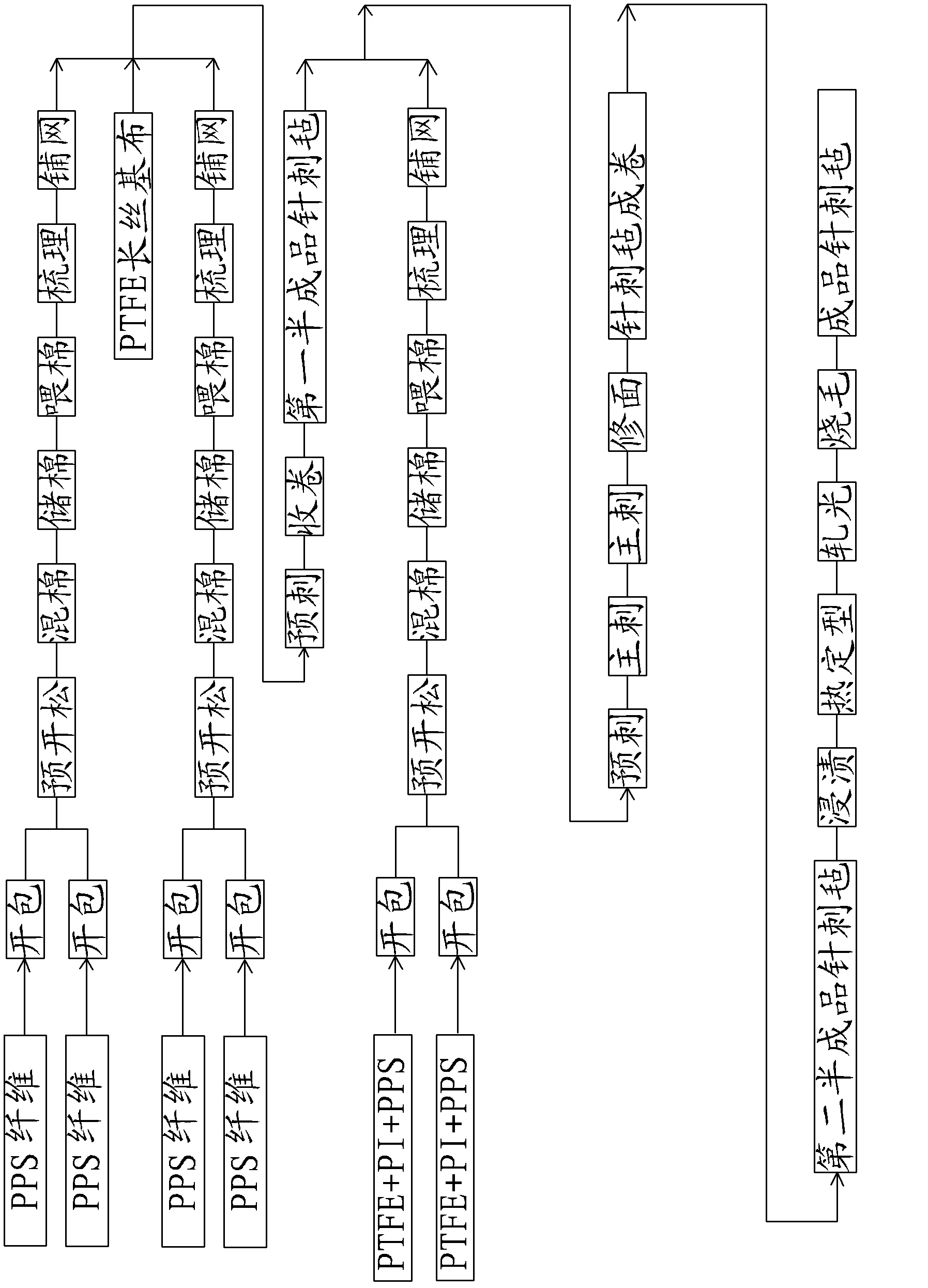

[0035] a. Preparation of plain felt:

