Patents

Literature

91results about How to "Simplify the production line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light-emitting diode device and method of manufacturing thereof

InactiveUS20060193121A1Favorable color mixtureSmall variation in chromaticityElectric circuit arrangementsSolid-state devicesEngineeringLength wave

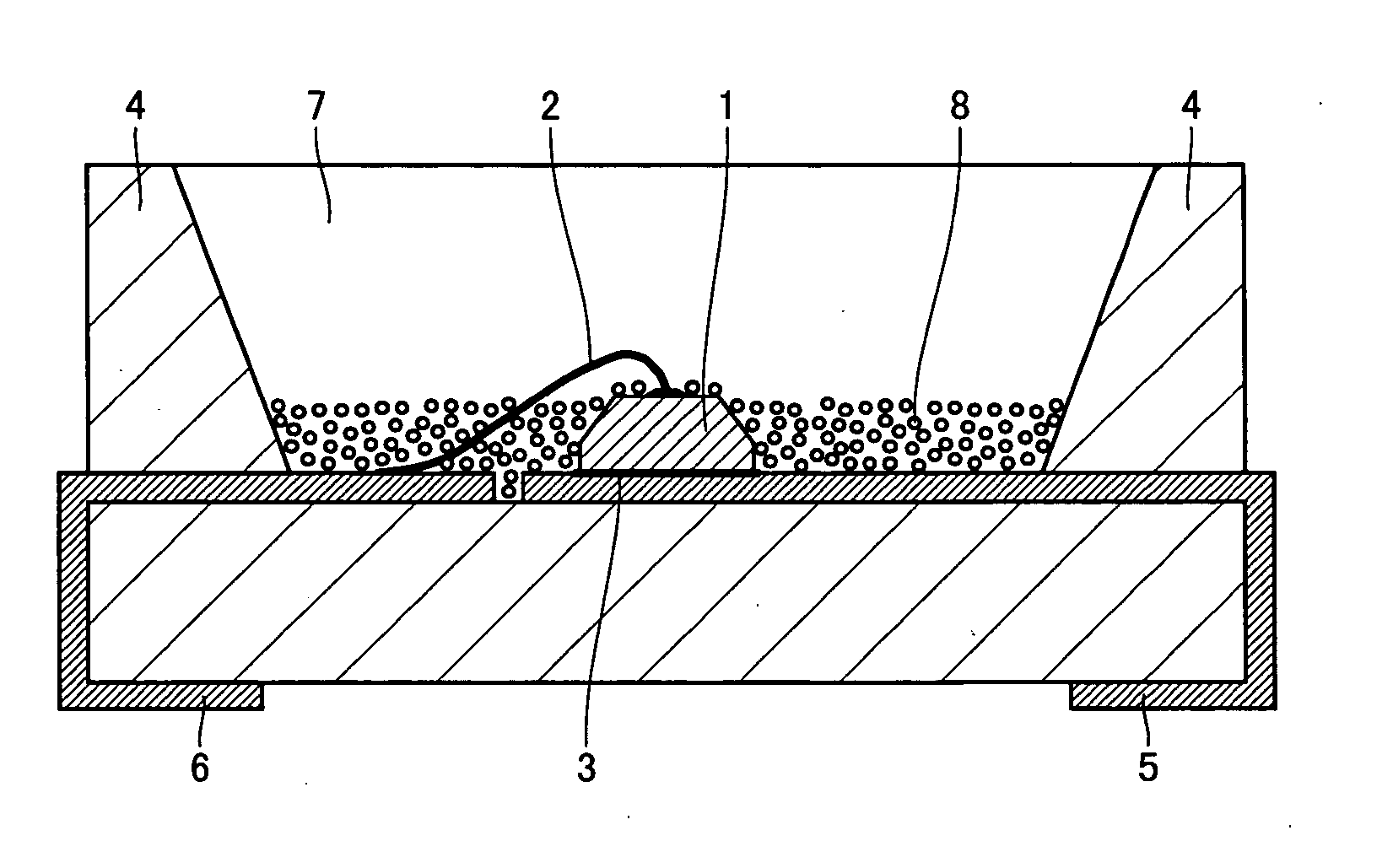

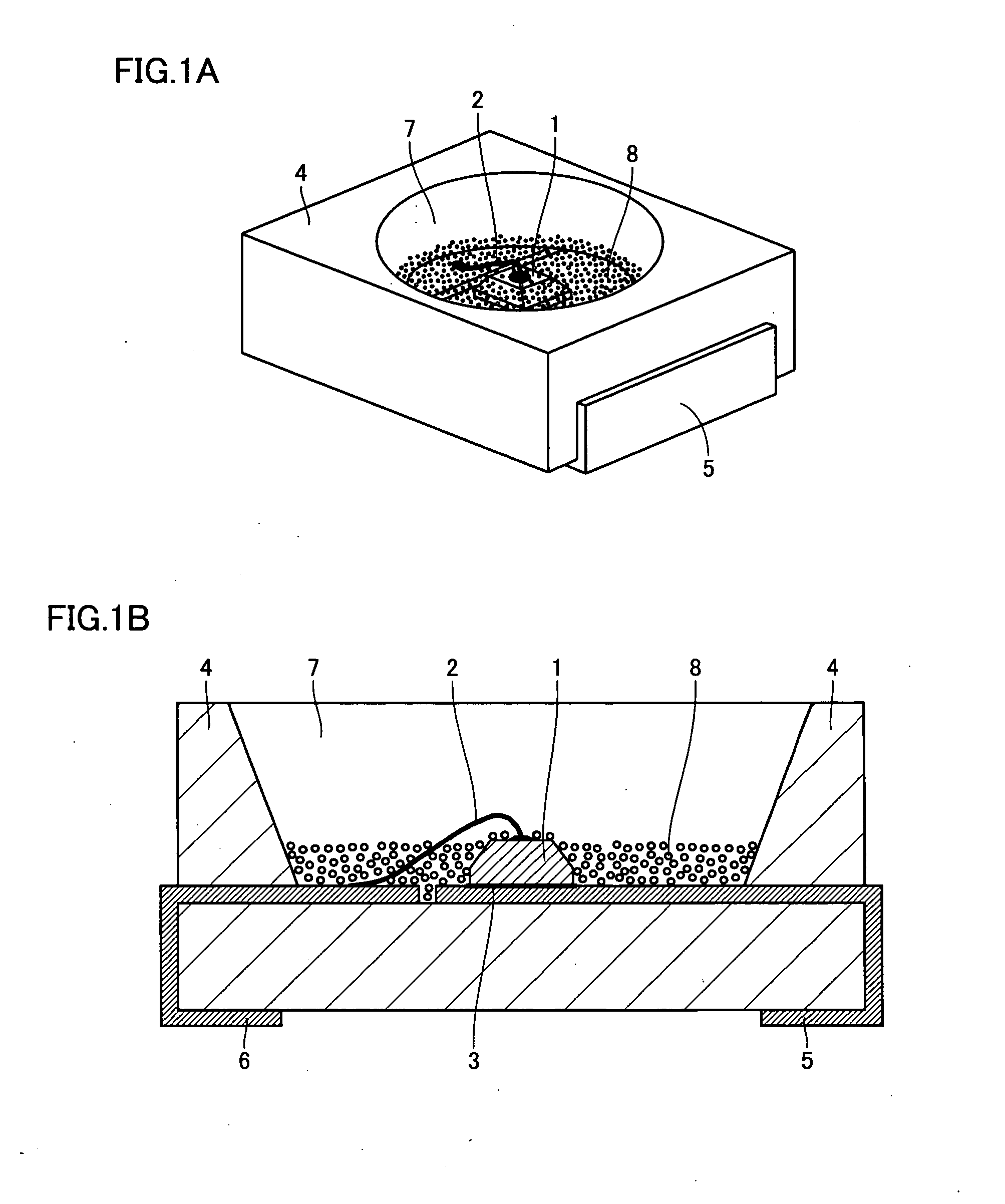

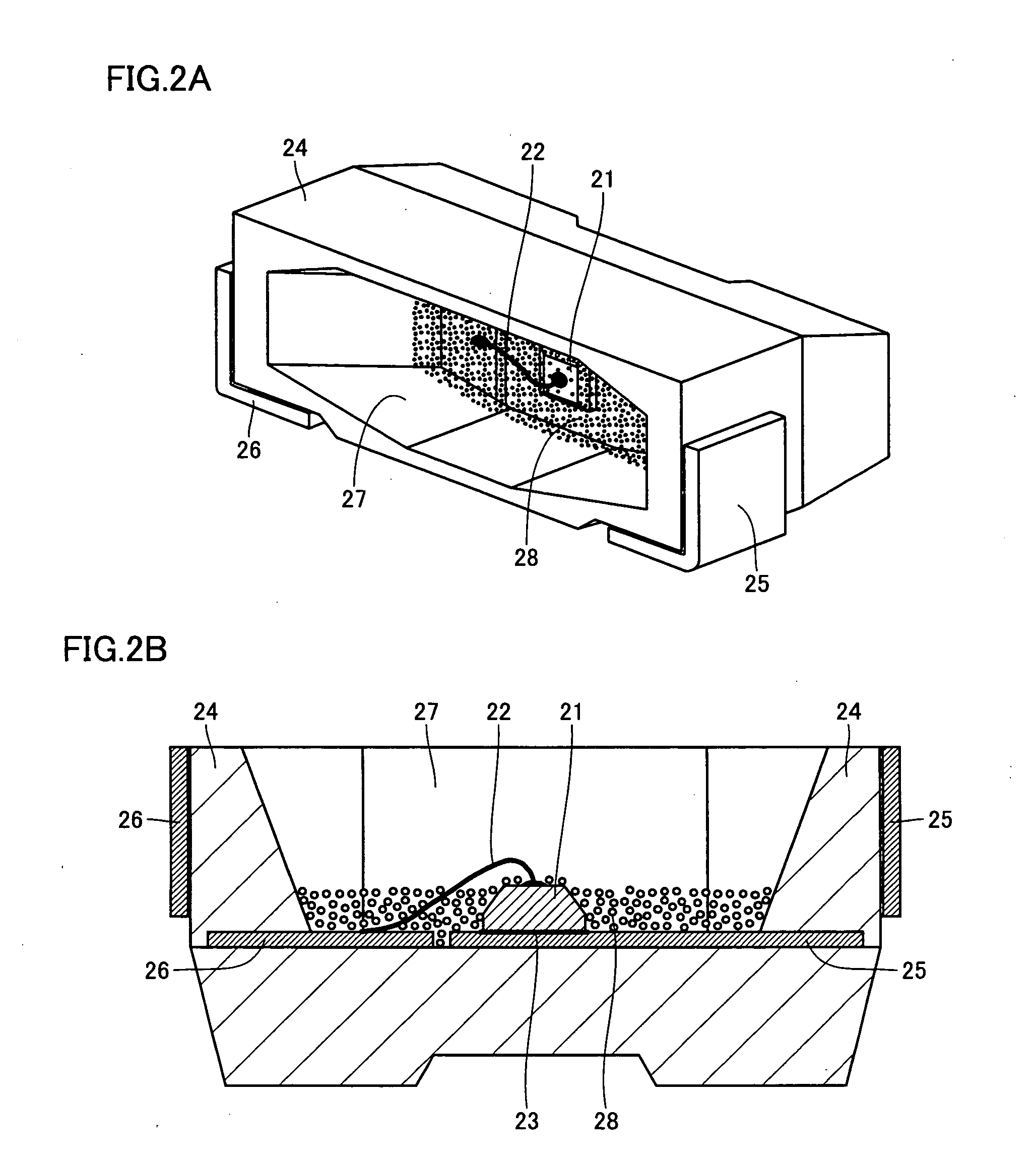

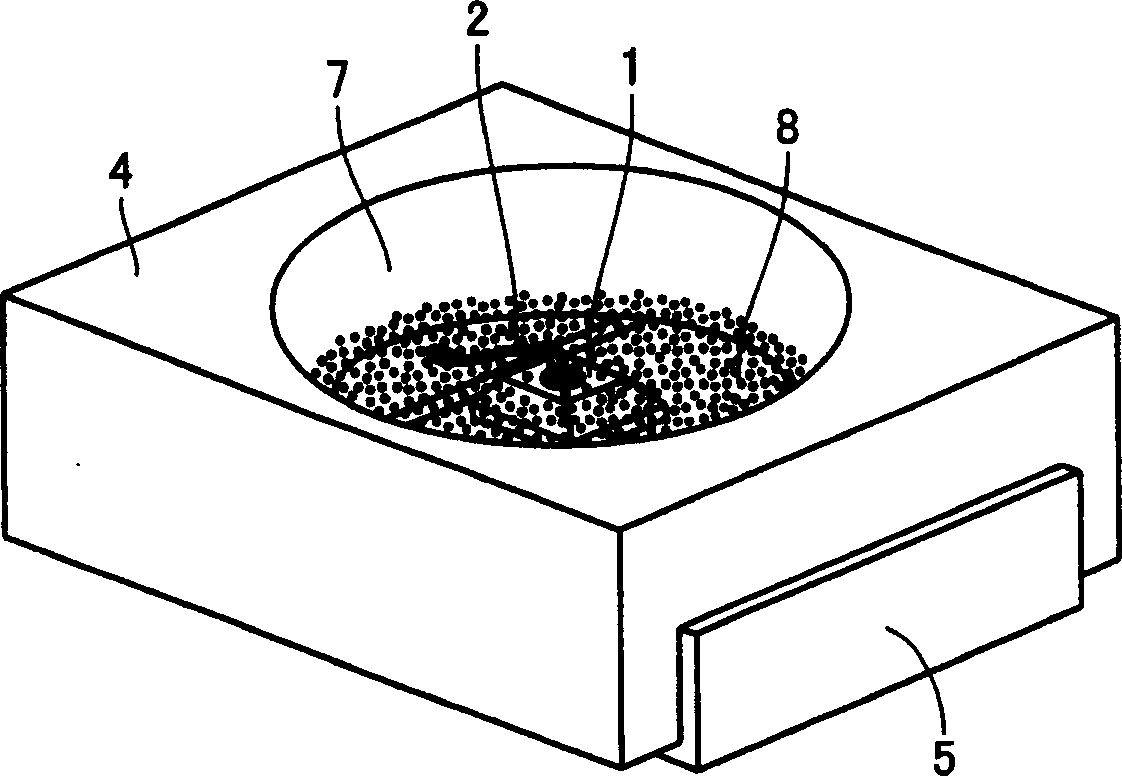

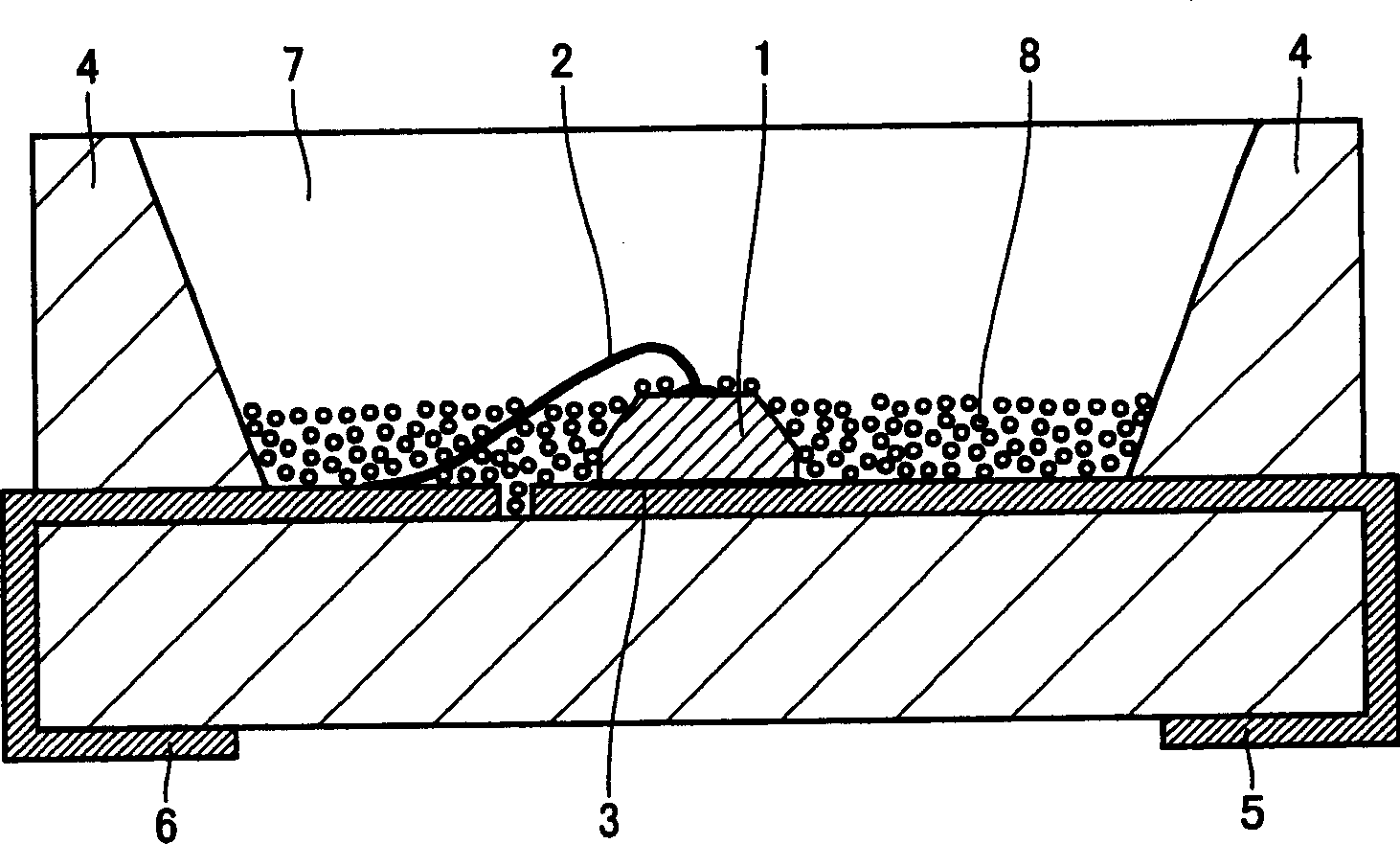

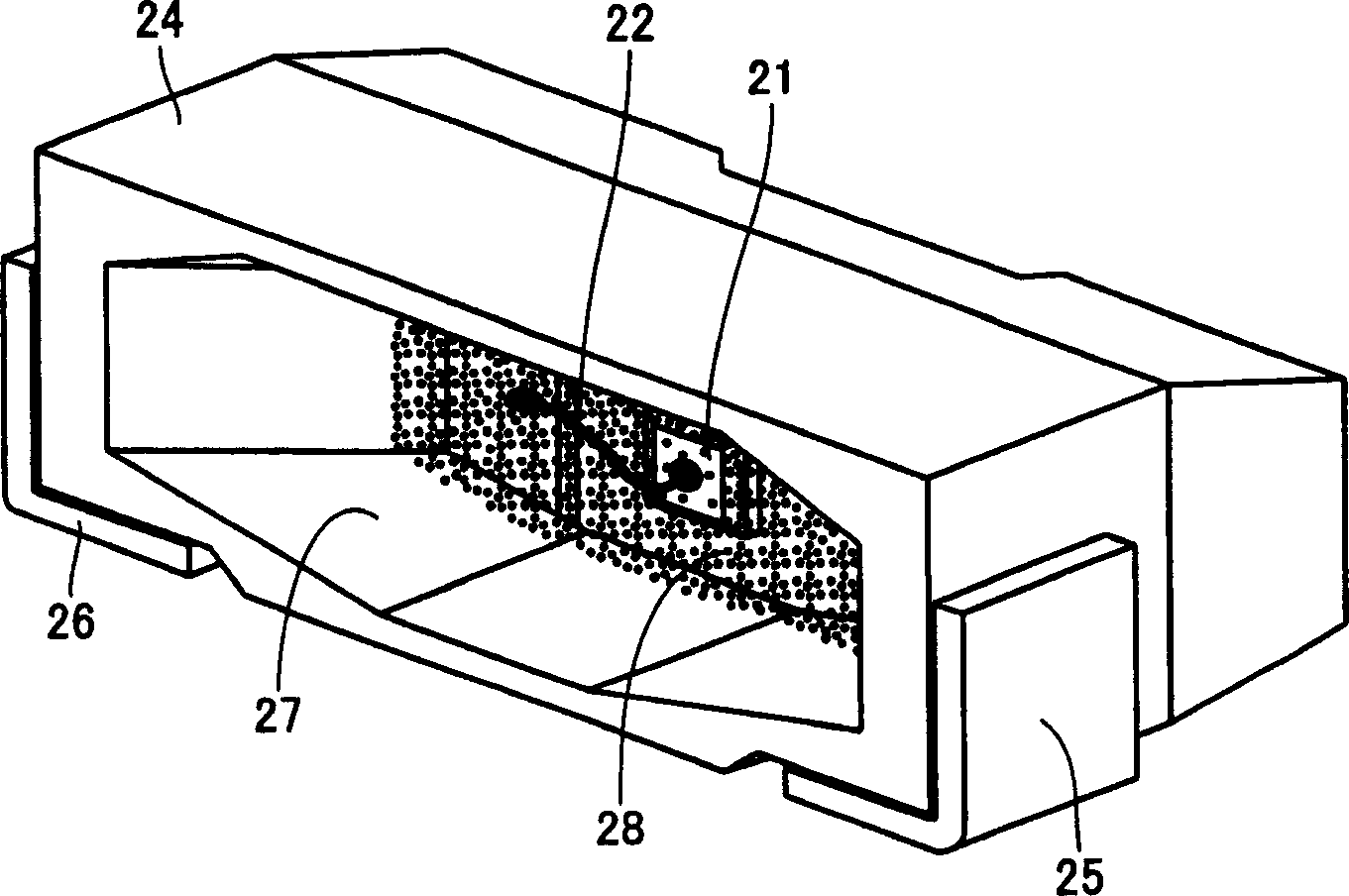

An LED device that is excellent in color mixture and small in variation of chromaticity is provided. The LED device includes, in a package, an LED chip, a fluorescent material excited by light from the LED chip to generate light with a wavelength different from that of the light from the LED chip, and a translucent resin holding the fluorescent material. The LED chip has a side-surface portion, a top-surface portion, a bottom-surface portion, and a light-emitting layer sandwiched between the top-surface portion and the bottom-surface portion, and the fluorescent material in the translucent resin is provided in a layer form on a bottom surface of the package to entirely or partially cover the side-surface portion of the LED chip.

Owner:SHARP KK

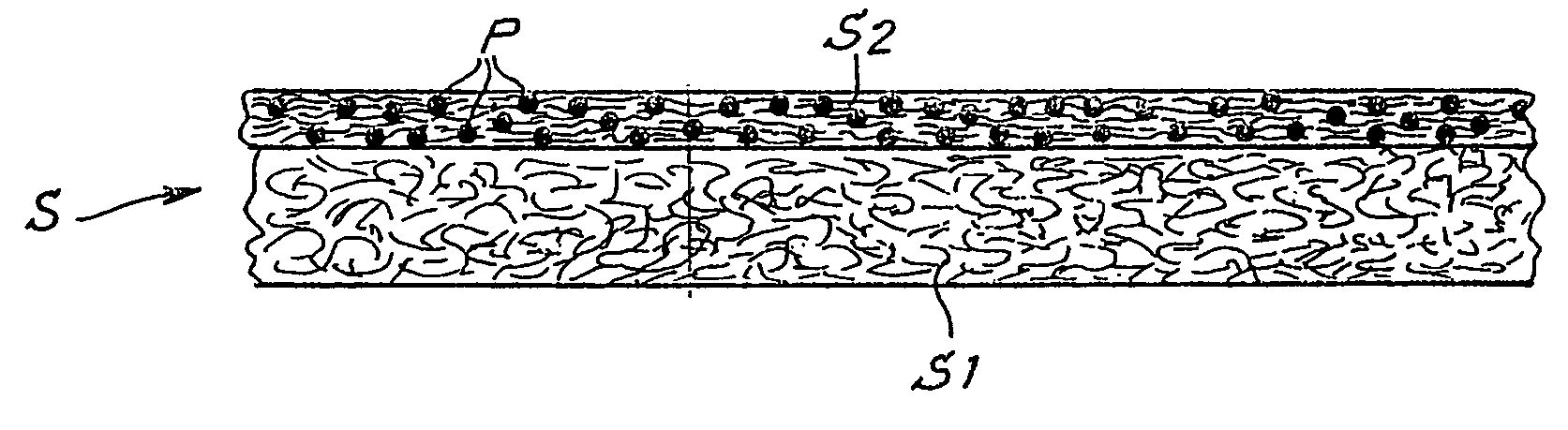

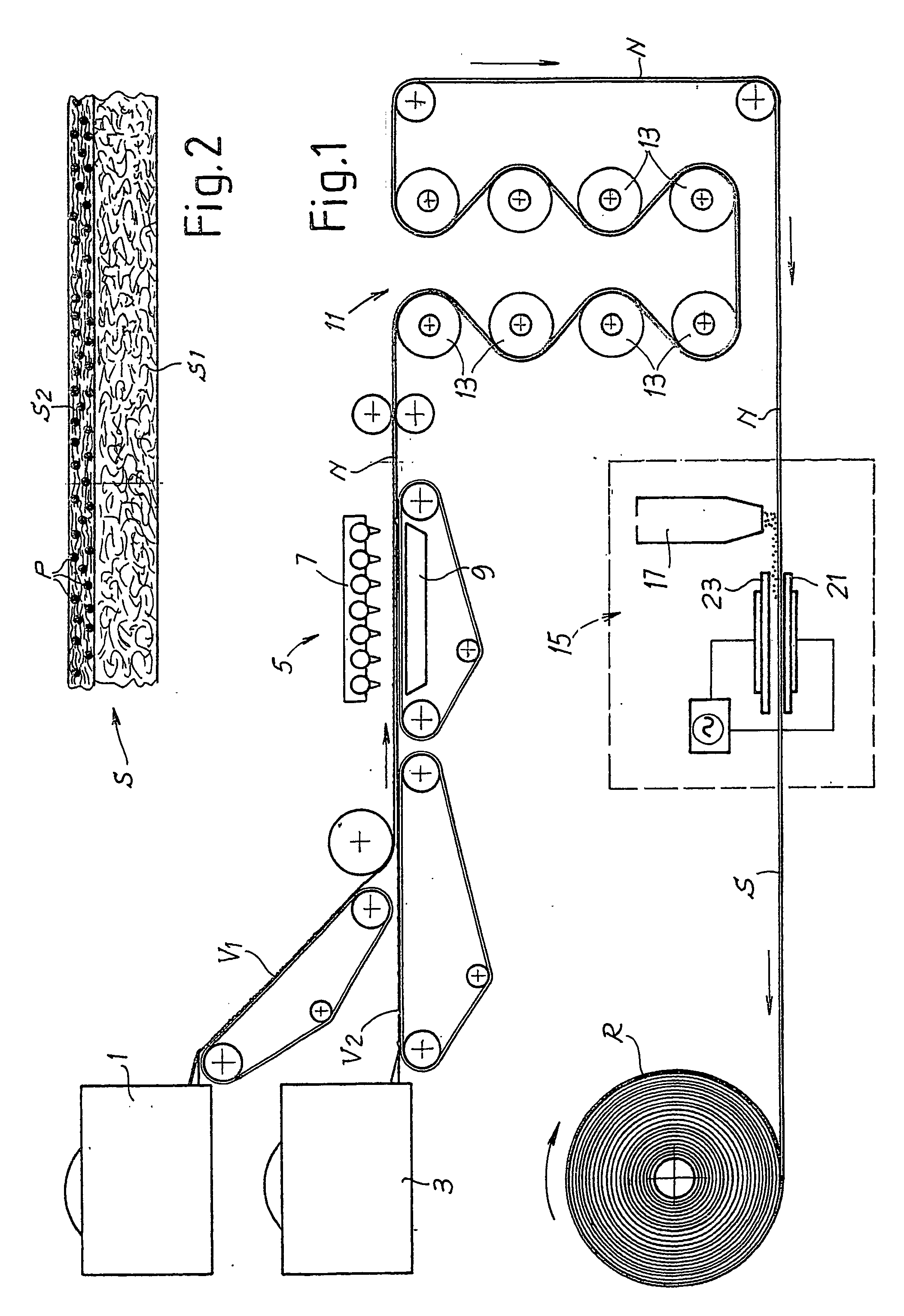

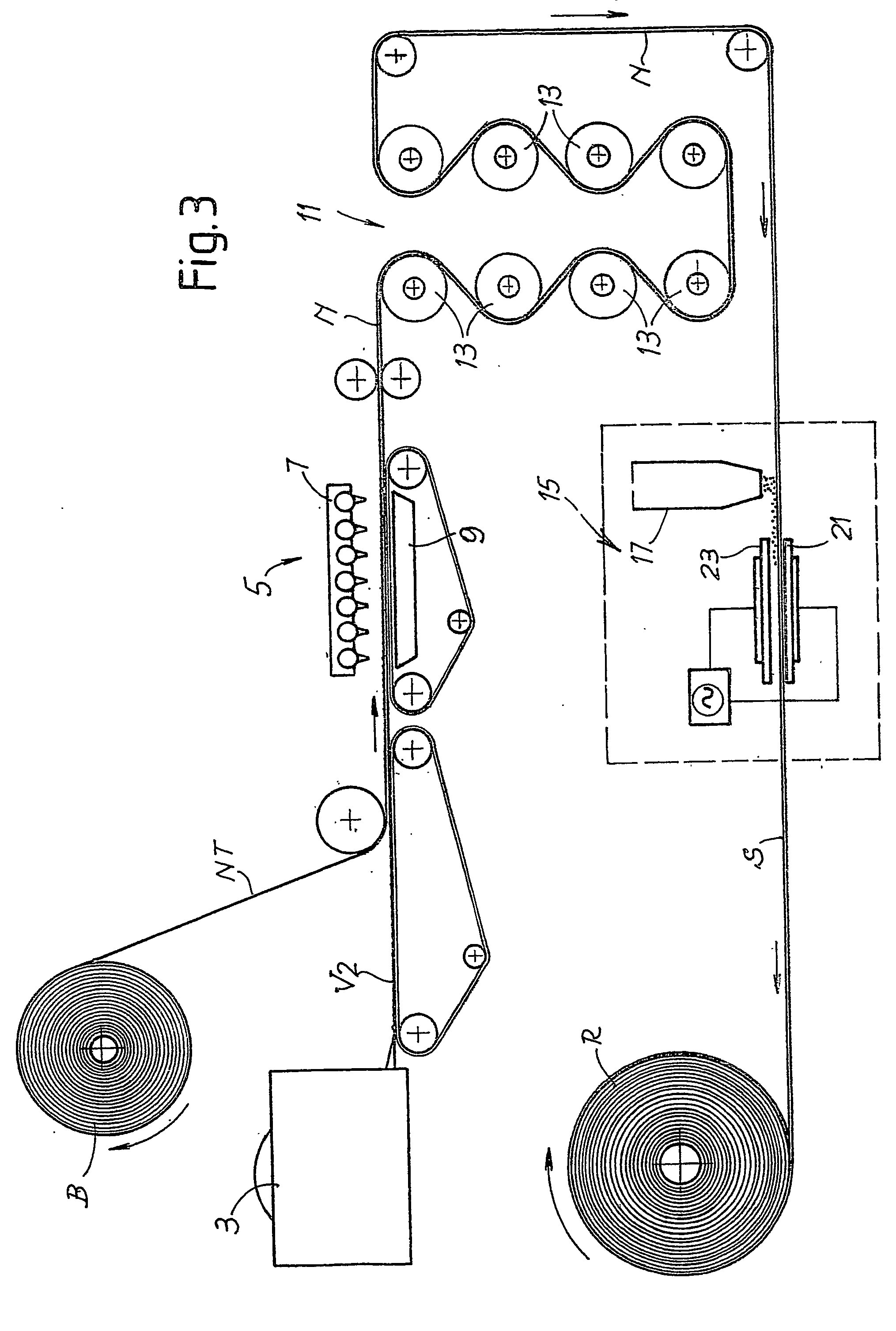

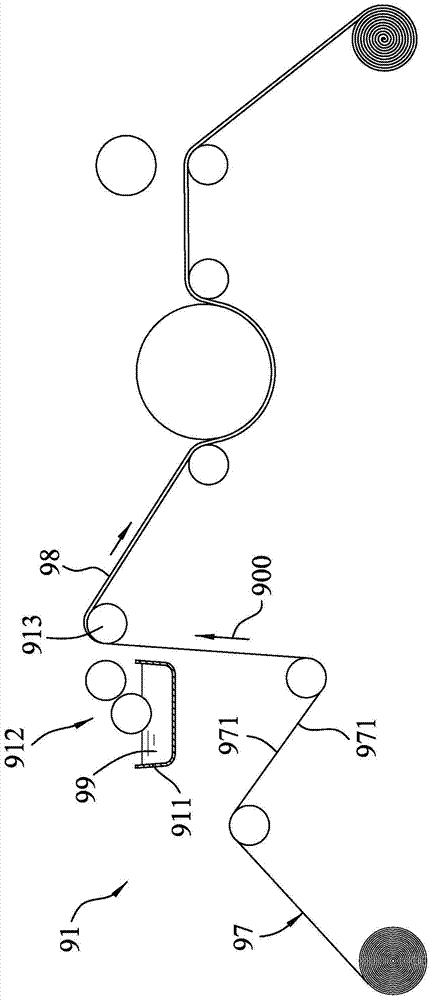

Composite absorbent structure for the production of diapers, sanitary napkins and associated production method

InactiveUS20050165371A1High densityLower the volumeLiquid surface applicatorsSanitary towelsEngineeringSuperabsorbent polymer

An absorbent structure is described, said structure comprising: a first acquisition and distribution layer (S1) formed by a nonwoven fabric consisting of non-absorbent fibers; a second absorbent layer (s2) formed by a nonwoven fabric consisting of absorbent fibers and comprising particles (P) of at least one superabsorbent polymer distributed in the nonwoven fabric, in which at least said second layer is formed by staple fibers.

