Manufacturing method of bamboo-wood composite laminated timber

A bamboo-wood composite and manufacturing method technology, applied in the direction of wood layered products, manufacturing tools, wood processing appliances, etc. The effect of reduced strength difference, increased lateral strength, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

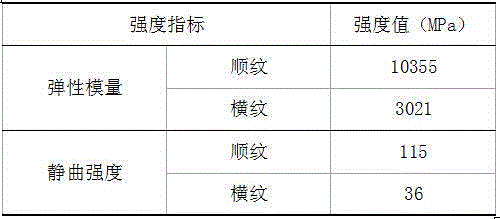

Embodiment 1

[0036] Embodiment 1: A kind of manufacturing method of bamboo-wood composite laminated lumber

[0037] 1) Raw material preparation

[0038] ① Bamboo beam processing

[0039] Using 3 to 5 years old moso bamboo and Ci bamboo as raw materials, the original bamboo is divided into 2 to 4 pieces by a bamboo breaking machine; the divided bamboo pieces are rolled into bamboo bundles by a bamboo silk processing machine, and the bamboo bundles are not connected to each other. Detachment, bamboo beam width is 5cm;

[0040] ②Wood processing

[0041] The wood veneer processed by rotary cutting, planing or sawing is used as raw material, and the thickness of the veneer is 3.0mm;

[0042] 2) dry

[0043] Bamboo bundles and wood veneers are dried to a moisture content of 10%;

[0044] 3) Bamboo bundle weaving

[0045] The bamboo bundles are processed into large-scale bamboo bundle veneers by weaving, the feed speed is 4m / min, and the distance between the braided wires is 20cm;

[0046]...

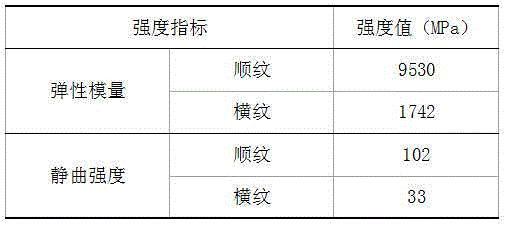

Embodiment 2

[0060] Embodiment 2: A kind of manufacturing method of bamboo-wood composite laminated lumber

[0061] 1) Raw material preparation

[0062] ① Bamboo beam processing

[0063] Using 3 to 5 years old moso bamboo and Ci bamboo as raw materials, the original bamboo is divided into 2 to 4 pieces by a bamboo breaking machine; the divided bamboo pieces are rolled into bamboo bundles by a bamboo silk processing machine, and the bamboo bundles are not connected to each other. Detachment, bamboo beam width is 6cm;

[0064] ②Wood processing

[0065] The wood veneer processed by rotary cutting, planing or sawing is used as raw material, and the thickness of the veneer is 5mm;

[0066] 2) dry

[0067] Bamboo bundles and wood veneers are dried to a moisture content of 8%;

[0068] 3) Bamboo bundle weaving

[0069] The bamboo bundles are processed into large-scale bamboo bundle veneers by weaving, the feed speed is 5m / min, and the distance between the braided wires is 30cm;

[0070] 4) d...

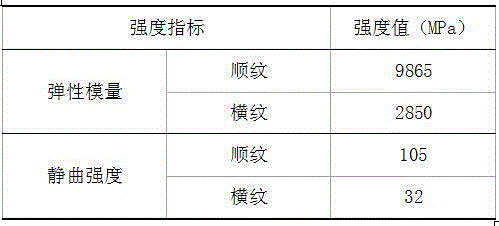

Embodiment 3

[0084] Embodiment 3: A kind of manufacturing method of bamboo-wood composite laminated lumber

[0085] 1) Raw material preparation

[0086] ① Bamboo beam processing

[0087] Using 3 to 5 years old moso bamboo and Ci bamboo as raw materials, the original bamboo is divided into 2 to 4 pieces by a bamboo breaking machine; the divided bamboo pieces are rolled into bamboo bundles by a bamboo silk processing machine, and the bamboo bundles are not connected to each other. Detachment, the width of the bamboo bundle is 7cm;

[0088] ②Wood processing

[0089] The wood veneer processed by rotary cutting, planing or sawing is used as raw material, and the thickness of the veneer is 1mm;

[0090] 2) dry

[0091] Bamboo bundles and wood veneers are dried to a moisture content of 12%;

[0092] 3) Bamboo bundle weaving

[0093] The bamboo bundles are processed into large-scale bamboo bundle veneers by weaving, the feed speed is 3m / min, and the distance between the braided wires is 40cm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com