Jade process plate production line

A technology for craft boards and production lines, which is applied to manufacturing tools, batching weighing instruments, and raw material supply devices for sales, etc. problems, to achieve moderate hardness, low water absorption, good moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

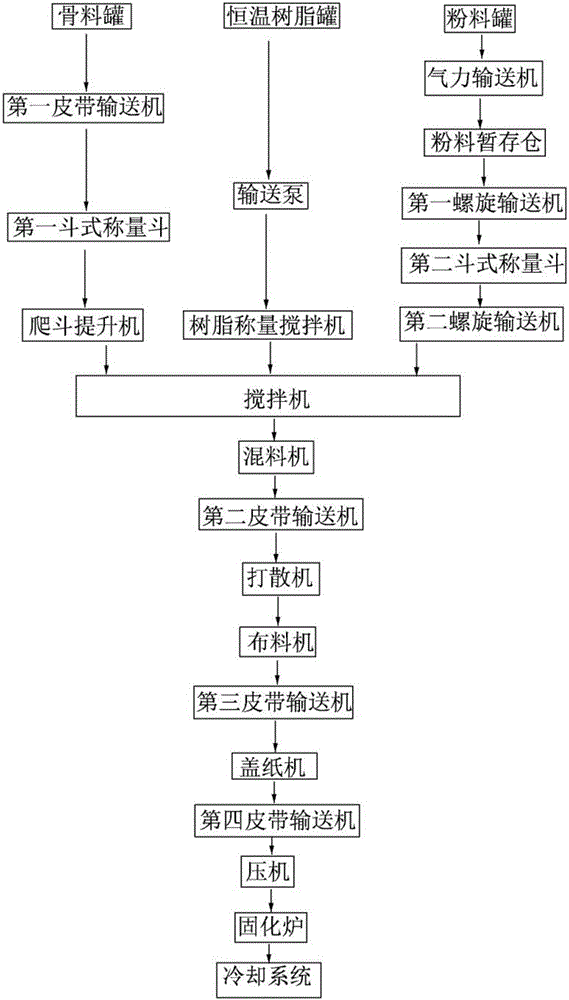

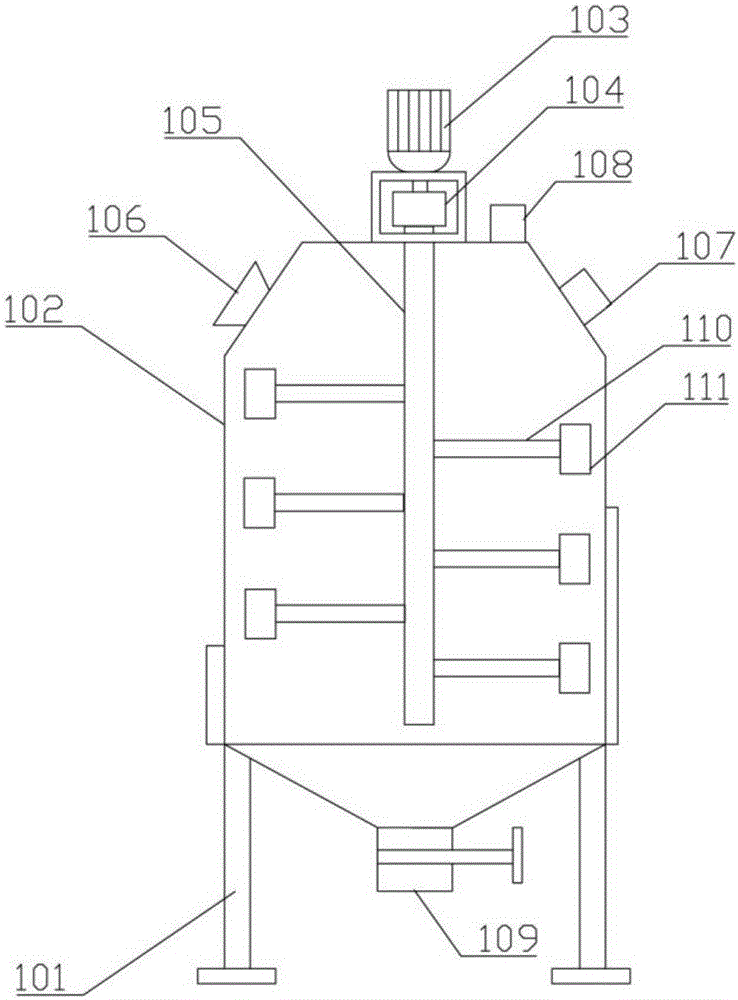

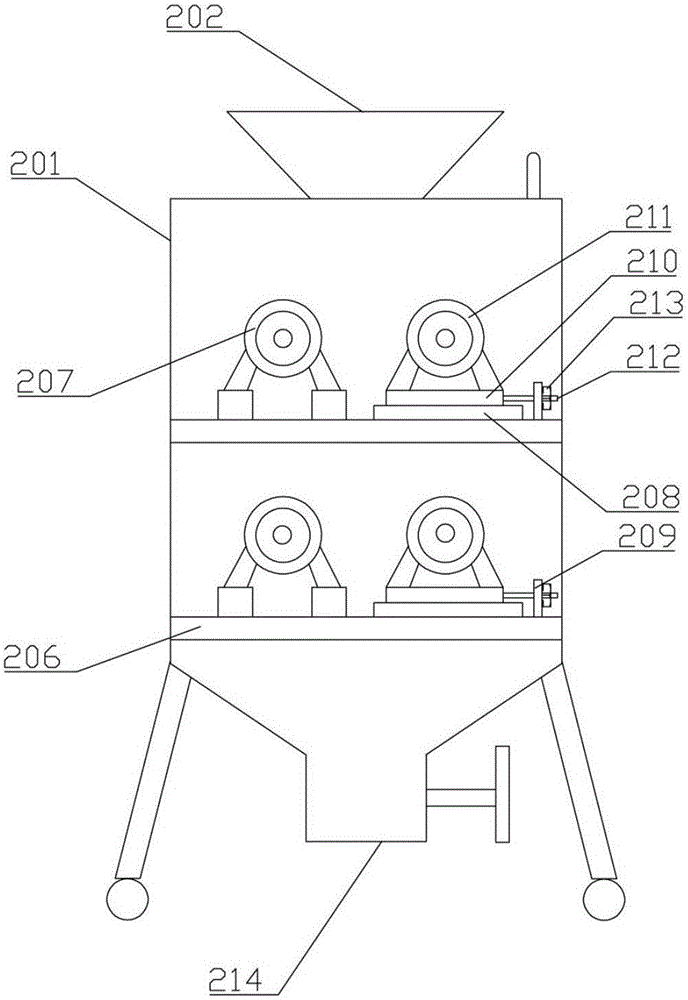

[0035] A jade craft board production line of the present invention includes a raw material storage and batching system, a stirring system, a material distribution system, a pressing system, a drying and solidification system, and a cooling system. The raw material storage and batching system includes an aggregate tank, a first bucket weighing hopper, Constant temperature resin tank, resin weighing mixer, powder tank, powder temporary storage bin, second bucket weighing hopper, aggregate tank, constant temperature resin tank and powder tank are installed side by side, and the aggregate tank is filled with quartz sand , the powder tank is filled with quartz powder, the first belt conveyor is installed between the aggregate tank and the first bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com