Owner:GIACOMETTI CLAUDIO

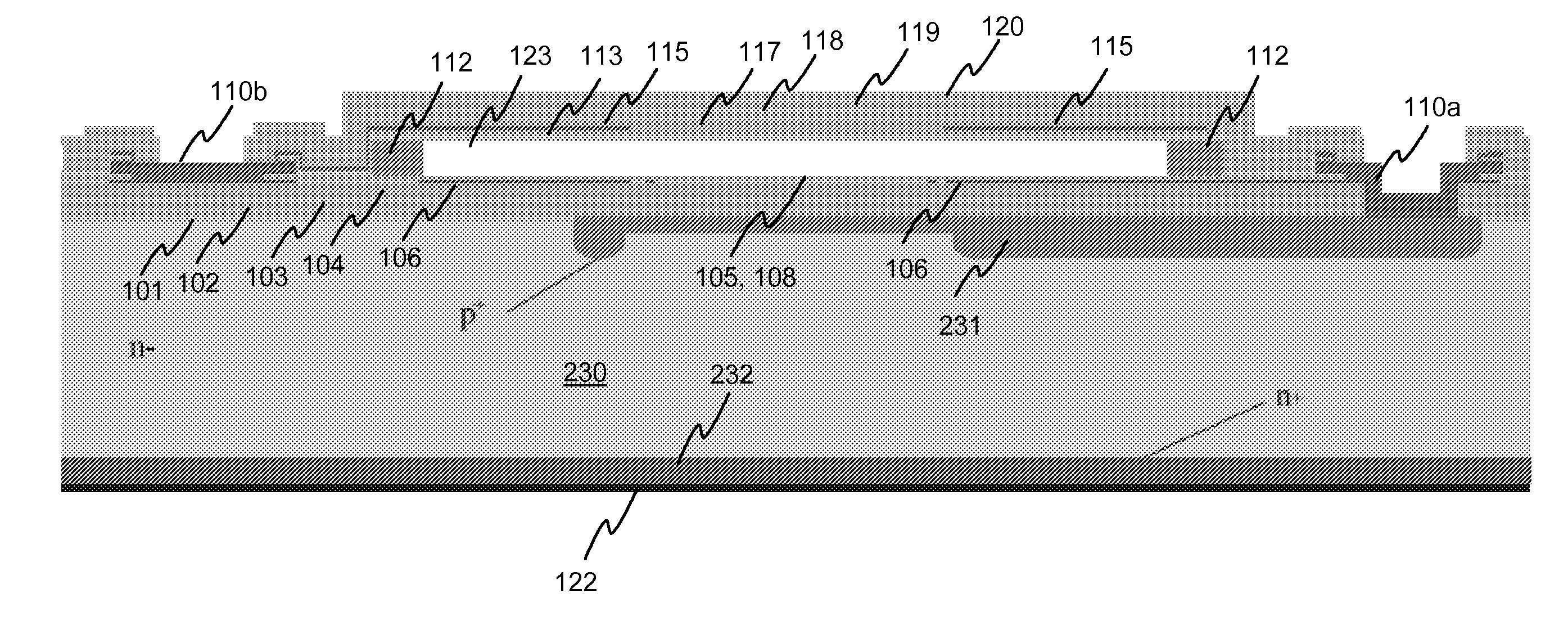

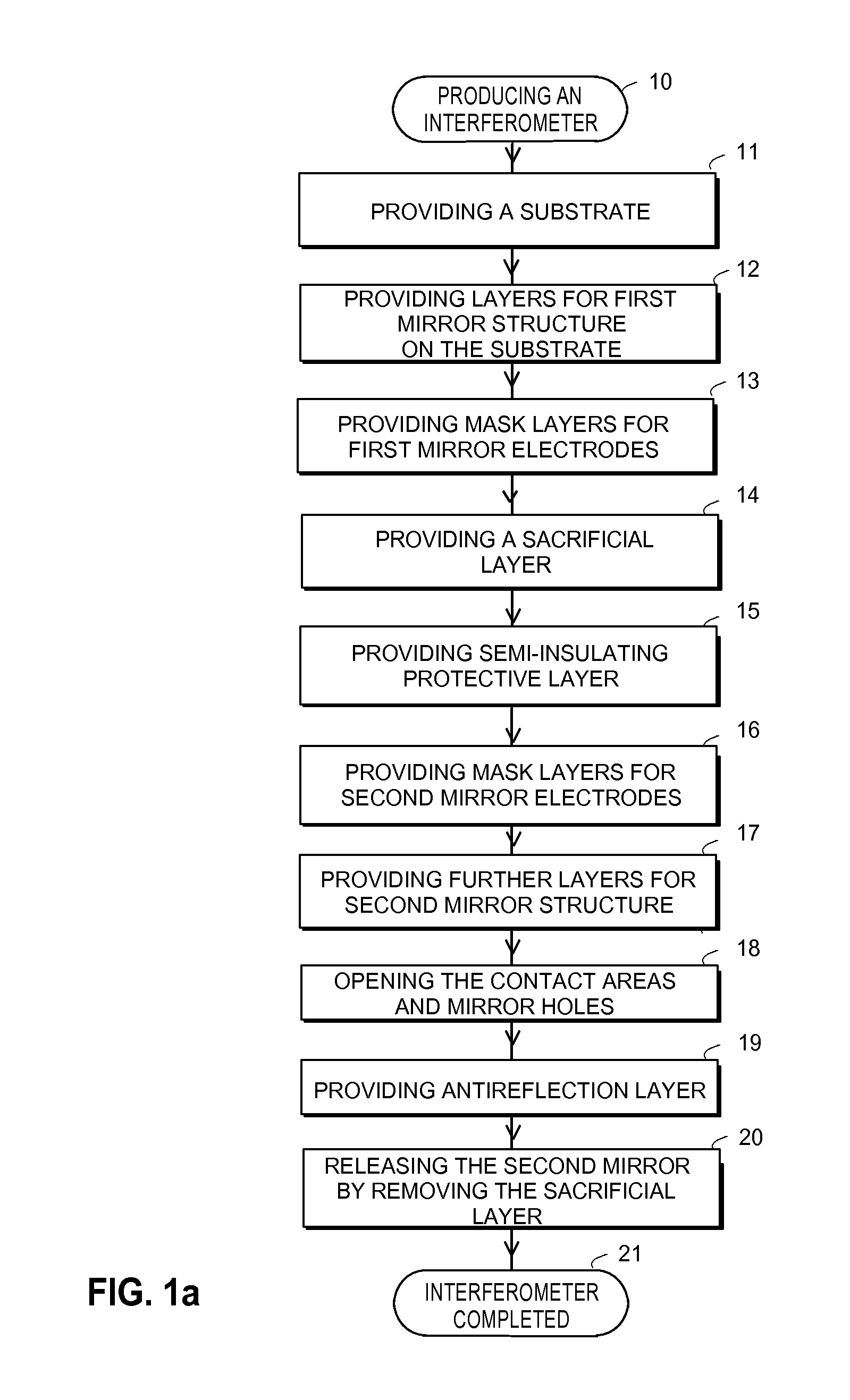

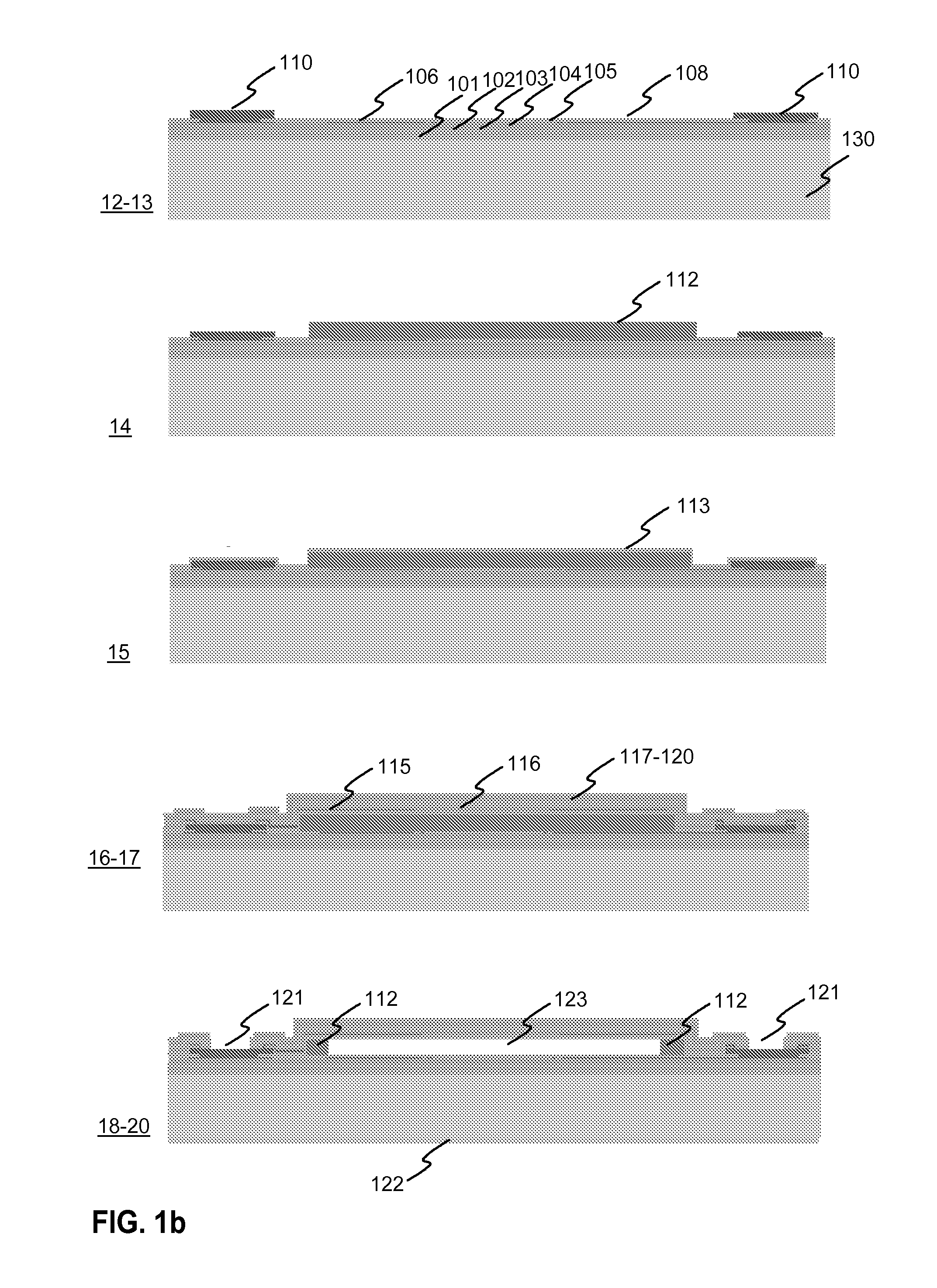

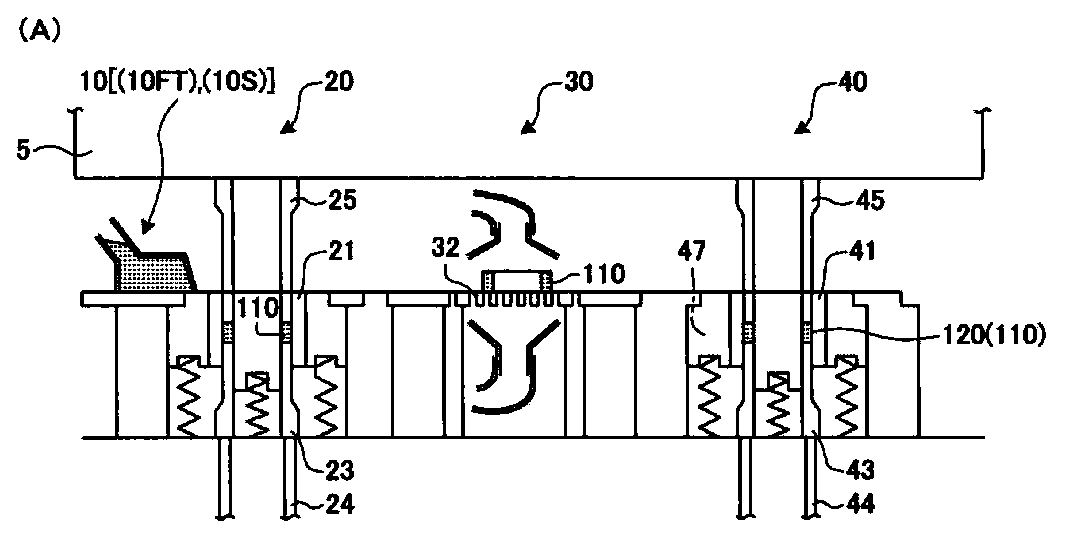

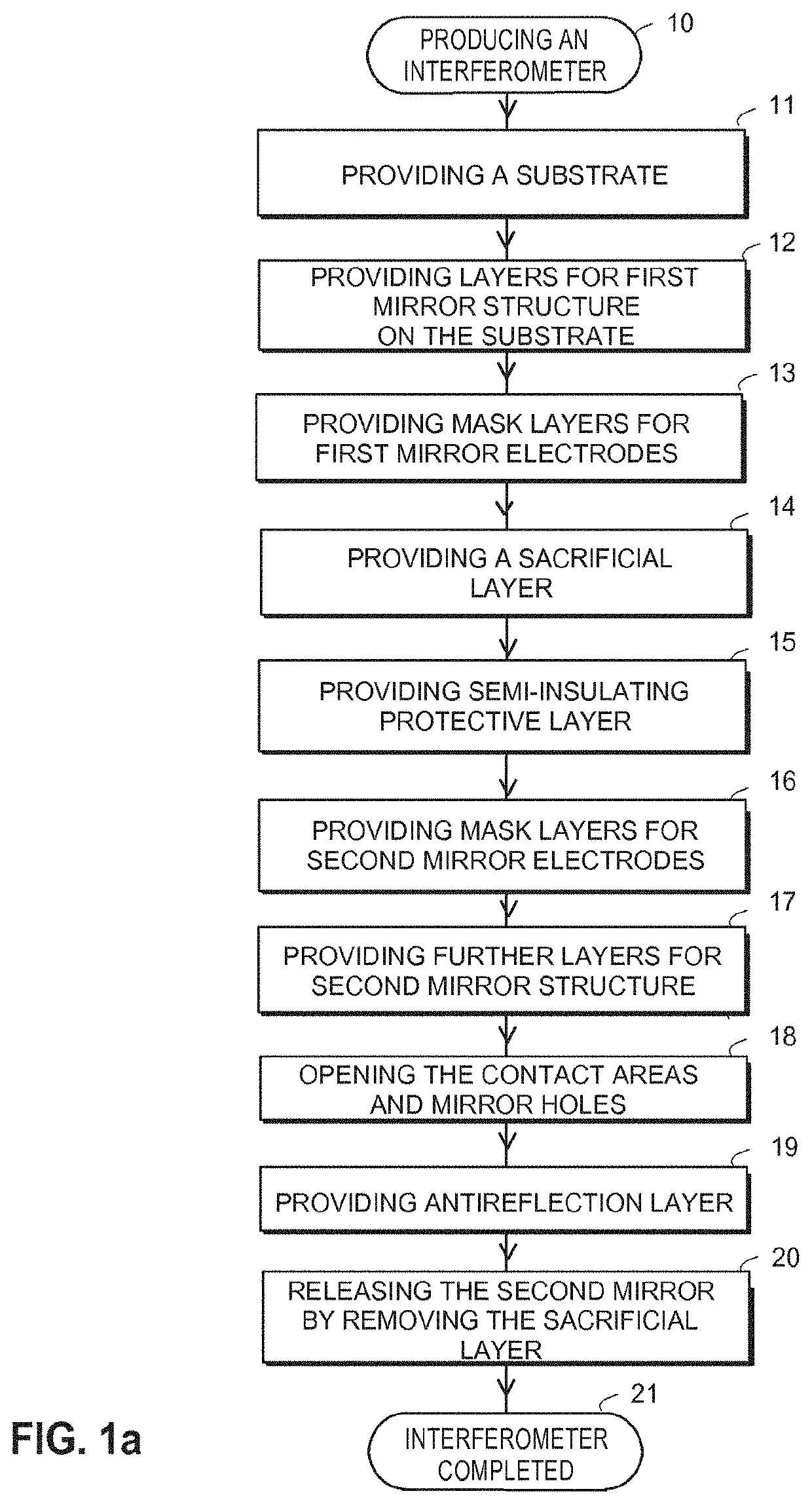

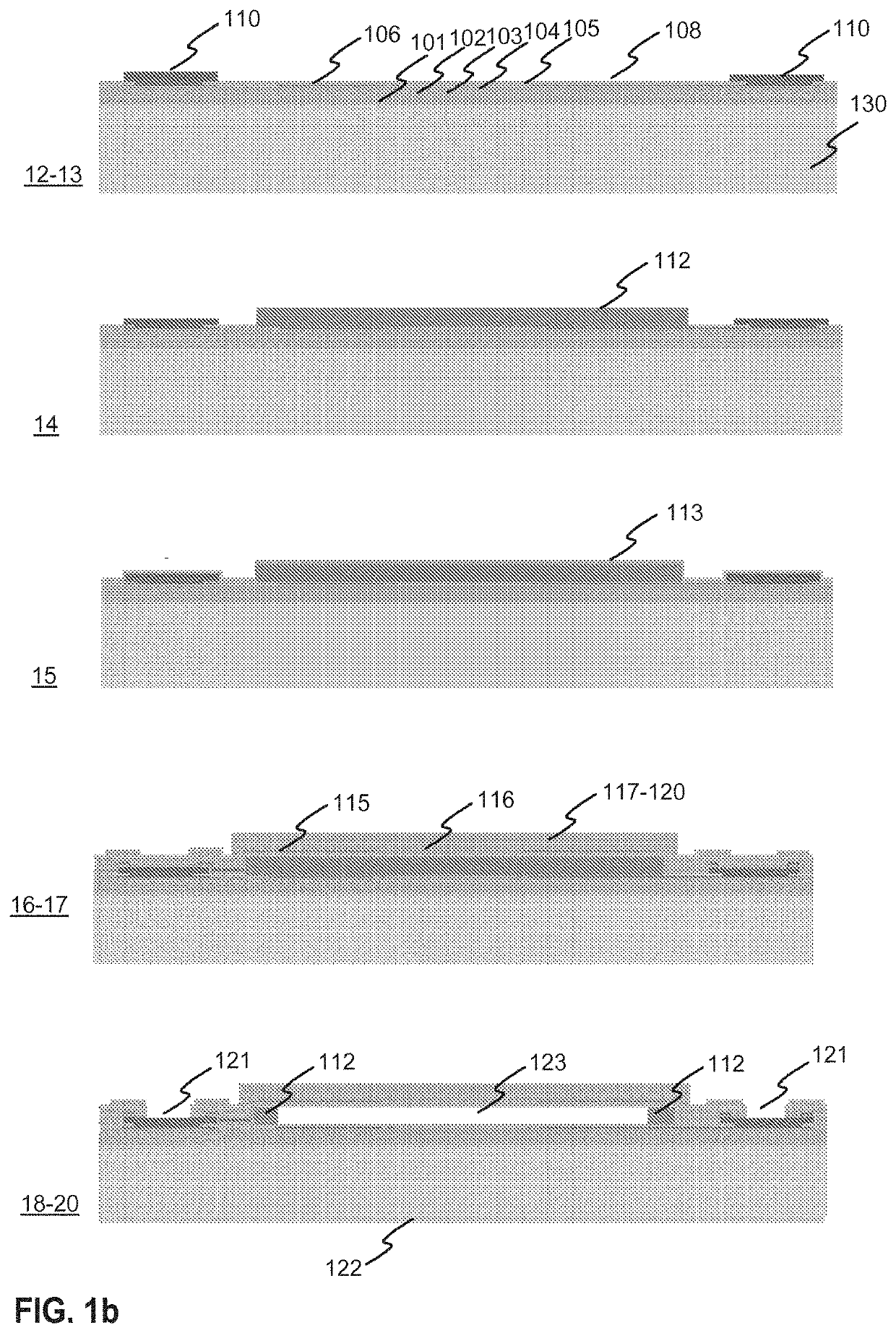

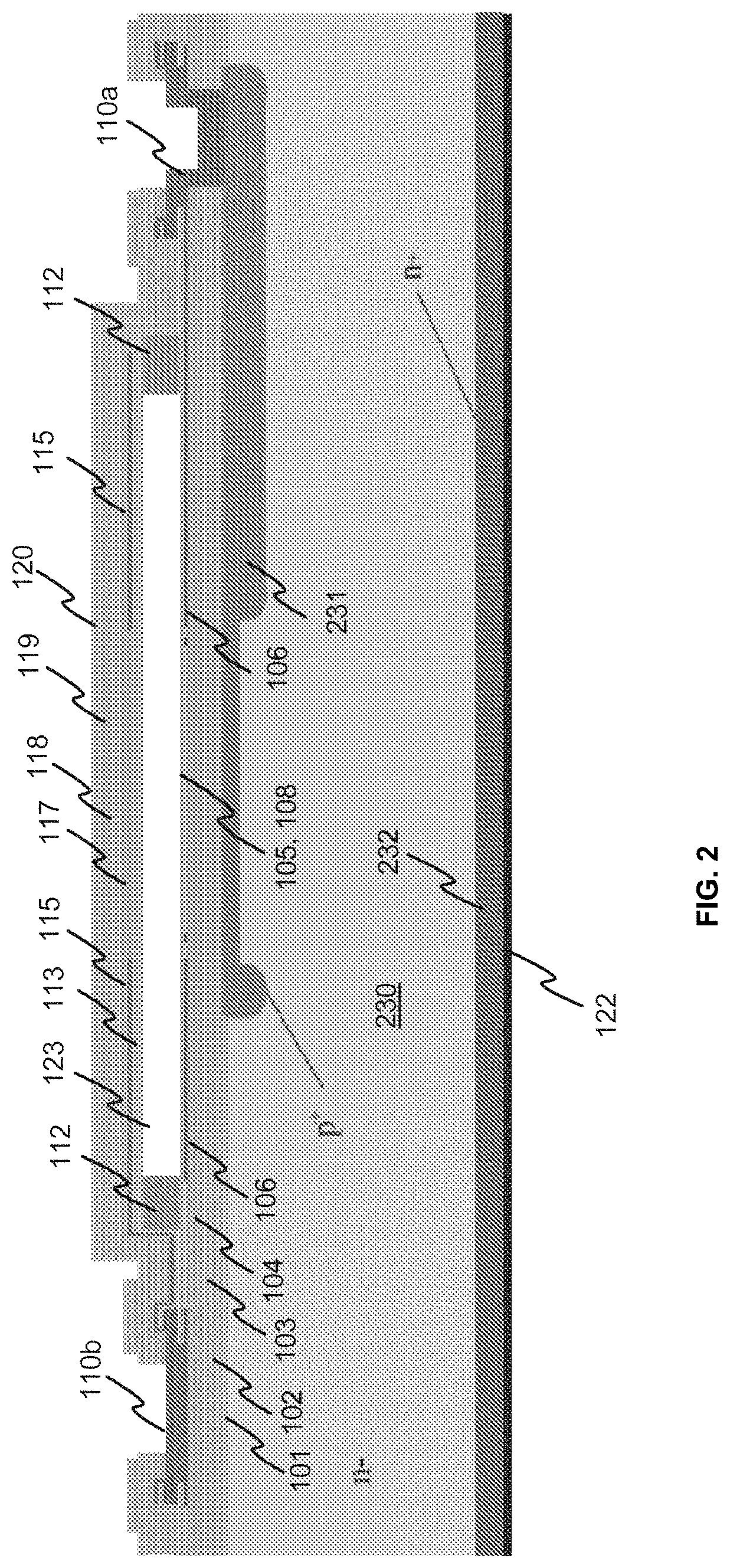

Electrically tunable fabry-perot interferometer, an intermediate product an electrode arrangement and a method for producing an electrically tunable fabry-perot interferometer

InactiveUS20110279824A1Prevents electrical short circuitPrevent electric chargeVacuum evaporation coatingSputtering coatingSputteringEvaporation

Electrically tunable Fabry-Perot interferometers which are produced with micromechanical (MEMS) technology. Producing interferometers with prior art processes includes costly and complicated production phases. Therefore, it has not been possible to apply interferometers in consumer mass products. According to the present solution, the Fabry-Perot cavity is made by removing a sacrificial layer (112) which has been polymer material. A mirror layer (113, 117-120) which is produced above the sacrificial layer can be made with atomic layer deposition technology, for example. According to a preferable embodiment, electrodes (106b, 115b) of the mirror structures are formed by using sputtering or evaporation. With the present solution it is possible to avoid the above mentioned problems related with prior art.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

