Coating device and coating method

A kind of coating equipment and coating technology, which is applied in the direction of surface coating liquid devices, coatings, printed circuit coatings, etc., can solve the problems of reducing manufacturing efficiency, increasing equipment costs, and film holes, etc., to improve products Quality, equipment cost reduction, and manufacturing time saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

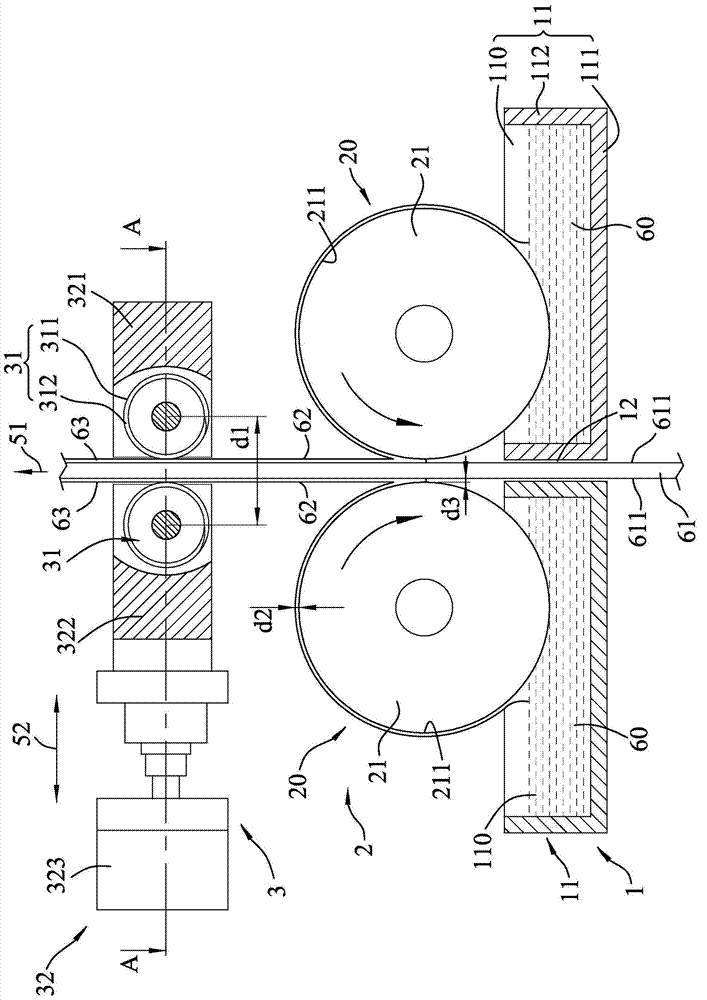

[0027] The present invention will be described in detail below with reference to the drawings and embodiments. It should be noted that in the following description, similar components are denoted by the same numbers.

