A flat glass chamfering machine

A flat glass and chamfering machine technology, which is applied to machine tools, grinders, and metal processing equipment suitable for grinding workpiece edges, and can solve problems such as complex connection control programs, large machine footprints, and low utilization of grinding wheels , to achieve the effect of simplifying machine configuration and control mode, reducing floor space and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

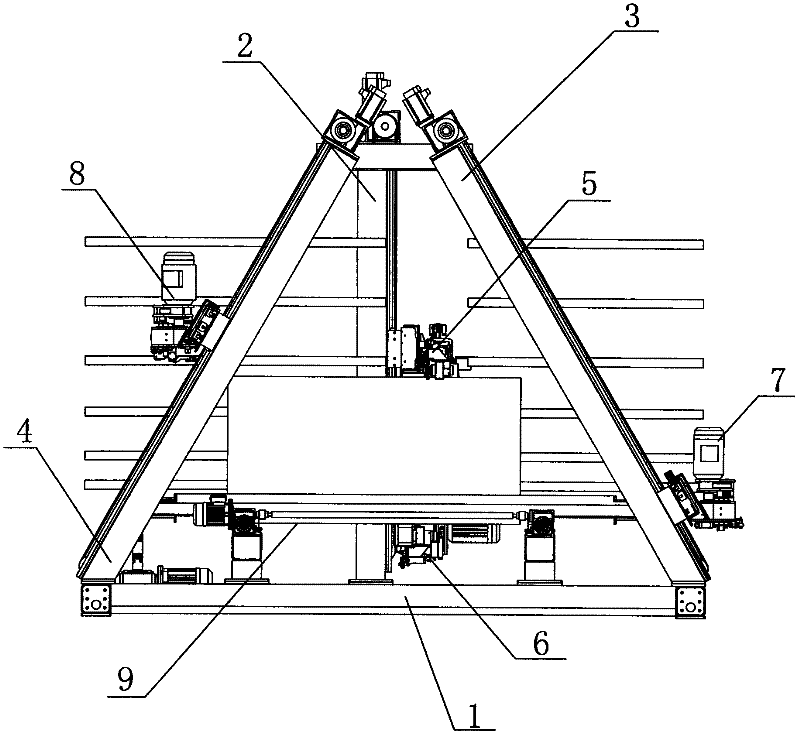

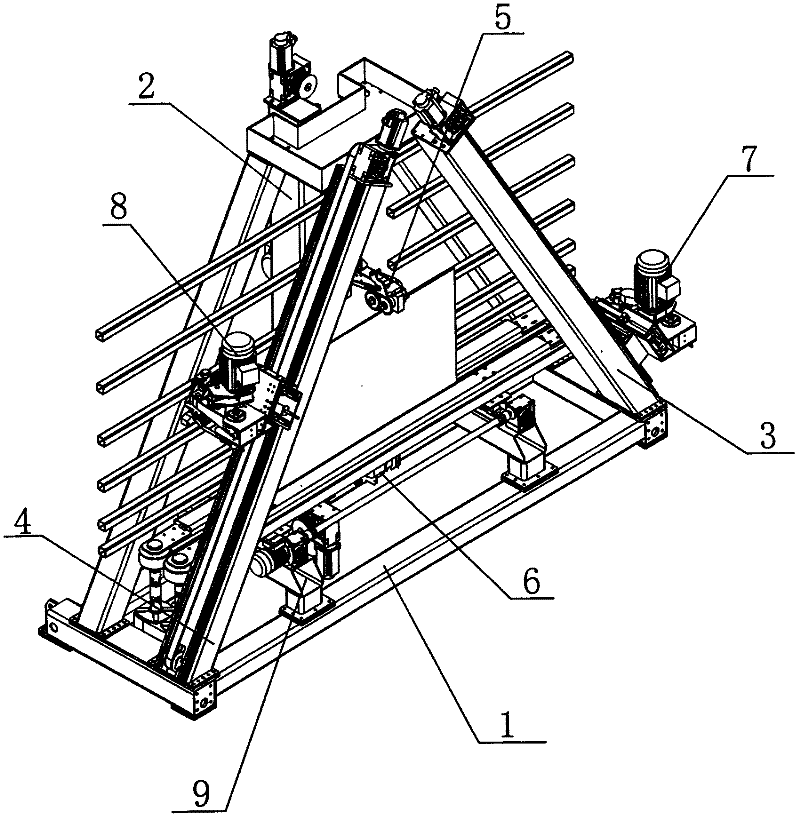

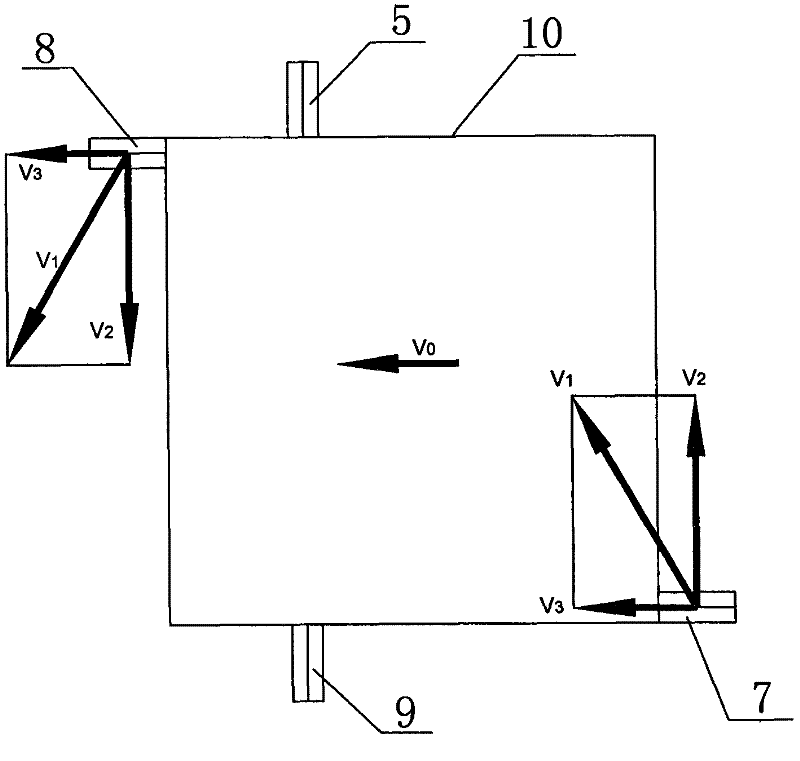

[0032] Such as Figure 1-11 As shown, a vertical plate glass chamfering machine includes a frame 1, a vertical guide rail 2, a right inclined guide rail 3, a left inclined guide rail 4, an upper edge grinding device 5, a lower edge grinding device 6, a right Along the grinding device 7, the left grinding device 8 and the clamp device 9, the clamp device 9 is arranged on the frame 1, the vertical guide rail 2 is arranged on the frame 1, and the right inclined guide rail 3 and the left inclined guide rail 4 are respectively It is obliquely arranged on the frame 1, and the upper edge grinding device 5 and the lower edge grinding device 6 are arranged on the vertical guide rail 2, and the right grinding device 7 is arranged on the right inclined guide rail 3, and the right grinding device 7 is arranged on the left inclined guide rail. 4 is provided with left grinding device 8.

[0033] The fixture device 9 includes a synchronous belt conveying type front chuck 91 and a rear chuck...

Embodiment approach 2