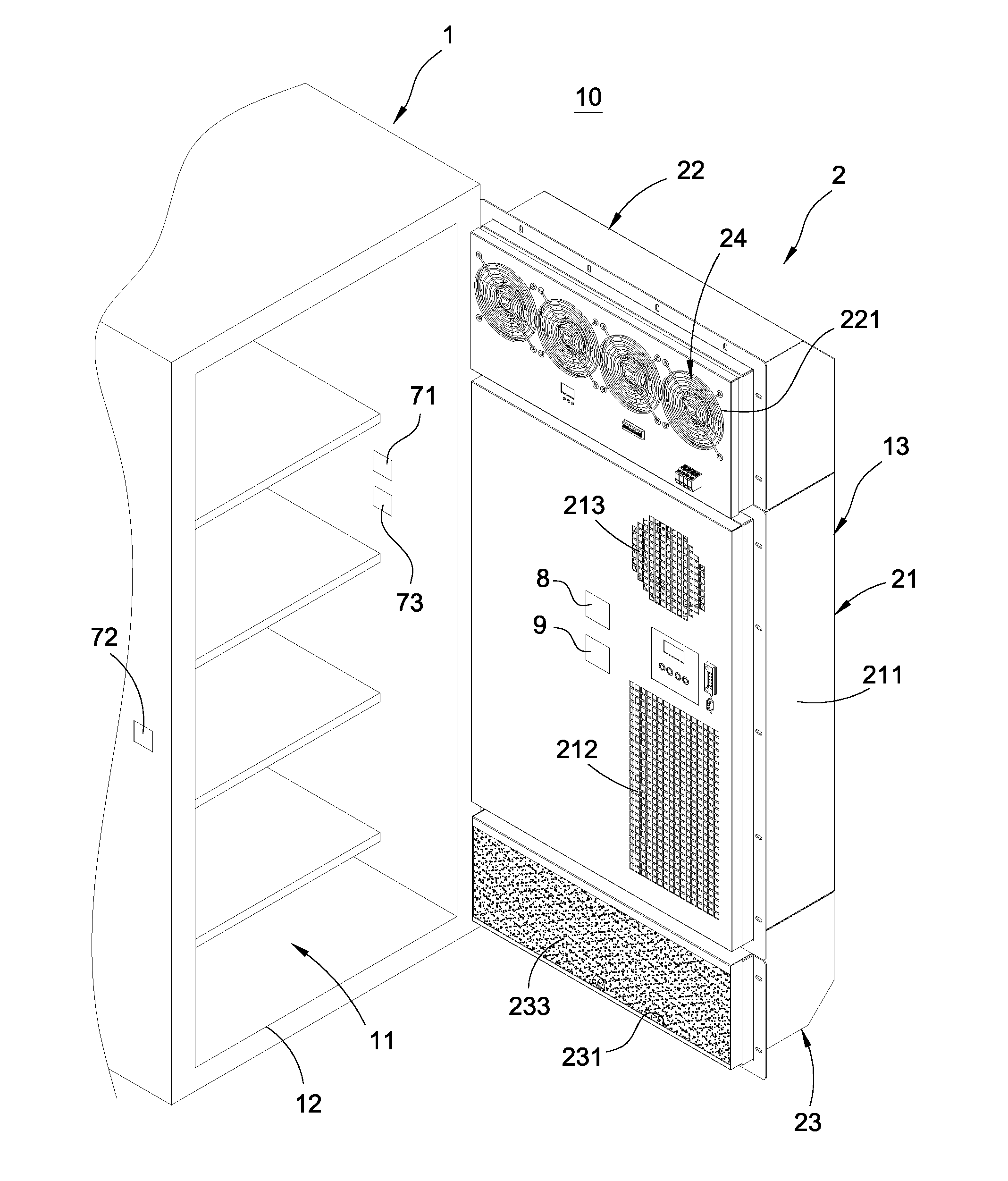

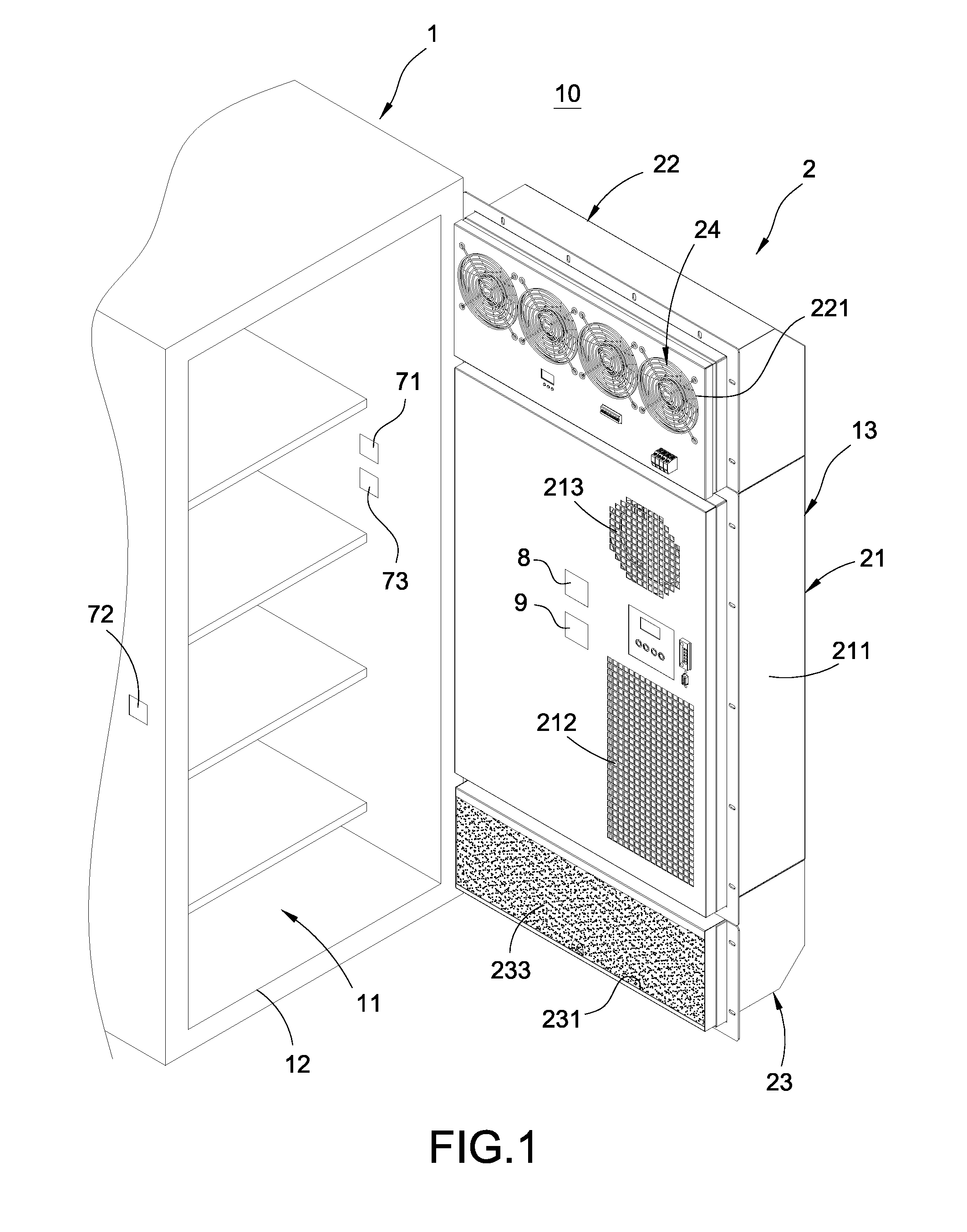

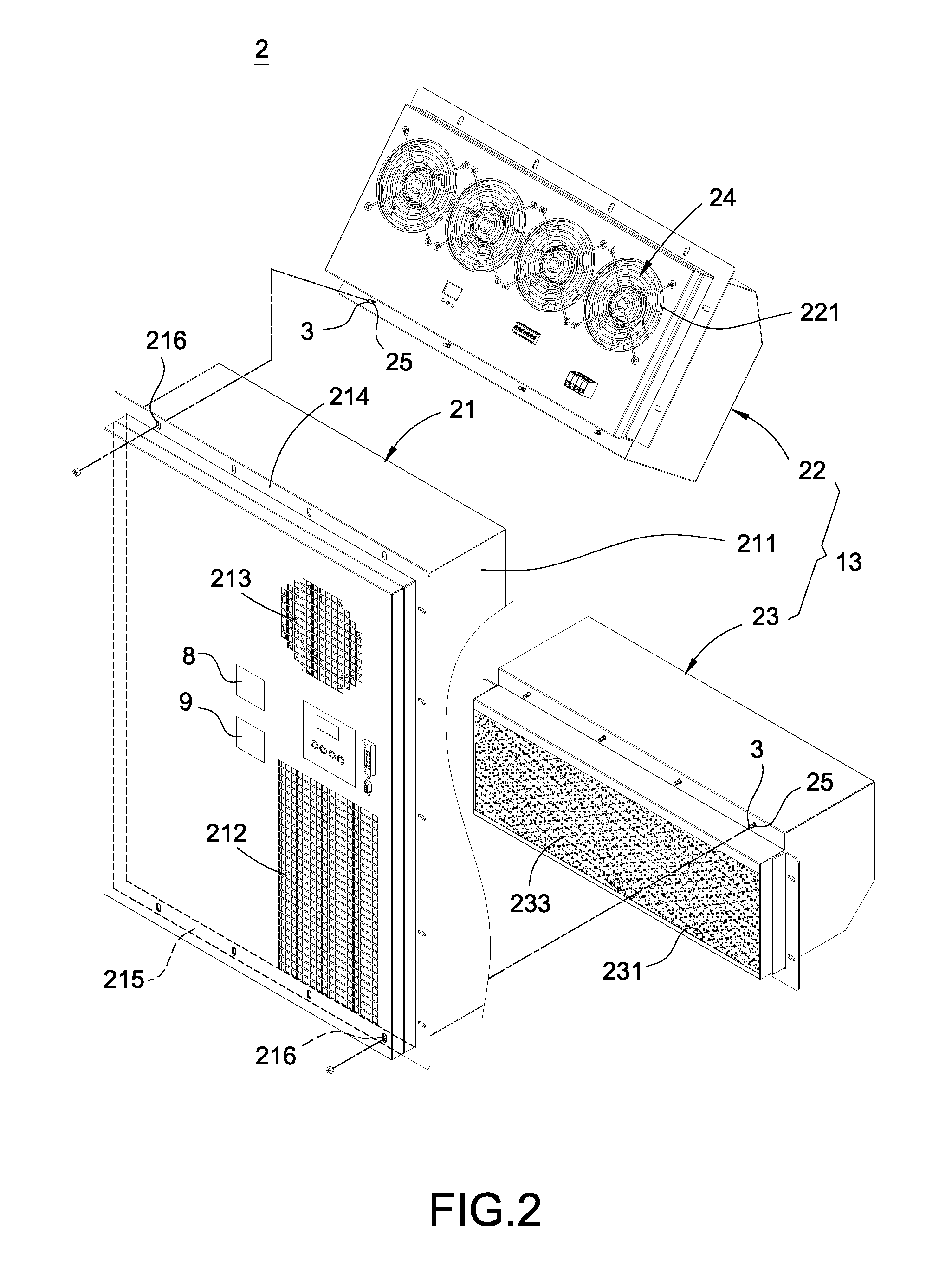

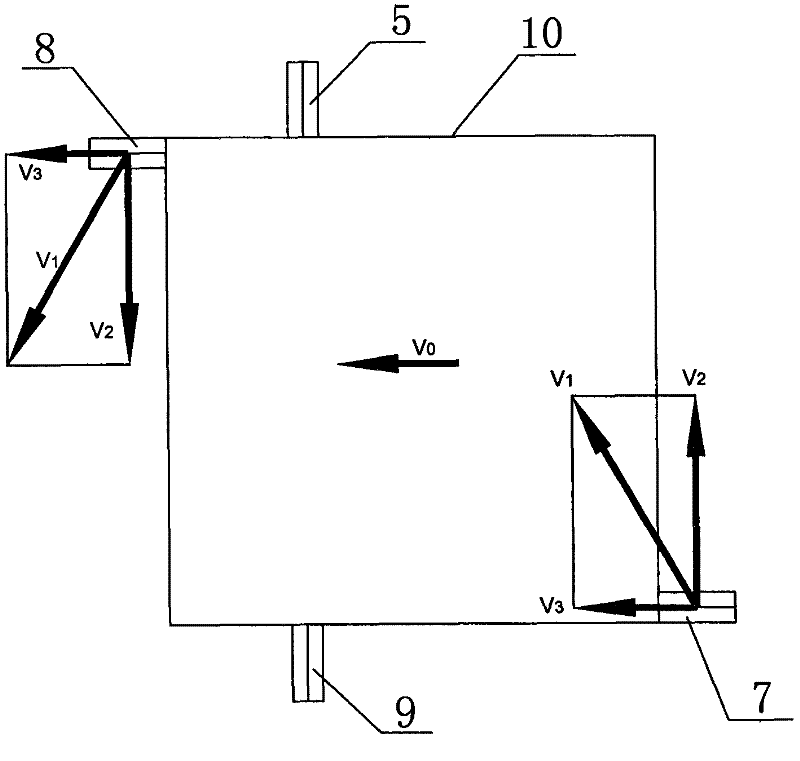

Temperature regulated cabinet

ActiveUS20160302326A1Save power consumptionImprove external airflow circulation efficiencyCooling/ventilation/heating modificationsEngineeringMechanical engineering

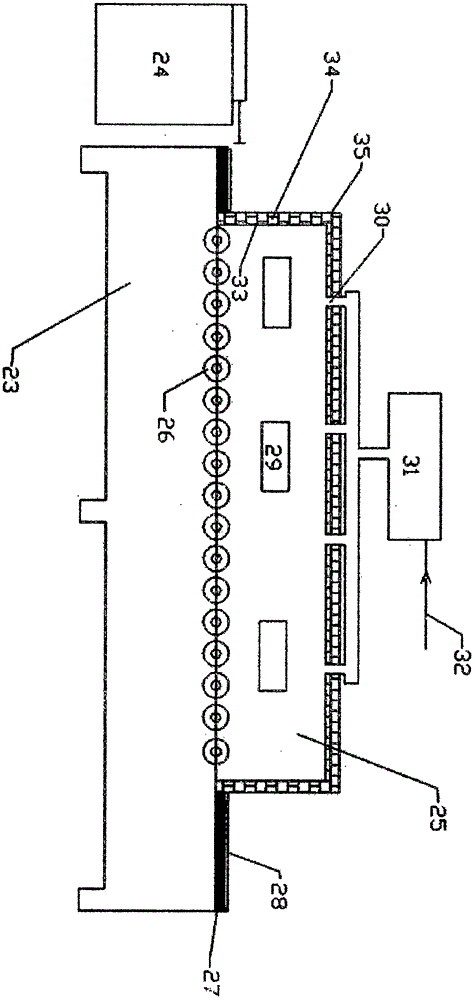

A temperature-regulated cabinet (10) includes a cabinet body (1) and a temperature regulating module (2). The cabinet body (1) has a containing space (11) formed inside the cabinet body (1) and an opening (12) communicated with the containing space (11). The temperature regulating module (2) is detachably installed to the cabinet body (1) and covered onto the opening (12) and includes a temperature regulator (21), a first hood (22), a second hood (23) and an exhaust fan (24). The temperature regulator (21) has a casing (211). The first hood (22) is detachably installed to the top of the casing (211), and the second hood (23) is detachably installed to the bottom of the casing (211). The exhaust fan (24) is installed inside the first hood (22) or the second hood (23). The cabinet has the advantages of simplifying the production line and lowering the construction and operation costs.

Owner:DELTA ELECTRONICS INC

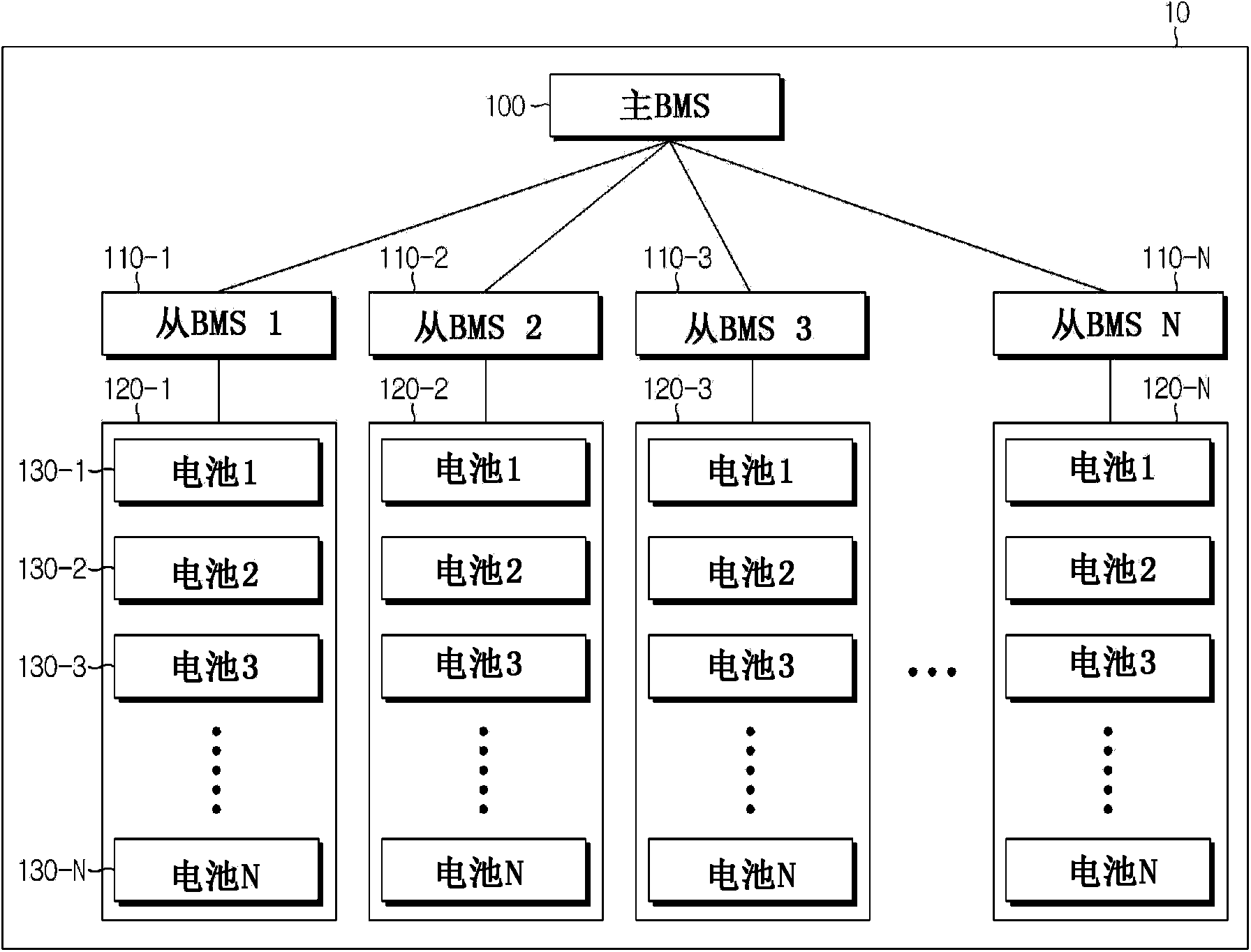

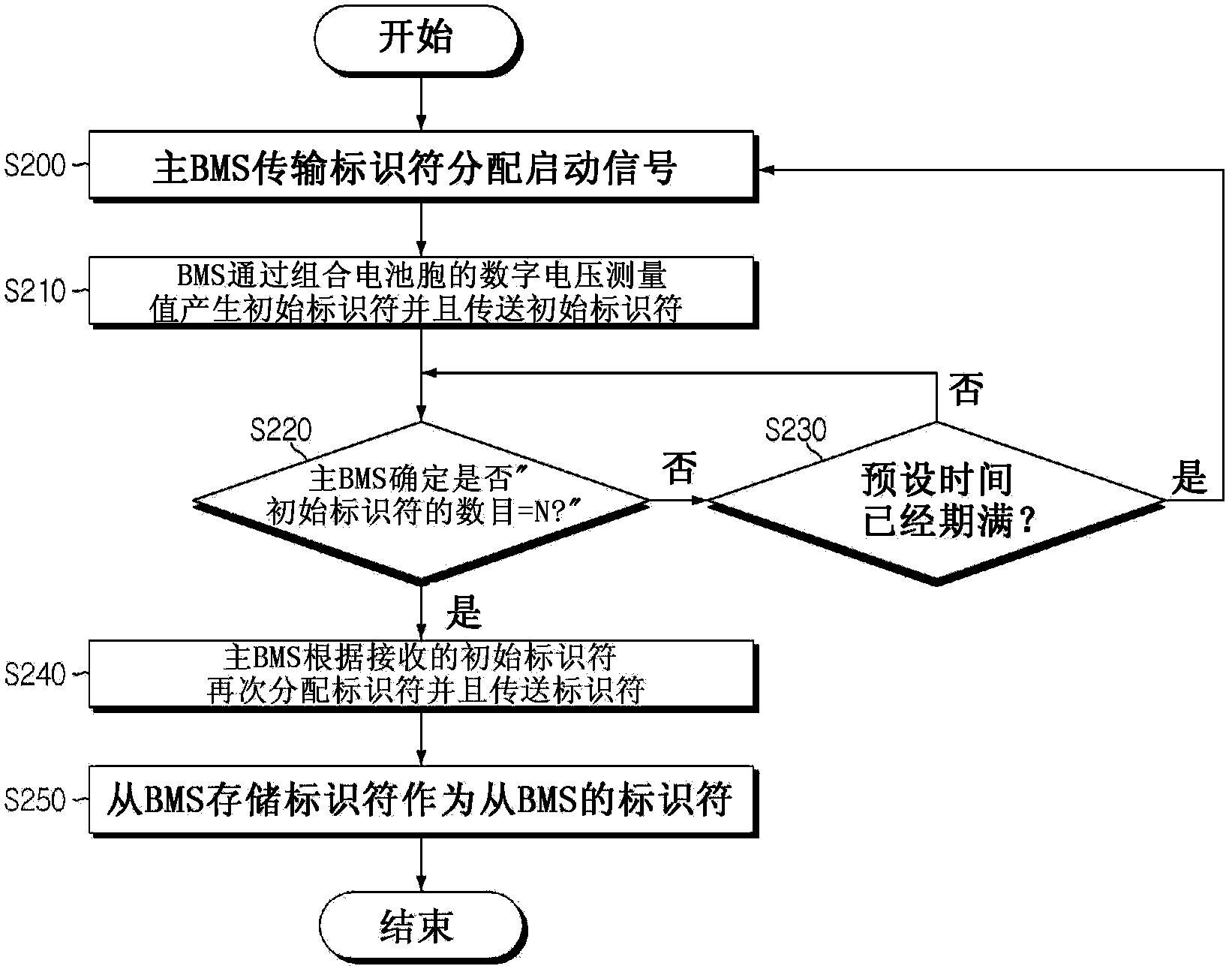

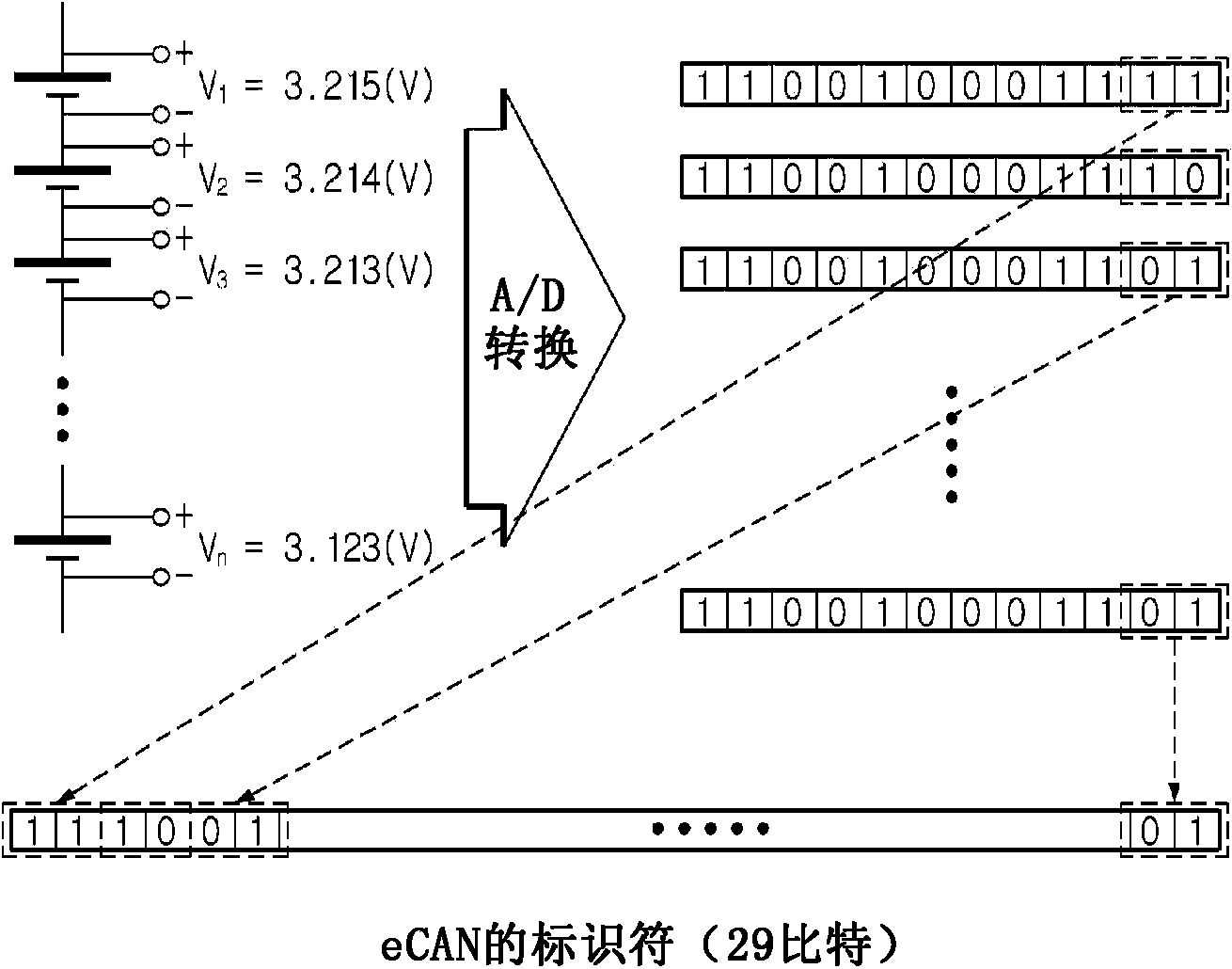

Method and system for allocating identifiers for multiple slaves of a battery pack

ActiveCN103650290AShort timeReduce manufacturing costSecondary cellsElectrical testingEngineeringBattery cell

The present invention relates to a method and system for allocating identifiers for multiple slaves of a battery pack. According to the present invention, a method in which a master battery management system (BMS) allocates identifiers for N (N being an integer greater than or equal to two) number of slave BMSs through a communication network comprises the steps of: (a) each slave BMS combining digital voltage measurement values of battery cells contained in battery modules managed by said each slave BMS so as to generate initial identifiers, and transmitting the initial identifiers to the master BMS; and (b) the master BMS re-allocating identifiers on the basis of the initial identifiers received from each slave BMS, and transmitting the allocated identifiers to each slave BMS. According to the present invention, identifiers can be allocated without pre-inputted identifiers for multi-slave BMSs and without a separate hardware configuration.

Owner:LG ENERGY SOLUTION LTD

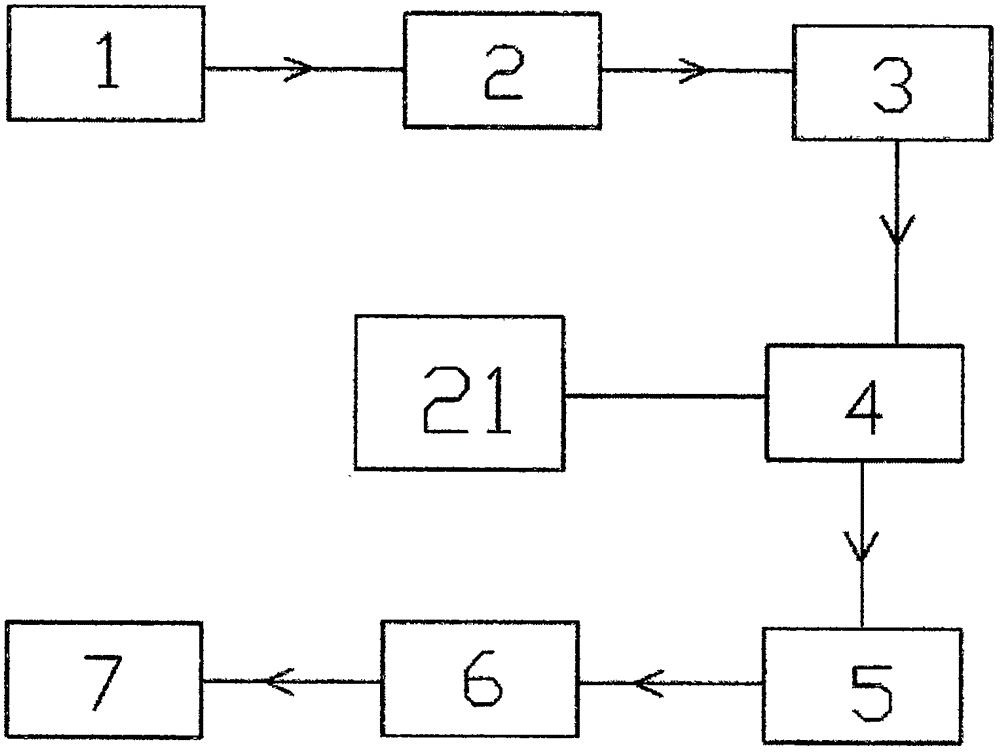

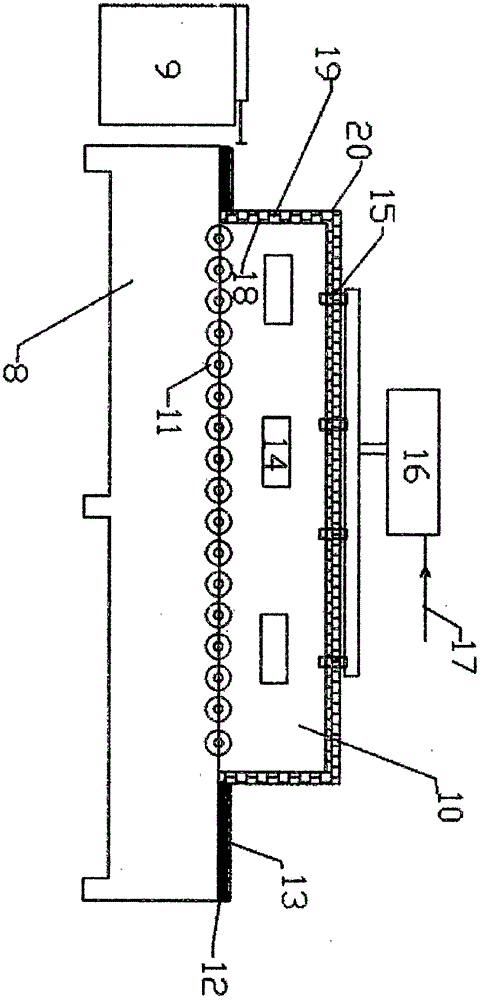

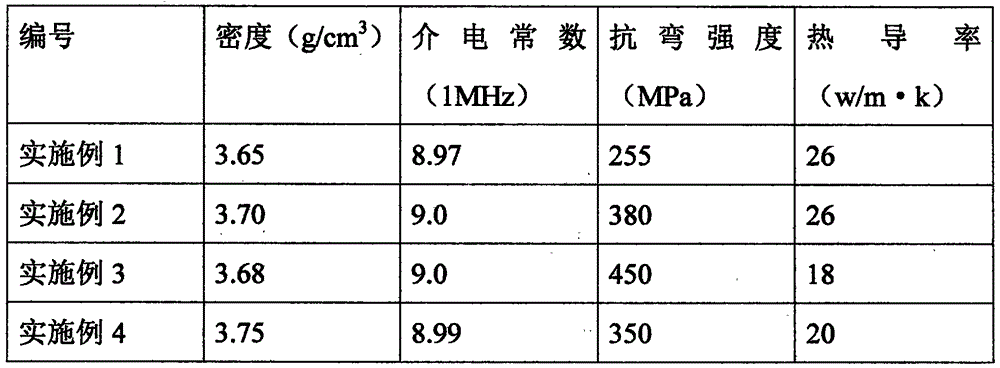

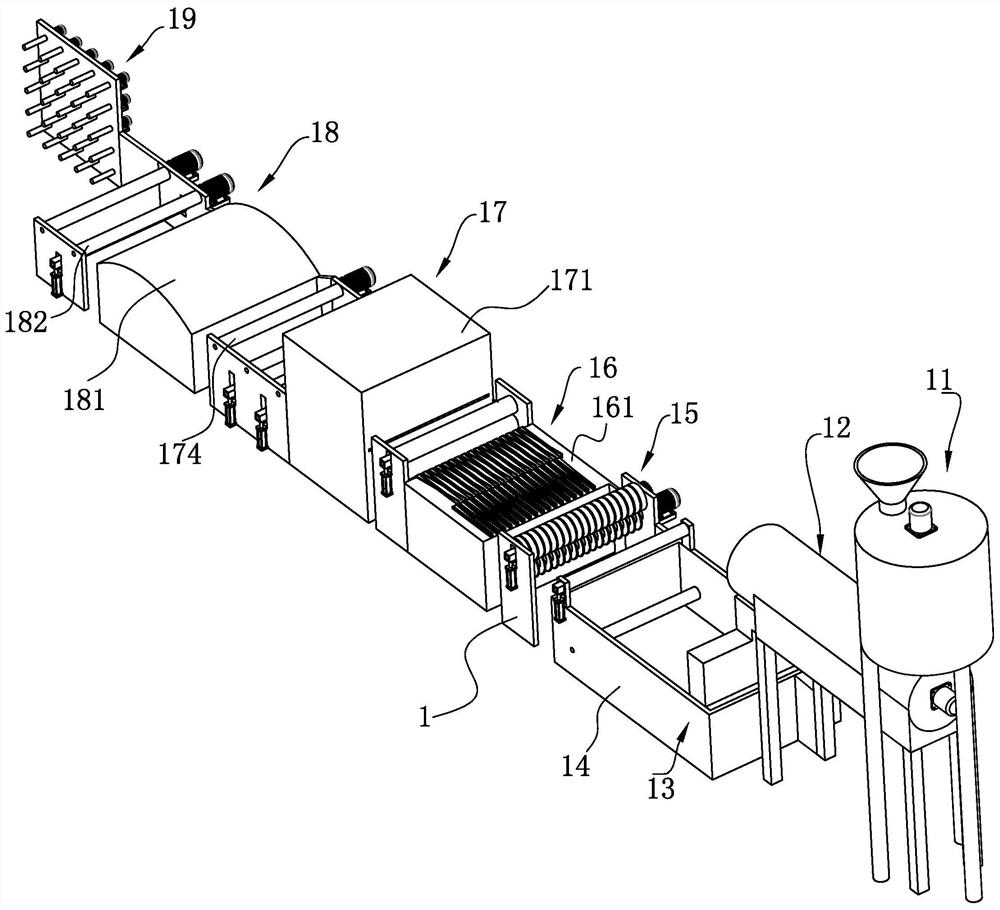

High-strength ceramic substrate and preparation method and production line thereof

InactiveCN105881700AHigh strengthHigh mechanical strengthCeramic shaping plantsProduction linePlasticizer

The invention discloses a high-strength ceramic substrate. The high-strength ceramic substrate is composed of ceramic powder, binders, dispersing agents, plasticizers and solvents, wherein the weight ratio of the ceramic powder to the binders to the dispersing agents to the plasticizers and to the solvents is 1 to 0.08-0.15 to 0.01-0.03 to 0.03-0.06 to 0.5-0.8; the ceramic powder is composed of alumina powder and zirconium oxide powder, and the content of the zirconium oxide powder accounts for 3-30% in the ceramic powder by weight. The invention further discloses a preparation method and a production line of the ceramic substrate. The ceramic substrate is excellent in mechanical strength, high in bending strength, good in heat conduction characteristic, high in stability at high temperature and capable of being machined into various complex shapes. The preparation method is simple, the number of processes is small, and the obtained substrate is uniform and compact in structure, high in bending strength, smooth in surface and low in cost. The production line is simple, small in occupied space and suitable for industrial application.

