Thin type backlight module

A backlight module, thin technology, applied in the direction of optics, optical components, nonlinear optics, etc., can solve the problems of difficult design products, high labor costs of multi-layer assembly, and unsimplified production process, so as to achieve cost reduction and production More, the effect of reducing the number of assembled components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

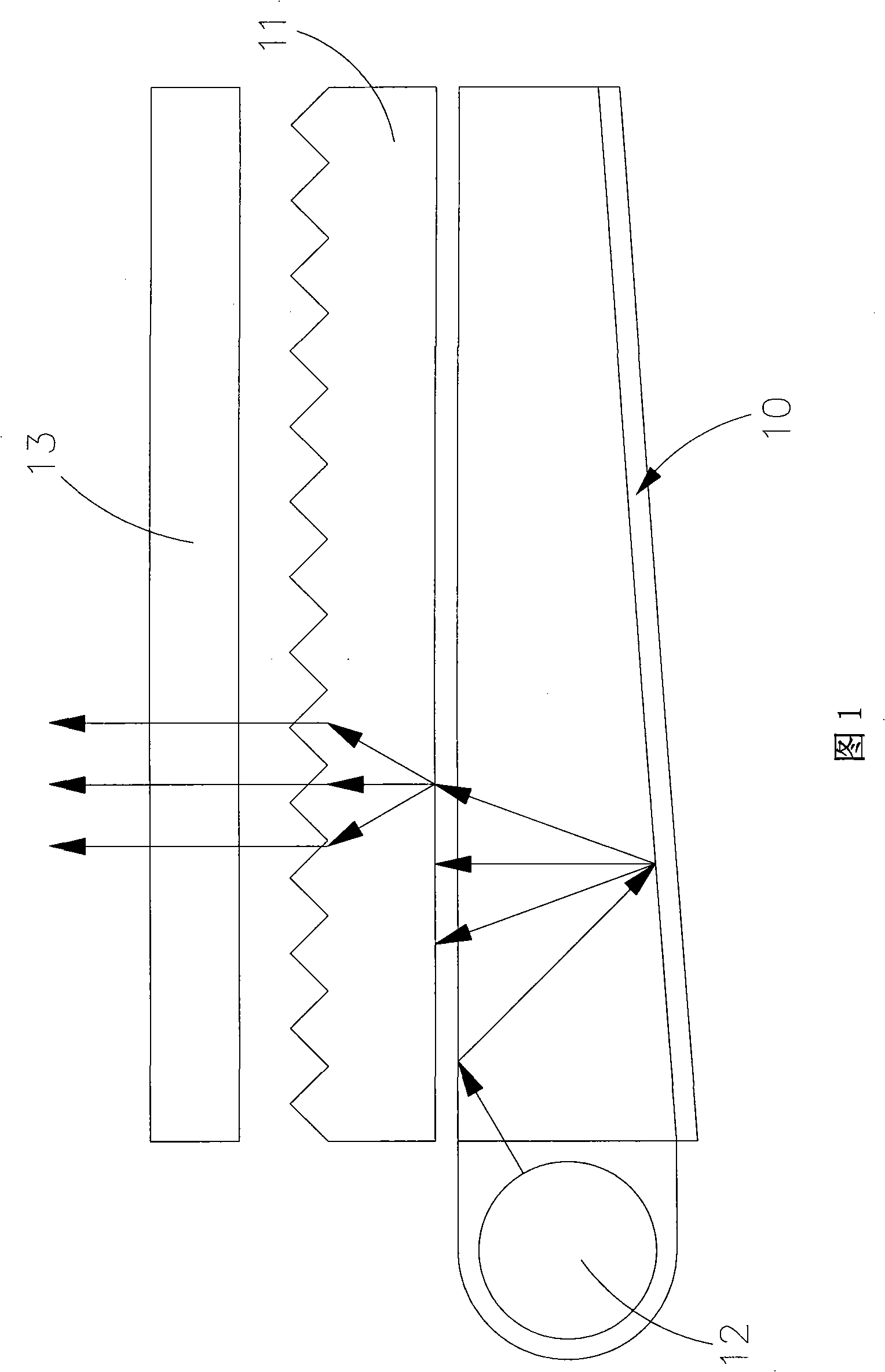

[0021] For the invention of this case to achieve the above-mentioned purpose, technology, means and other effects adopted, hereby enumerate a preferred embodiment and cooperate with the accompanying drawings to describe in detail as follows. It is believed that the purpose, characteristics and other advantages of the invention of the present case can be obtained by it. learn.

