Forklift transmission assembling line

A technology for assembling production lines and transmissions, applied to assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to apply, low production efficiency, and high labor intensity of staff, and achieve easy operation, simple production line, and low equipment cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

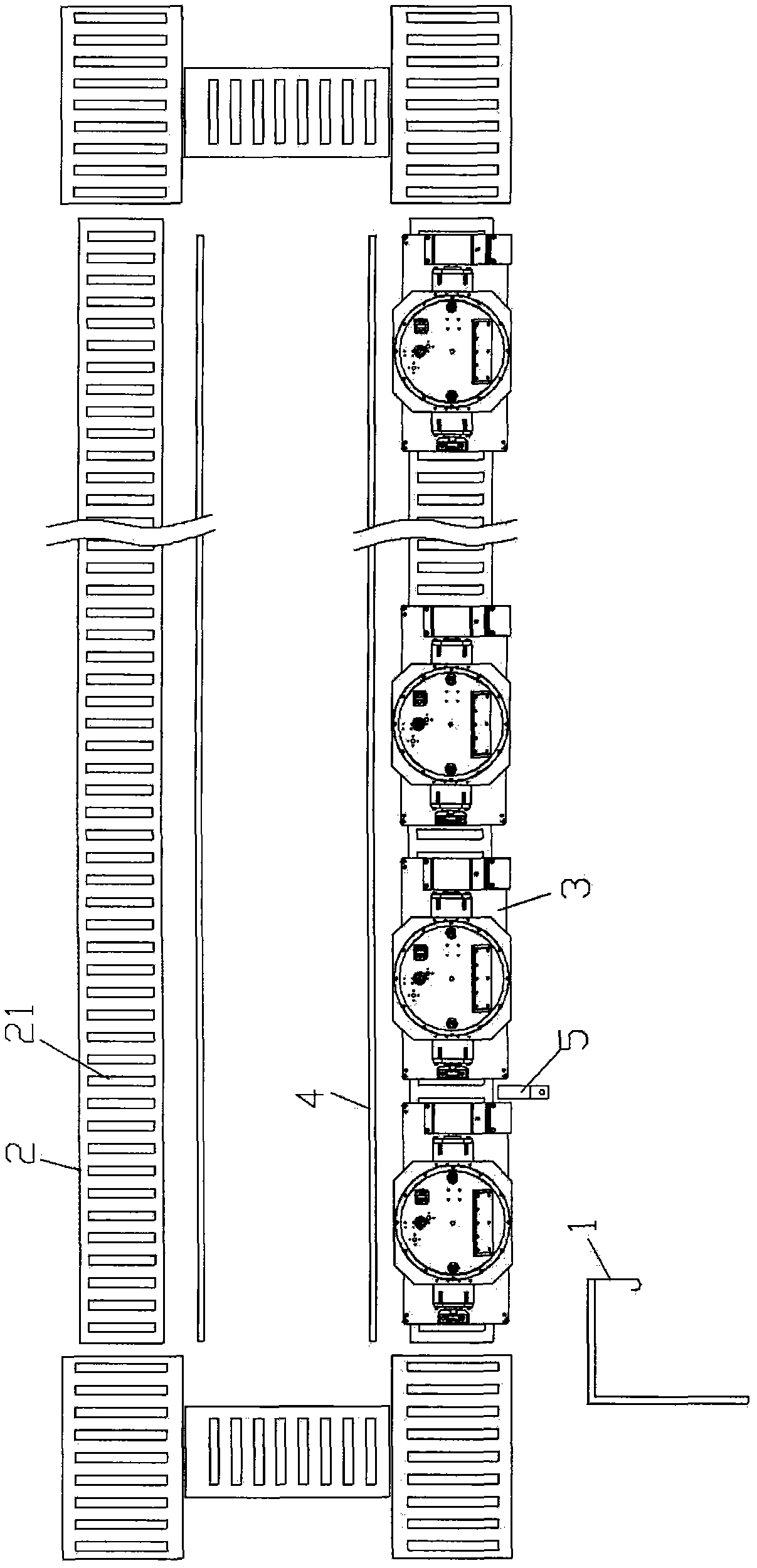

[0023] Example: see Figures 1 to 6 As shown, the forklift transmission assembly production line includes a cantilever crane 1 and a roller conveyor frame 2 arranged in a ring. The cantilever crane 1 is placed on the ground on one side of the periphery of the roller conveyor frame 2, and the traveling wheels 31 of the assembly line mobile trolley 3 are placed on On the roller 21 of the roller conveyor frame 2;