Owner:SINOCERAM TECH (ZHENGZHOU) CO LTD

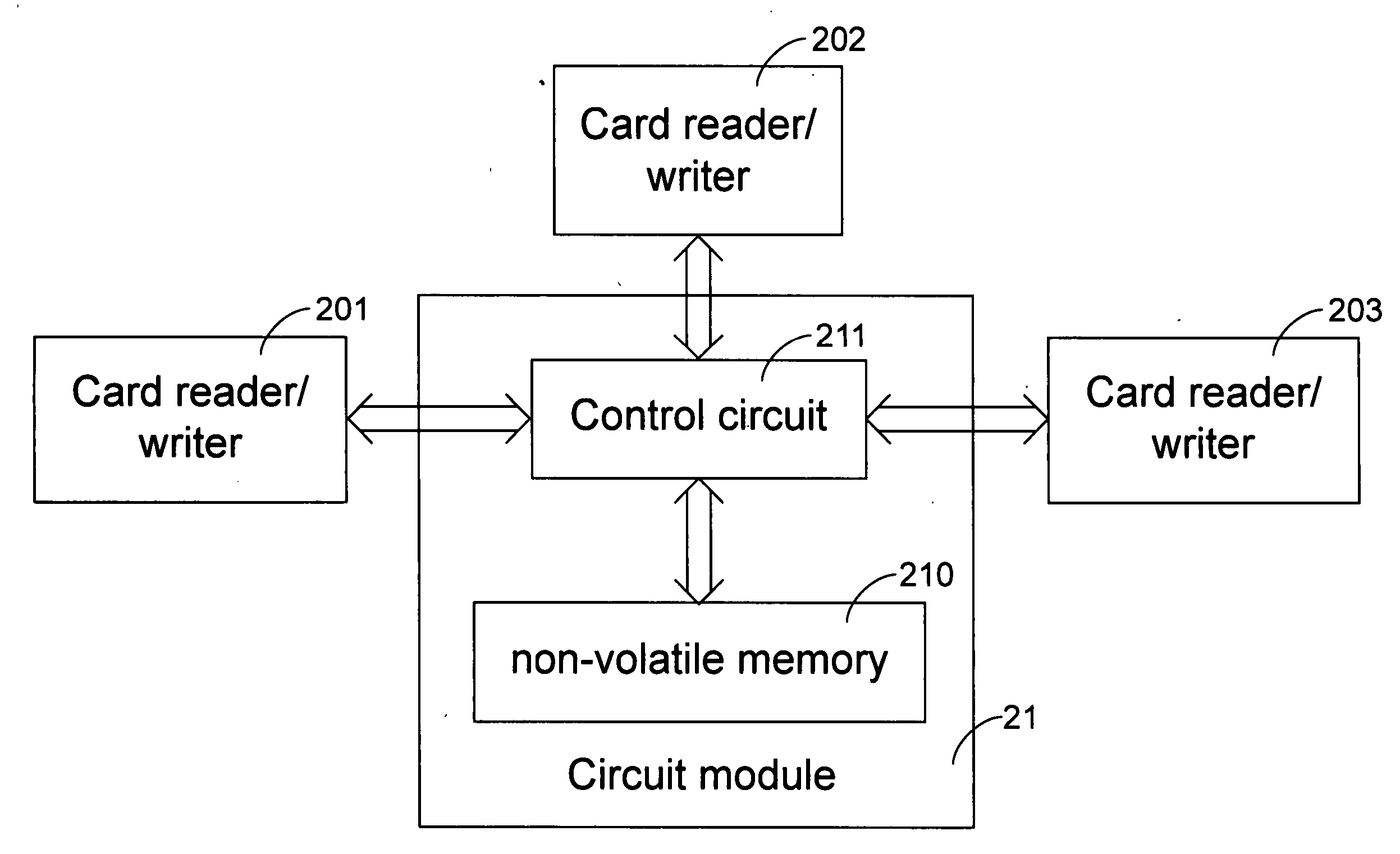

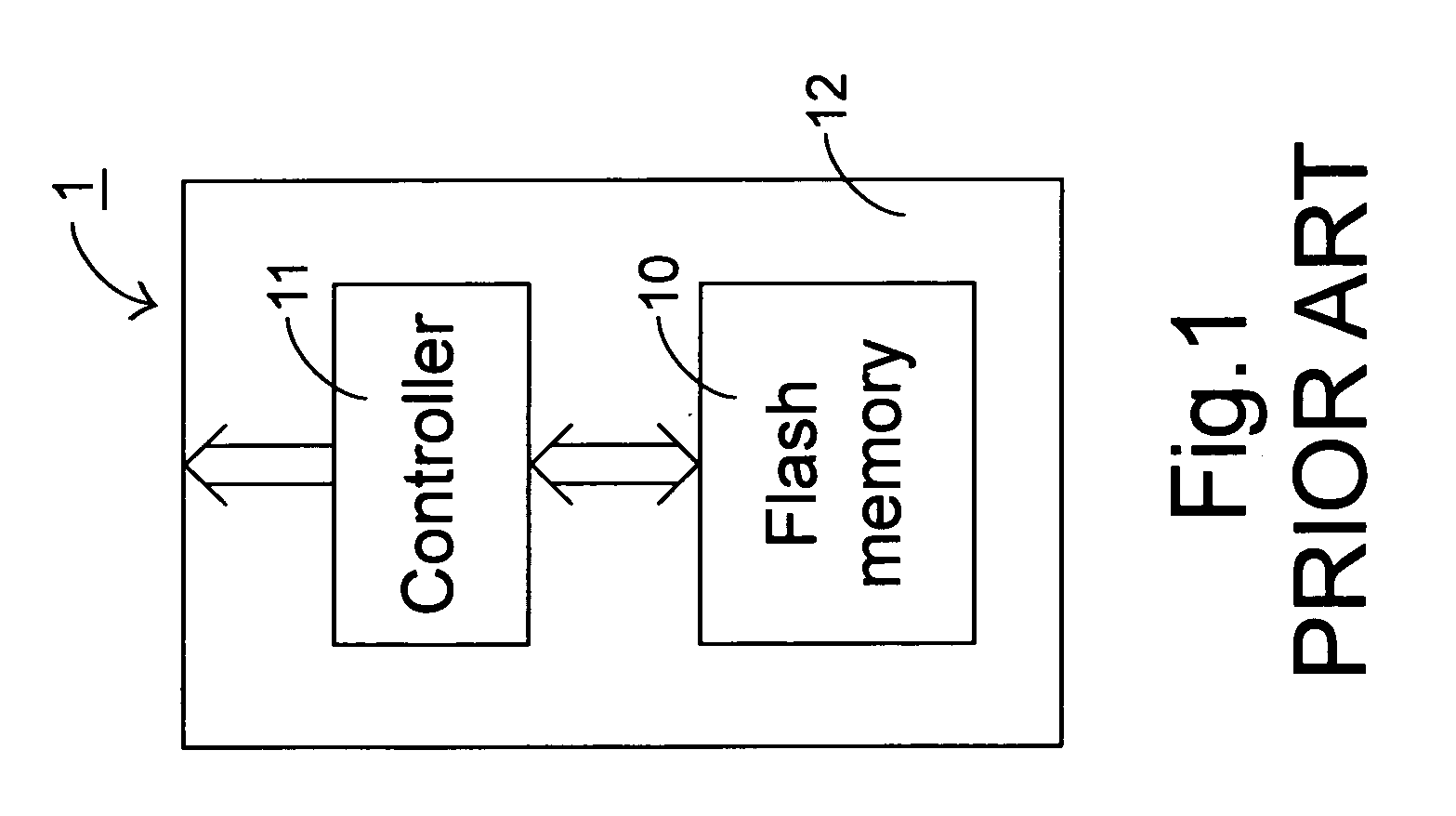

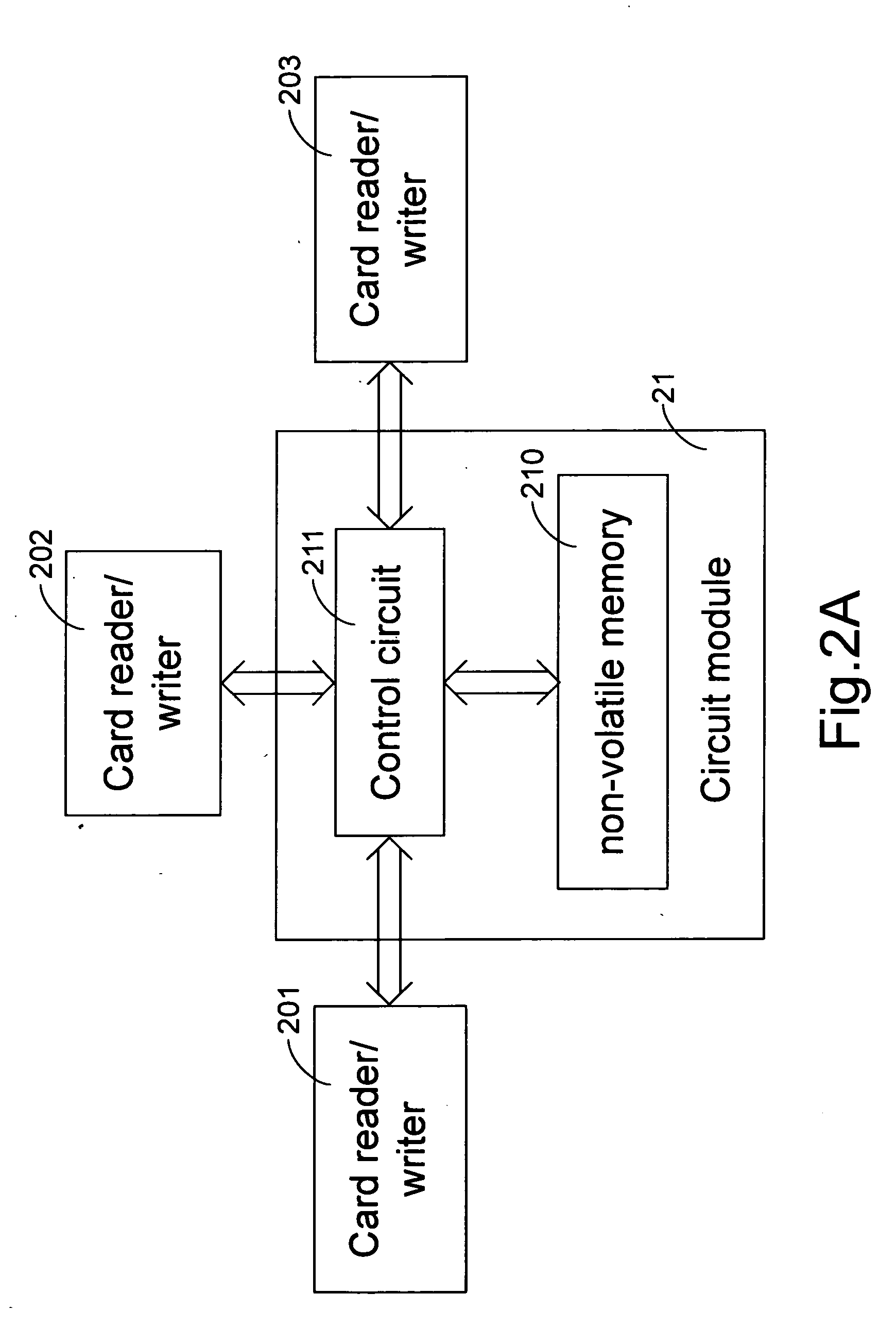

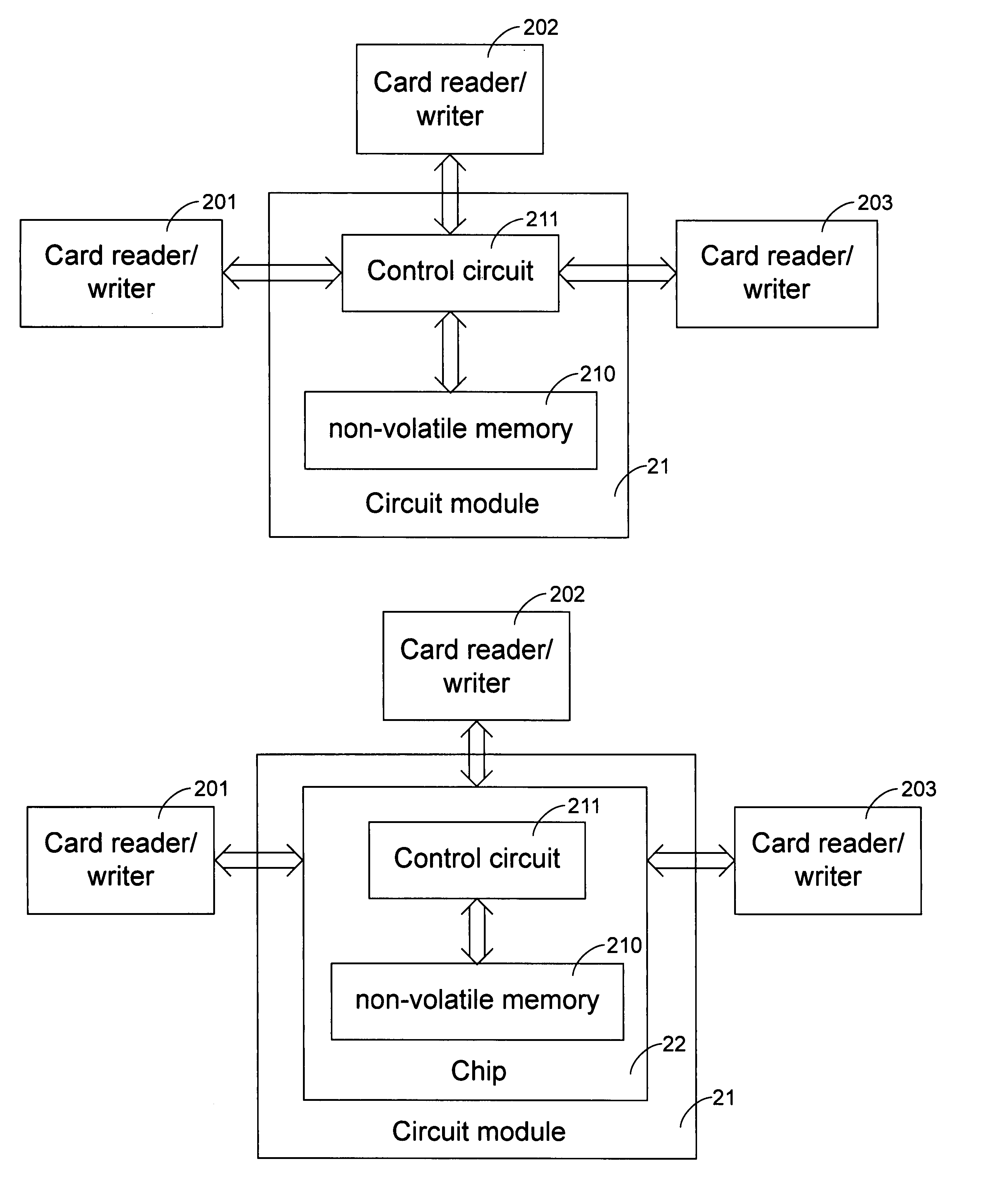

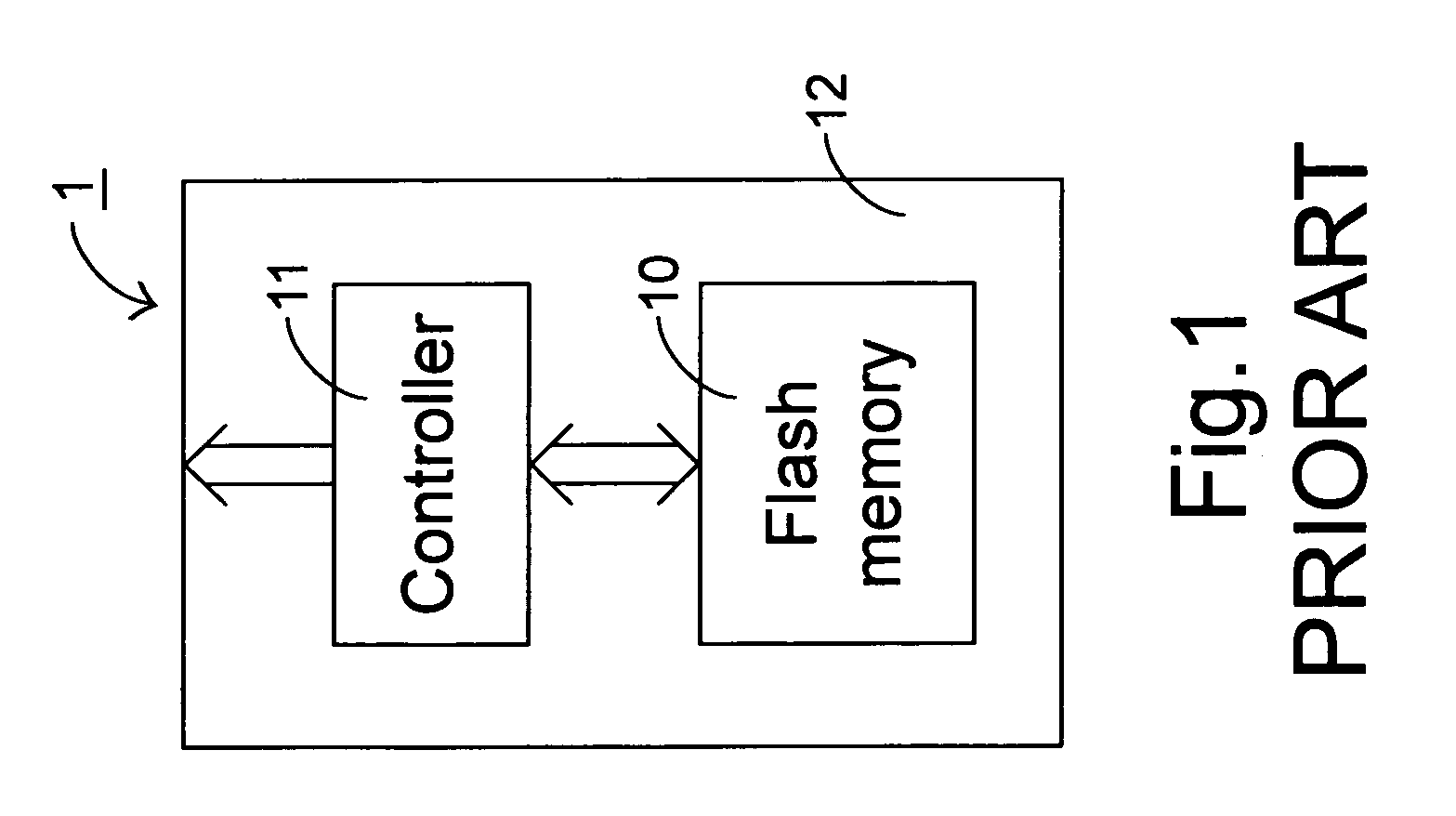

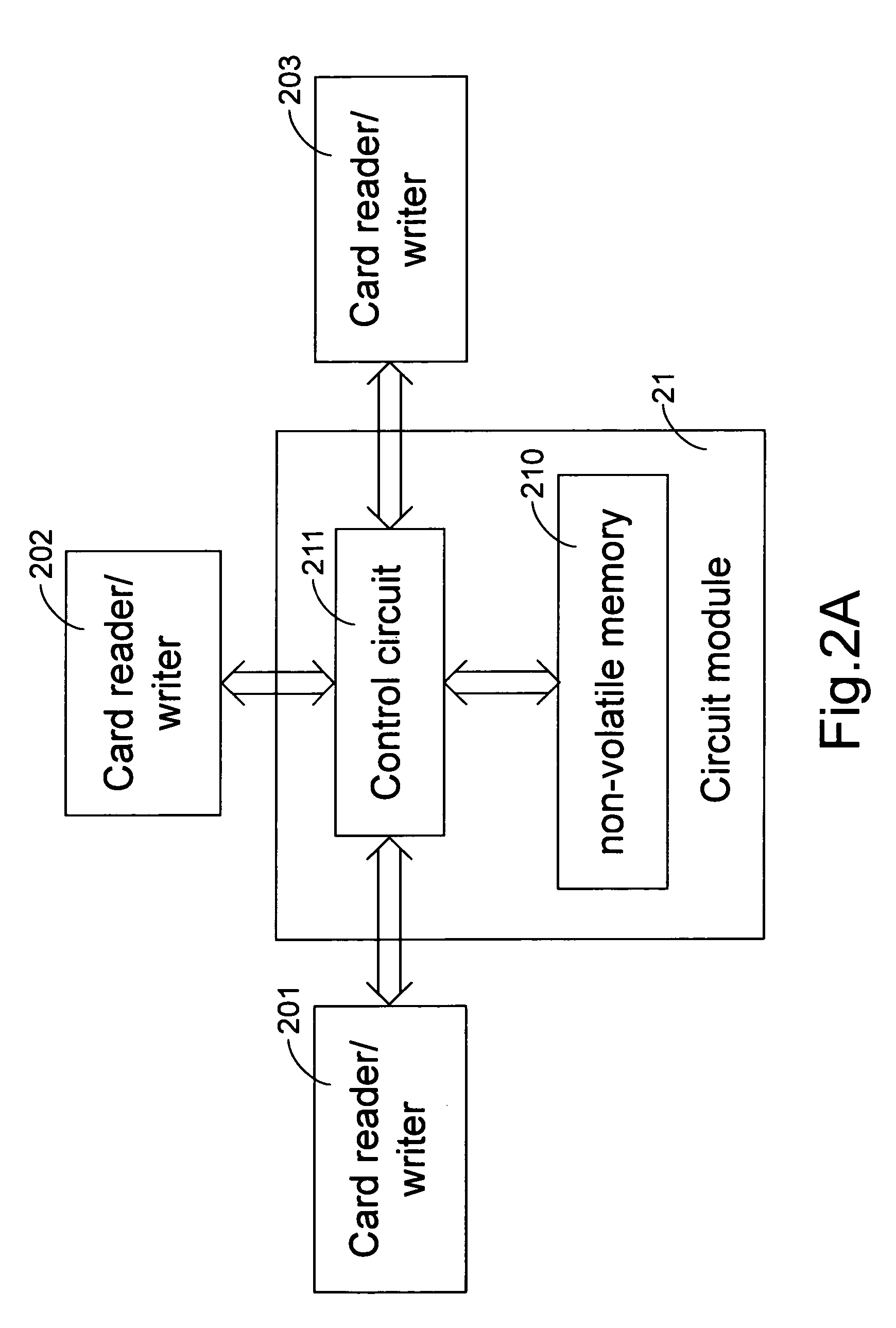

Circuit module and memory card kit compliant with various access protocols

ActiveUS20050279839A1Simplify the production lineReduce inventory costsSensing record carriersRecord carriers used with machinesCard readerData transmission

A circuit module of a memory card is selectively used with card readers / writers compliant with different access protocols. The circuit module includes a shared non-volatile memory; a first transmission control unit communicable with a first card reader / writer for controlling data transmission from / to the first card reader / writer; a second transmission control unit communicable with a second card reader / writer for controlling data transmission from / to the second card reader / writer; and a data buffer and memory access controller coupled to the non-volatile memory and the first and second transmission control units for conducting a data transmission path between a designated transmission control unit and the non-volatile memory, thereby allowing data transmission between the designated card reader / writer and the non-volatile memory. The circuit module can be grouped with different carrier housings to produce a memory card kit.

