Device for high-density molding and method for high-density molding of mixed powder, and high-density three-layer-structured powder compact

A mixed powder, high-density technology, applied in the direction of material molding presses, presses, transportation and packaging, etc., can solve the problem that the density cannot meet the needs, and achieve the effects of reducing material costs, increasing selectivity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

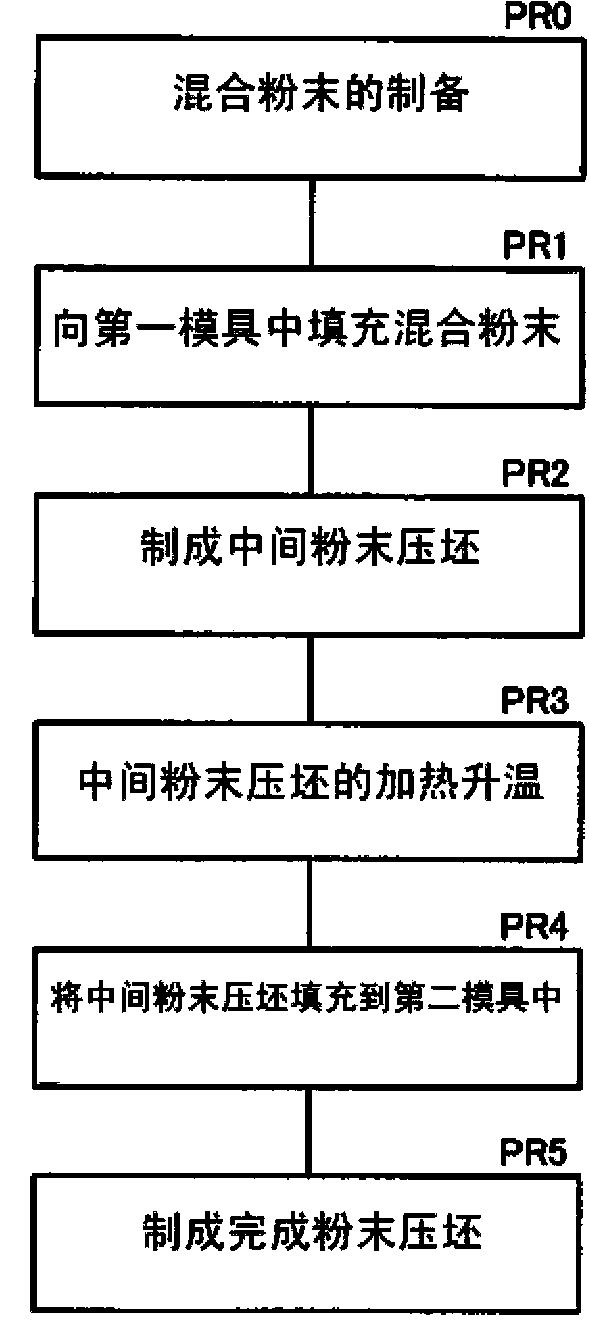

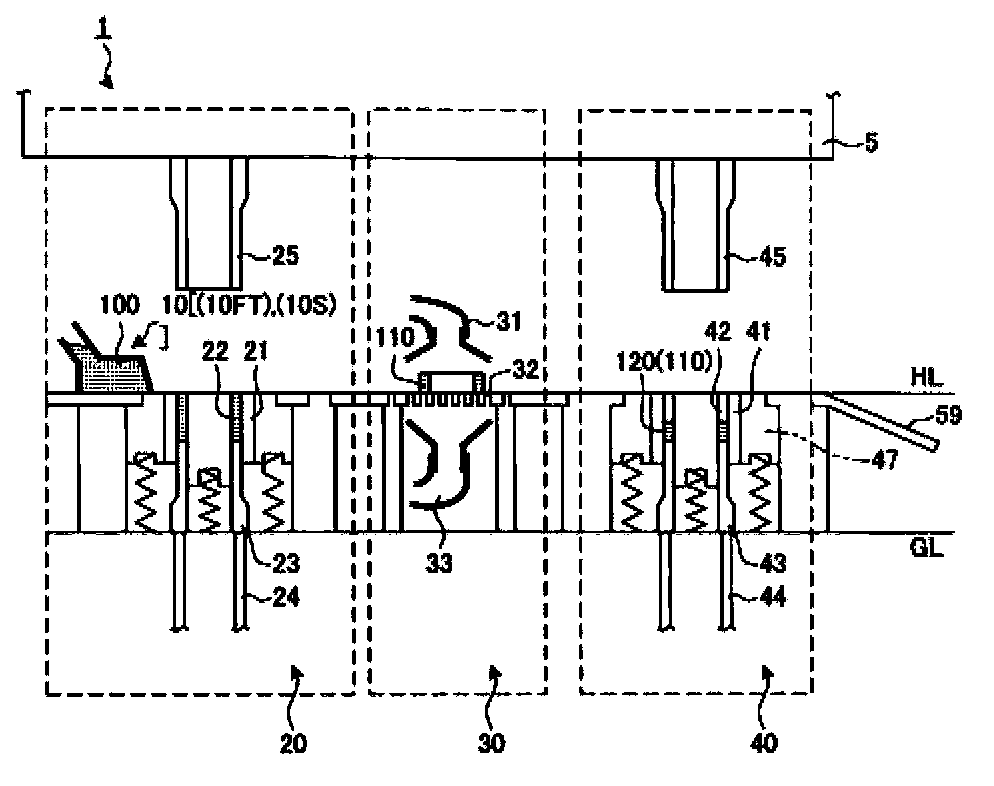

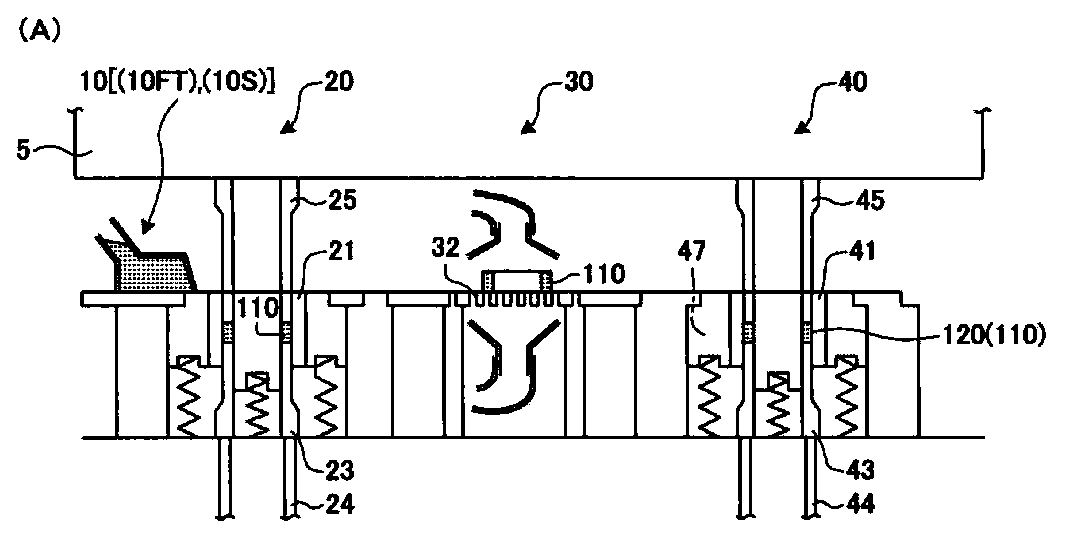

[0082] The high-density molding device of this mixed powder 1 such as Figure 1 to Figure 7 As shown, there is a mixed powder supply machine 10, a first pressure molding machine 20, a heating and heating machine 30 and a second pressure molding machine 40, which can stably and reliably implement the high-density molding method of this mixed powder and can be manufactured and provided in A high-density three-layer structure powder compact with superior performance in mechanical post-processing. The high-density forming method of the mixed powder consists of the following steps: filling the mixed powder into the mixed powder in the first mold (lower mold 21) Filling step (PR1), the mixed powder is a mixture of base metal powder and low-melting lubricant powder, filled with the mixed powder 100F for the first layer according to the small particle size of the base metal powder, and the large particle size of the base metal powder The mixed powder 100S for the second layer and the ...

Embodiment )

