Method and apparatus for removing foreign matters from tabacco

A technology for tobacco materials and foreign bodies, applied in the fields of tobacco, tobacco preparation, chemical instruments and methods, etc., can solve the problems of single performance of foreign body removal equipment and complicated production lines, and achieve the effect of simplifying tobacco production lines, ensuring product quality, and improving use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

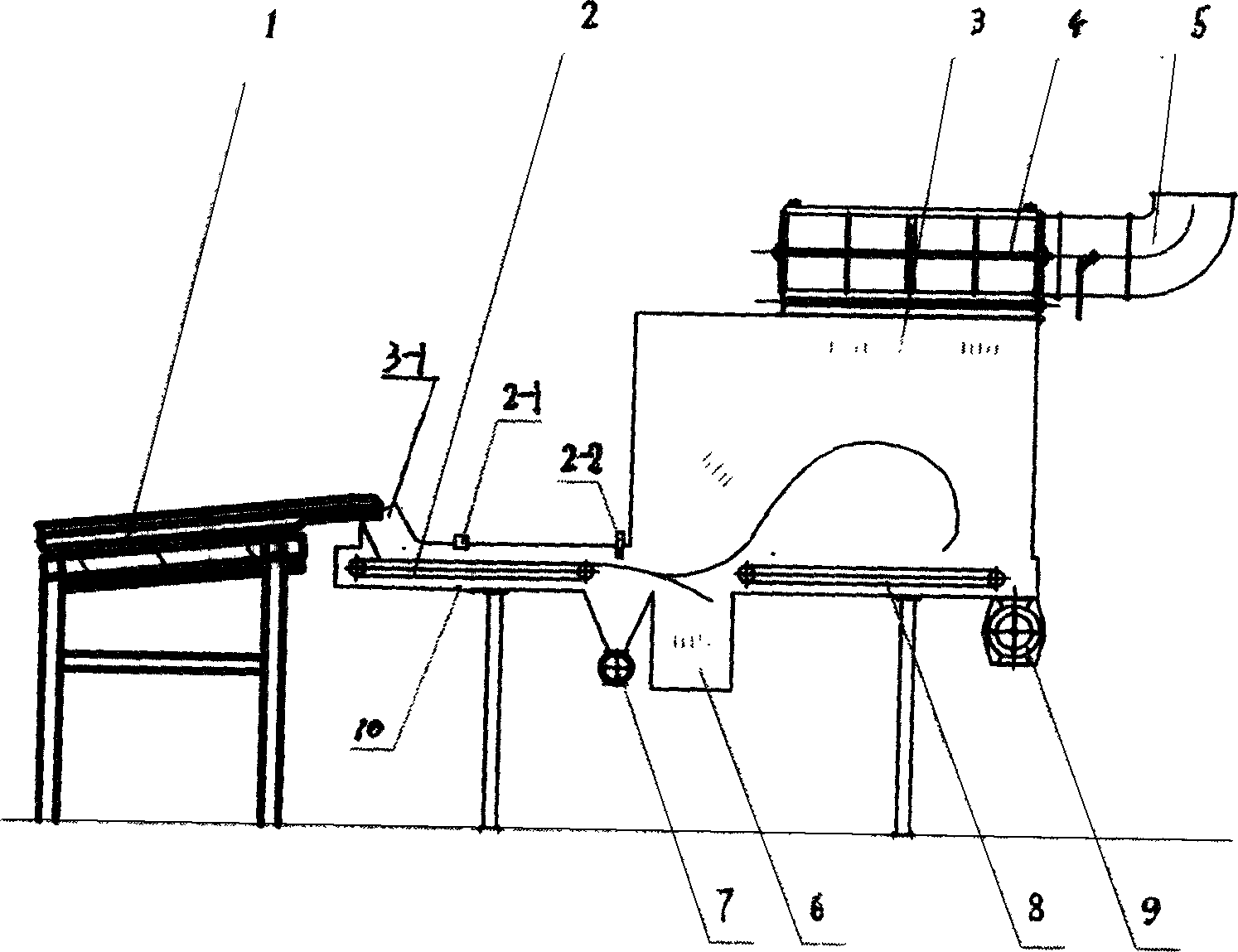

[0012] As shown in the figure, the purpose of this embodiment is to separate the foreign matter from the rehydrated tobacco sheet, mainly to separate foreign objects such as plastics, mildewed smoke, chicken feathers, stones, tobacco stems, metal objects and other foreign objects contained in the tobacco sheet, as well as tobacco The agglomeration of the slices is separated from the smoke slices to improve the purity of the smoke slices.

[0013] As shown in the figure, below the feeding device 1 is the feeding port 3-1 of the box body 3, and the high-speed belt conveyor 2 and the bottom belt 8 are connected as a whole through the frame 10. Between the high-speed belt conveyor 2 and the bottom belt 8, a miscellaneous air lock 7 and an air separation chamber 6 are successively installed. Imaging device 2-1 is housed above or below the high-speed belt conveyor 2, and compressed air blowing device 2-2 is housed above the miscellaneous air lock 7 in the place ahead of high-speed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com