Spiral Wound Type Grip Tape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]The features and practice of the present invention will be illustrated below in detail through preferred embodiments with reference to the accompanying drawings.

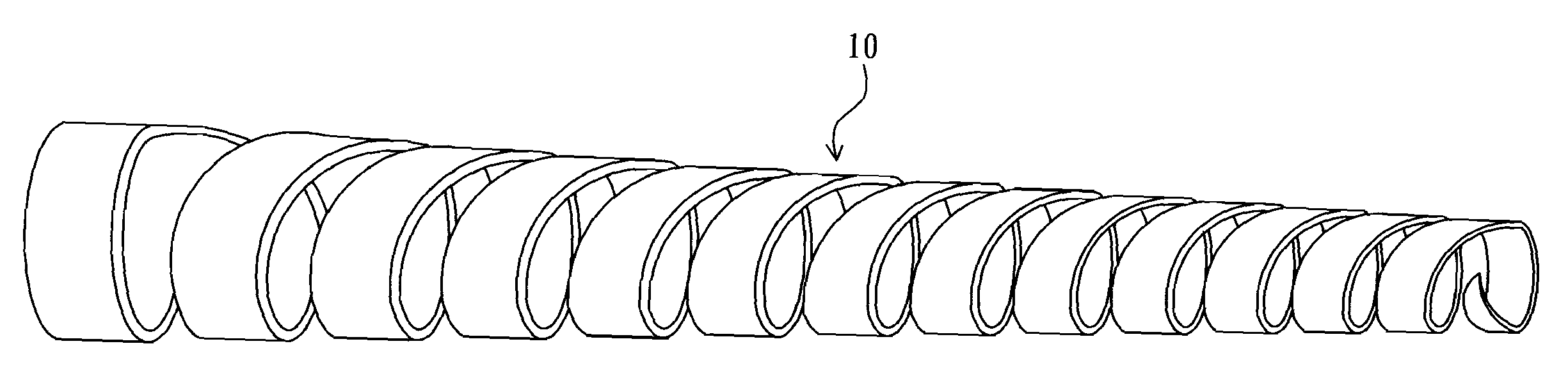

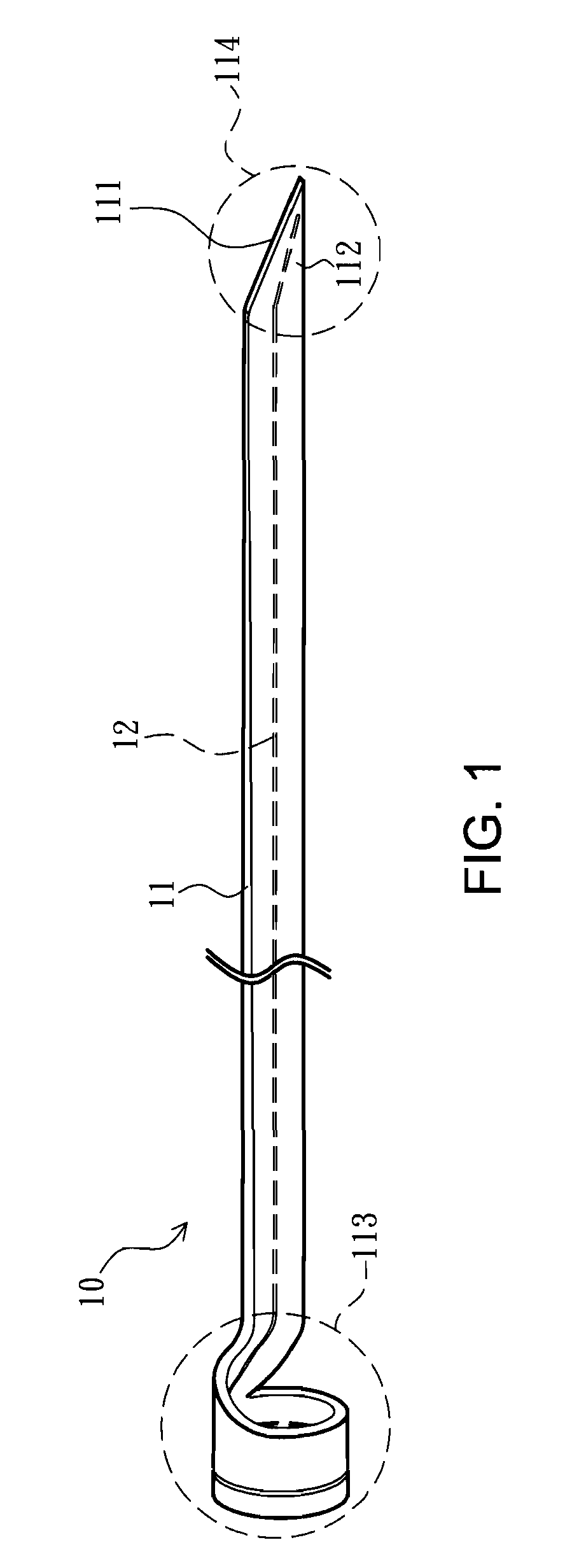

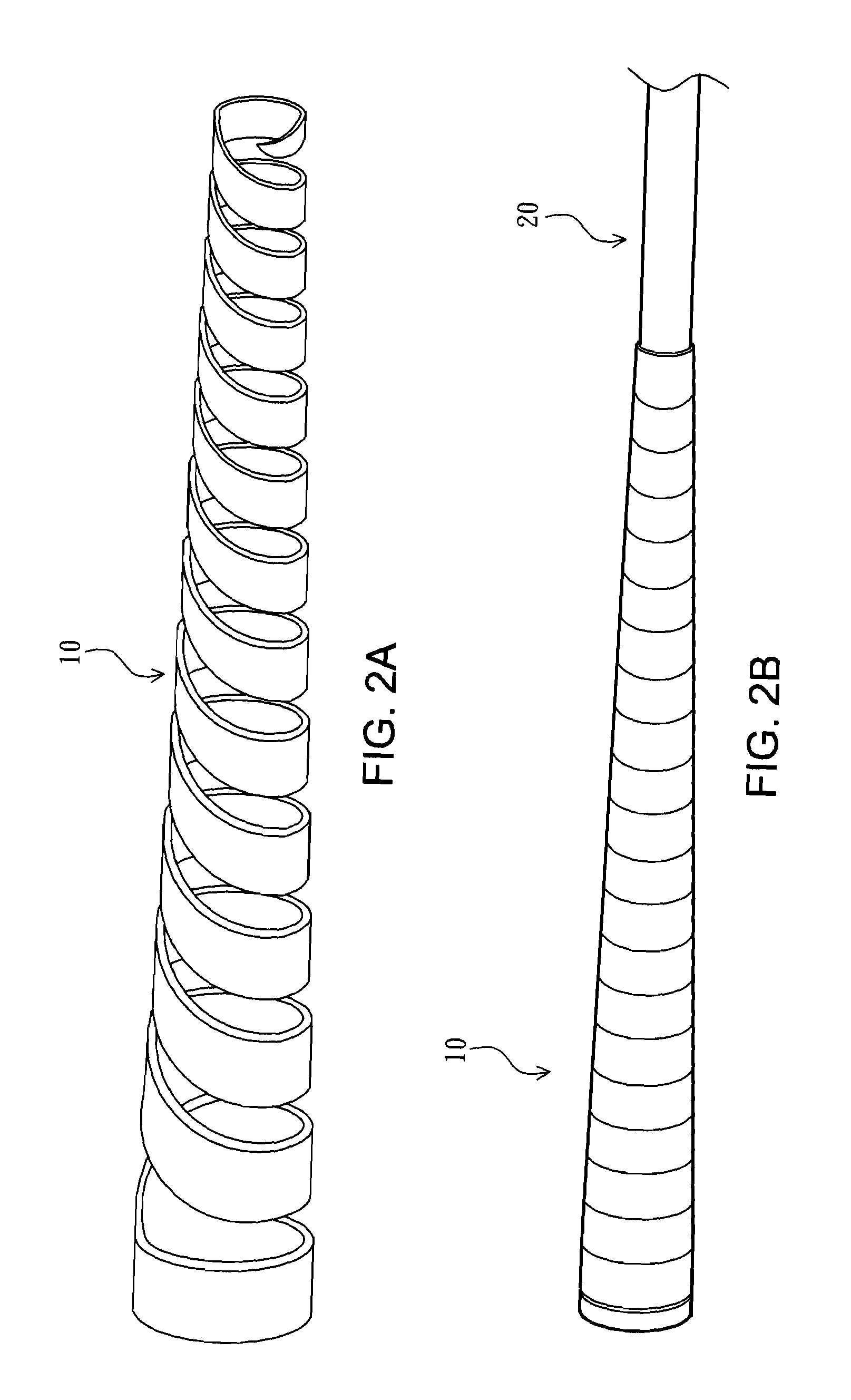

[0022]Referring to FIGS. 1 and 2A, it is a spiral wound type grip tape 10. The grip tape 10 comprises an elastic strip 11 and a flexible thread 12. The material of the elastic strip 11 is a rubber material; therefore, the hardness and softness of the elastic strip 11 can be adjusted according to the differences of the sports equipment. Wherein, the elastic strip 11 can also be made of a plastic material. The inner surface 112 of the elastic strip 11 are formed with textures, such that the friction between the inner surface 112 of the elastic strip 11 and the grip surface of the sports equipment can be increased so as to make the grip tape 10 firmly attach to the grip of the sports equipment. In addition, the shapes and textures of the outer surface 111 of the elastic strip 11 can be adjusted according to the sports equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com