Hard-state tin-coated copper-clad steel wire processing technology

A tinned copper-clad steel and wire processing technology, applied in the manufacture of extensible conductors/cables, etc., can solve the problems of unfavorable wire properties, low bonding force between the coating and the substrate, and achieve increased safety performance, excellent toughness and resistance. Torsion, reliable soldering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

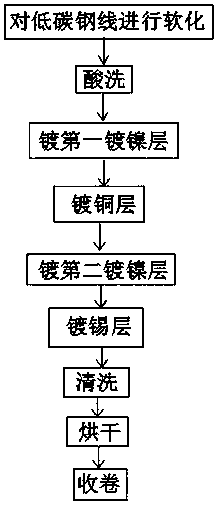

[0043] A process for processing hard-state tinned copper-clad steel wire, comprising the following steps:

[0044] Step 1: Soften and straighten the low carbon steel wire 1;

[0045] Step 2: pickling; the pickling solution used in pickling is: sulfuric acid solution, the concentration is 100-250g / l;

[0046] Step 3: Plating the first nickel plating layer 2; the method of nickel plating is electroplating, the solution of electroplating is nickel sulfamate solution, the concentration is 30-80g / l, nickel chloride and nickel plate are placed in the solution;

[0047] Step 4: Copper plating layer 3; the method of copper plating is electroplating, and the electroplating solution is copper sulfate solution with a concentration of 100-200g / l;

[0048] Step 5: Plating the second nickel plating layer 4; the nickel plating method is electroplating, the electroplating solution is nickel sulfamate solution, the concentration is 30-80g / l, and nickel chloride and nickel plate are placed in ...

Embodiment 2

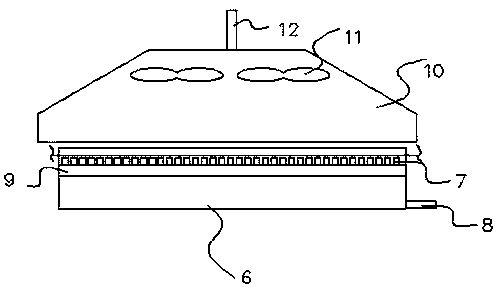

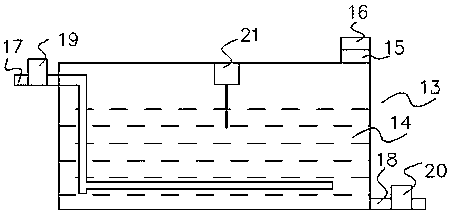

[0059] As an optimization of Example 1, a volatile gas collection cover 10 is provided above the pickling tank 6, a suction fan 11 is provided in the cover, and a collection pipe 12 is provided on the top of the collection cover; The collection pipe 12 leads to the filter box 13, the filter box 13 is provided with an absorption liquid 14, the end of the collection pipe 12 is buried in the absorption liquid 14, and the filter box 13 is provided with a gas outlet 15, Described other outlet is provided with activated carbon filter layer 16; Described filter casing 13 is provided with feed pipe 17 and discharge pipe 18, and described feed pipe 17 is communicated with filter casing 13 tops, and described discharge pipe 18 It communicates with the lower part of the filter box 13; the feed pipe 17 and the discharge pipe 18 are respectively provided with a feed valve 19 and a discharge valve 20, and the filter box 13 is also provided with a concentration monitoring sensor 21. The conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com