Light-emitting diode device and method of manufacturing thereof

A technology of light-emitting diodes and devices, which is applied in chemical instruments and methods, luminescent materials, electric solid devices, etc., can solve the problems of reduced light extraction efficiency of LED devices, and achieve the effects of low product cost and simplified production lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] LED device

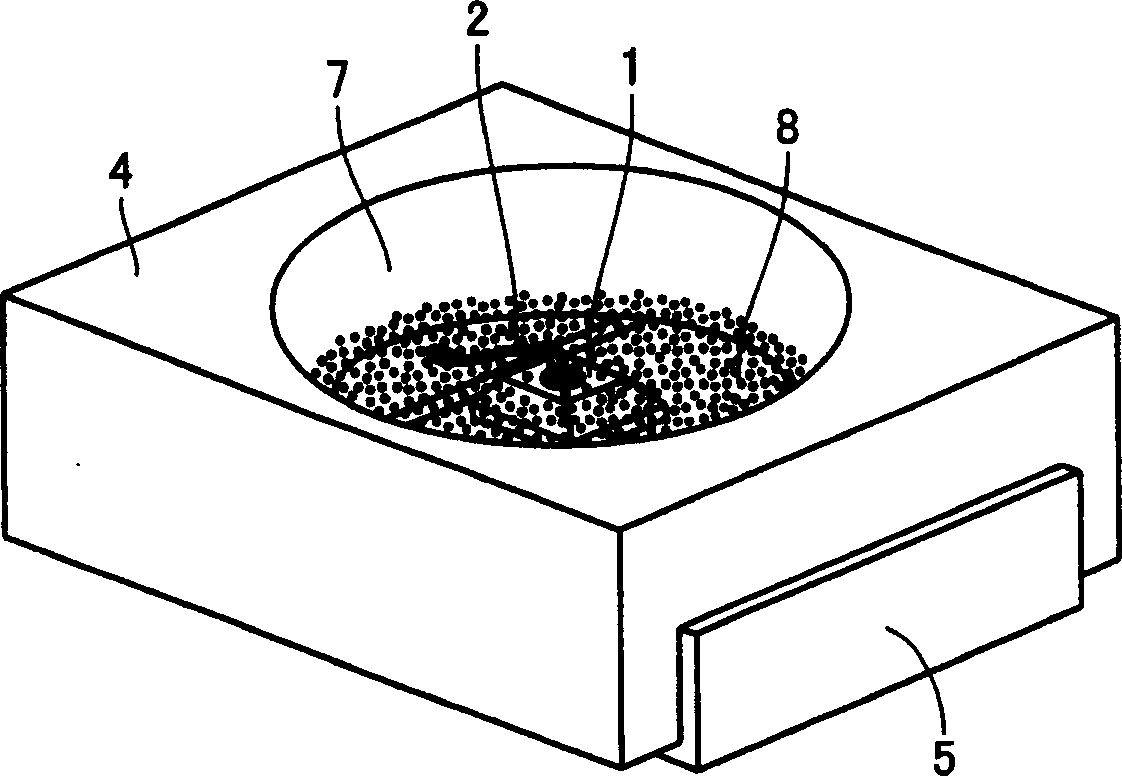

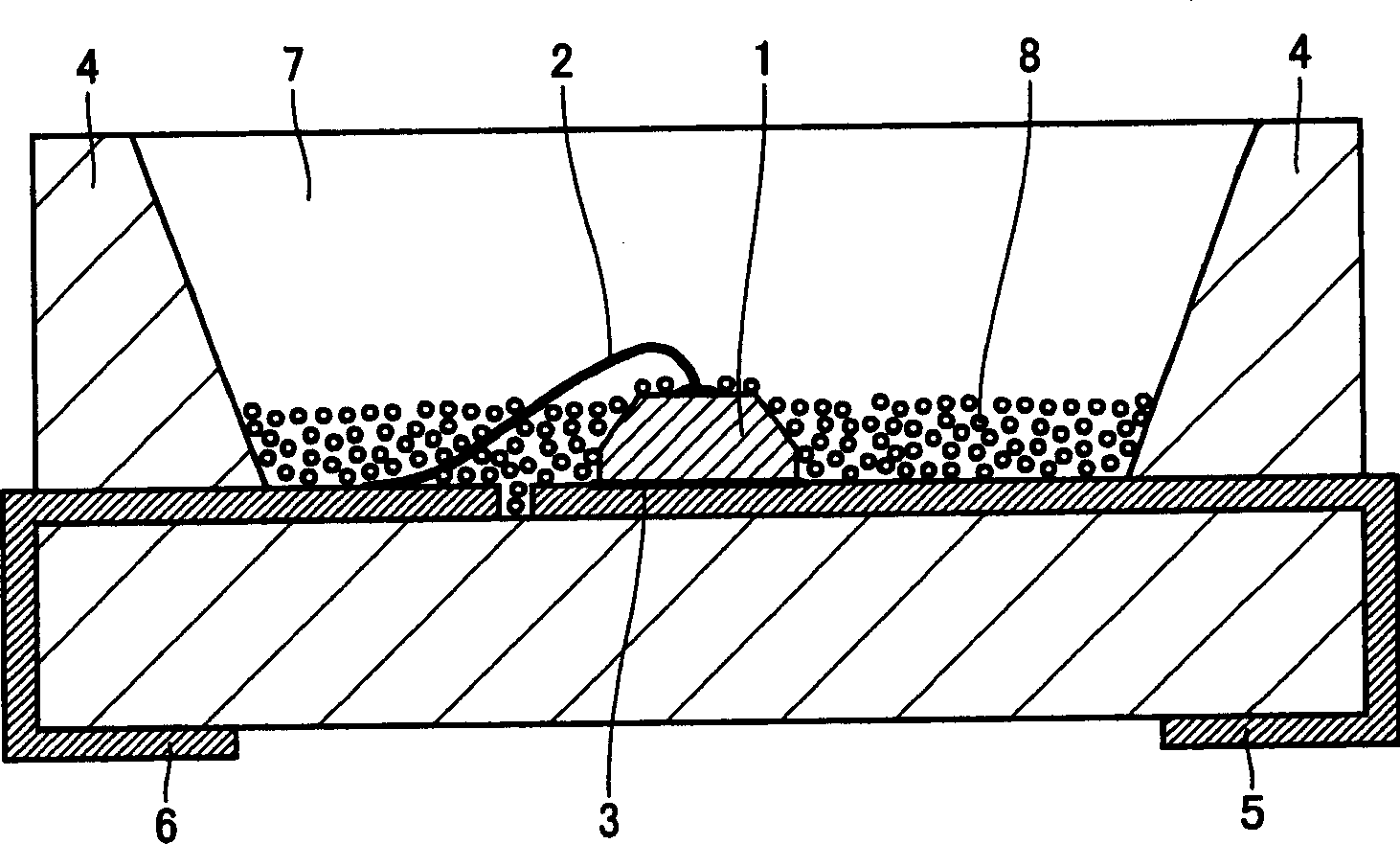

[0032] Figure 1A It is a perspective view of a surface mount type light emitting diode device as a typical example of the LED device of the present invention. Figure 1B is a cross-sectional view of the LED device. The device comprises positive and negative electrode pairs 5, 6 formed of metal plates, and a case 4 made of heat-resistant resin. The housing 4 can be formed by insert molding and takes the shape of a reflective cup. The LED substrate 1 has a side portion and a top portion, and a part of the side portion is a slope. The LED substrate 1 is electrically connected to the electrode 5 through the conductive material 3 in the housing 4 , and is electrically connected to the other electrode 6 through the metal wire 2 .

[0033] The casing 4 is sealed with a translucent resin 7, and near its bottom surface, a fluorescent material 8 having a substantially uniform thickness is provided in a layered form. The fluorescent material layer 8 is formed to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com