Floor slab for wooden structural building and producing method thereof

A technology for floor panels and wood structures, applied in floor panels, buildings, building components, etc., can solve the problems of immature technology, high cost, poor durability, etc., and achieve the effect of reducing thermal conductivity, preventing mildew, and improving horizontal and vertical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

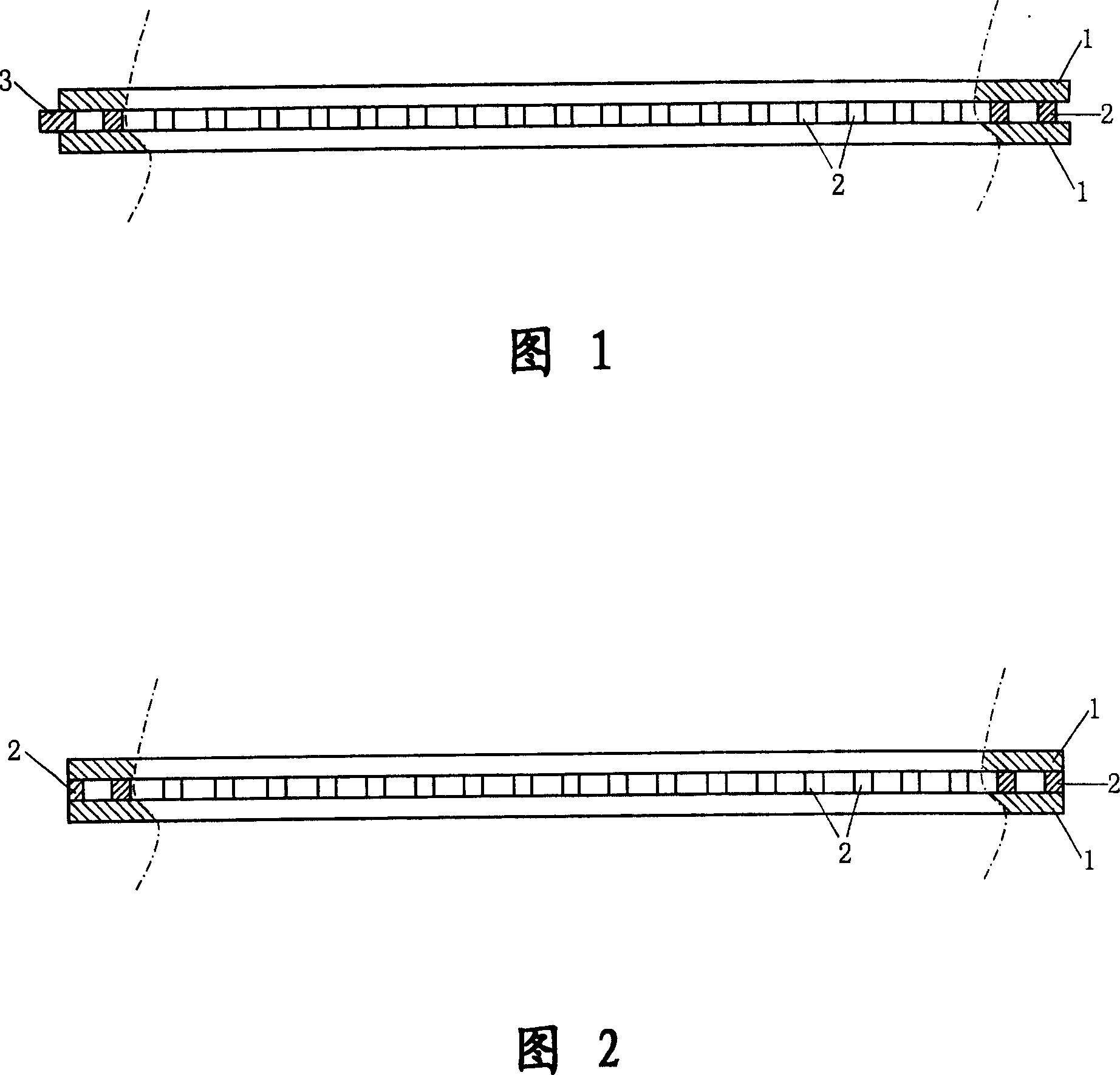

[0034] Use fir or poplar wood as raw material, sawn into sawn timber and dried to a moisture content of 8-10%, and further processed into three specifications of planks and strips (when the length of the wood is insufficient, it can be extended by finger joints):

[0035] Board 1: 50mm(width)×25mm(height)×1200mm(length)

[0036] Narrow wooden strip 2: 25mm (width) × 25mm (height) × 400mm (length)

[0037] Wide wooden strip 3: 50mm (width) × 25mm (height) × 400mm (length)

[0038] Utilize described plank and wood strip to be processed into and be used for wooden structure building floor board in the following manner:

[0039] As shown in Figure 1, apply two-component API glue on the side of the board 1, and the amount of glue on one side is about 240-260g / m 2 , using the lateral pressure of 1.5-2MPa when cold-pressing by the jigsaw machine, and the cold-pressing time is 50-60 minutes, to obtain the upper laminate and the lower laminate respectively;

[0040] After applying t...

Embodiment 2

[0045] Use fir or poplar wood as raw material, sawn into sawn timber and dried to a moisture content of 8-10%, and further processed into three specifications of planks and strips (when the length of the wood is insufficient, it can be extended by finger joints):

[0046] Board 1: 100mm (width) × 10mm (height) × 1200mm (length)

[0047] Narrow wooden strip 2: 10mm (width) × 10mm (height) × 800mm (length)

[0048] Utilize plank 1 and narrow strip 2 to be processed into the floor panel of three-layer structure according to the method for embodiment 1, but middle layer only adopts narrow strip 2 to be arranged in parallel with 1-2 times spacing, and does not form tongue and groove.

[0049] FIG. 2 is a schematic cross-sectional view of the floor slab, and its performance index refers to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com