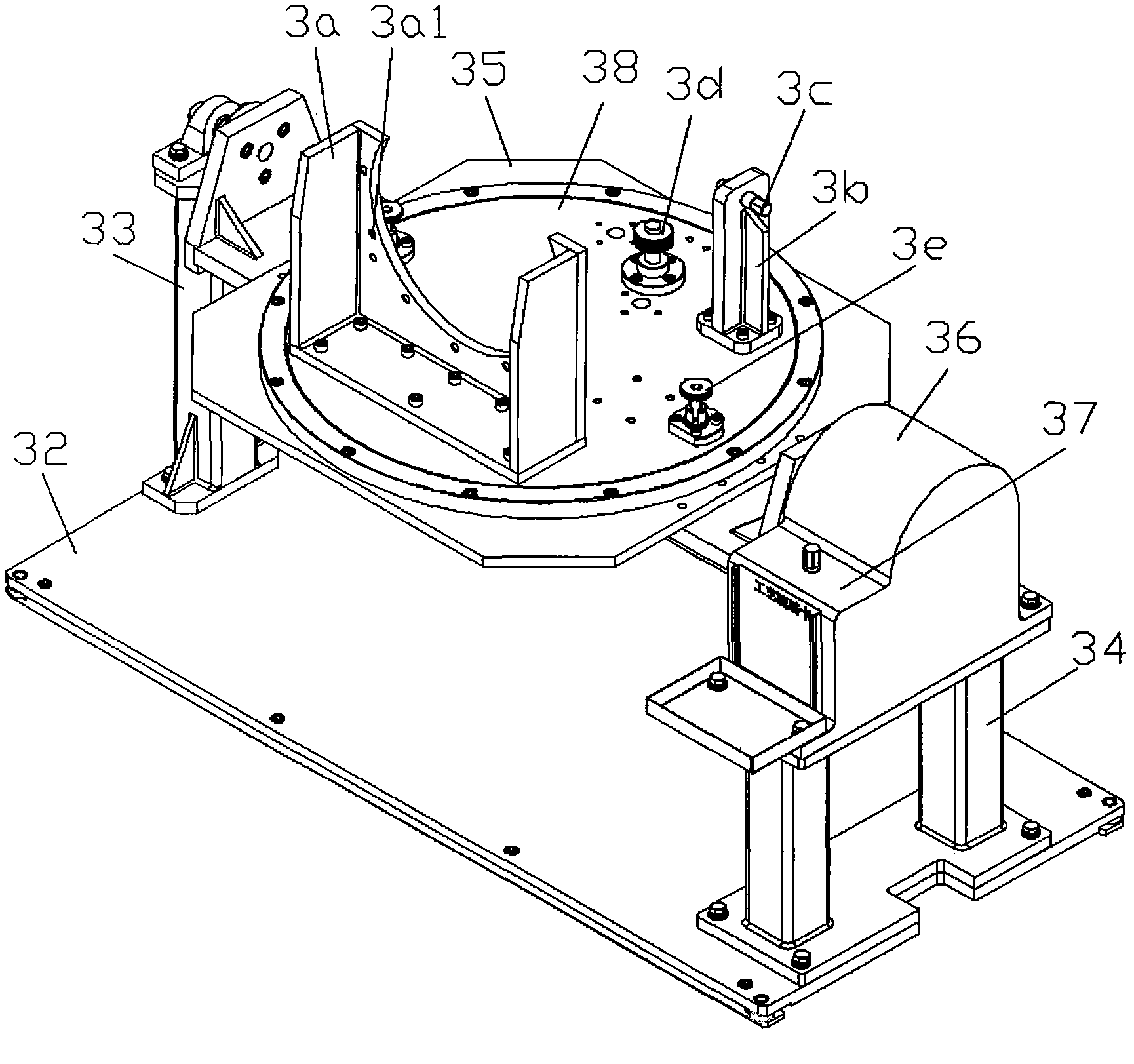

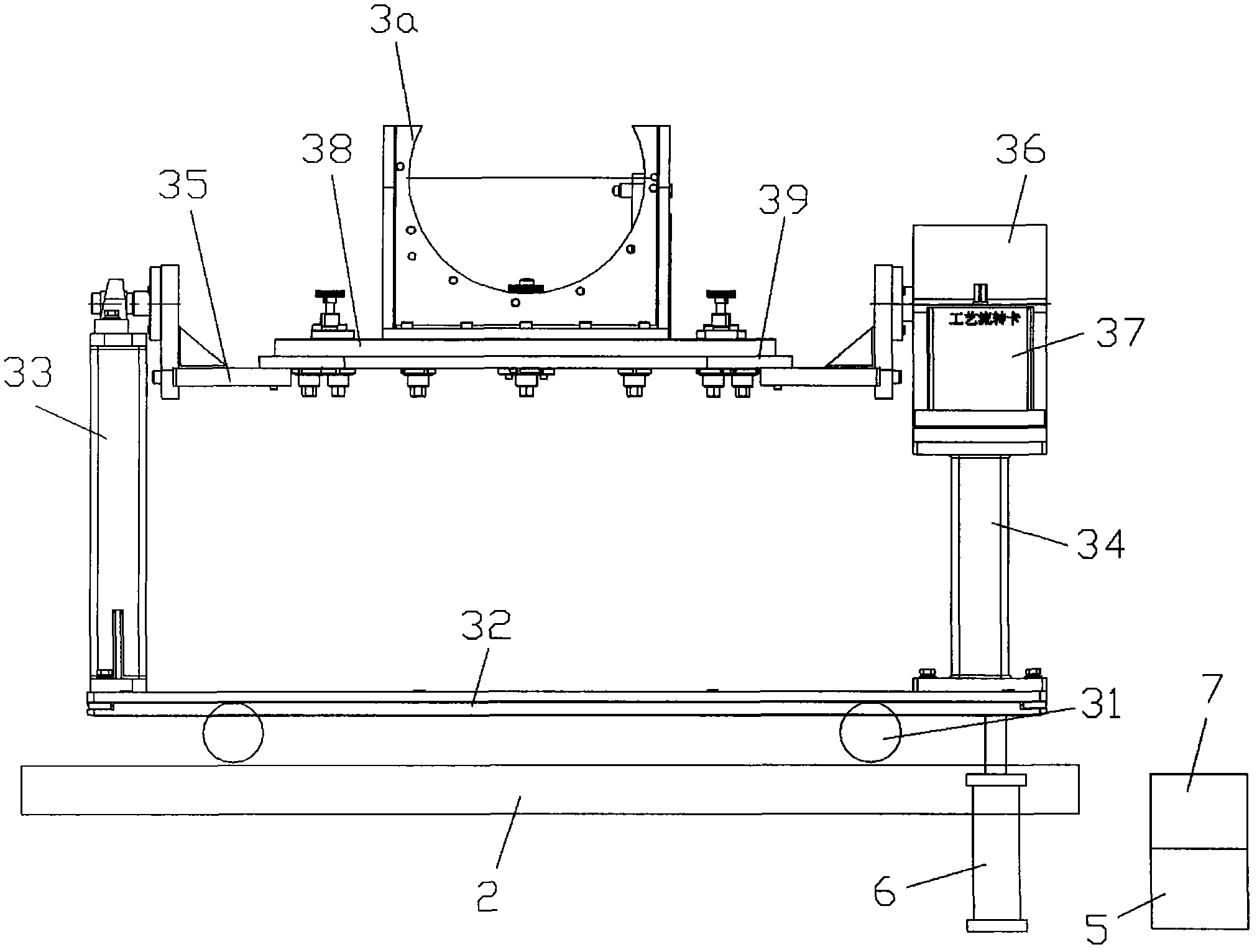

[0024] The structure of the moving trolley 3 on the assembly line is that a traveling wheel 31 is installed on the trolley chassis 32, a left bracket 33 and a right bracket 34 are fixed on the trolley chassis 32, and one end of the supporting platform 35 is hinged on the left bracket 33, and the other end is fixed on the worm wheel. On the power output shaft 363 of the worm reducer 36, a gear 372 is fixed on the pneumatic rotating shaft 371 of the pneumatic wrench 37. The worm gear reducer 36 is composed of a worm 361, a worm gear 362 and a power output shaft 363. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com