Owner:VIA TECH INC

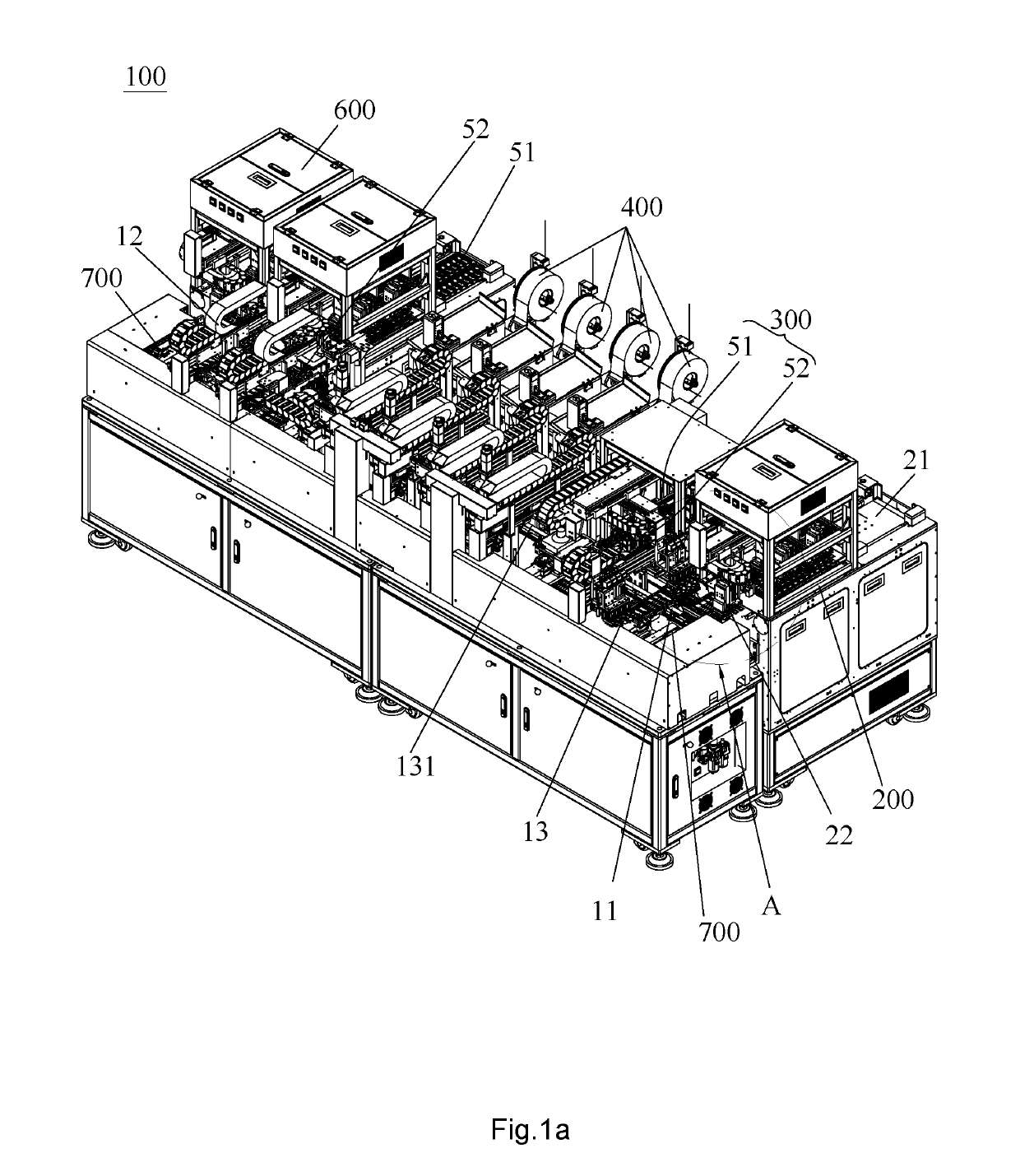

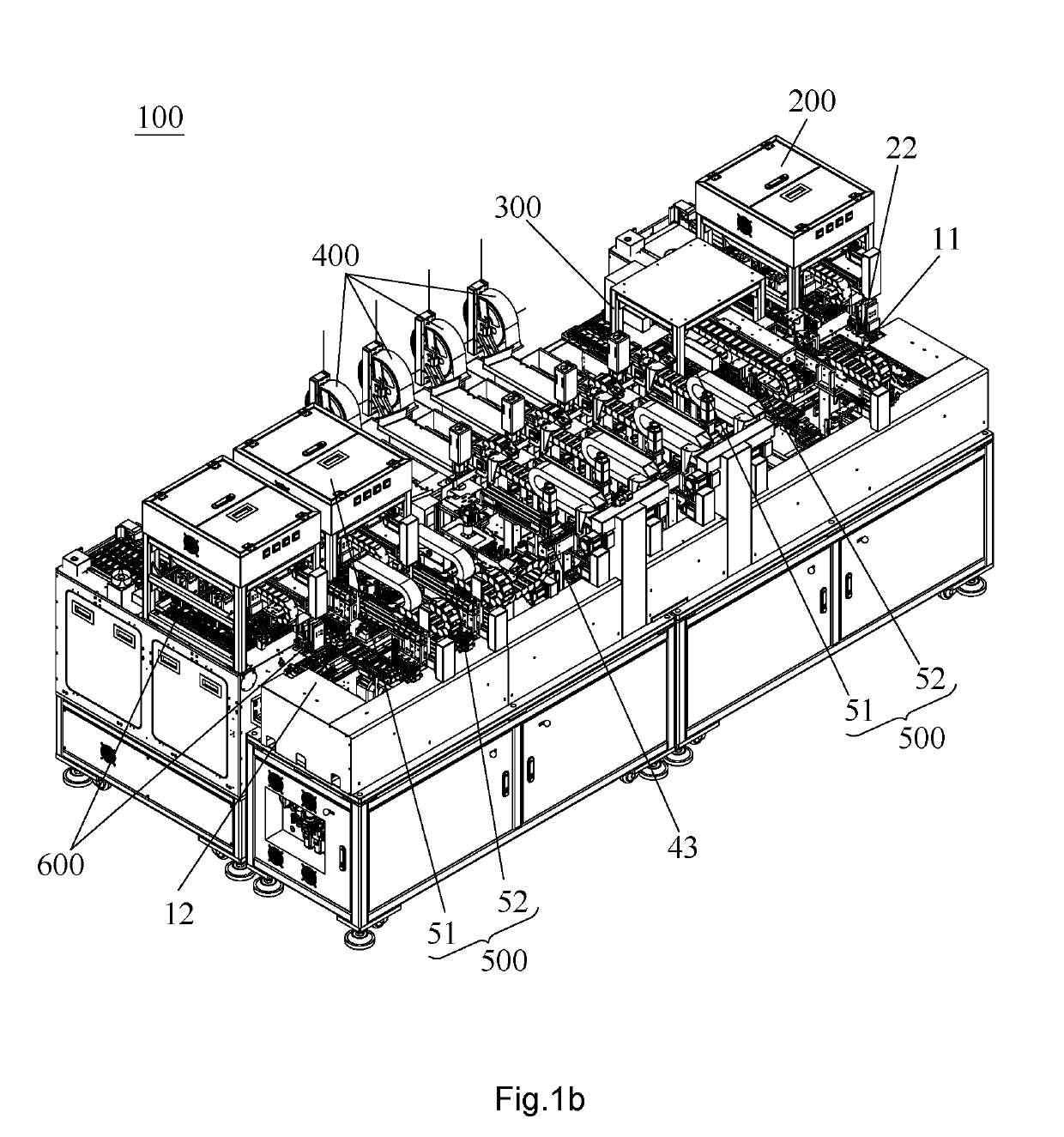

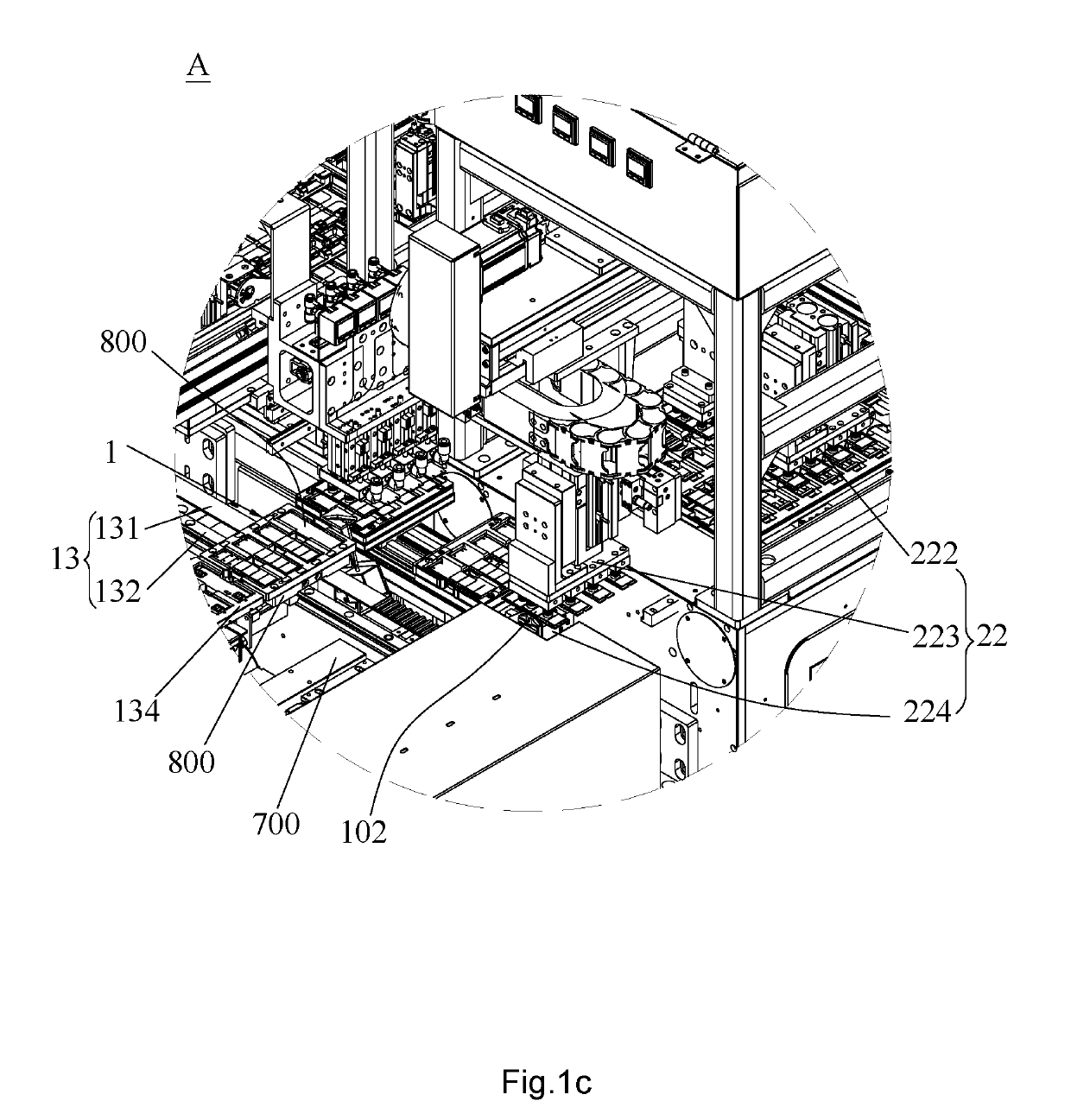

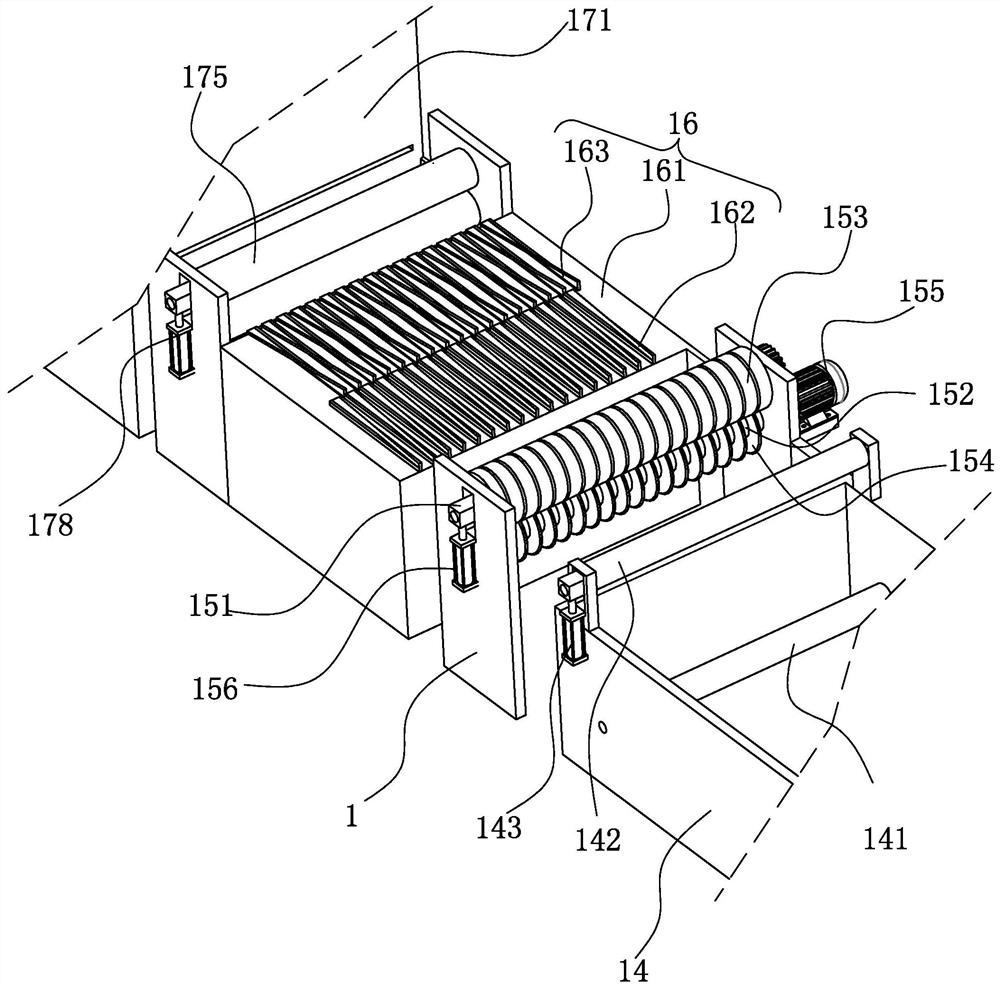

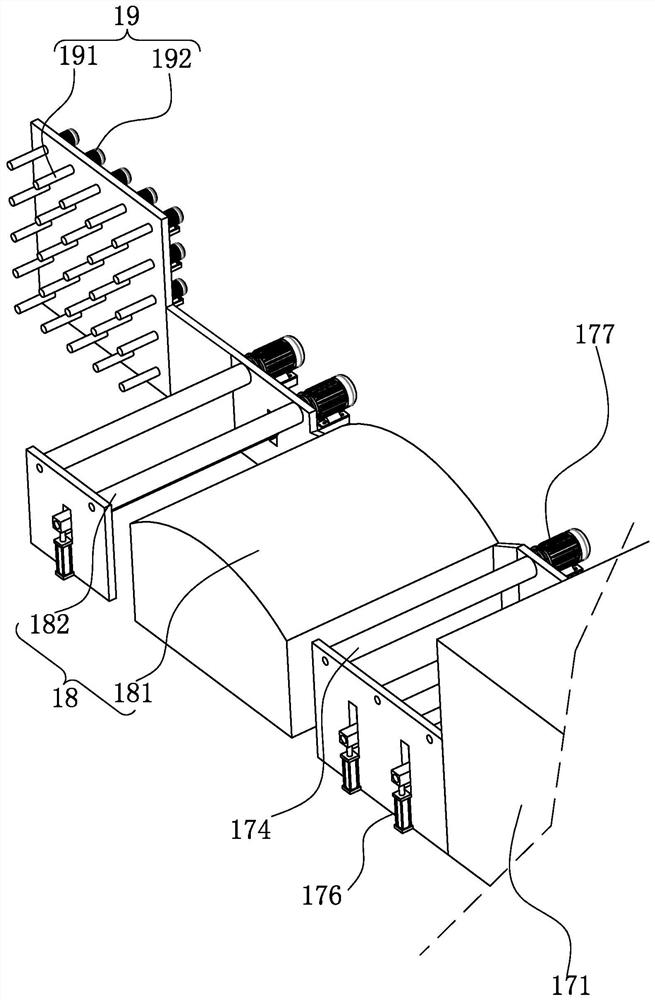

Automatic labeling production line for solid state disk

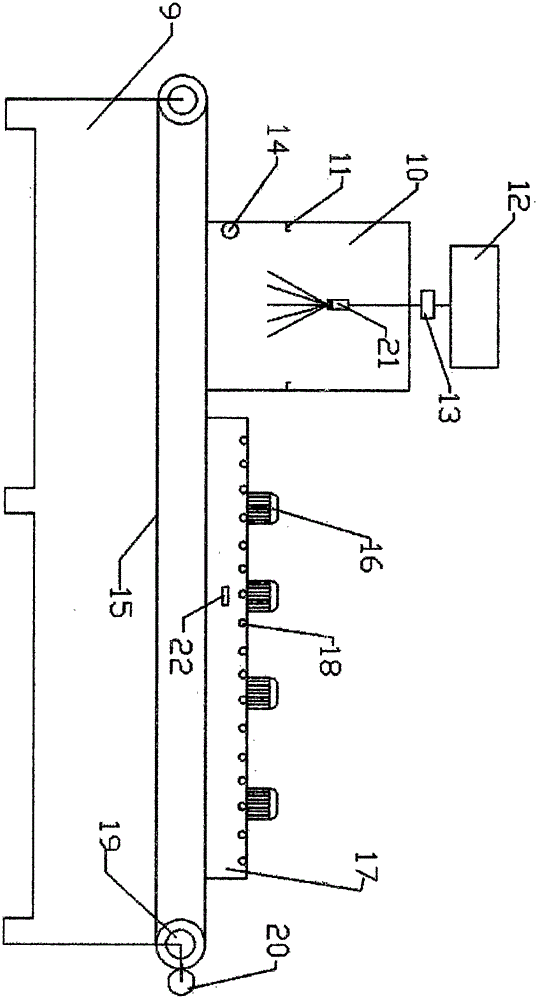

ActiveUS20190308220A1Increase productionFlexible in labelingSortingLabelling flat rigid surfacesProduction lineVisual inspection

An automatic labeling production line for solid state disk includes a production conveyor belt, a fixture disposed on the production conveyor belt and provided with a fixture code, and a loading mechanism provided with a product scanning mechanism detecting the memory and marking out a first defective memory, a first fixture scanning mechanism, a first and a second recycling mechanism recycling a defective memory, an automatic labeling mechanism, a visual inspection mechanism, a second fixture scanning mechanism identifying the fixture code, and an unloading mechanism unloading the memory which are arranged along the production conveyor belt in turn. The first fixture scanning mechanism scans the fixture code and records the original code and the corresponding fixture code. The visual inspection mechanism detects the memory and marks out a second defective memory. Thus, the production line is simplified, automatic labeling for memory is achieved, and the label process is more flexible.

Owner:DONGGUAN WORLD PRECISION MACHINERY

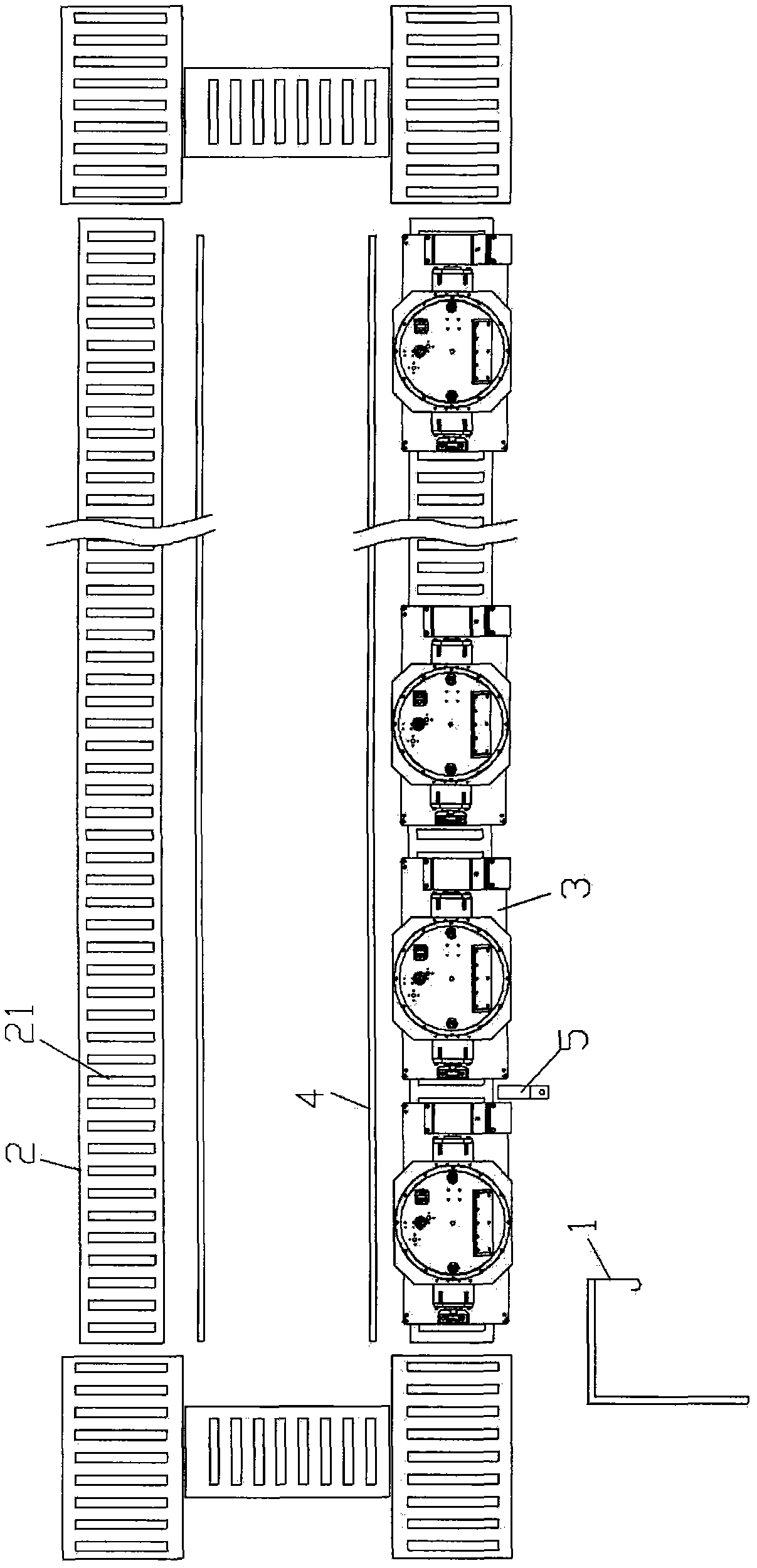

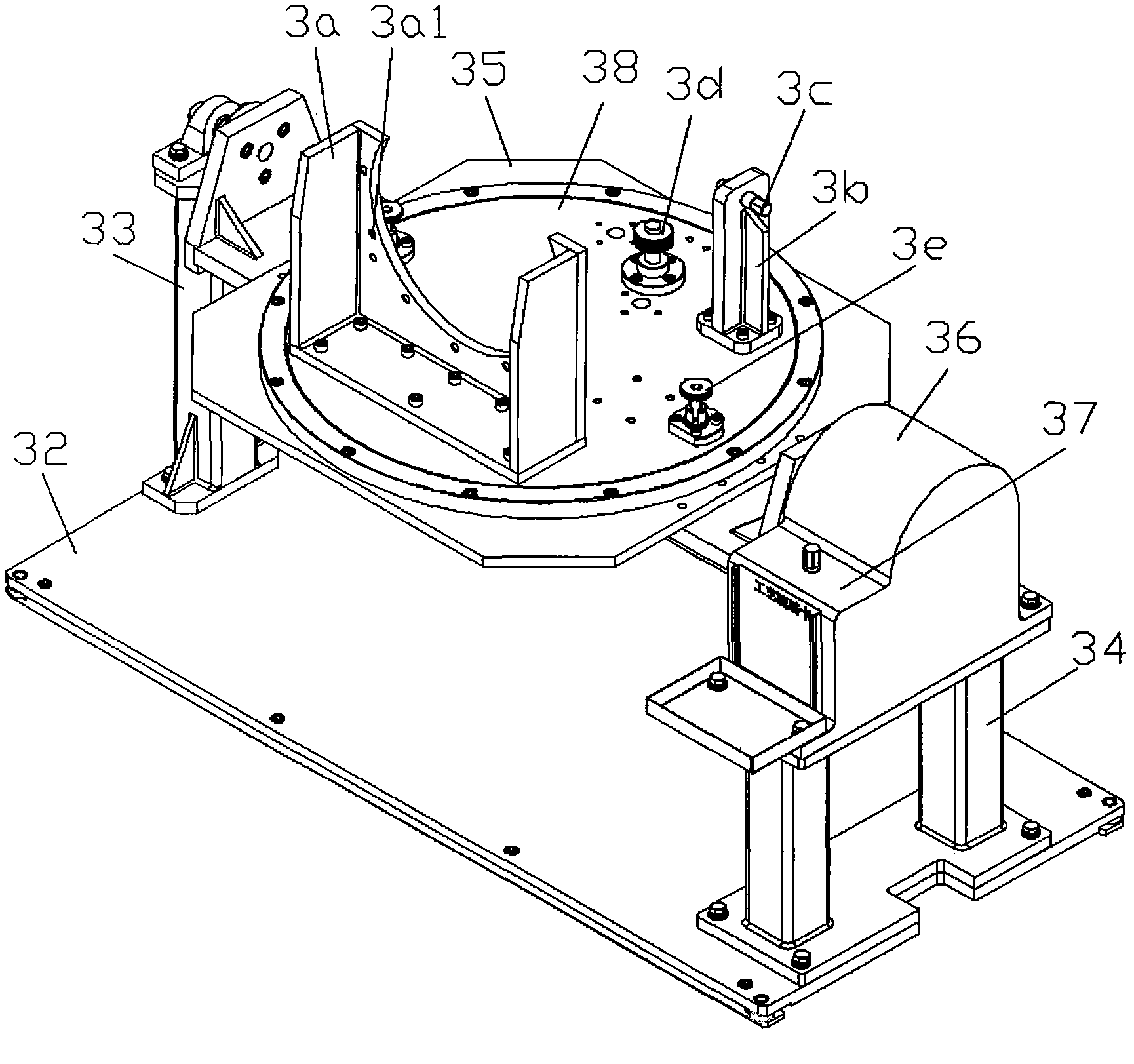

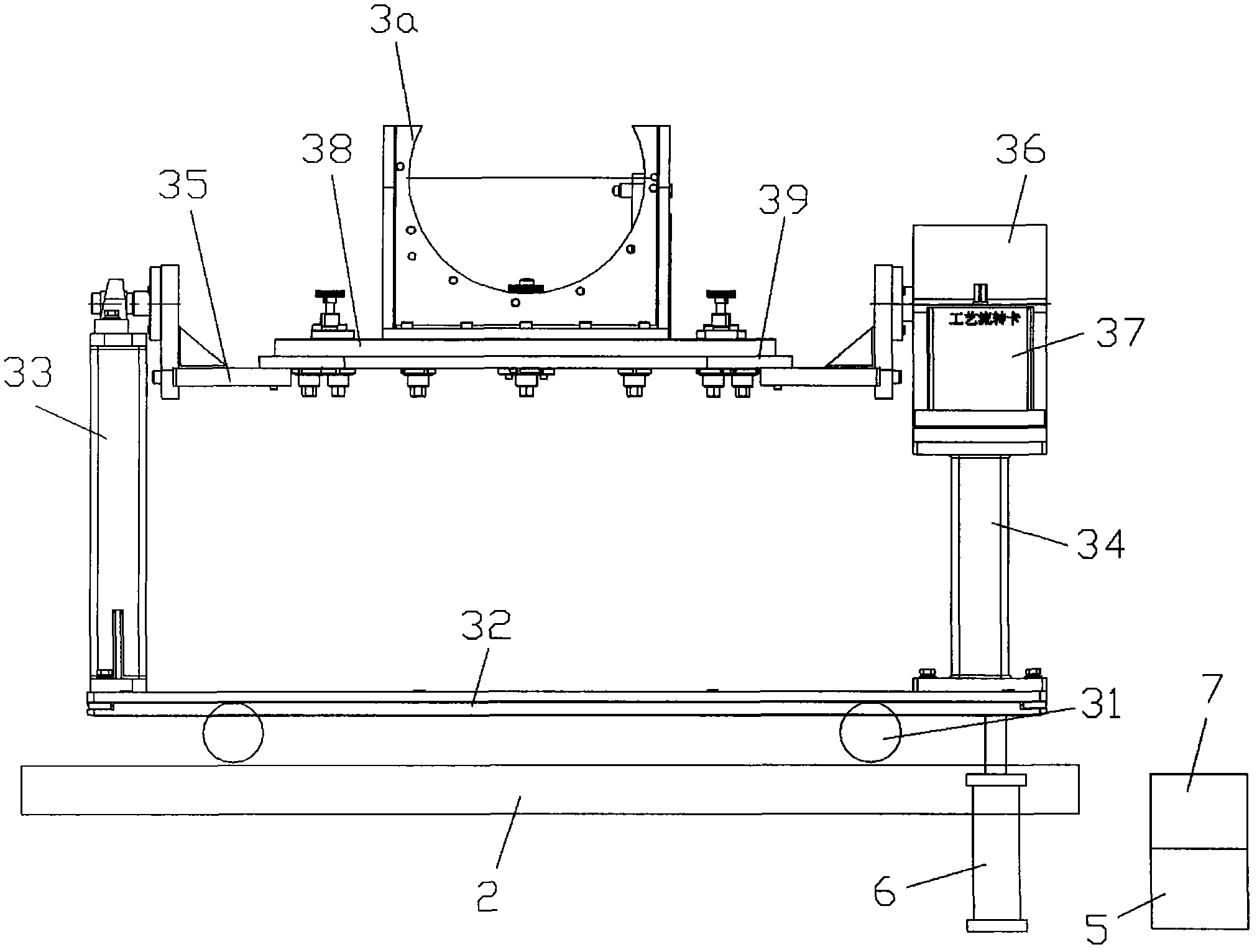

Forklift transmission assembling line

Provided is a forklift transmission assembling line. A suspension arm is disposed on the ground on one side of the periphery of a roller transmission rack in a suspended mode. A traveling wheel of a movable trolley of an assembling line is placed on a roller of the roller transmission rack. Trolley-stop blocking cylinders are fixed on the ground of each station and fixed on the ground on two sides of the roller transmission rack, and a pneumatic switch of the trolley-stop blocking cylinder is disposed on an operating platform of each station. A breast board is placed on the inner-side ground of the roller transmission rack arranged in the shape of a ring, and words for operating steps and precautions are arranged on the breast board. A support platform of the forklift transmission assembling line can rotate 360 degrees, and a workbench of the forklift transmission assembling line can rotate 360 degrees on the surface of the operating platform. During direction changes in assembly, carrying trouble of workers can be removed. The forklift transmission assembling line uses a spring pin for locating after rotation of the workbench so as to avoid rotation of the workbench during assembly. The forklift transmission assembling line is especially suitable for production and assembly of forklift transmissions and low in equipment cost, lowers labor intensity of workers, improves production efficiency, and simultaneously is convenient for management and operation of workers.

Owner:ZHEJIANG ZHONGCHAI MACHINERY

Circuit module and memory card kit compliant with various access protocols

ActiveUS7219846B2Simplify the production lineReduce inventory costsSensing record carriersRecord carriers used with machinesCard readerData transmission

A circuit module of a memory card is selectively used with card readers / writers compliant with different access protocols. The circuit module includes a shared non-volatile memory; a first transmission control unit communicable with a first card reader / writer for controlling data transmission from / to the first card reader / writer; a second transmission control unit communicable with a second card reader / writer for controlling data transmission from / to the second card reader / writer; and a data buffer and memory access controller coupled to the non-volatile memory and the first and second transmission control units for conducting a data transmission path between a designated transmission control unit and the non-volatile memory, thereby allowing data transmission between the designated card reader / writer and the non-volatile memory. The circuit module can be grouped with different carrier housings to produce a memory card kit.

Owner:VIA TECH INC

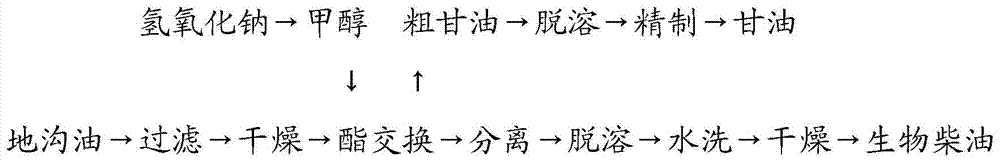

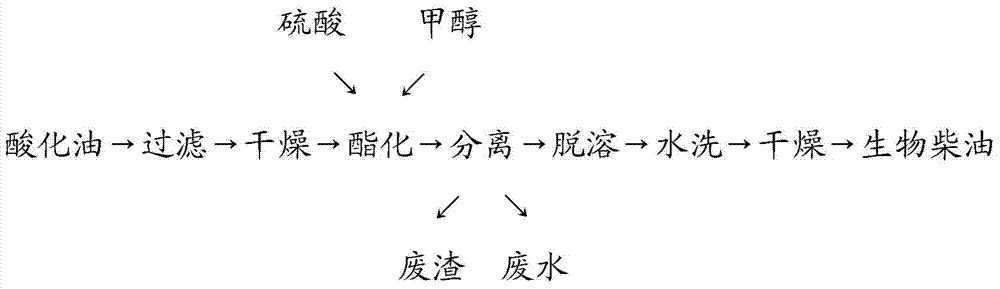

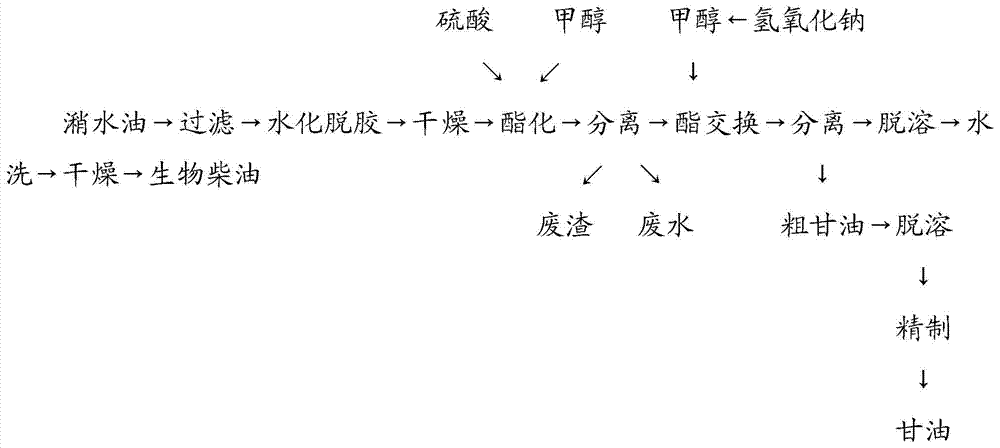

Method for preparing biodiesel from illegal cooking oil, acid oil and waste animal and plant grease

ActiveCN104232141AImprove technical levelSimplify the production lineBiofuelsLiquid hydrocarbon mixture productionOil and greaseMolecular rearrangement

The invention relates to a method for preparing biodiesel from illegal cooking oil, acid oil and waste animal and plant grease. The method comprises the following steps: with the illegal cooking oil, the acid oil and the waste animal and plant grease as main raw materials, degumming and removing impurities, vaporizing to separate out heavy oil, and through catalytic cracking chemical decomposition reaction, processing macromolecular grease through catalytic cracking, molecular rearrangement, removal of carboxyl groups and an oxygen element and other reaction mechanisms so as to convert the animal and plant grease into the biodiesel which meets national standard requirements for gasoline and diesel in hydrocarbon molecular structural composition, condensation point, density, viscosity, cetane number and octane number and other technical indexes. The method is wide in application range; by the method, strong technical supports are provided for enterprises to simplify the production line, lower the production cost and the management cost and the technical level of the biodiesel is greatly improved; the quality of the prepared biodiesel is obviously higher than that of the existing biodiesel; therefore, the method has quite remarkable social and economic benefits.

Owner:深圳泰利能源有限公司

Large-size ceramic substrate, and preparation method and production line thereof

InactiveCN105906331AHigh mechanical strengthGood thermal conductivityCeramic shaping plantsAdhesiveSolvent

The invention discloses a large-size ceramic substrate which is prepared from the following components in parts by weight: 1 part of ceramic powder, 0.04-0.14 part of adhesive, 0.005-0.018 part of dispersing agent, 0.02-0.06 part of plasticizer and 0.3-0.9 part of solvent. The ceramic powder is prepared from the following raw materials in percentage by weight: 93-96% of aluminum oxide, 0.5-3% of silicon dioxide, 0.3-2% of magnesium oxide, 0.2-1% of calcium oxide, 0.1-2% of yttrium oxide, 0.1-2.5% of barium carbonate, 0.05-1% of zirconium oxide and 0.1-2% of bismuth oxide. The invention also discloses a production method of the ceramic substrate and a production line required by the production method. The ceramic substrate has the characteristics of excellent mechanical strength and favorable heat conductivity. The preparation method is simple and is low in cost. The production line is simple, does not occupy the space, and effectively improves the quality of products.