[0039] The technical solution of Embodiment 1 of the present invention can also be applied to the equivalent structural solution of a horizontal chamfering machine, wherein the frame 1 is a plane frame, and the vertical guide rail 2, the right inclined guide rail 3, and the left inclined guide rail 4 are all set on the same plane for positioning the flat glass in a horizontal conveying state, wherein the clamping device 9 is arranged on the frame 1, and the clamping device 9 can be set as a suction cup fixed structure to locate and transport the glass, and the vertical guide rail 2 is arranged on the horizontal guide rail. On the frame 1, the right inclined guide rail 3 and the left inclined guide rail 4 are arranged on the frame 1 obliquely with the horizontal guide rail respectively, and are correspondingly arranged horizontally, and the upper edge grinding device 5 and the vertical guide rail 2 are provided on the vertical guide rail 2 The lower edge grinding device 6 corres...

Embodiment approach 3

[0041] The technical scheme of Embodiment 1 of the present invention can also be applied to a backrest vertical plate glass chamfering machine with front and back symmetry, and its frame 1, vertical guide rail 2, right oblique guide rail 3, and left oblique guide rail 4 are arranged as corresponding backrests Symmetrical structure, the upper edge grinding device 5, the lower edge grinding device 6, the right edge grinding device 7, the left edge grinding device 8, and the fixture device 9 can be shared by the same linkage mechanism or independent mechanisms. Can achieve. Realize the technical effect of simplifying the production line and reducing the occupied area. When two sets of independent upper edge grinding device 5, lower edge grinding device 6, right edge grinding device 7, left edge grinding device 8, and clamping device 9 are respectively arranged in the front and back, the plate glass chamfering machine with two backrests Then realize the technical effect of indepe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com