Production line and production technology of flat filaments of flexible freight bags

A container bag and production line technology, which is applied in the field of container bag flat yarn production line and its production process, can solve the problems of complicated operation and long production line, and achieve the effects of simplified process, convenient operation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

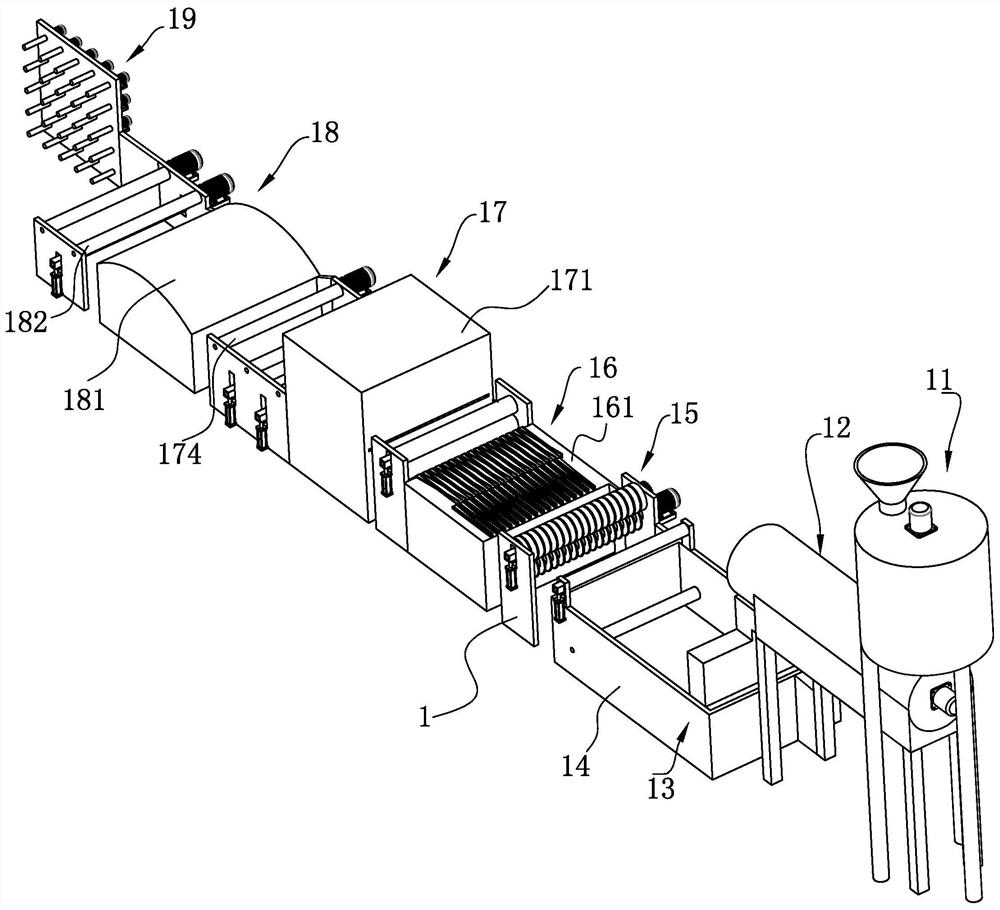

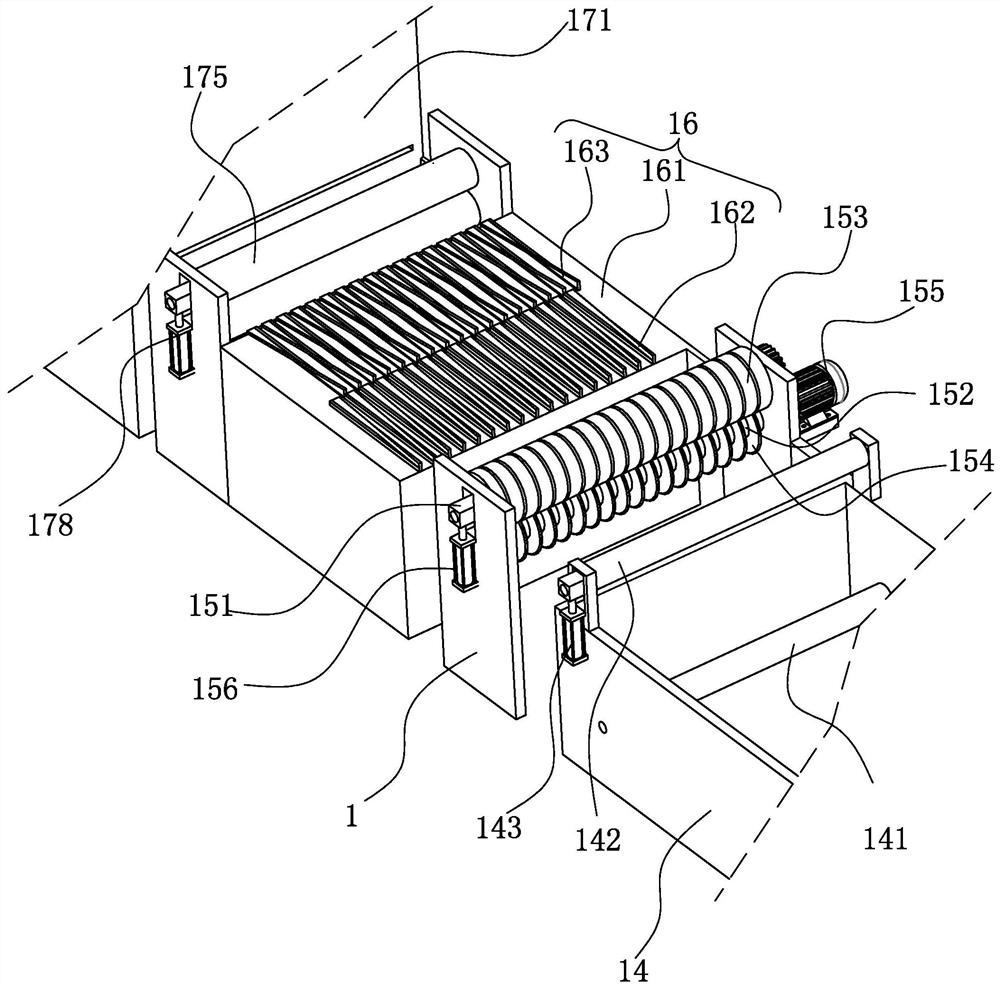

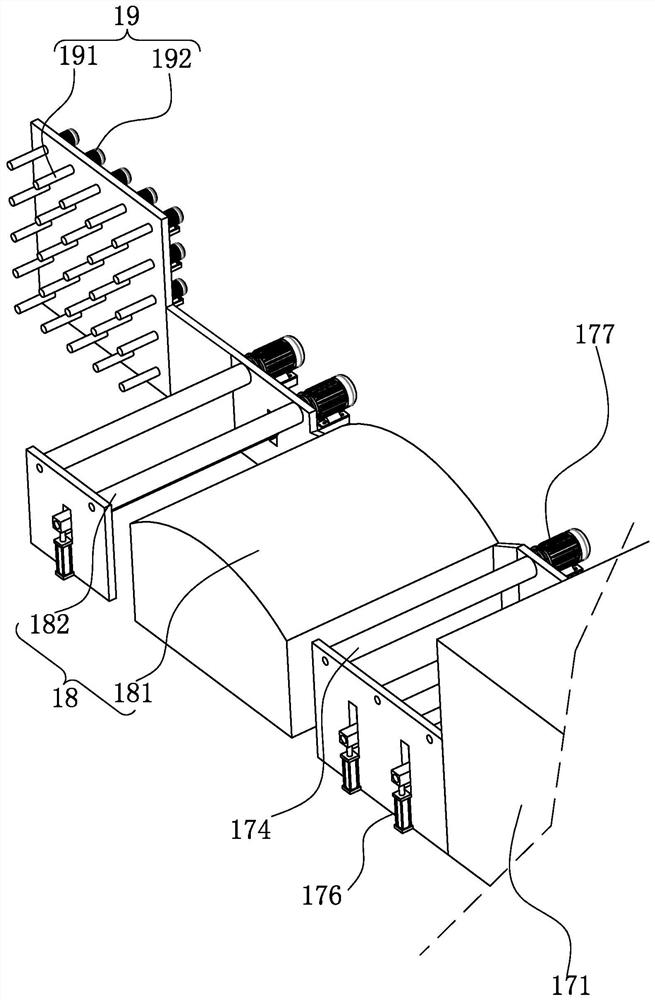

[0043] The following is attached Figure 1-4 The application is described in further detail.

[0044] The embodiment of the present application discloses a container bag flat yarn production line. refer to figure 1 , the container bag flat yarn production line includes a frame 1, which is sequentially provided with a stirring device 11, a melting conveying device 12, an extrusion device 13, a cooling pool 14, a cutting device 15, a folding device 16, and a thermal stretching device 17 , heat setting device 18 and winding device 19. When in use, plastic particles of different colors enter the stirring device 11 for stirring and mixing, and the stirred plastic particles are melted into a liquid state through the melting conveying device 12, and then extruded through the extrusion device 13 and cooled by the cooling pool 14 to form a film The sheet is cut into strips by the cutting device 15, and folded by the folding device 16 to form a three-layer flat wire structure. The st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com