Owner:SINOCERAM TECH (ZHENGZHOU) CO LTD

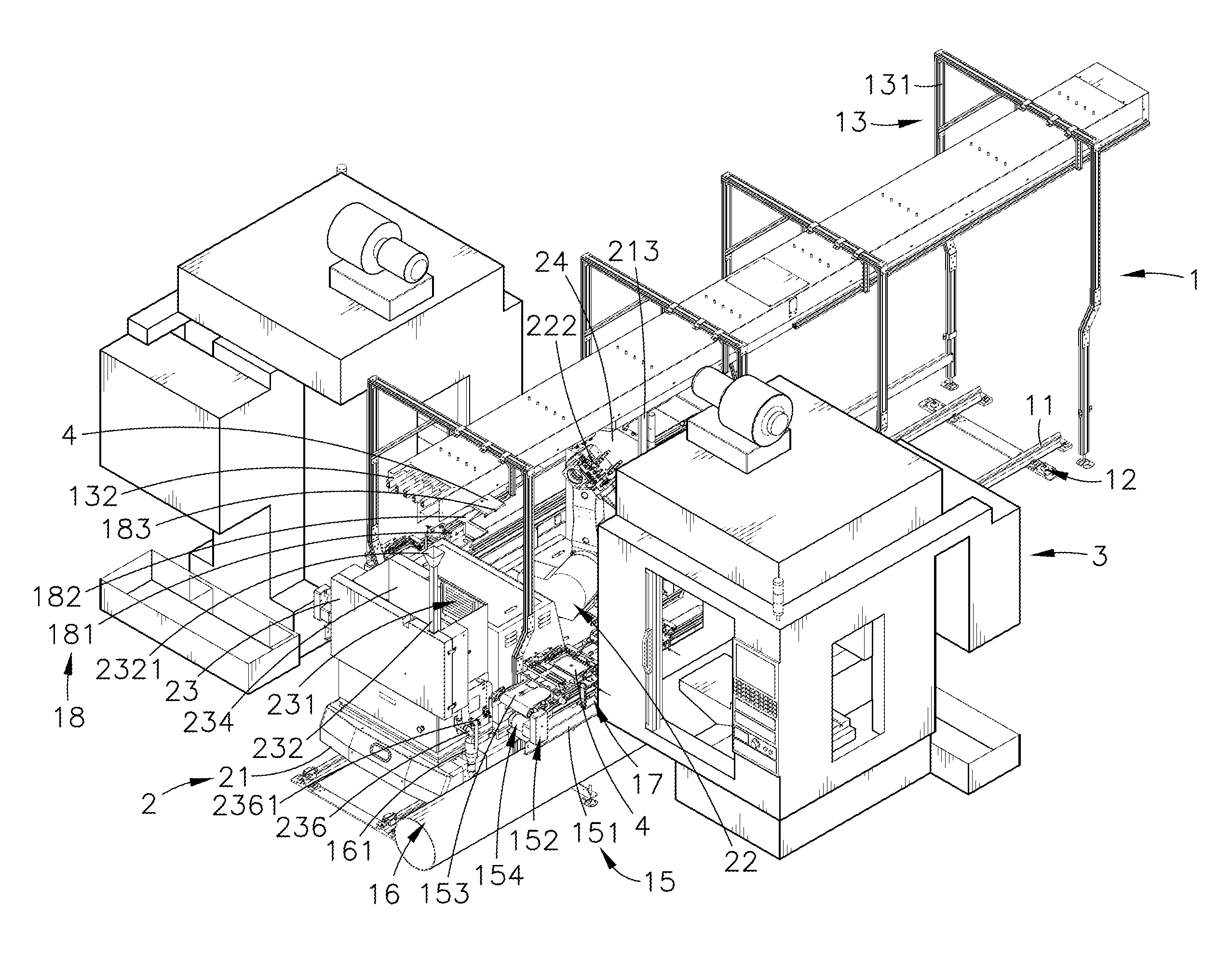

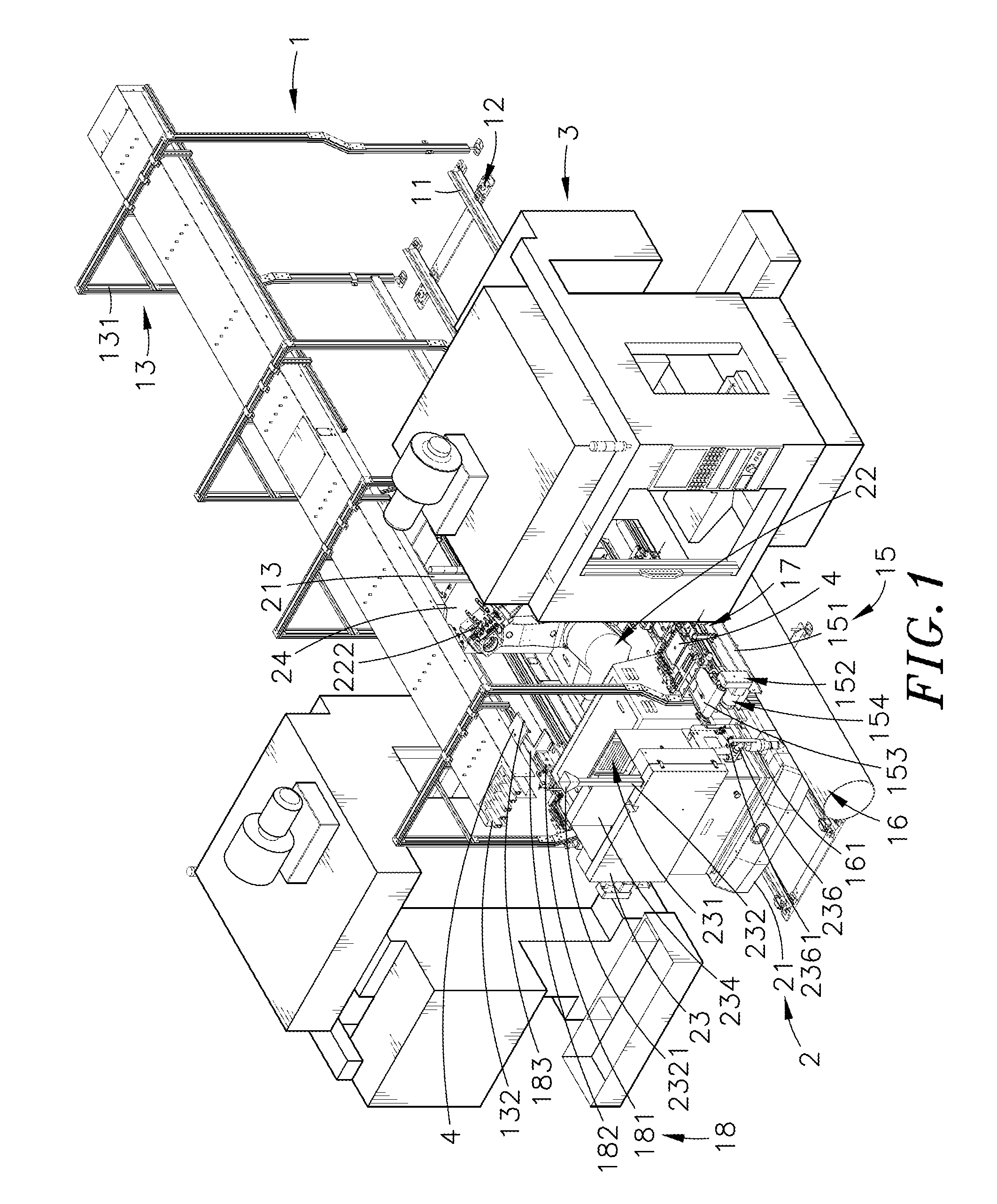

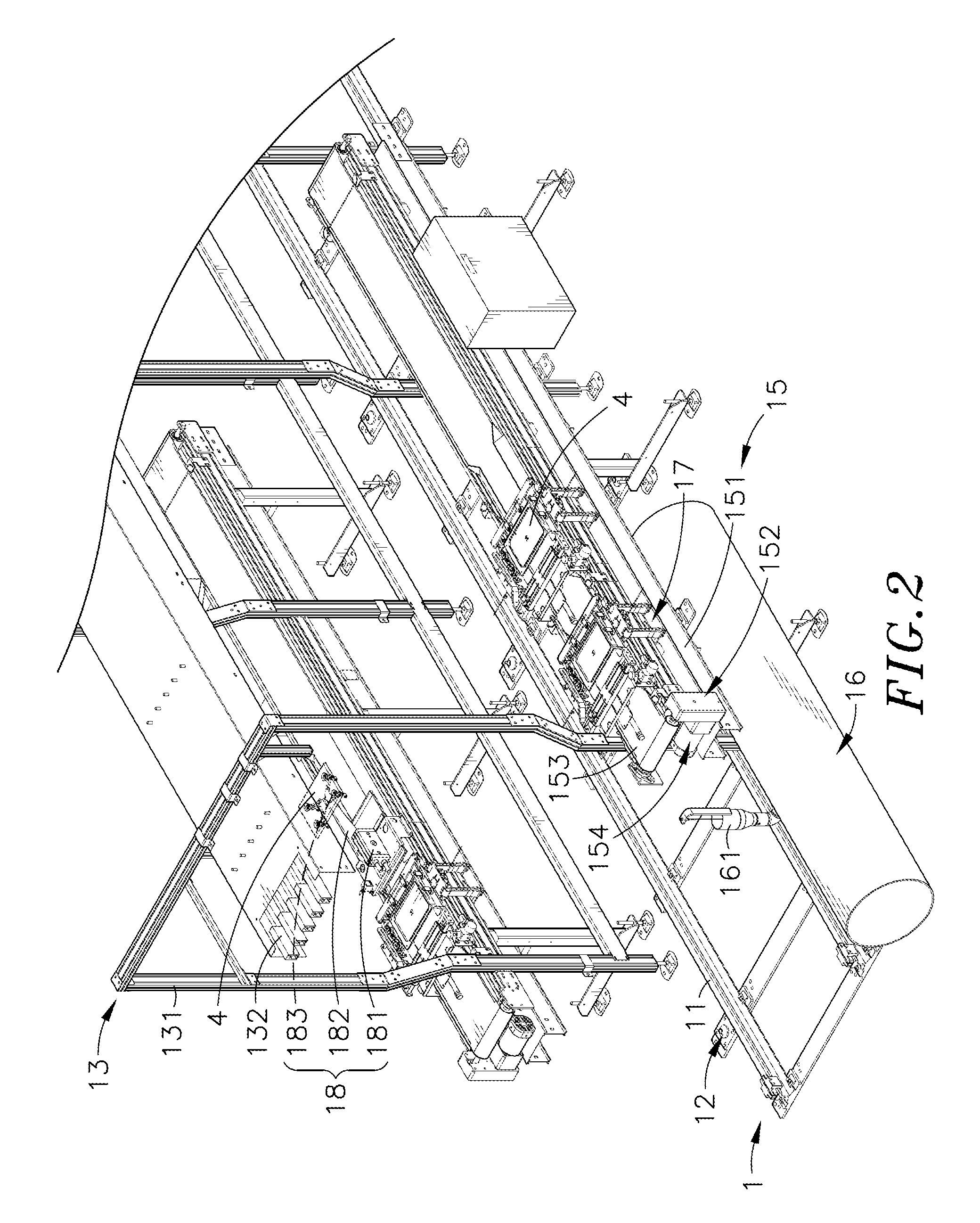

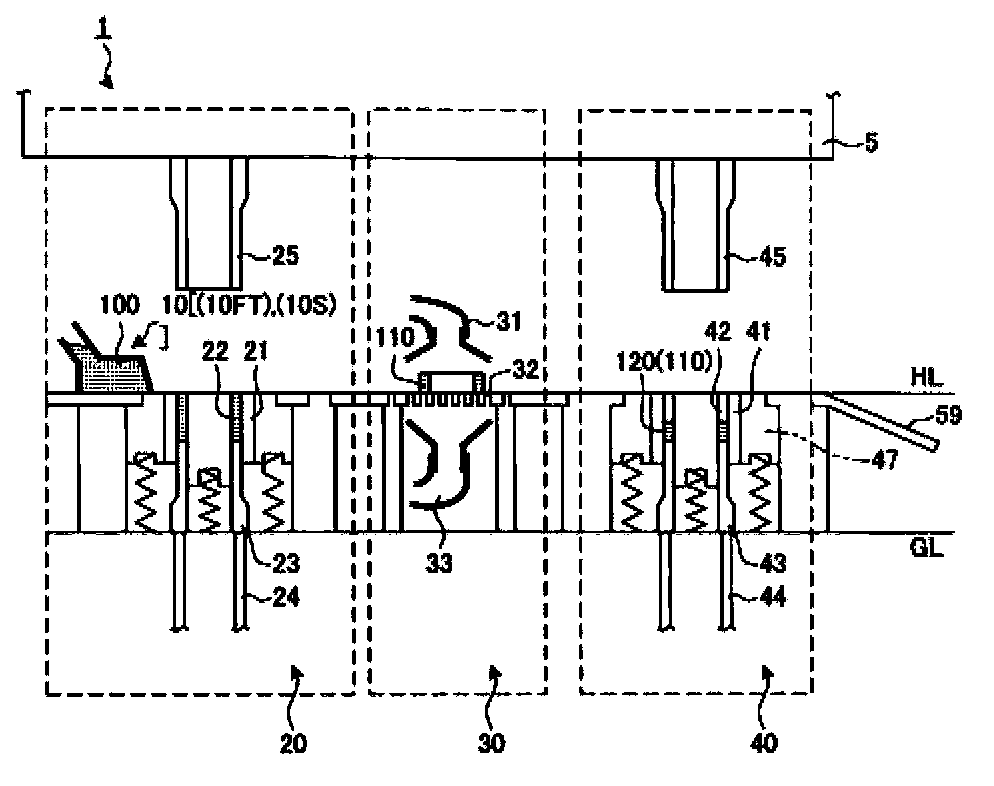

Mobile robotic trolley-based processing system and mobile robotic trolley thereof

InactiveUS9465386B2High operating requirementsImprove processing efficiencyRobotCleaning using liquidsControl systemEngineering

A mobile robotic trolley-based processing system includes a conveyor platform including a conveying track, air supply valves arranged along the conveying track, a gantry support unit providing a catenary and a water supply unit, mobile robotic trolleys each including a wheeled trolley chassis movable along the conveying track, connectors connectable to the air supply valves for collecting compressed air, a pantograph kept in contact with the catenary for collecting electrical power, a robot arm for transferring profile materials individually, a cleaner having a water inlet pipe connectable to the water supply unit for collecting water or cleaning solution and a drive control system for controlling the operation of the robot arm and the cleaner, and machine tools for processing profile materials being transferred by the robot arm of each mobile robotic trolley.

Owner:HONGFUJIN PRECISION ELECTRONICS (CHENG DU) CO LTD

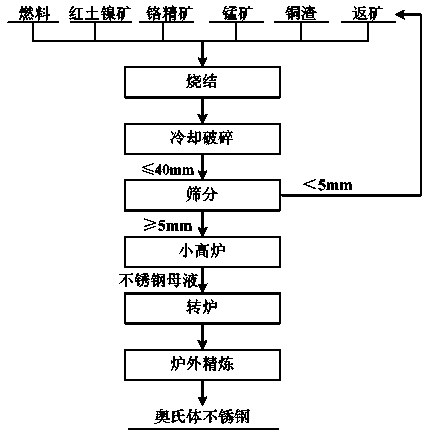

Compact production method of austenitic stainless steel

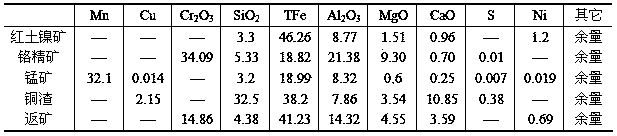

InactiveCN103866076ASimple processReduce the temperatureManufacturing convertersProduction lineManganese

The invention provides a compact production method of austenitic stainless steel. According to the method provided by the invention, the original four production lines for production of ferronickel, ferrochromium and manganese-iron alloys as well as mixed smelting steel-making are combined into one production flow, and nickel laterite, ferrochromium concentrate, manganese ore and copper slag are directly subjected to mixed sintering and smelting to produce the austenitic stainless steel, thus simplifying the process flow, reducing a sintering ignition temperature and the proportion of carbon, and reducing energy consumption and reducing production cost; and moreover, stainless steel mother solution containing chromium, nickel, manganese and copper is directly obtained by smelting, and the obtained thermal stainless steel mother solution is directly blown in a converter to produce stainless steel, thus further reducing heat loss, decreasing energy consumption, facilitating simplification of a production line of austenitic stainless steel, avoiding the problem of increase of equipment management and maintenance costs due to decentralized flow, and opening up a novel way for a production process of the austenitic stainless steel.

Owner:CHONGQING UNIV

Method and apparatus for removing foreign matters from tabacco

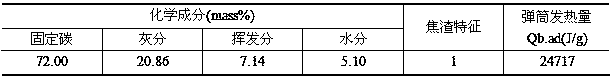

InactiveCN1939164ASimplify the production lineImprove efficiencyTobacco preparationGas current separationProduction lineForeign matter

A method and its apparatus for removing impurities from tobacco are disclosed. Said apparatus is composed of a feeder, an impurities removing unit consisting of a supporting frame and a shaped case with front feeding inlet, high-speed conveying belt for accelerating material, imaging unit and impurities outlet having a pneumatic lock, a compressed air sprayer above said impurities outlet, and a pneumatic separator.

Owner:周鸣红

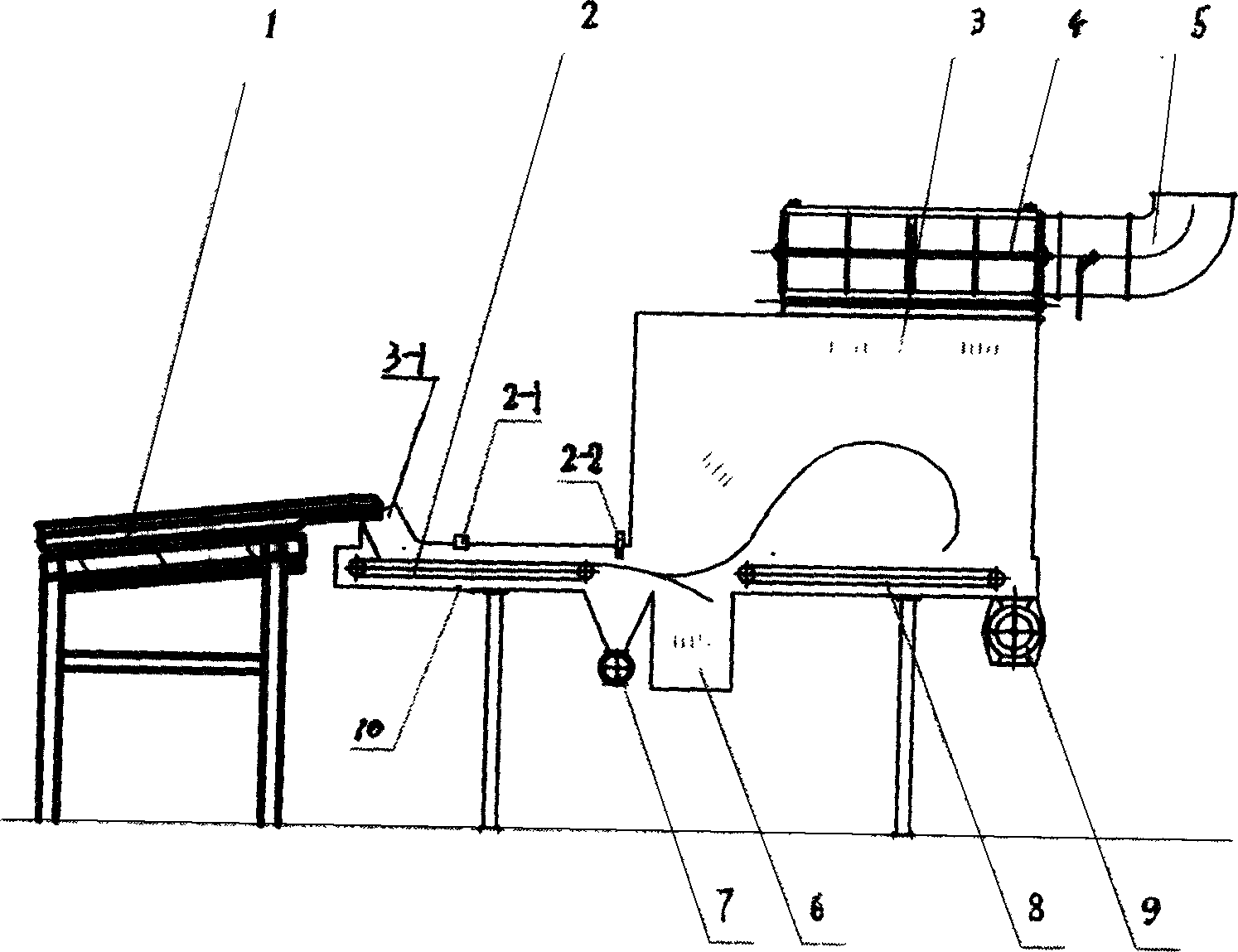

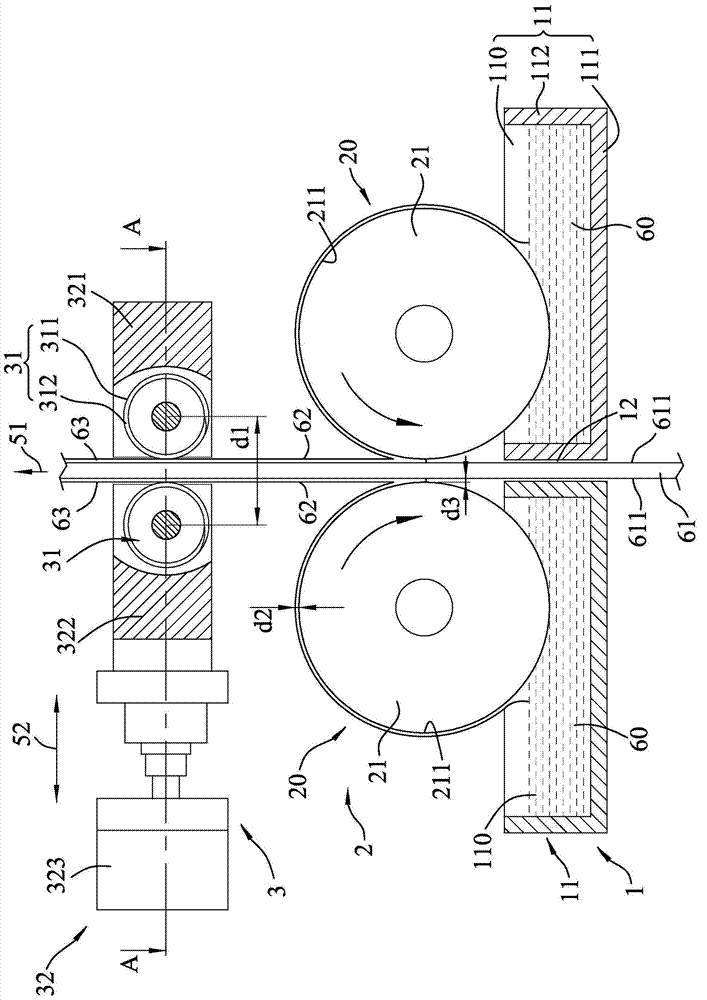

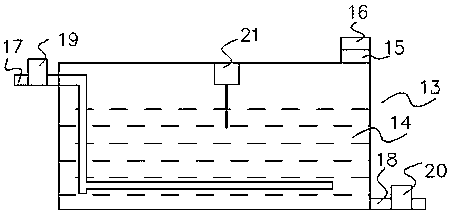

Coating device and coating method

ActiveCN104707756ASimplify the production lineLow costLiquid surface applicatorsCoatingsProduction lineEngineering

The disclosure provides a coating device and a coating method. The coating device is used for coating viscous ink on a substrate to form a film. The substrate includes two opposite mounting surfaces. The coating device comprising: an accommodating mechanism, a coating mechanism and a forming mechanism. The coating mechanism includes two coating units. Each coating unit includes a rotatable filling roller for filling with pressure the viscous ink in the hole on the corresponding mounting surface to form an initial layer. The forming mechanism is used for scraping the initial layer covering on the mounting surfaces to form the film. The method of coating and then adjusting the thickness of the film may improve the quality of the products. By using the above disclosure, the production line can be simplified to lower the device costs, and the manufacturing time can be reduced to improve the manufacturing efficiency.

Owner:MICROCOSM TECH

Light-emitting diode device and method of manufacturing thereof

InactiveCN1828957AImprove color mixingLittle change in chromaticitySolid-state devicesLuminescent compositionsLength waveLight-emitting diode

An LED device that is excellent in color mixture and small in variation of chromaticity is provided. The LED device includes, in a package, an LED chip, a fluorescent material excited by light from the LED chip to generate light with a wavelength different from that of the light from the LED chip, and a translucent resin holding the fluorescent material. The LED chip has a side-surface portion, a top-surface portion, a bottom-surface portion, and a light-emitting layer sandwiched between the top-surface portion and the bottom-surface portion, and the fluorescent material in the translucent resin is provided in a layer form on a bottom surface of the package to entirely or partially cover the side-surface portion of the LED chip.

Owner:SHARP KK

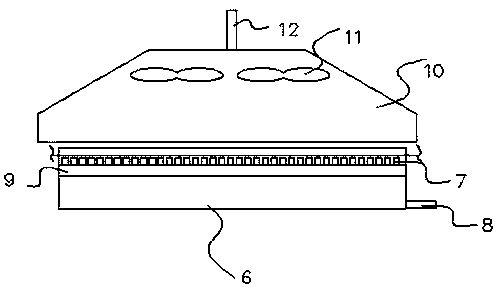

Thin type backlight module

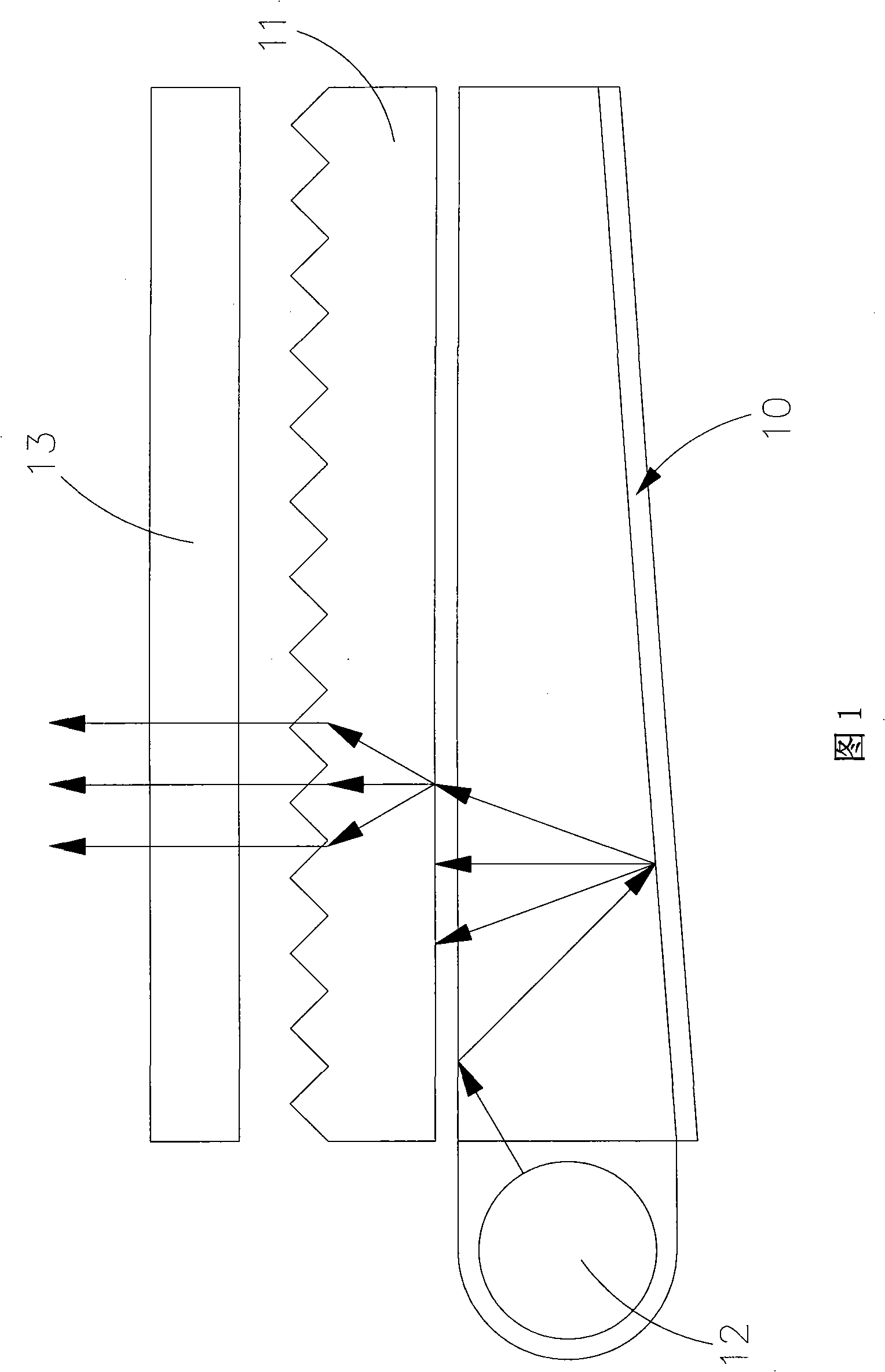

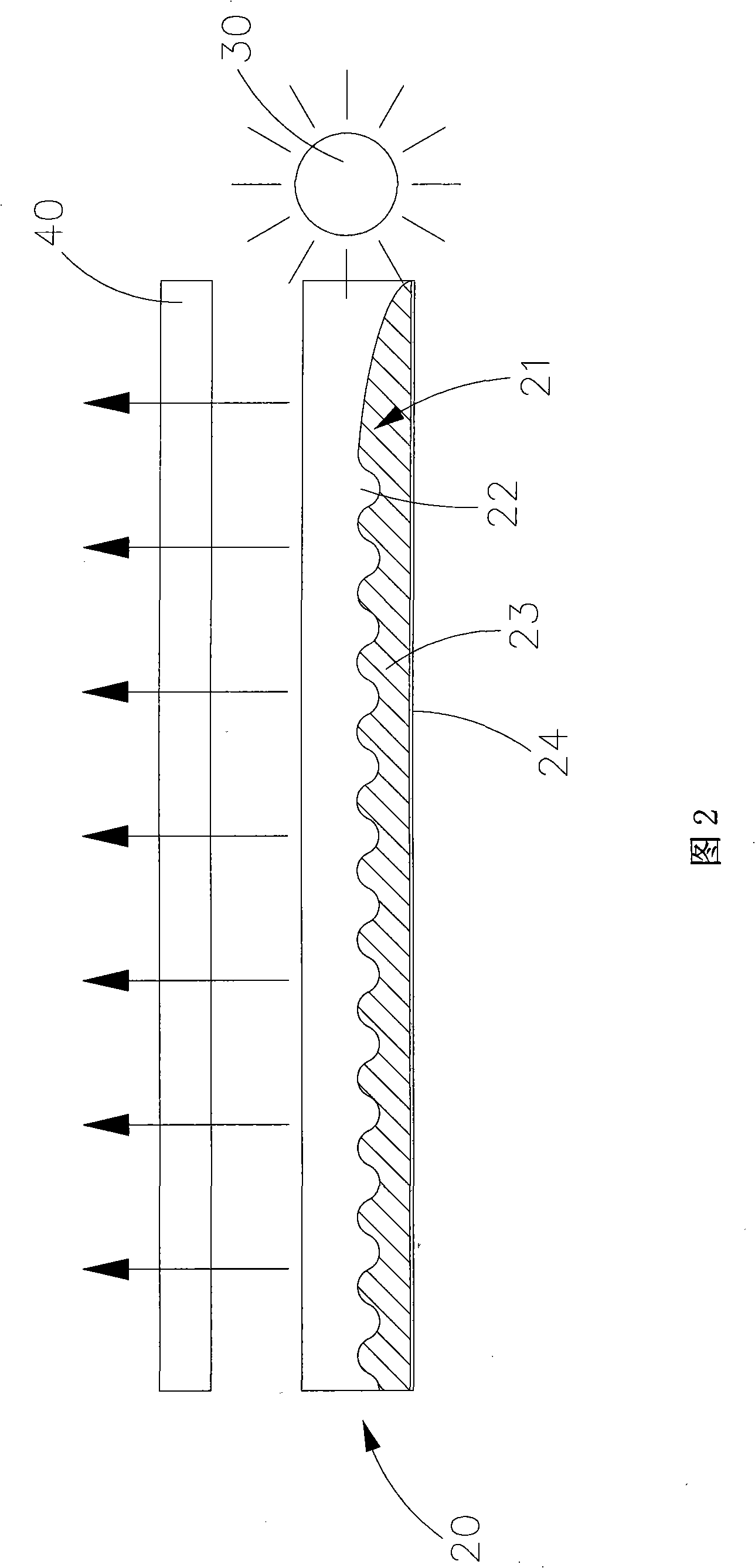

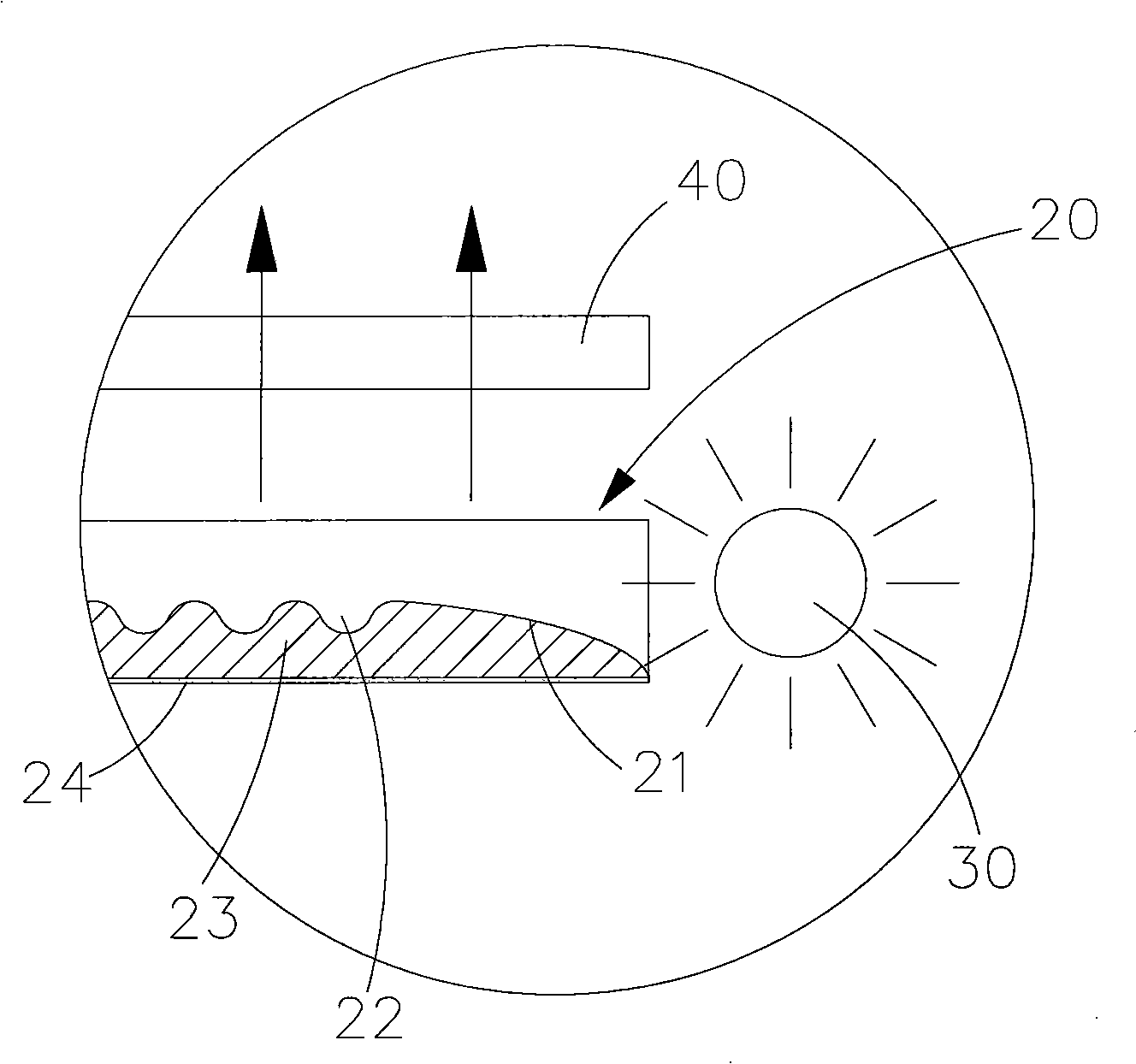

PendingCN101334551ASimplify the production lineReduced number of assembly componentsNon-linear opticsOptical elementsDiffusionOptoelectronics

The invention discloses a thin back light module, comprising at least a light guiding plate, at least a light source and a display panel; the surface of the light guiding plate is provided with a concavo-convex light guiding diffusion structure; furthermore, the concavo-convex light guiding diffusion structure is covered by a reflection metal layer; the exposed surface of the reflection metal layer is covered by an anti-oxidant film; therefore, the concavo-convex light guiding diffusion structure of the light guiding plate is matched with the reflection metal layer so as to guide the light source to diffuse and refract towards the display panel; furthermore, the thickness of the existing back light module design is effectively reduced.

