Laser welding system

A technology of laser welding and hinge joint, which is applied in the direction of laser welding equipment, welding equipment, welding/welding/cutting items, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, preferred embodiments of the present invention will be explained in detail by referring to the accompanying drawings.

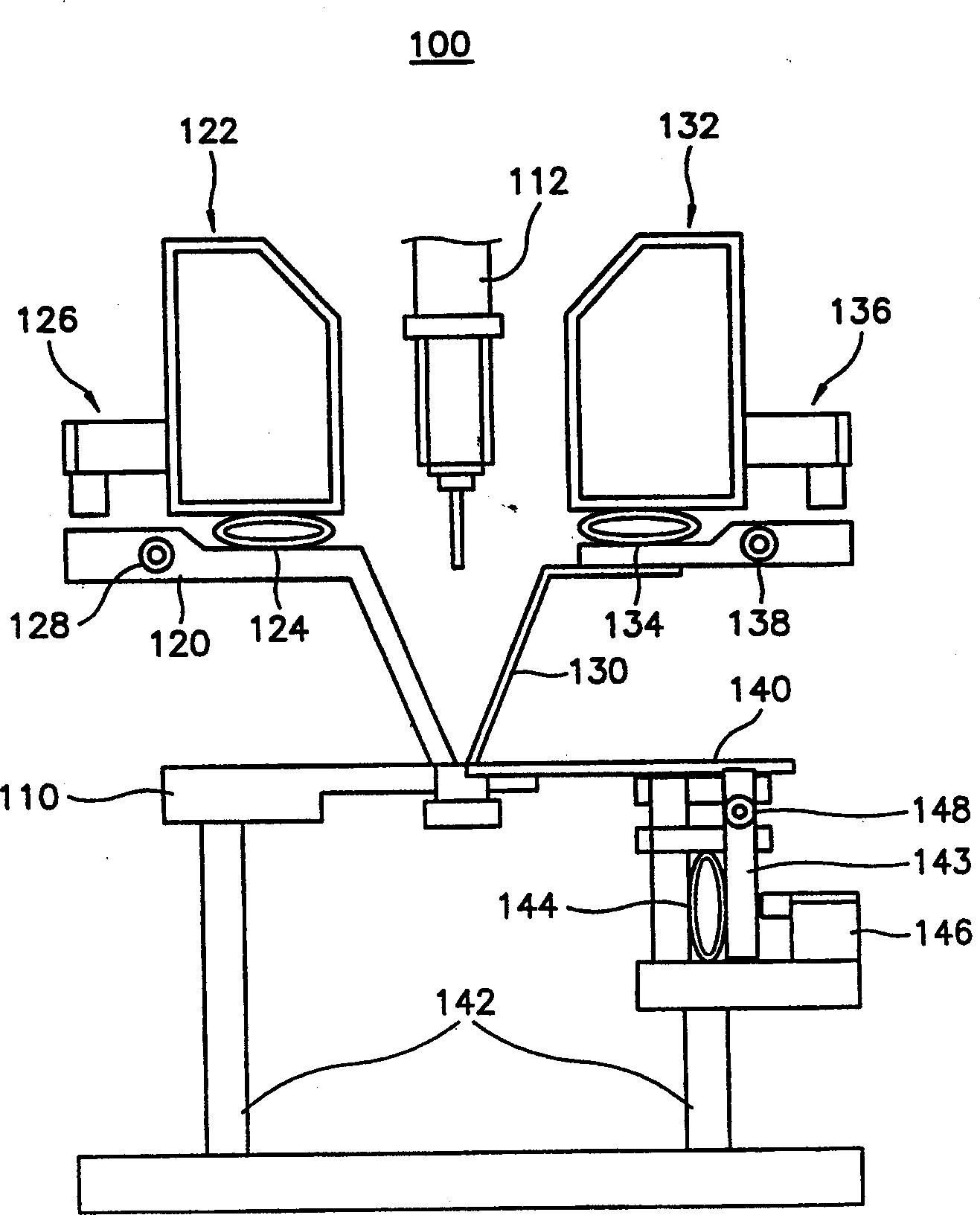

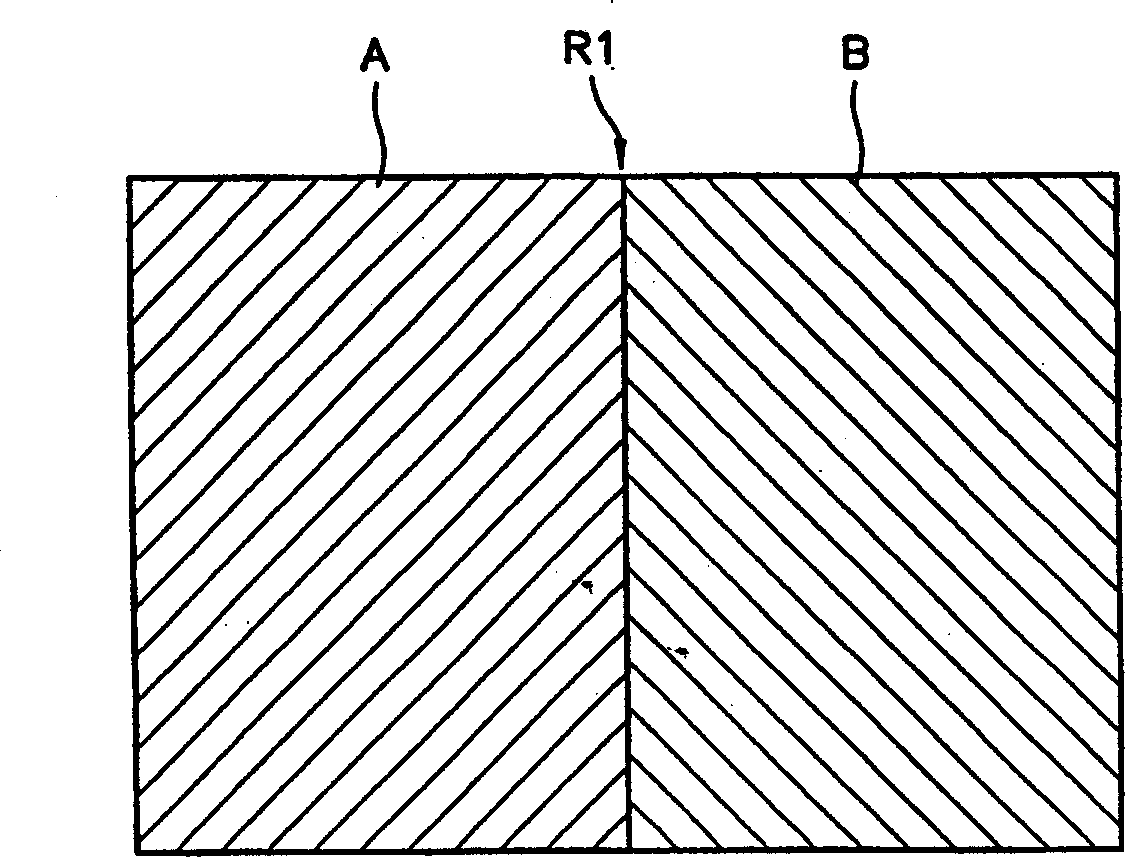

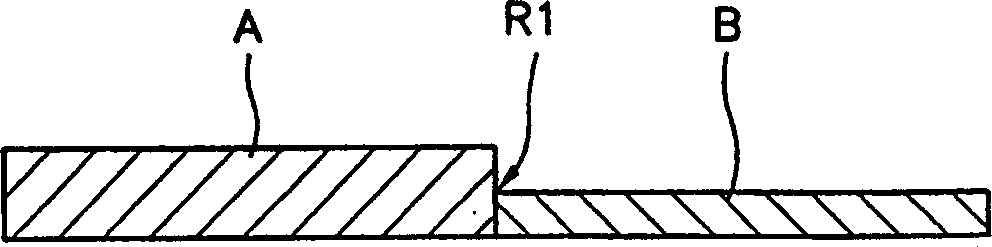

[0031] figure 1 It is a side view of a laser welding system based on the preferred embodiment of the present invention. figure 2 and image 3 respectively figure 1 Side and top views of a welded entity fabricated by the laser welding system shown in .

[0032] see figure 1 , the laser welding system according to the present invention includes a welding frame 110 , a first clamping element 120 , a second clamping element 130 , an anvil 140 and a laser welding head 112 .

[0033] The first steel plate A to be welded is placed on the welding frame. The first clamping member fixes the first steel plate A placed on the welding frame 110 , and the first clamping member is installed on the welding frame 110 .

[0034] At least one second clamping element 130 is also installed for fixing the second steel plate B to be welded near the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com