High-electrical-conductivity graphene carbon-fiber electrical-conductive paper and preparation method thereof

A graphene-carbon fiber, high-conductivity technology, applied in the field of high-conductivity graphene-carbon fiber conductive paper and its preparation, can solve the problems of power drop, reduced electrical conductivity, limited contact conductivity, etc., so as to improve electrical conductivity and thermal efficiency, and improve contact conductivity. The effect of uniform distribution of carbon fiber and carbon fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments.

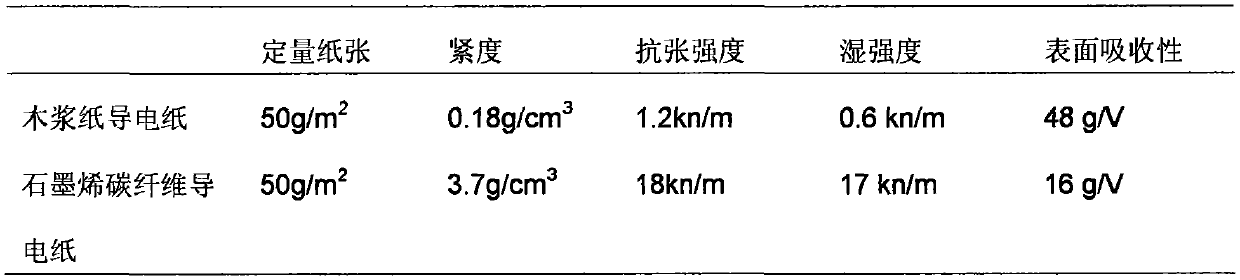

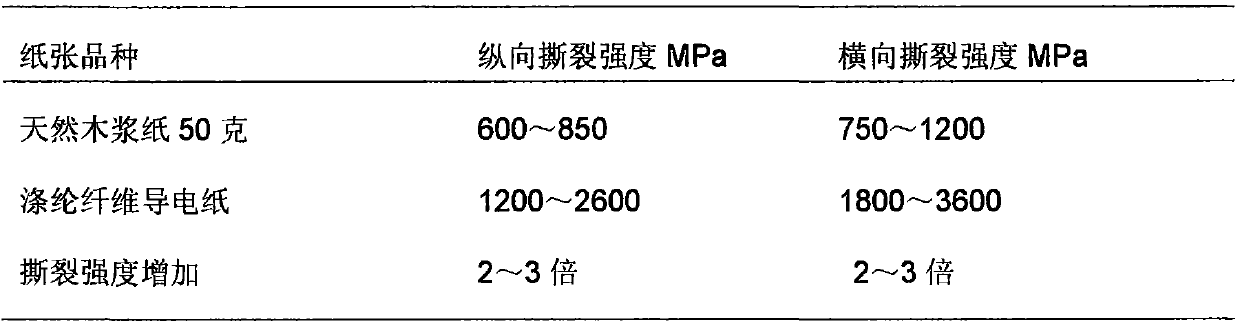

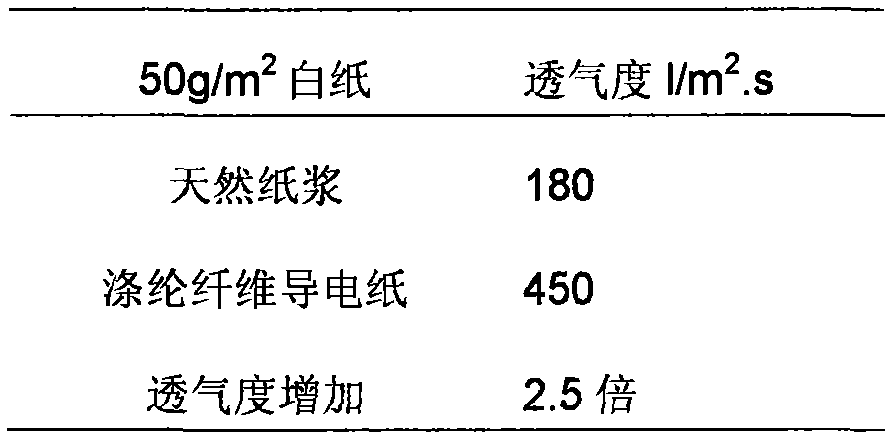

[0028] A highly conductive graphene carbon fiber conductive paper, comprising 50%-60% of polyester ultra-short fiber, 1%-3% of graphene powder, 25%-35% of wood pulp fiber, and 5%-15% of chopped carbon fiber.

[0029] The length of the chopped carbon fibers is 3 mm to 6 mm. The graphene powder is a multilayer graphene nano powder. The polyester ultra-short fiber has a length of 3 mm to 6 mm and a thickness of 0.8 to 1.6 mm. The wood pulp fiber is natural color wood pulp of chemical fiber.

[0030] The preparation method of above-mentioned a kind of highly conductive graphene carbon fiber conductive paper comprises the following steps:

[0031] 1) First take by weight 50% to 60% of polyester ultra-short fiber, 1% to 3% of graphene powder, 25% to 35% of wood pulp fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com