[0197] by Figure 11 Ring shaped as shown, a finished powder compact 120 having an outer diameter of 50 mm, an inner diameter of 40 mm and a thickness of 5 mm was produced. The amount of shedding and the Figure 7 (A) Shown is a cylindrical shape compared to an increased toroid. Choose Somaloy110i for the first layer of mixed powder 100F and the third layer of mixed powder 100T【 (ヘガネス) company manufacturing]. The base metal powder is iron powder coated with a glassy insulating coating for magnetic cores, and the mixing ratio of the lubricant is 0.5 wt%. The particle diameter of the base metal powder is 20 μm to 100 μm, and the average particle diameter is 50 μm. Also, as the mixed powder 100S for the second layer, I chose Somaloy700【 (ヘガネス) company manufacturing]. The base metal powder was iron powder coated with a vitreous insulating coating for a magnetic core, and the mixing ratio of the lubricant was 0.4 wt%. The particle diameter of the base metal powder is 80 μm...

no. 2 approach )

[0220] The implementation is as Figure 12 shown. Compared with the case of the first embodiment, it is characterized in that the mixed powder supply machine 10 and the first press molding machine 20 are installed as they are, and the heating and temperature raising machine 30 and the second press molding machine 40 are integrally formed.

[0221] That is, the high-density molding device is formed by the heating and pressing molding machine 70 integrally integrating the functions of the heating and temperature raising machine 30 in the first embodiment and the function of the second pressing and molding machine 40 . The heating and pressing molding machine 70 is formed by a plurality of (two in this embodiment) heating and pressing molding sub-machines 70A and 70B. Sequential actions can be selected during the manufacturing cycle.

[0222] The basic configuration of each heat press molding sub-machine 70A ( 70B) is set to be the same as that of the second press molding machi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com