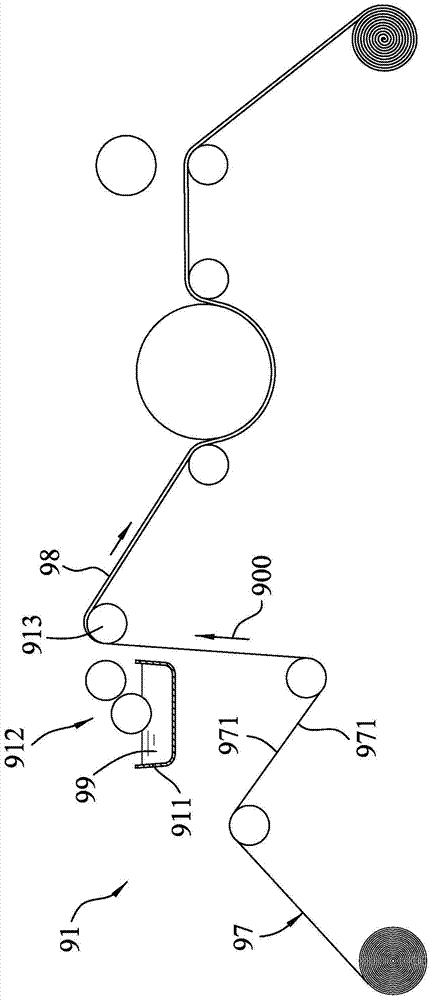

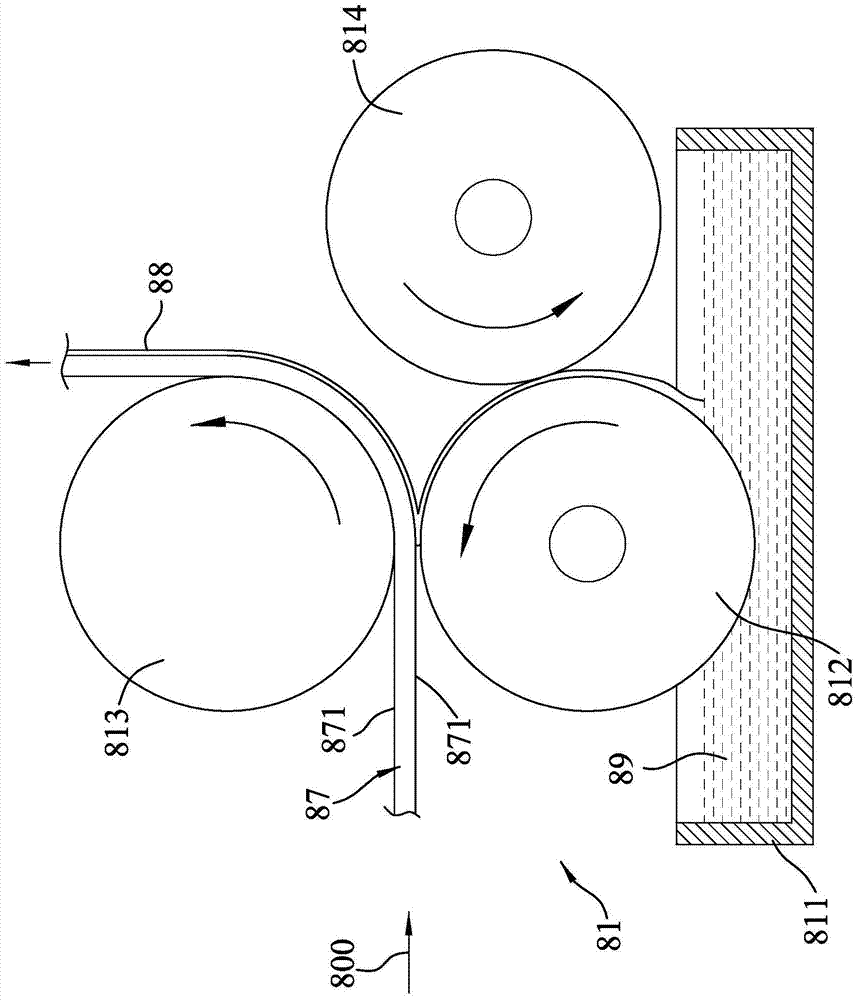

[0028] refer to image 3 , 4 5. A first preferred embodiment of the coating equipment of the present invention is one of the machines used in the process of manufacturing flexible printed circuit boards (Flexible Printed Circuit Board, FPCB for short). When a substrate 61 is transported to the coating device of this embodiment along a vertical direction 51 , the coating device is used to coat the substrate 61 with the viscous ink 60 to coat and form a film layer 63 .

[0029]In this embodiment, the substrate 61 is continuously conveyed from bottom to top along the vertical direction 51 to the coating equipment of this embodiment in a roll-to-roll (Roll To Roll) manner. Of course, in practice, the base material 61 can also be transported in a single sheet (Shee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com