High-density solid wood floor and producing method thereof

A technology for solid wood flooring and production method, which is applied in the direction of floor, building, building structure, etc., can solve the problems of affecting the overall decoration and beautiful floor life, insufficient compression density, large wood consumption, etc., to improve the utilization value and use. value, reduction in sawdust generation, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The production method of high-density solid wood flooring comprises steps as follows:

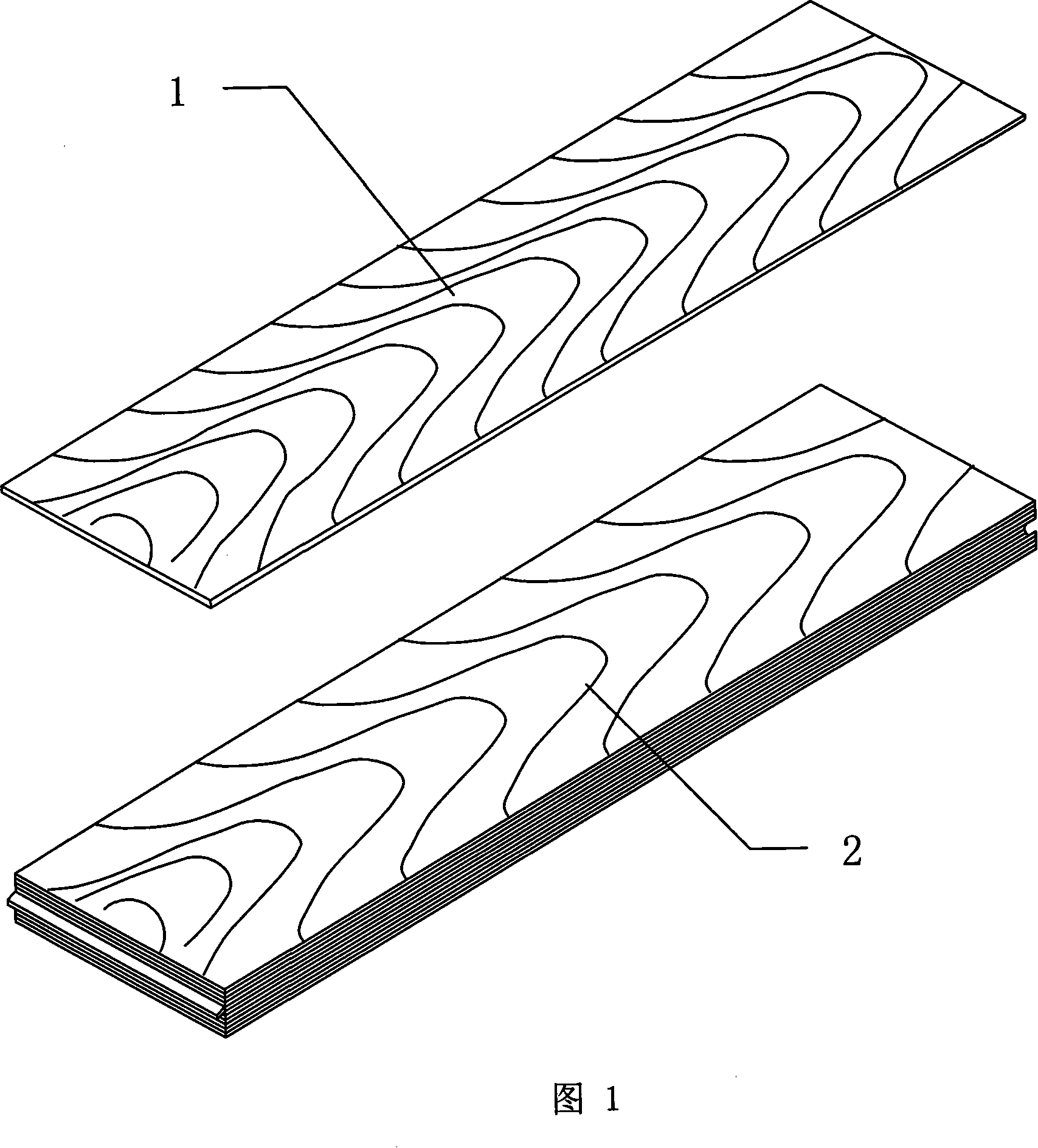

[0029] 1), the selected wood is rotary-cut into a rotary-cut veneer with a thickness of 1.3mm, and after cutting, it is used as a substrate 2 blank;

[0030] 2), the wood of the same tree species as in step 1) is cut vertically into a straight-cut veneer with a thickness of 2.5mm, and it is used as a panel 1 blank after cutting;

[0031] 3) The veneers obtained in the above steps 1) and 2) are boiled, degreased, and dried; the boiled veneers are baked and dried at a temperature of 60° C., so that the moisture content of the veneers is controlled within 6% ;

[0032] 4), apply adhesive to the rotary-cut veneer obtained in step 3) to form a blank, and the wood fiber direction of the 21-layer rotary-cut veneer of the described blank is consistent, and is the same as the length direction of the floor;

[0033] 5), applying pressure to the rotary-cut veneer obtained in step 4) to synthe...

Embodiment 2

[0039] The production method of high-density solid wood flooring comprises steps as follows:

[0040] 1), the selected wood is rotary-cut into a rotary-cut veneer with a thickness of 1mm, and after cutting, it is used as a substrate 2 blank;

[0041] 2), the wood of the same tree species as in step 1) is cut vertically into a straight-cut veneer with a thickness of 2mm, and it is used as a panel 1 blank after cutting;

[0042] 3), the veneers obtained in the above steps 1) and 2) are boiled, degreased, and dried; the boiled veneers are air-dried under natural conditions, so that the moisture content of the veneers is controlled within 6%;

[0043] 4), apply adhesive to the rotary-cut veneer obtained in step 3) to form a blank, the wood fiber direction of the 28-layer rotary-cut veneer of the described blank is consistent, and is the same as the length direction of the floor;

[0044] 5), press the rotary-cut veneer obtained in step 4) to form a high-density substrate 2 with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com