Owner:柳广德

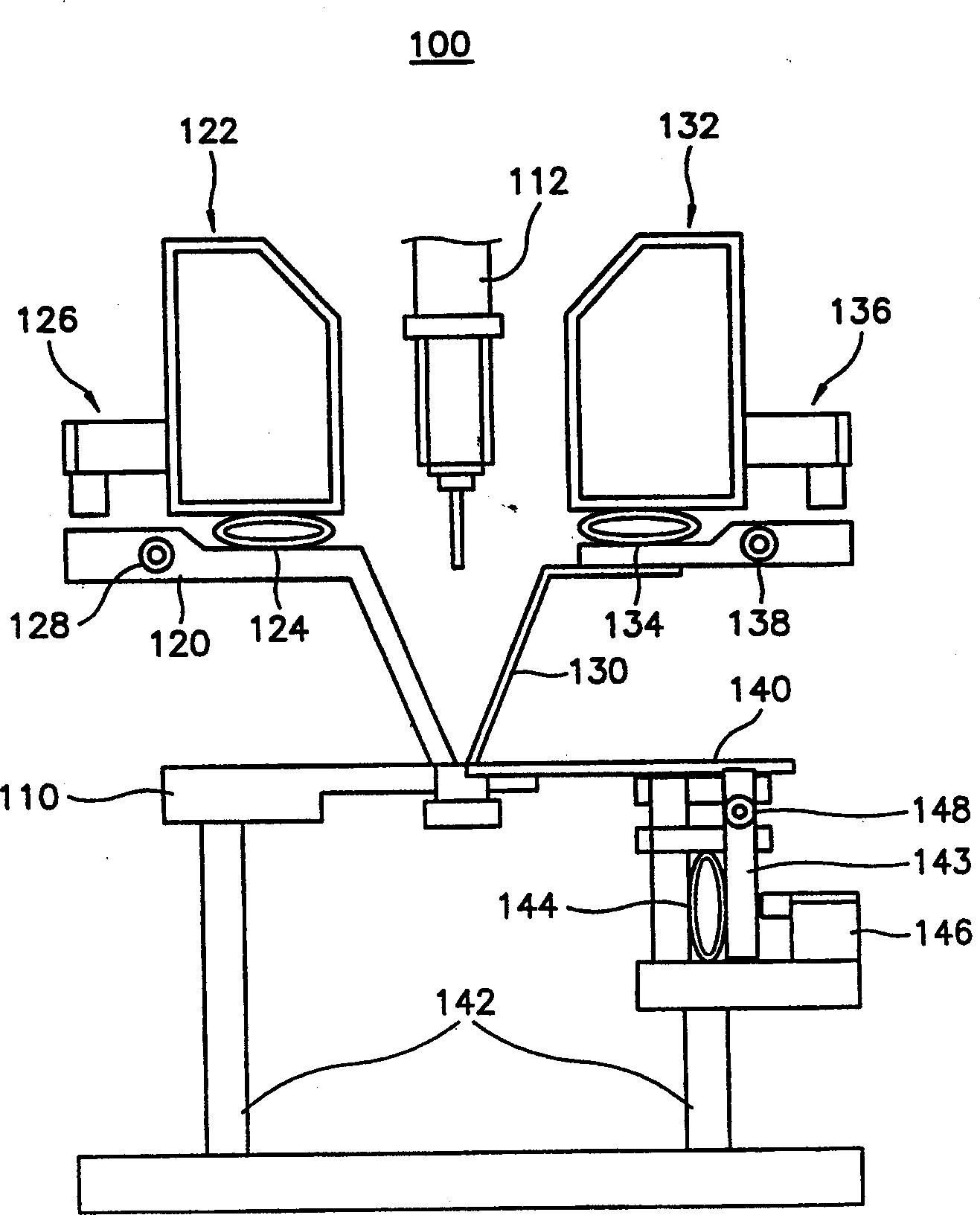

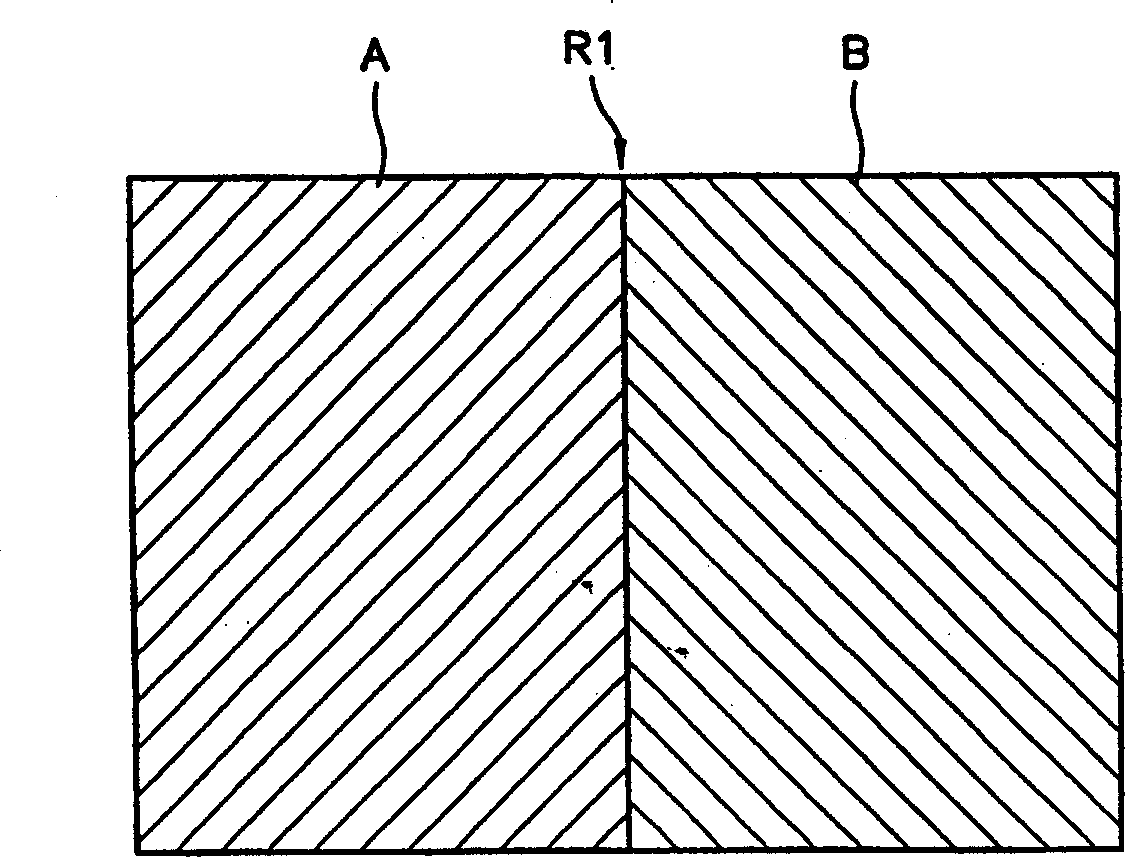

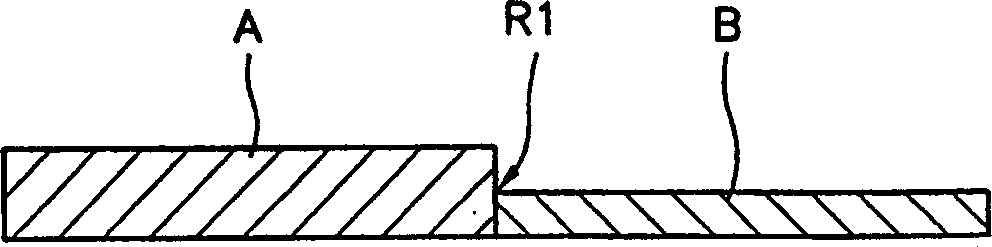

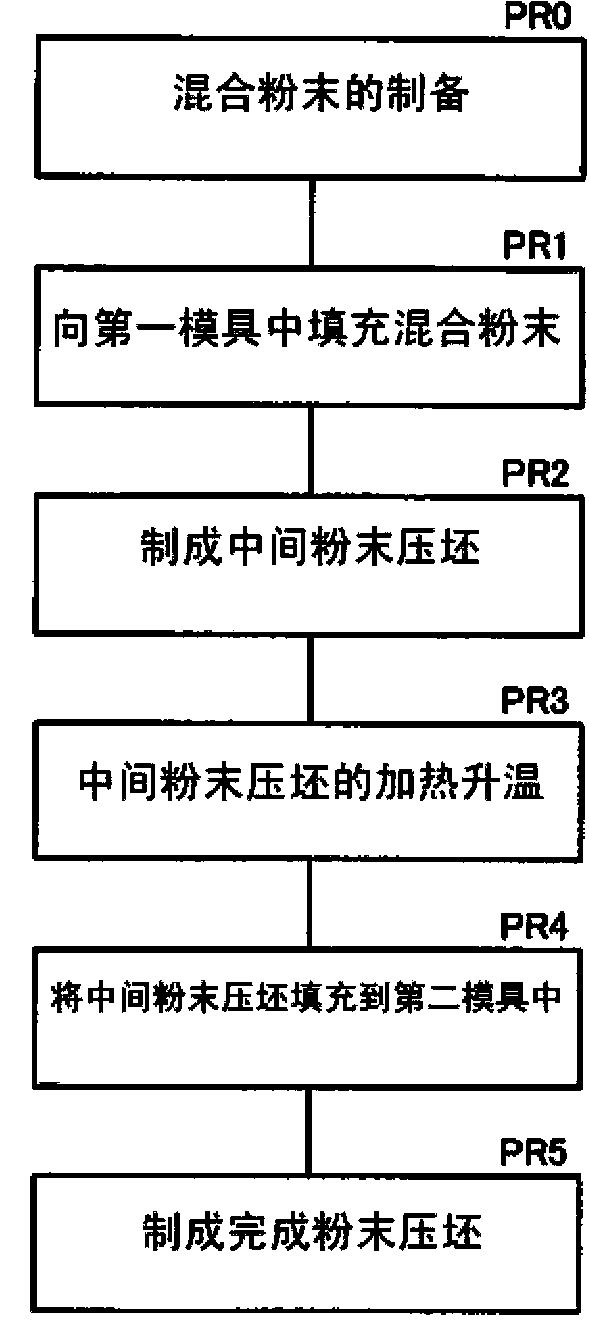

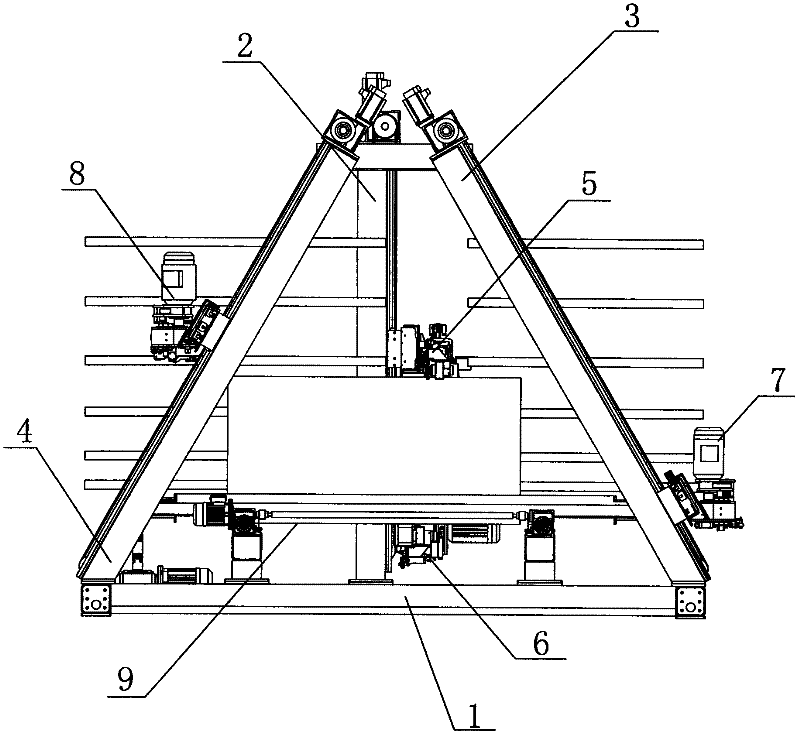

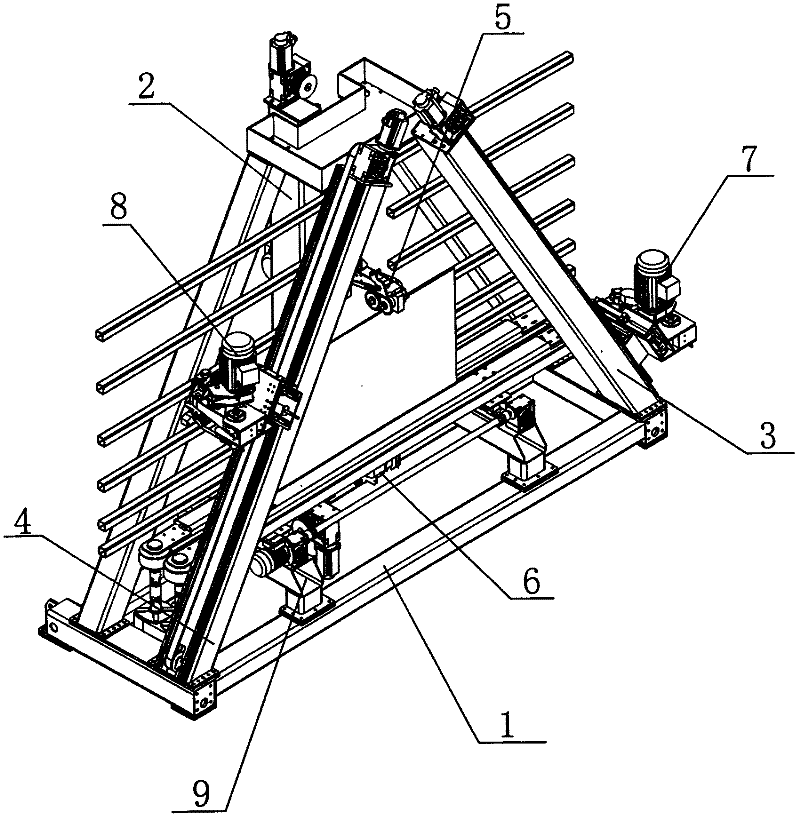

Laser welding system

InactiveCN1346304AImprove reliabilityQuality improvementWelding/soldering/cutting articlesMetal working apparatusSheet steelEngineering

The laser welding system comprising a welding frame for receiving a first steel plate to be welded thereupon, at least one first clamping member installed above the welding frame, for fixing the first steel plate received on the welding frame, at least one second clamping member for fixing a second steel plate to be welded in close vicinity to a position at which the first steel plate is to be engaged with and welded with the second steel plate, an anvil on which the second steel plate is received, for moving the second steel plate to the position at which the first steel plate is to be engaged with and welded with the second steel plate, and a laser welding head for welding the first and second steel plates at the position at which the first steel plate is to be welded with the second steel plate. The first and second clamping members and the anvil are operated by air bags. The portions of the first and second members have saw-teeth, while a portion of the anvil has saw-teeth.

Owner:SUNG WOO HITECH

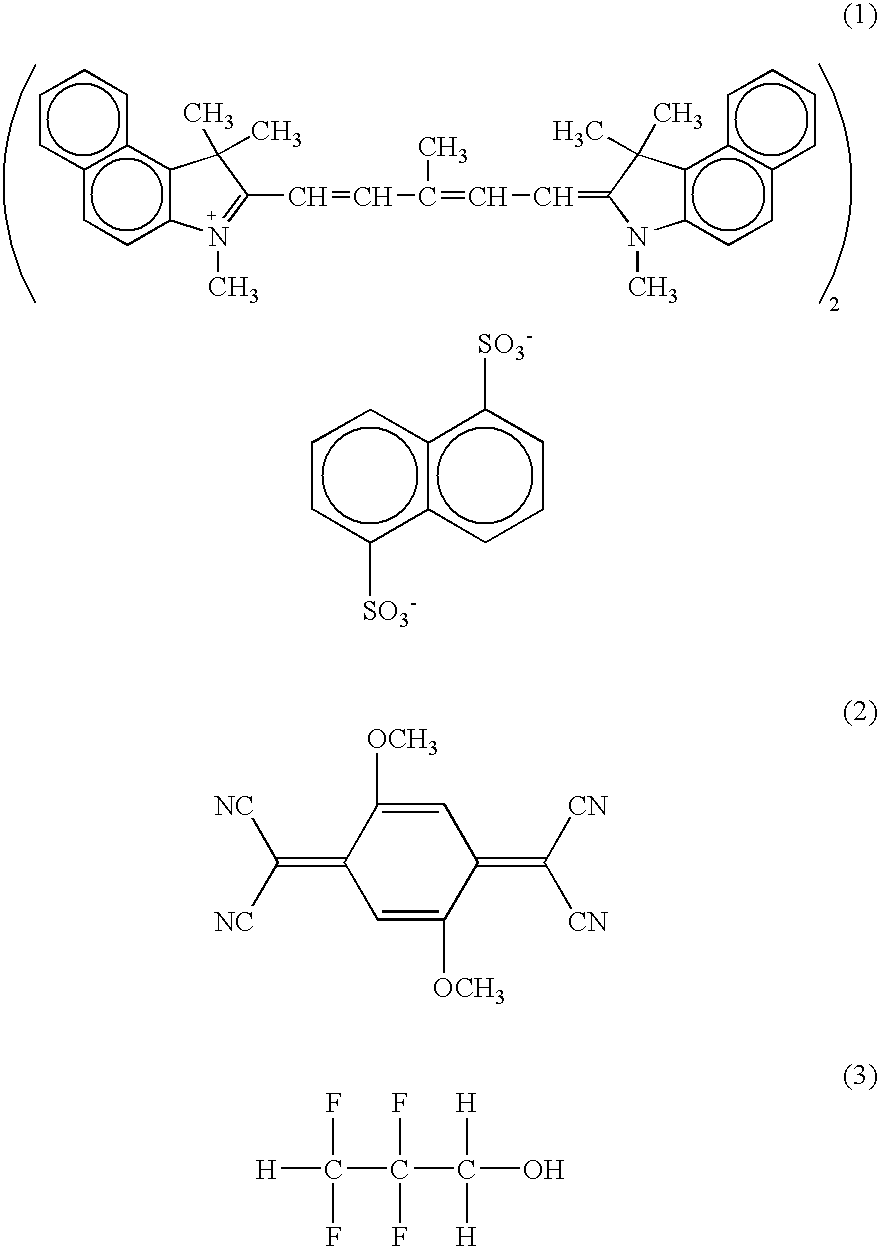

Information-recording medium and method for producing the same

InactiveUS6821459B1Good recording characteristicSpeed up the flowRecord carriersDrying solid materials without heatEngineeringRecording layer

Disclosed is a method for producing an information-recording medium comprising, on a substrate, a dye recording layer capable of recording information, the method comprising the step of drying the substrate formed with the dye recording layer by allowing clean air to flow while rotating the substrate at a high speed; wherein an intake for introducing the clean air is narrowed by arranging a lid having a circular opening at a central portion, at an opening disposed at an upper portion of an apparatus for rotating the substrate at the high speed.

Owner:FUJIFILM HLDG CORP +1

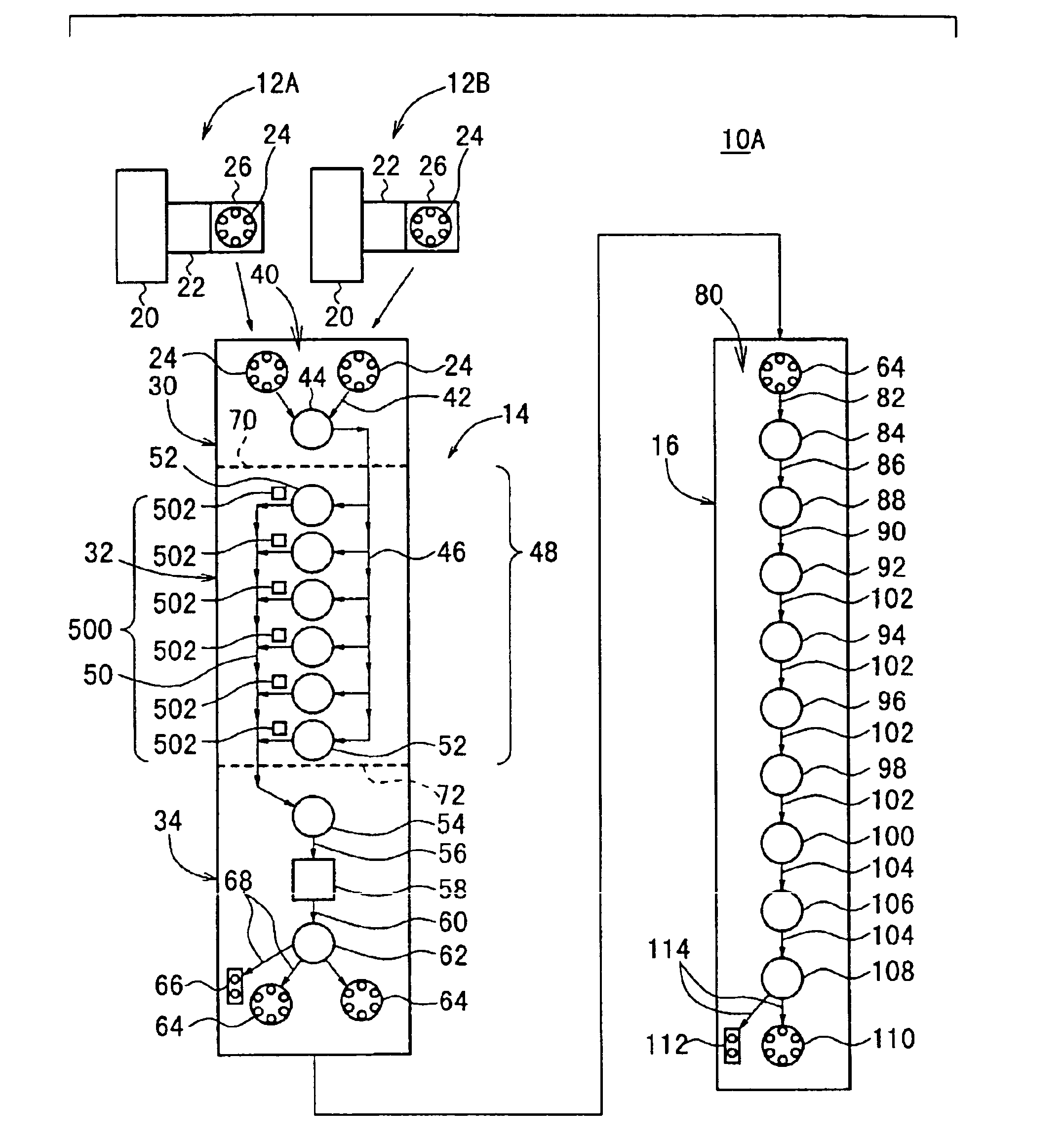

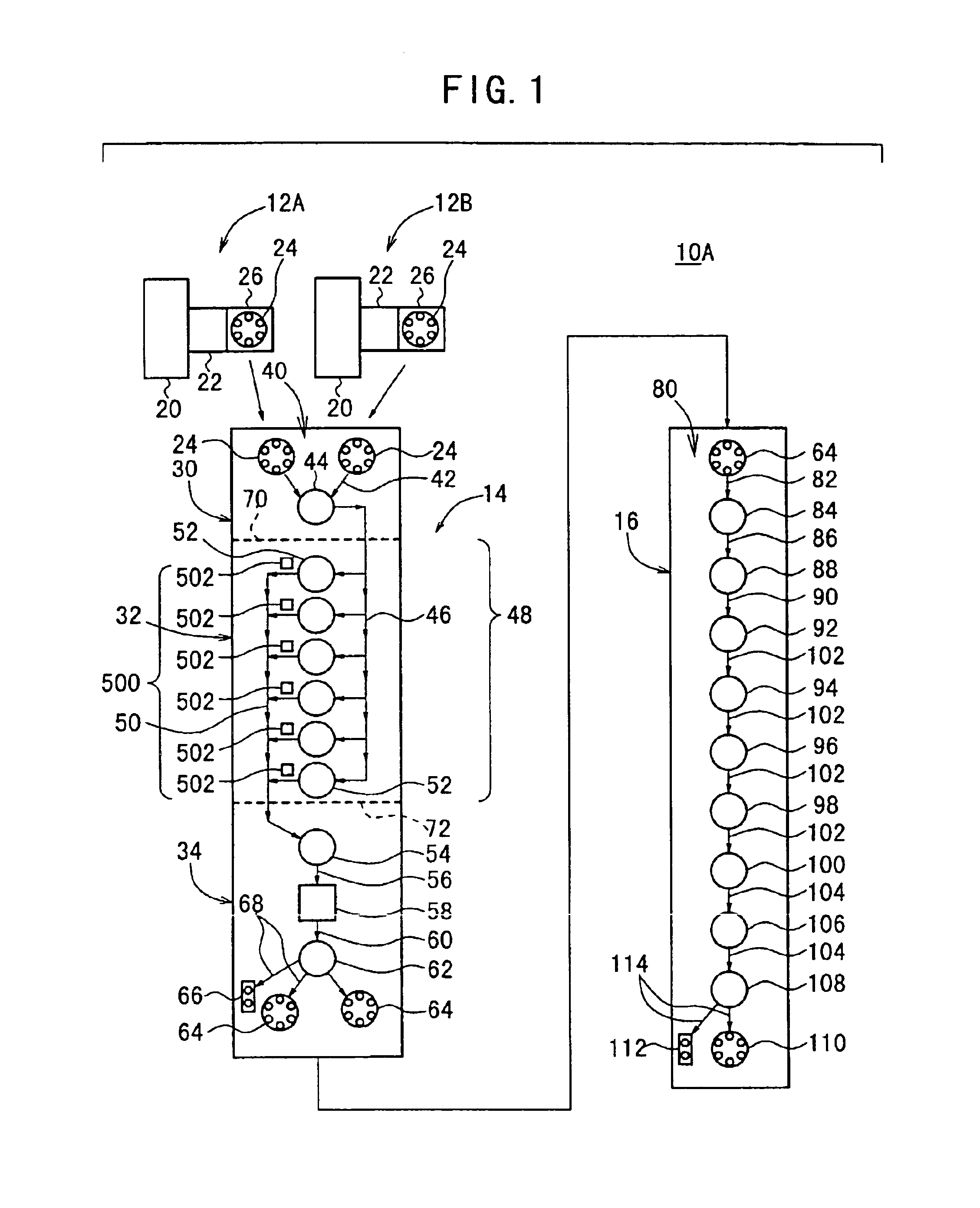

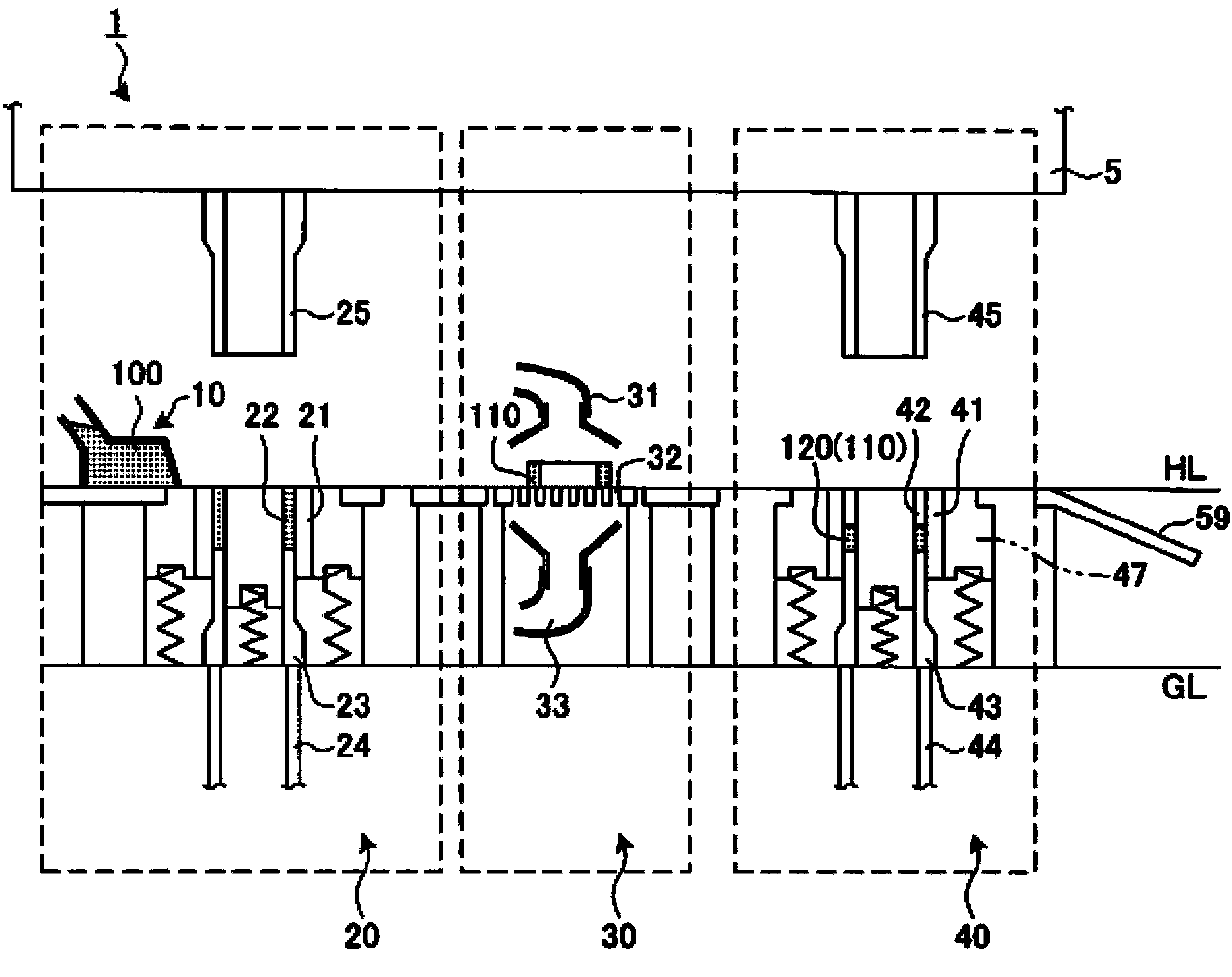

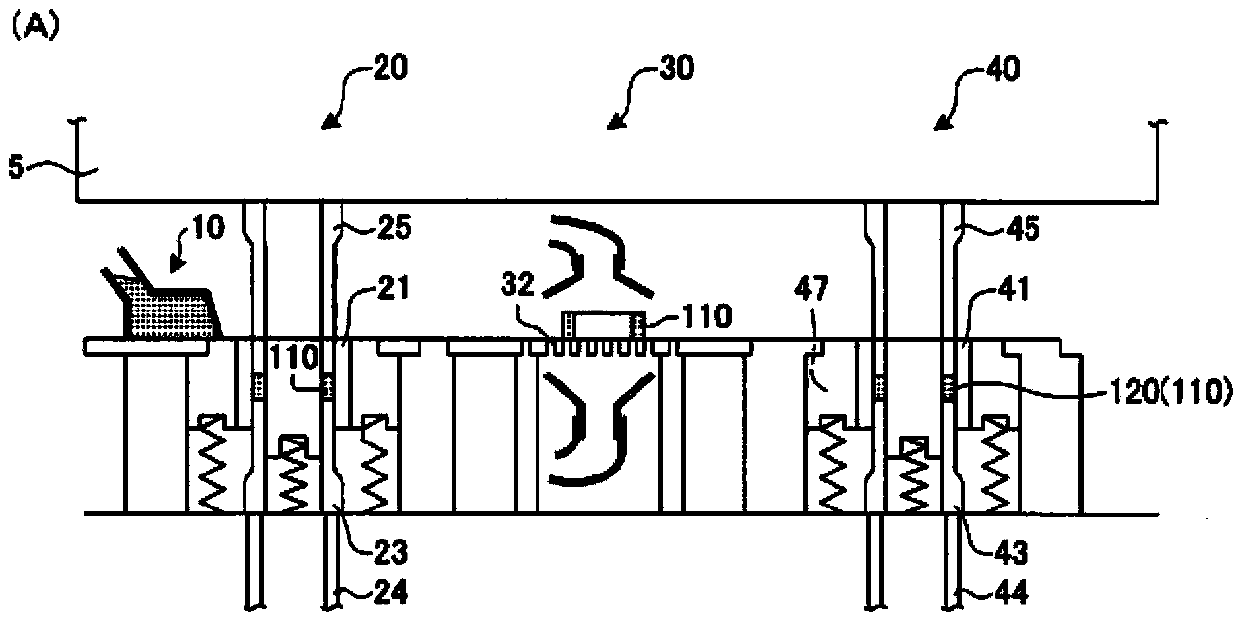

Device for high-density molding and method for high-density molding of mixed powder, and high-density three-layer-structured powder compact

