High-density molding device and high-density molding method for mixed powder

A mixed powder, high-density technology, applied in the direction of material forming presses, magnetic objects, manufacturing tools, etc., can solve the problems of insufficient density, reduced quality of powder compacts, and insufficient mechanical strength, etc., to promote production lines and operations Easy, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

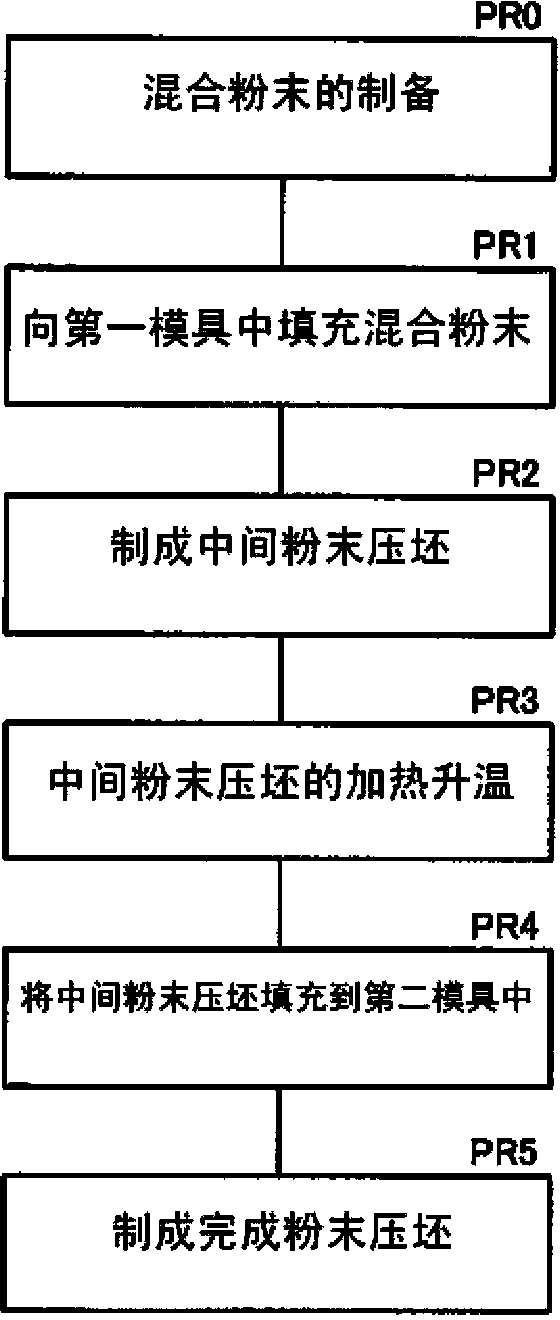

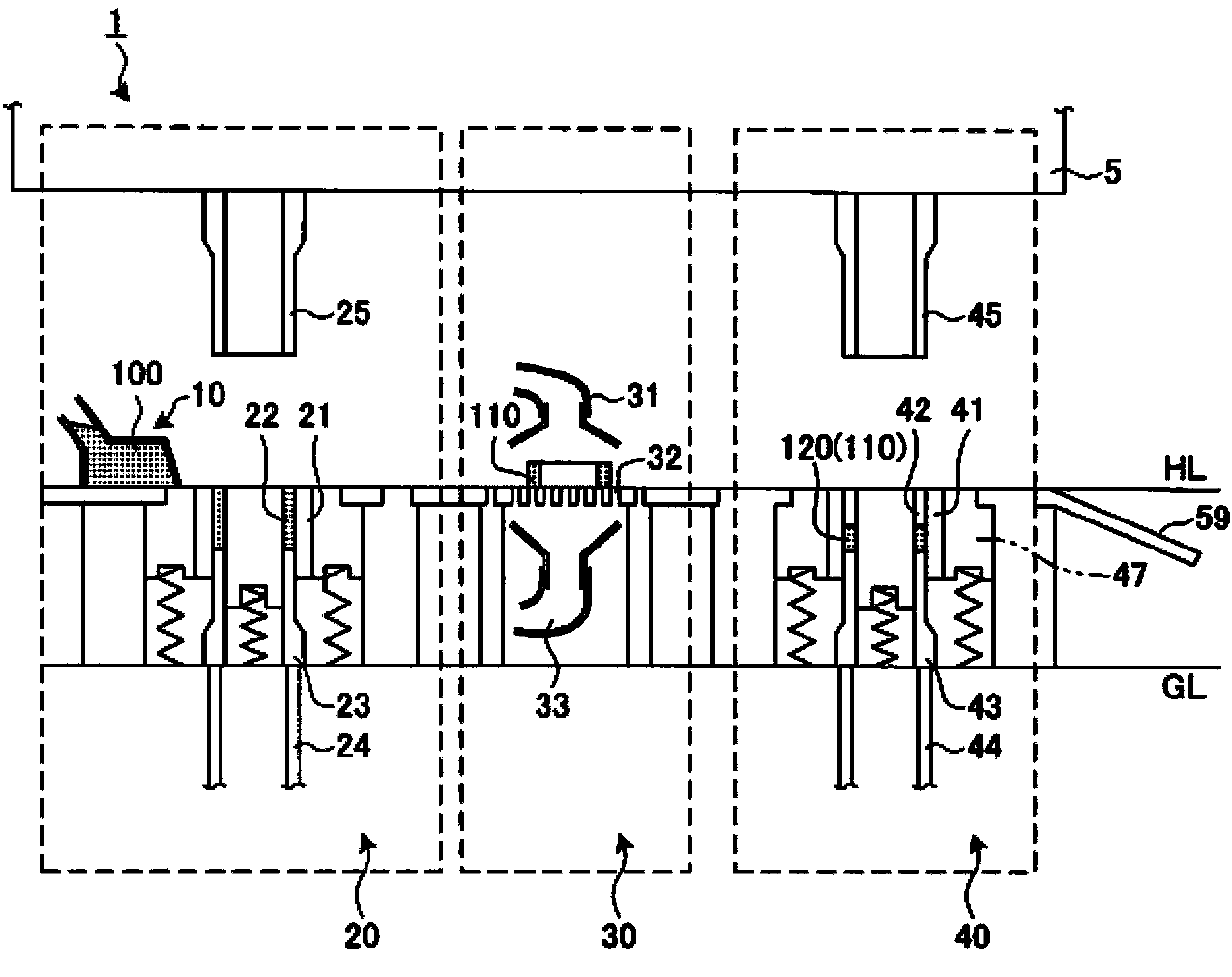

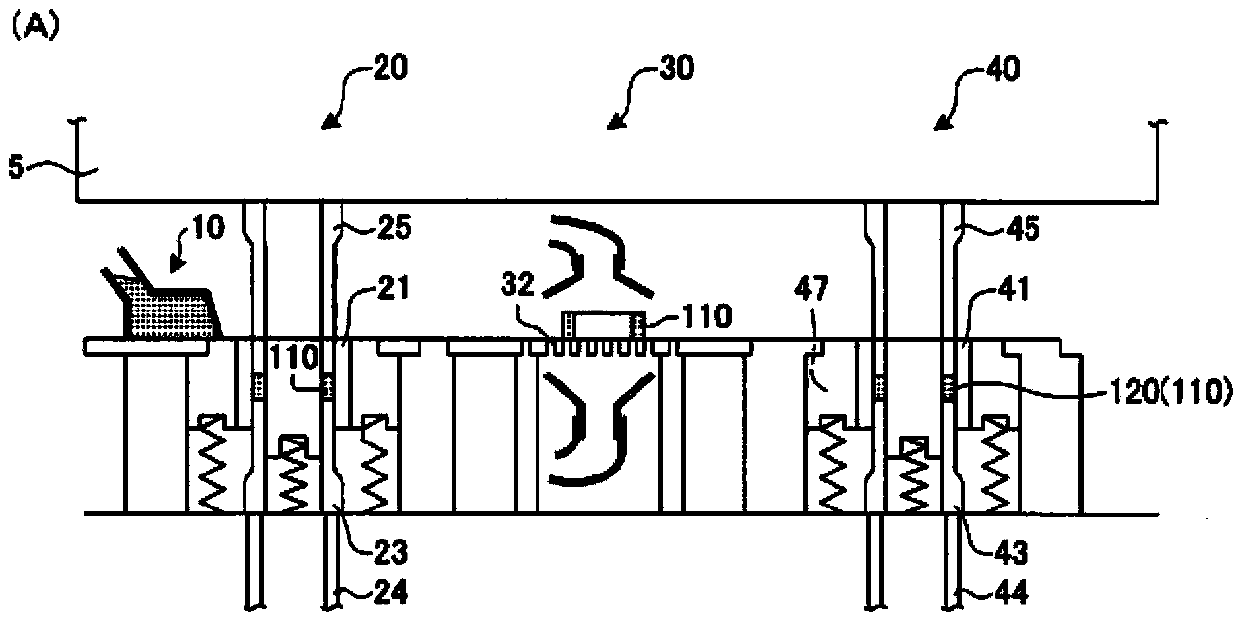

[0062] The high-density molding device of this mixed powder 1 such as Figure 1 ~ Figure 5E As shown, there is a mixed powder supply machine 10, a first pressure molding machine 20, a heating and heating machine 30, and a second pressure molding machine 40, and the high-density molding method of this mixed powder can be stably and reliably implemented. The high-density molding method consists of the following steps: the mixed powder filling step (PR1) of filling the mixed powder 100 into the first mold (lower mold 21), the mixed powder 100 is 0.2% to 0.1% (0.2 Wt%~0.1wt%) weight ratio to the base metal powder mixed with a mixture of lubricant powder with a low melting point; in the first mold (lower mold 21) to apply the first pressure (P1) to the mixed powder in the first mold, the forming true density ratio is 80 %~90% mixed powder intermediate compact (hereinafter sometimes referred to as intermediate powder compact 110) intermediate powder compact forming step (PR2); heati...

no. 2 approach )

[0148] The implementation is as Image 6 shown. Compared with the case of the first embodiment, it is characterized in that the mixed powder supply machine 10 and the first press molding machine 20 are provided as they are, and the heating and temperature raising machine 30 and the second press molding machine 40 are integrally formed.

[0149]That is, the high-density molding device is formed by the heating and pressing molding machine 70 integrally integrating the functions of the heating and temperature raising machine 30 in the first embodiment and the function of the second pressing and molding machine 40 . The heating and pressing molding machine 70 is formed by a plurality of (two in this embodiment) heating and pressing molding sub-machines 70A and 70B. Sequential actions can be selected during the manufacturing cycle.

[0150] The basic configuration of each heat press molding sub-machine 70A ( 70B) is set to be the same as that of the second press molding machine 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com