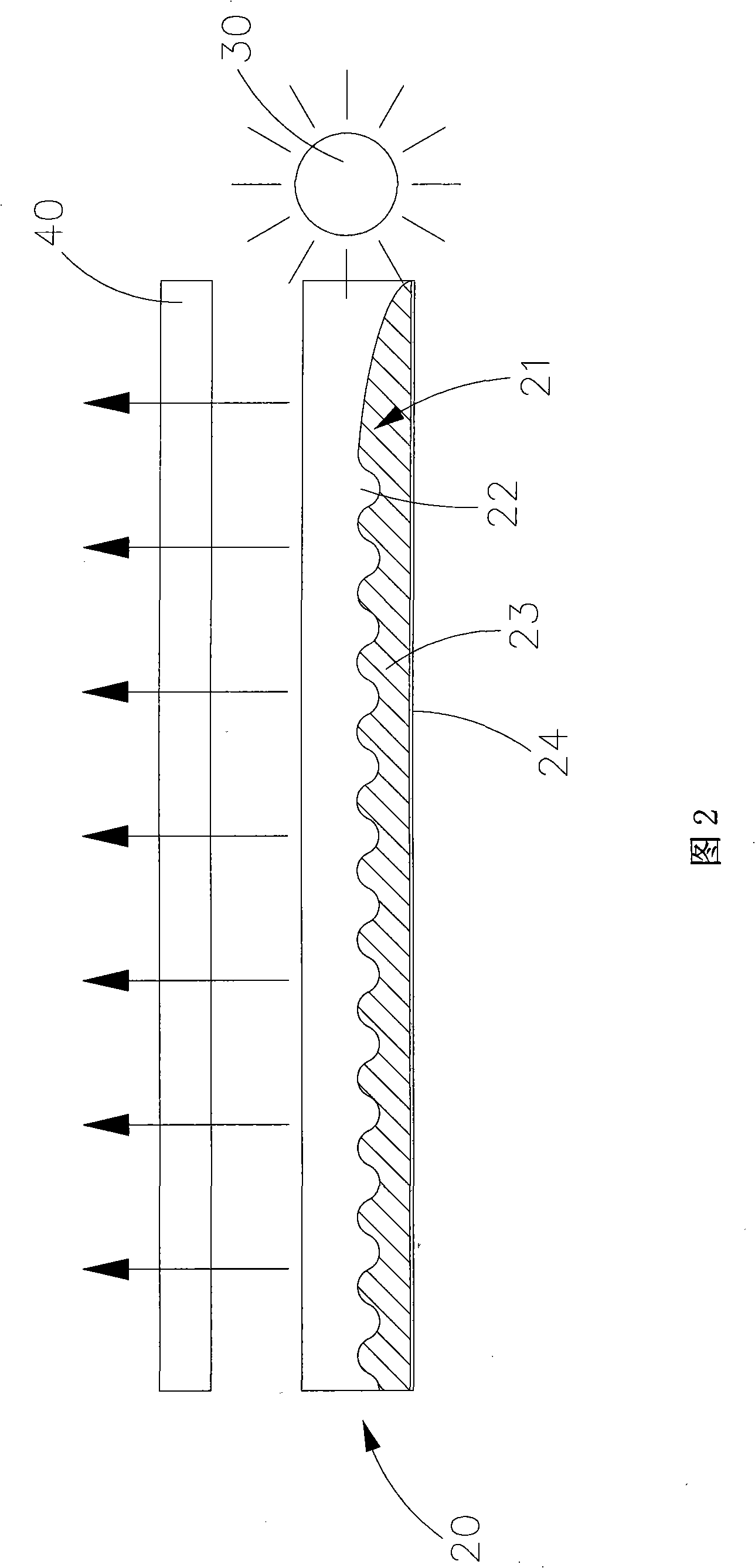

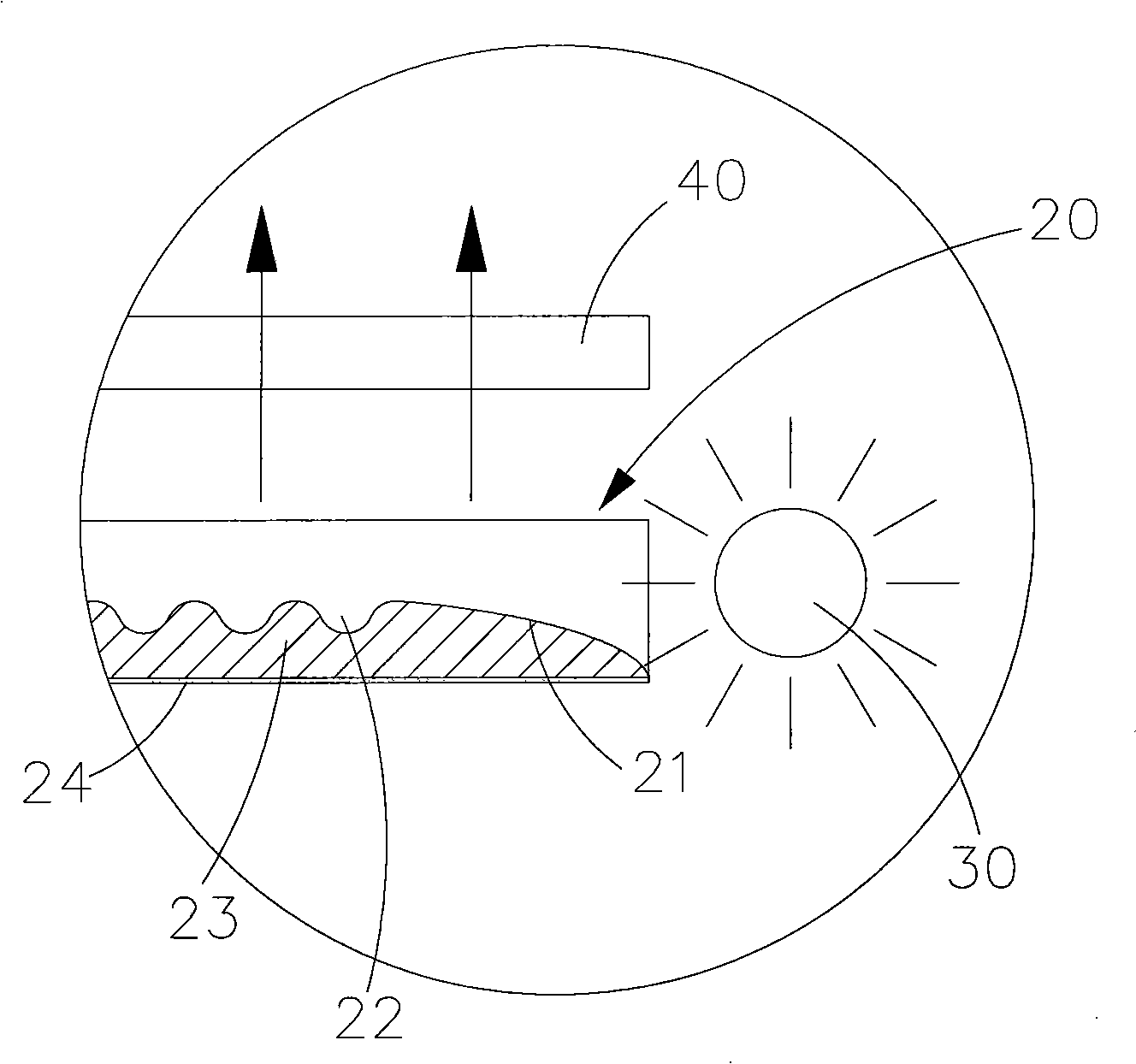

[0022] Embodiment of the present invention please refer to Fig. 2 to image 3 , the thin backlight module of the embodiment of the present invention is an edge-lit backlight module, but the present invention does not only limit the edge-lit backlight module as the only implementation mode;

[0023] The thin backlight module of the present invention is assembled with at least one light guide plate 20, at least one light source 30 and a display panel 40; its structural features are:

[0024] In the light guide plate 20, at least one surface 21 of the light guide plate 20 has a concave-convex light-guiding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com