Fully-automatic disk core shooter

A core shooter and fully automatic technology, applied in the field of aluminum alloy casting, can solve the problems of manual operation and occupation of space, and achieve the effect of improving utilization rate, low cost and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

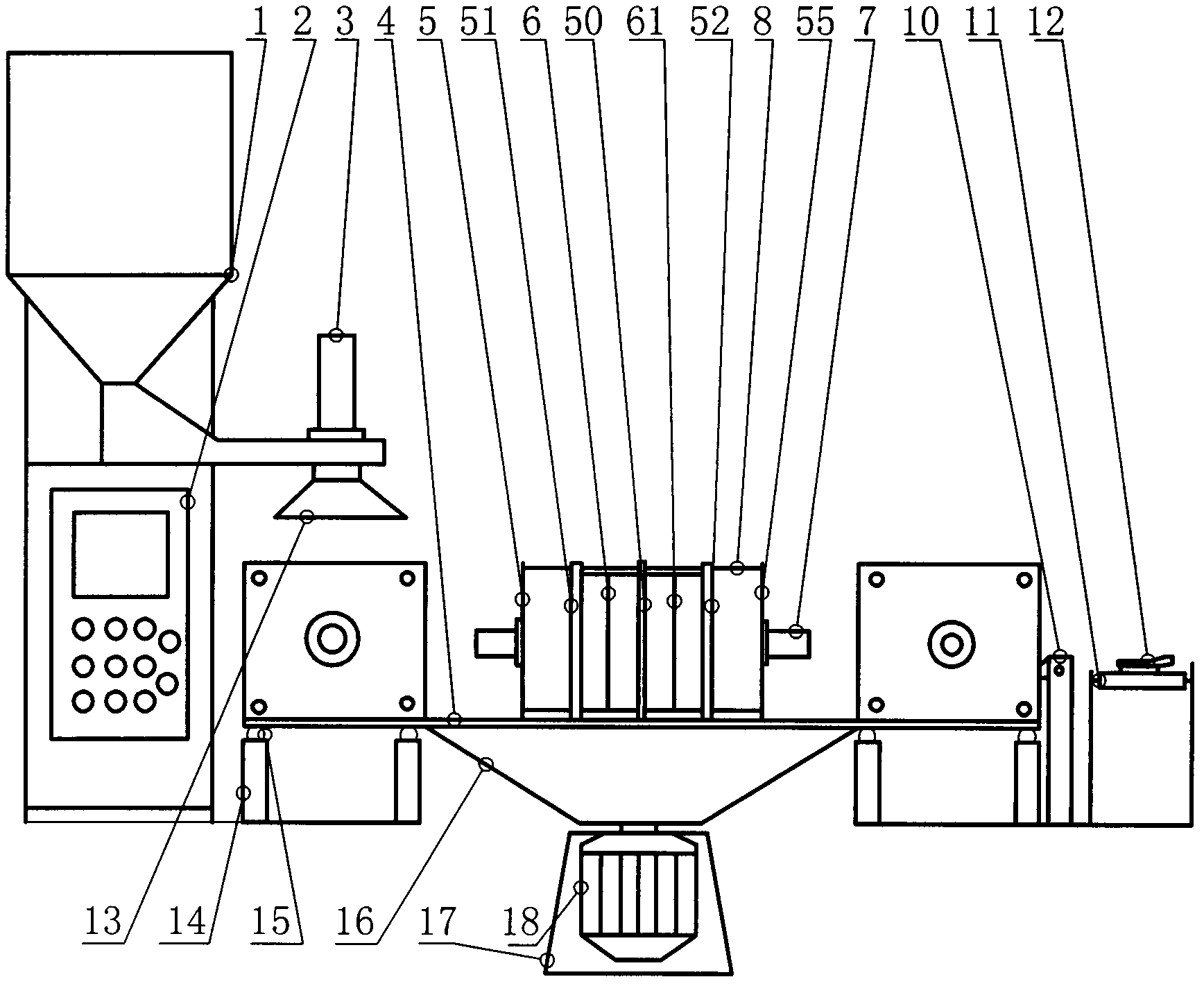

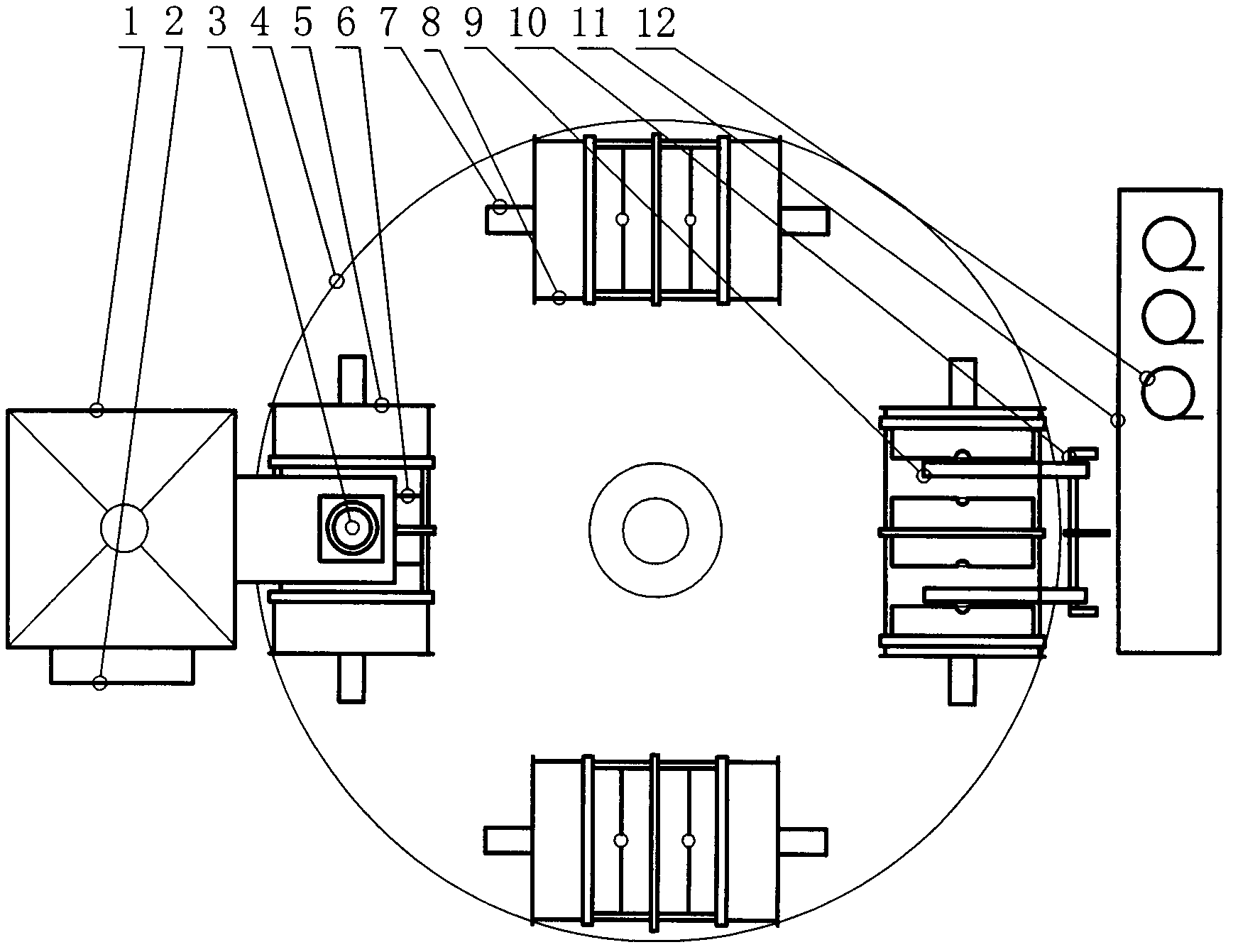

[0014] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] figure 1 , figure 2 It includes a hopper 1, a control cabinet 2, a cylinder 3, a coated sand injection device 13, a garden platform 4, a fixed plate at both ends 5, a fixed plate in the middle 50, a mobile hydraulic plate 51, a mobile hydraulic plate 52, a fixed plate at both ends 55, Sand core mold 6, hydraulic cylinder 7, guide column 8, pick-up arm 9, pick-up machine frame 10, sand core output machine 11, product 12, injection device 13, slide rail 14, pulley 15, disc support 16, Motor support 17, turntable motor 18 etc.

[0016] Such as figure 1 , figure 2 As shown, the present invention is a fully automatic disc core shooter, including a core shooter mechanism, a mold hydraulic mechanism, a disc machine mechanism, a mechanical pick-up mechanism, a control mechanism, and the like.

[0017] The core shooter mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com