InactiveCN103418793AStable manufacturingShedding is minimizedAdditive manufacturing apparatusInorganic material magnetismHigh densityMetal powder

Owner:AIDA ENG LTD

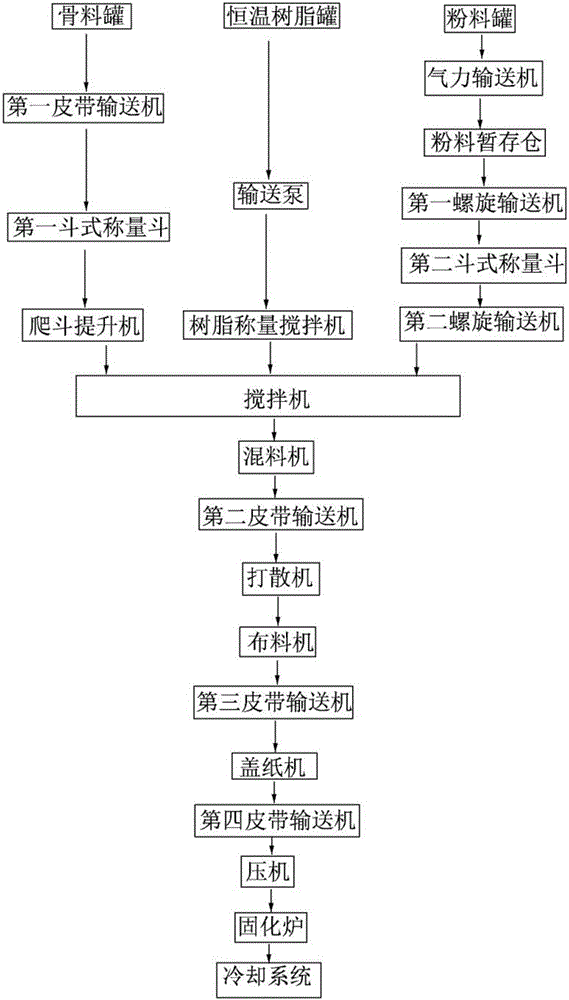

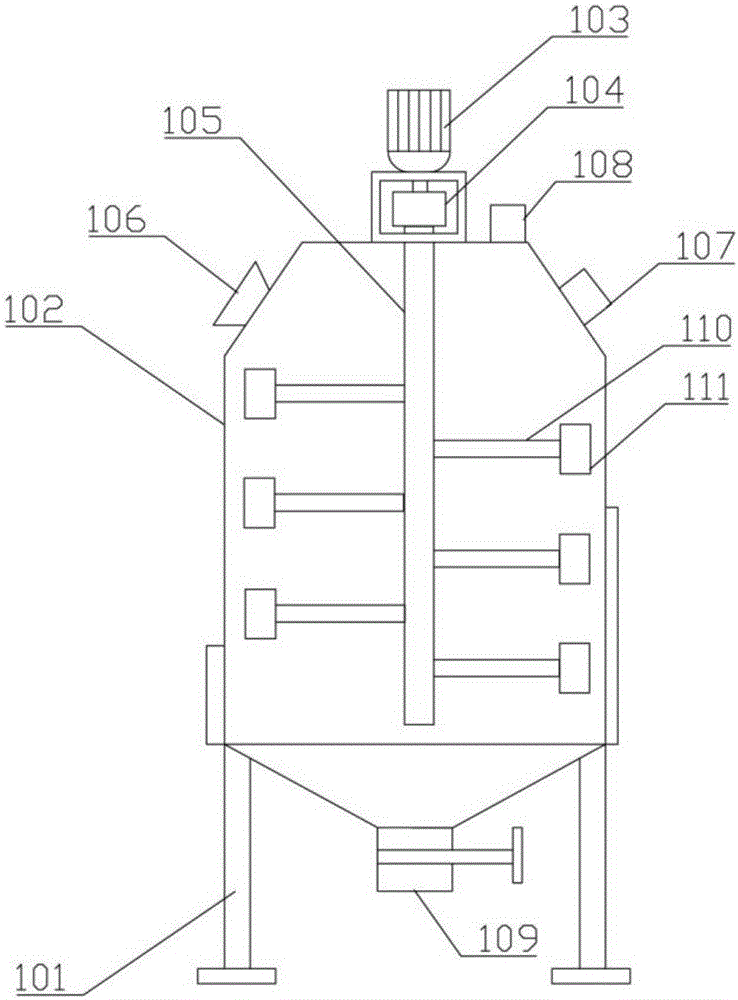

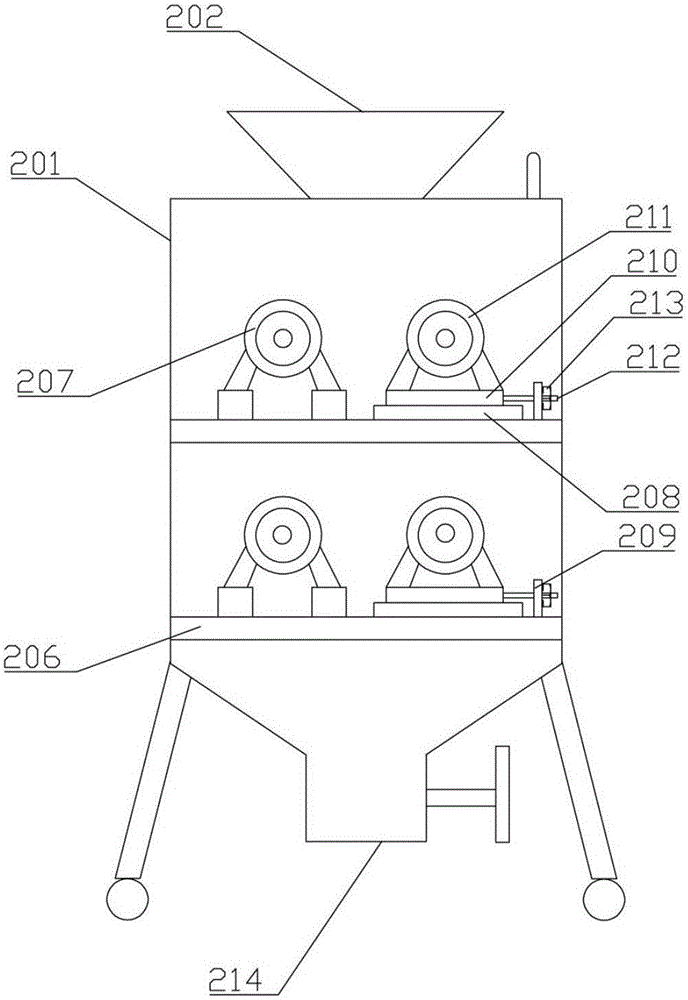

Jade process plate production line

InactiveCN106553266AIncrease productivityModerate hardnessDischarging apparatusMixing operation control apparatusBreaking strengthProduction line

The invention belongs to the technical field of machining of jade process plates, and in particular, relates to a jade process plate production line. The jade process plate production line comprises a raw material storage batching system, a stirring system, a distribution system, a pressing system, a drying curing system and a cooling system; the raw material storage batching system includes an aggregate tank, a first hopper weighing hopper, a constant-temperature resin tank, a resin weighing stirrer, a powder tank, a powder temporary storage bin and a second hopper weighing hopper; the stirring system includes a stirrer, a mixer and a beater; the pressing system includes a fourth belt conveyor and a press; the distribution system includes a paper paving machine, a laser cutting machine, a distributor and a paper covering machine; the drying curing system includes a plate inlet lifting frame and a plate outlet lifting frame; and the cooling system includes a roller table, a cooling tank and an air blower. The production line is simple, shorter in production period and higher in productivity; and produced process plates are proper in hardness, higher in compressive strength and breaking strength and lower in water absorption.

Owner:青海稀宝玉石有限公司

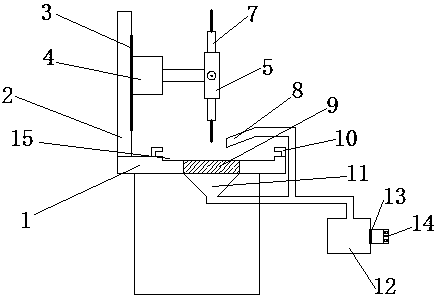

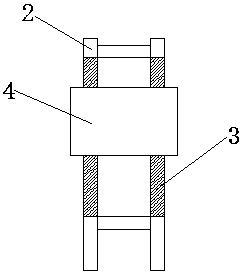

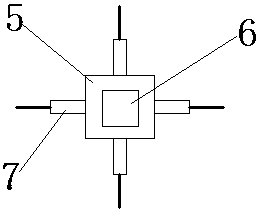

Circuit board drilling equipment

InactiveCN108237239AAvoid flyingKeep healthyMaintainance and safety accessoriesBoring/drilling machinesElectric machineryIndustrial engineering

The invention discloses circuit board drilling equipment comprising a drilling table, a motor, a rotating block and a chip box. A rack is fixed to the surface of the drilling table, and a guide rail is arranged on the surface of the rack; a protecting shell is arranged on the outer side of the motor, the motor is slidably connected with the guide rail through the protecting shell, and an output shaft of the motor is fixedly connected with a rotating block internally provided with a high-speed motor; drilling machines are fixed to the periphery of the rotating block, and an output shaft of thehigh-speed motor is in transmission connection with the drilling machines; a groove is formed in the position, below the rotating block, of the drilling table, and fixing blocks are arranged on the two sides of the groove; a strip-shaped dust suction opening is formed above the fixing blocks and communicates with the chip box through a pipeline; a screen net is arranged on the lower portion of thegroove, a conical dust suction opening is formed in the lower portion of the screen net and communicates with the chip box through a pipeline; and a fan is arranged on the right side of the chip box.The drilling efficiency is high, and the production efficiency is improved.

Owner:惠州市源名浩科技有限公司

Method for concurrently forming silicon wafer suede and PN junction during solar cell manufacture

InactiveCN1937259ASimplify the production lineAvoid pollutionFinal product manufactureSemiconductor devicesImpurity diffusionThin layer

Using method of low pressure chemical vapor deposition (LPCVD) creates coarse structure of pile fabrics composed of thin layer of semisphere silicon crystal grains, and carries out N type impurity diffusion at low temperature (ex. phosphorus diffusion) to form N trap, PN junction in P type silicon chip on surface of silicon chip at same time.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

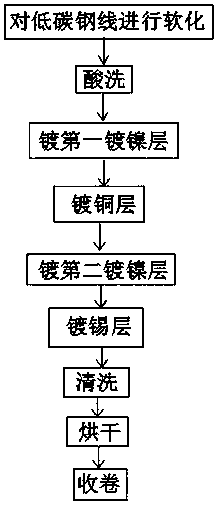

Hard-state tin-coated copper-clad steel wire processing technology

InactiveCN107564624ASimplify the production lineImprove bindingManufacturing extensible conductors/cablesTinningCopper plating

The invention discloses a hard-state tin-coated copper-clad steel wire processing technology comprising the following steps: 1, softening a low carbon steel wire, and aligning same; 2, pickling; 3, coating a first nickel coating; 4, copper plating; 5, plating a second nickel coating; 6, tin coating; 7, cleaning; 8, drying; 9, rolling. According to the method, the nickel plating is done before copper plating and tin plating, thus enhancing the bonding force between coatings and the base material; in addition, the copper easy processability is combined with the steel toughness, thus providing excellent toughness and anti-torsion ability.

Owner:JIANGYIN SIX CIRQUE ALLOY WIRE CO LTD

A flat glass chamfering machine

InactiveCN102294632ACompact structureReasonable layoutEdge grinding machinesFlat glassControl manner

The invention relates to a flat glass chamfering machine, comprising a rack, a vertical guide rail, a right oblique guide rail, a left oblique guide rail, an upper edge grinding device, a lower grinding device, a right edge grinding device, a right edge grinding device and a fixture device, wherein the fixture device is arranged on the rack; the vertical guide rail is arranged on the rack; the right oblique guide rail and the left oblique guide rail are respectively and slantwise arranged on the rack; the upper edge grinding device and the lower edge grinding device are arranged on the vertical guide rail; anda right grinding device is arranged on the right oblique guide rail while a left grinding device is arranged on the left oblique guide rail. The flat glass chamfering machine provided by the invention is applied to the industry of glass deep processing; chamfer processing is carried out on eight prisms of two surfaces of the flat glass, and grinding on an edge when glass moves is realized; and a mechanical device is adopted for compensating glass error; the flat glass chamfering machine is compact in structure and reasonable in layout; and the machine configuration and control mode of the machine are simplified, so that the cost thereof is reduced.

Owner:GUANGDONG IVACO GLASS TECH

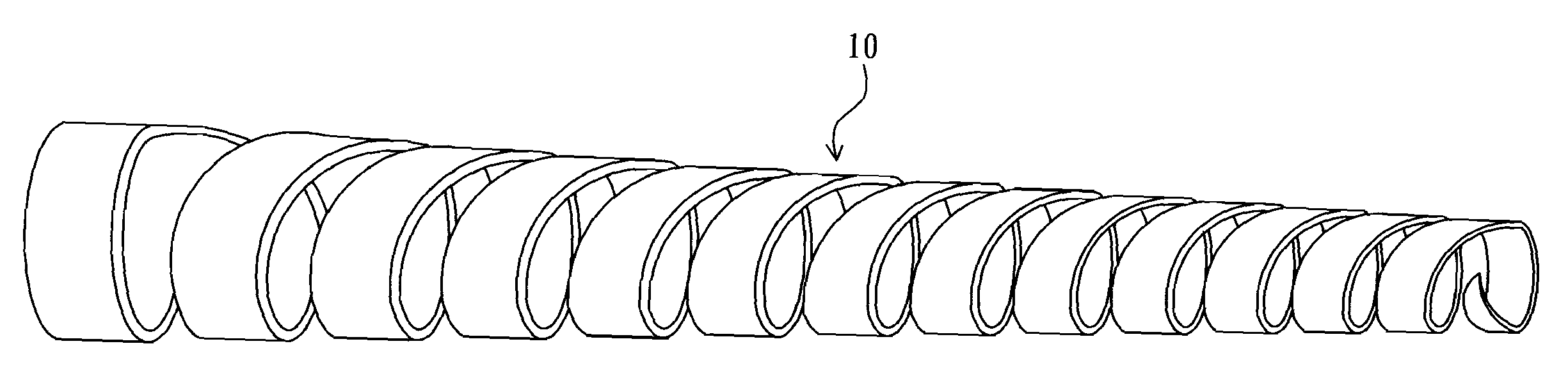

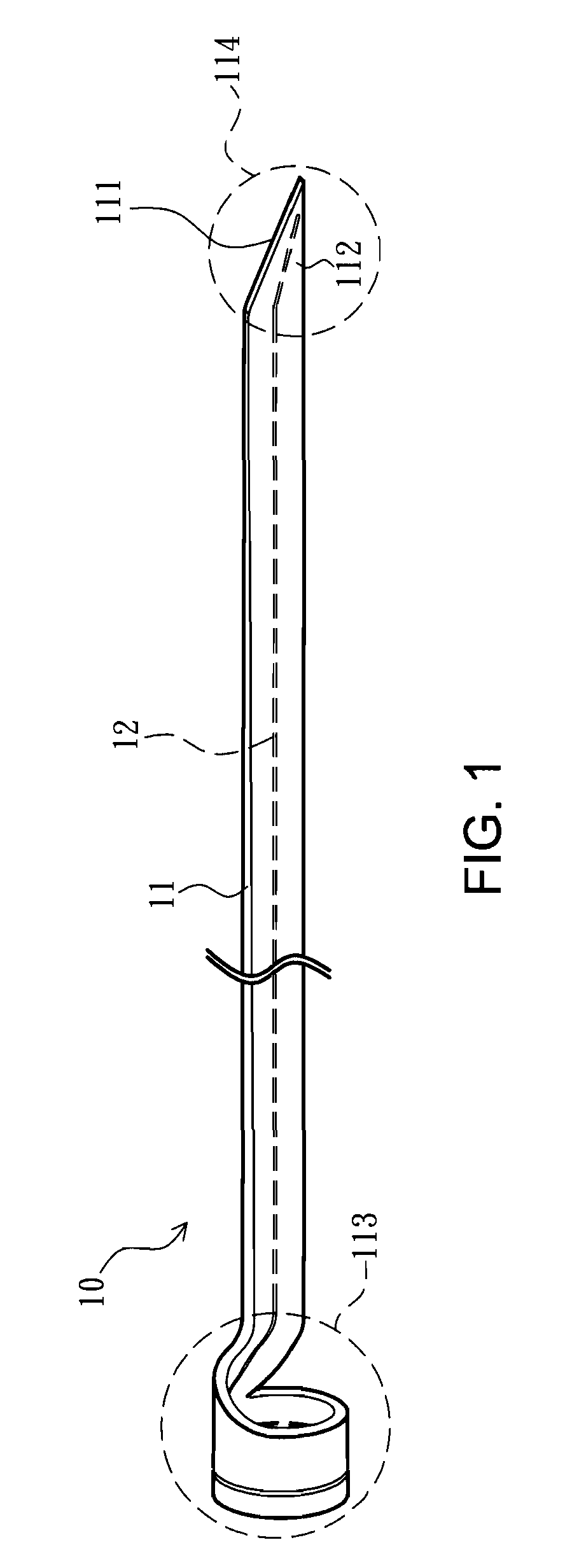

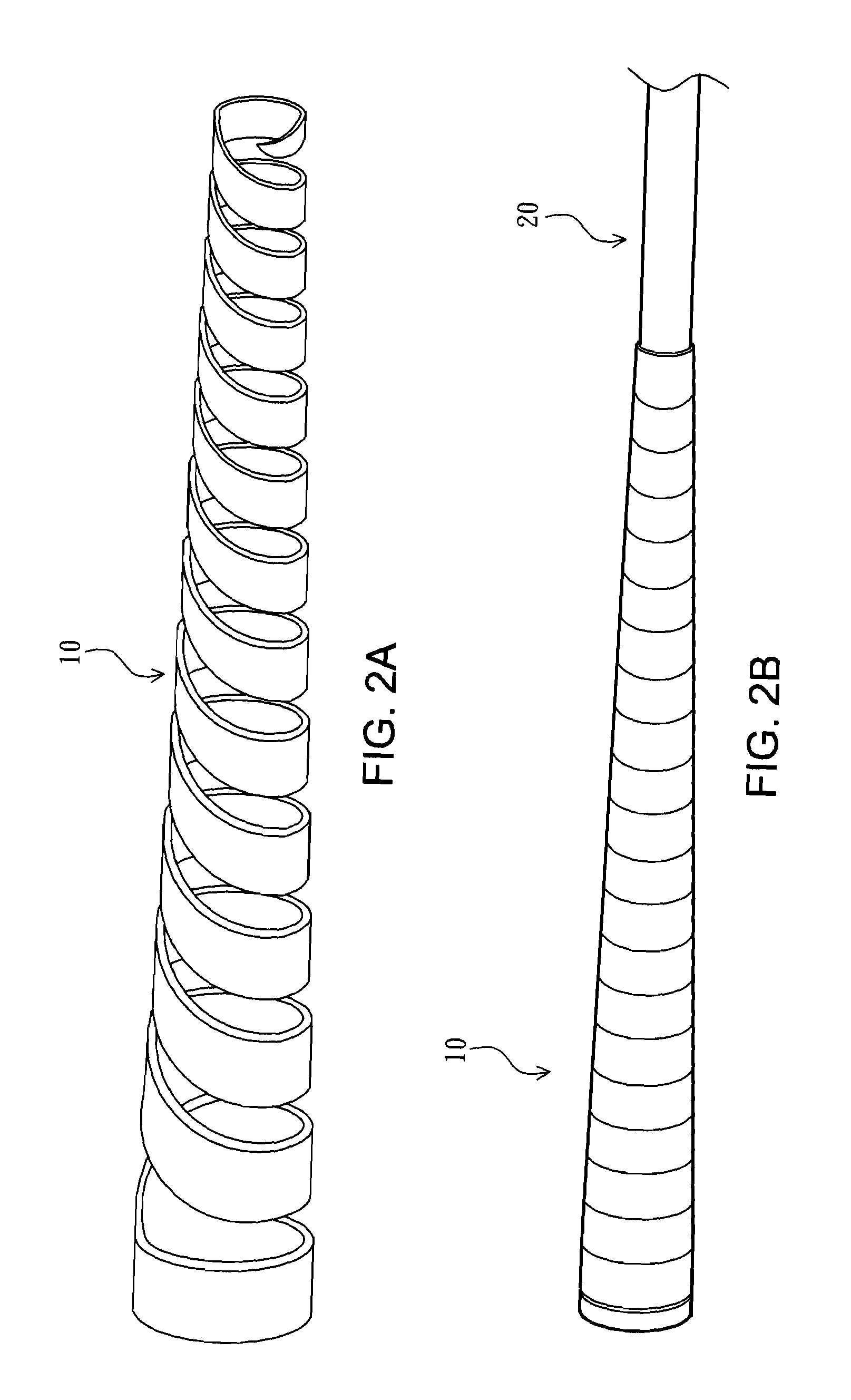

Spiral Wound Type Grip Tape

InactiveUS20090114756A1Facilitate purchaseProduction cost be reduceGolf clubsStringed racketsBaseball batEngineering

A spiral wound type grip tape is provided. The spiral wound type grip tape includes an elastic strip and at least one flexible thread. The flexible thread is disposed in the elastic strip, such that the grip tape can be spirally wound on the surface of a grip. The spiral wound type grip tape can be easily installed on a grip, and can be applied to the grips of the golf clubs, baseball bats, or tennis rackets of sports equipment.

Owner:HUNG CHI FENG

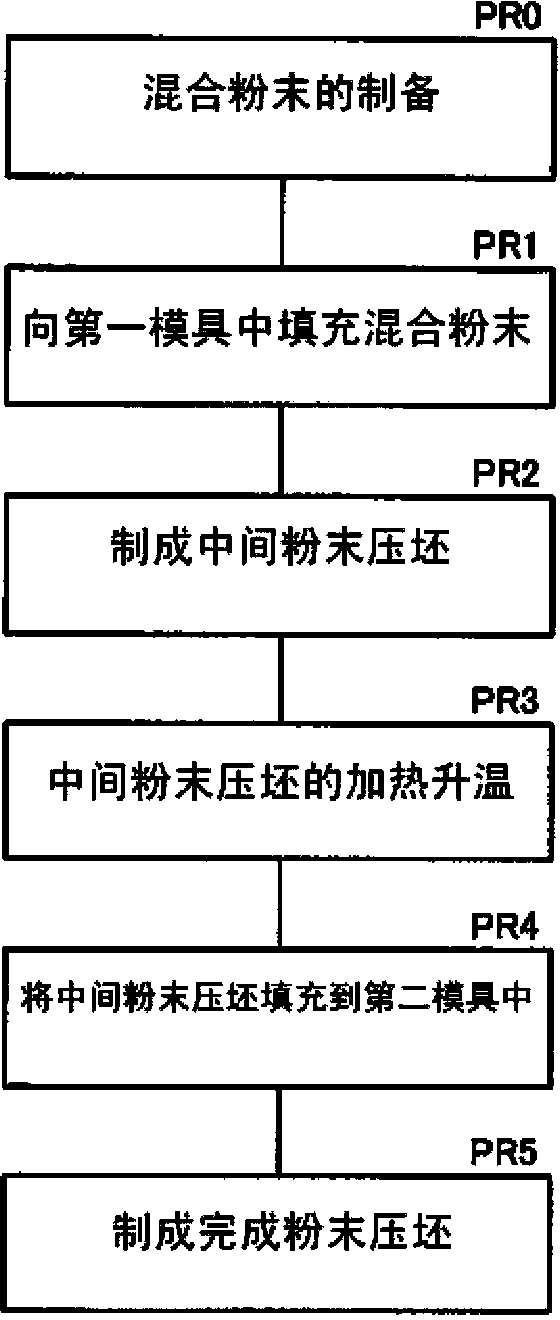

High-density molding device and high-density molding method for mixed powder

InactiveCN103372646AStable manufacturingReduce usageInorganic material magnetismInductances/transformers/magnets manufactureDensity ratioHigh density

In the present invention, a first die is filled with a mixed powder resulting from admixing 0.1-0.2% by weight ratio of a low-melting-point lubricant powder to a basic metal powder, a first applied pressure is applied within the first die, molding a mixed powder intermediate compact having a real density ratio of 80-90%, the mixed powder intermediate compact is heated, actively raising the temperature of the mixed powder intermediate compact to a melting point equivalent temperature of the lubricant powder, the temperature-elevated mixed powder intermediate compact is set in a second die that has been warmed to the melting point equivalent temperature, and a second applied pressure is applied to the mixed powder intermediate compact within the second die, molding a high-density mixed powder completed compact.

Owner:AIDA ENG LTD

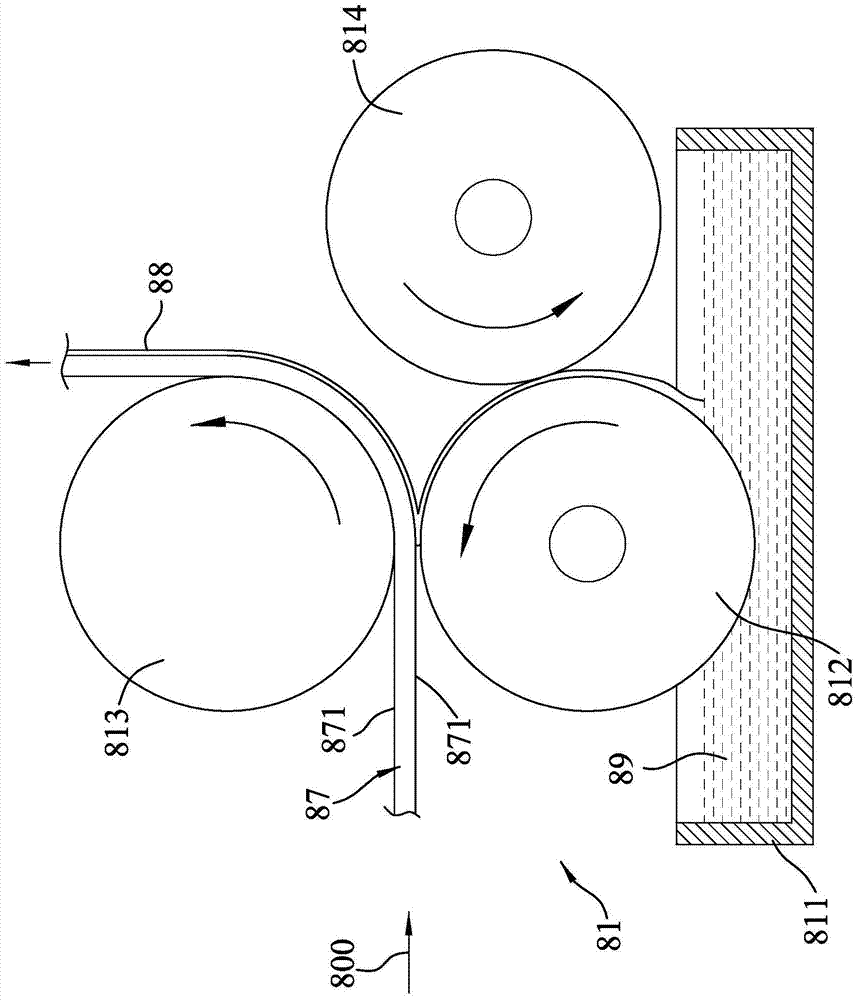

Production line and production technology of flat filaments of flexible freight bags

The invention relates to a production line and production technology of flat filaments of flexible freight bags, and belongs to the technical field of packaging supply production. The production line of the flat filaments of the flexible freight bags comprises a stirring device, a melting and conveying device, an extrusion device, a cooling pond, a cutting device, a folding device, a hot stretching device, a heat setting device and a winding device which are arranged in sequence, wherein the cutting device comprises an upper roller and a lower roller which are horizontally arranged, the upper roller and the lower roller rotate oppositely and reversely, the upper roller slides up and down, multiple annular bulges are fixedly arranged on the upper roller, gaps are formed among the annular bulges, annular blades are fixedly connected with the positions, corresponding to the gaps, of the lower roller, and the annular blades are embedded into the gaps. According to the production line and production technology of the flat filaments of the flexible freight bags, cooled membranes are made to pass through space between the upper roller and the lower roller, the upper roller is made to slide downwards, thus the annular blades are embedded into the gaps, through cooperation of the annular blades and the annular bulges, each membrane can be cut and folded into a long strip shape with two sides turned upwards, operation is convenient and quick, functions of cutting and preliminary folding are achieved at the same time, the technology is simplified, and the operation is more convenient and quicker.

Owner:烟台海湾塑料制品有限公司

Electrically tunable fabry-perot interferometer, an intermediate product an electrode arrangement and a method for producing an electrically tunable fabry-perot interferometer

ActiveUS20200026063A1Simplify the production lineLow production costSpectrum generation using multiple reflectionOptical elementsEvaporation (deposition)Sputtering

Electrically tunable Fabry-Perot interferometers which are produced with micromechanical (MEMS) technology. Producing interferometers with prior art processes includes costly and complicated production phases. Therefore, it has not been possible to apply interferometers in consumer mass products. According to the present solution, the Fabry-Perot cavity is made by removing a sacrificial layer (112) which has been polymer material. A mirror layer (113, 117-120) which is produced above the sacrificial layer can be made with atomic layer deposition technology, for example. According to a preferable embodiment, electrodes (106b, 115b) of the mirror structures are formed by using sputtering or evaporation. With the present solution it is possible to avoid the above mentioned problems related with prior art.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com