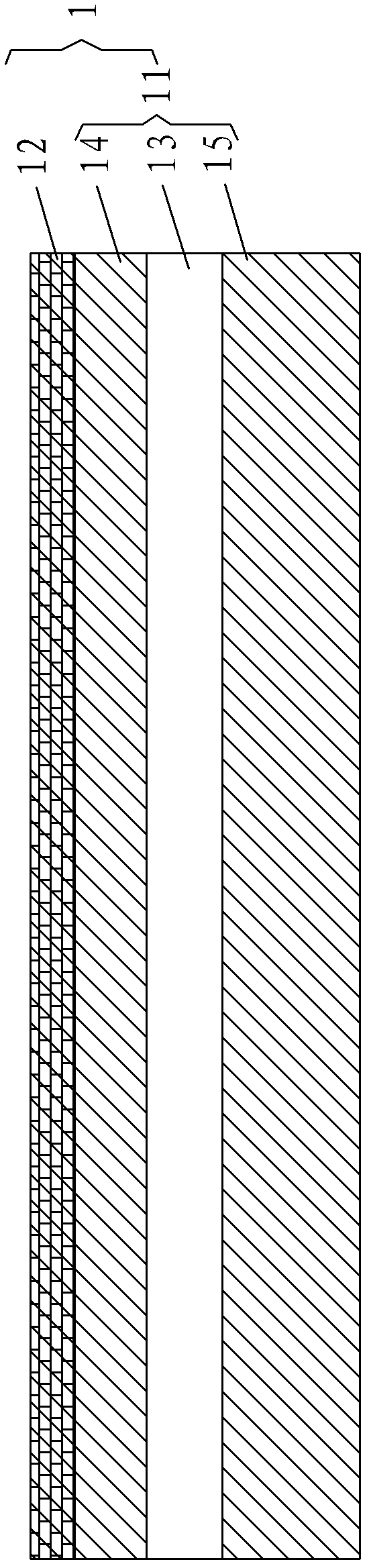

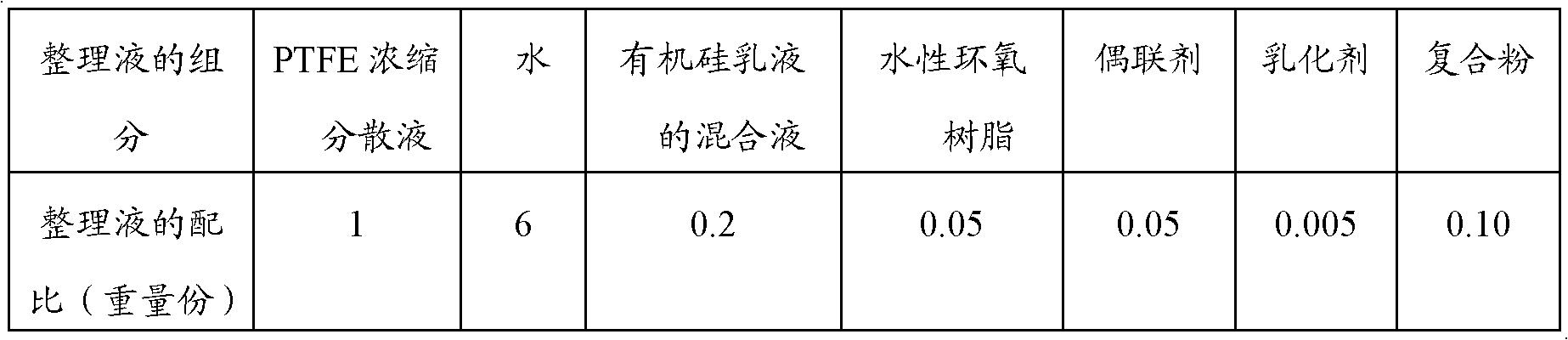

[0036] Weaving warp and weft with 100% PTFE filaments into a grammage of 130g / m 2 The reinforced base cloth layer 13 of the reinforced base cloth layer 13, after unpacking the 2 groups of PPS fibers respectively, carry out loosening, mixing and carding in sequence, respectively laying 2 groups of carded PPS fibers on the upper and lower surfaces of the reinforced base cloth layer 13, through this laying The first semi-finished needle-punched felt 11 is rolled into a roll after prepunching; the first semi-finished needle-punched felt 11 includes an auxiliary filter layer 14 punctured by PPS fibers that are needle-punched up and down sequentially, and a reinforced base cloth woven by PTFE filaments. Layer 13, and the support layer 15 punctured by PPS fibers, the number of laying layers is: 12 layers on the support layer 15, 6 layers on the auxiliary filter layer 14, and the weight after pre-stabbing is guaranteed to be 440g / m 2 ; By contro...

Embodiment 2

[0055] a. Preparation of plain felt:

[0056] Weaving warp and weft with 100% PTFE filaments into a grammage of 130g / m 2 The reinforced base cloth layer 13 of the reinforced base cloth layer 13, the two groups of PPS fibers are respectively unpacked and then pre-opened, mixed and carded sequentially, and two groups of carded PPS fibers are respectively laid on the upper and lower surfaces of the reinforced base cloth layer 13, through which The first semi-finished needle-punched felt 11 is formed into a roll after laying and prepunching; the first semi-finished needle-punched felt 11 includes an auxiliary filter layer 14 made of PPS fibers that are needle-punched up and down sequentially, and a reinforcement made of PTFE filaments. The base fabric layer 13, and the support layer 15 punctured by PPS fibers, the number of laying layers is: 12 layers on the support layer 15, 6 layers on the auxiliary filter layer 14, and the weight after pre-stabbing is guaranteed to be 440g / m 2...

Embodiment 3

[0067] a. Preparation of plain felt:

[0068] Weaving warp and weft with 100% PTFE filaments into a grammage of 130g / m 2 The reinforced base cloth layer 13 of the reinforced base cloth layer 13, after unpacking the 2 groups of PPS fibers respectively, carry out loosening, mixing and carding in sequence, respectively laying 2 groups of carded PPS fibers on the upper and lower surfaces of the reinforced base cloth layer 13, through this laying The first semi-finished needle-punched felt 11 is rolled into a roll after prepunching; the first semi-finished needle-punched felt 11 includes an auxiliary filter layer 14 punctured by PPS fibers that are needle-punched up and down sequentially, and a reinforced base cloth woven by PTFE filaments. Layer 13, and the support layer 15 punctured by PPS fibers, the number of laying layers is: 12 layers on the support layer 15, 6 layers on the auxiliary filter layer 14, and the weight after pre-stabbing is guaranteed to be 440g / m 2 ;

[0069]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Warp strength | aaaaa | aaaaa |

| Warp strength | aaaaa | aaaaa |

| Weft strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com