Tomato crushing and beating machine

A beater, tomato technology, applied in juice extraction, food processing, food science, etc., can solve the problems of poor crushing effect, low tomato pulp output, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

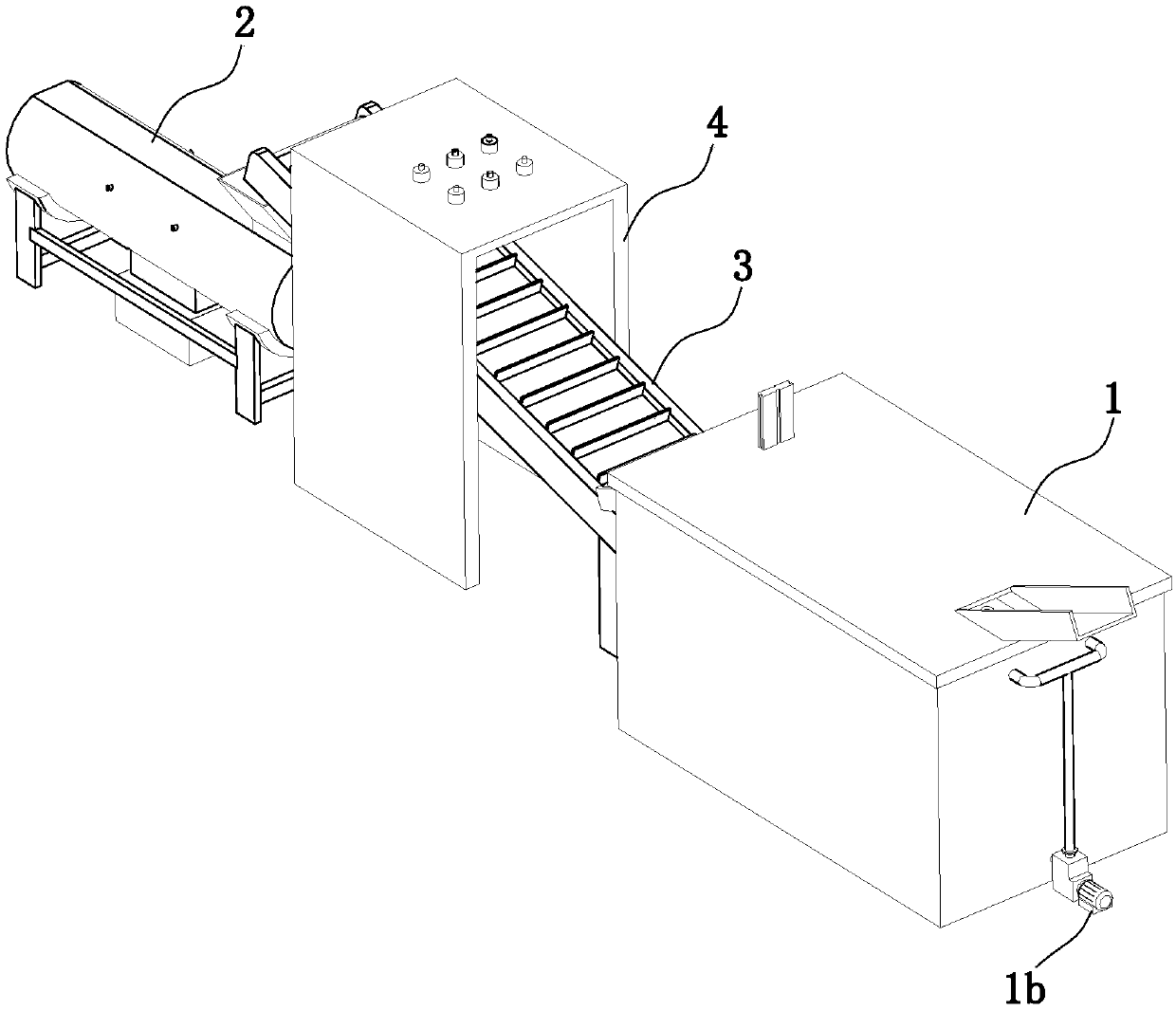

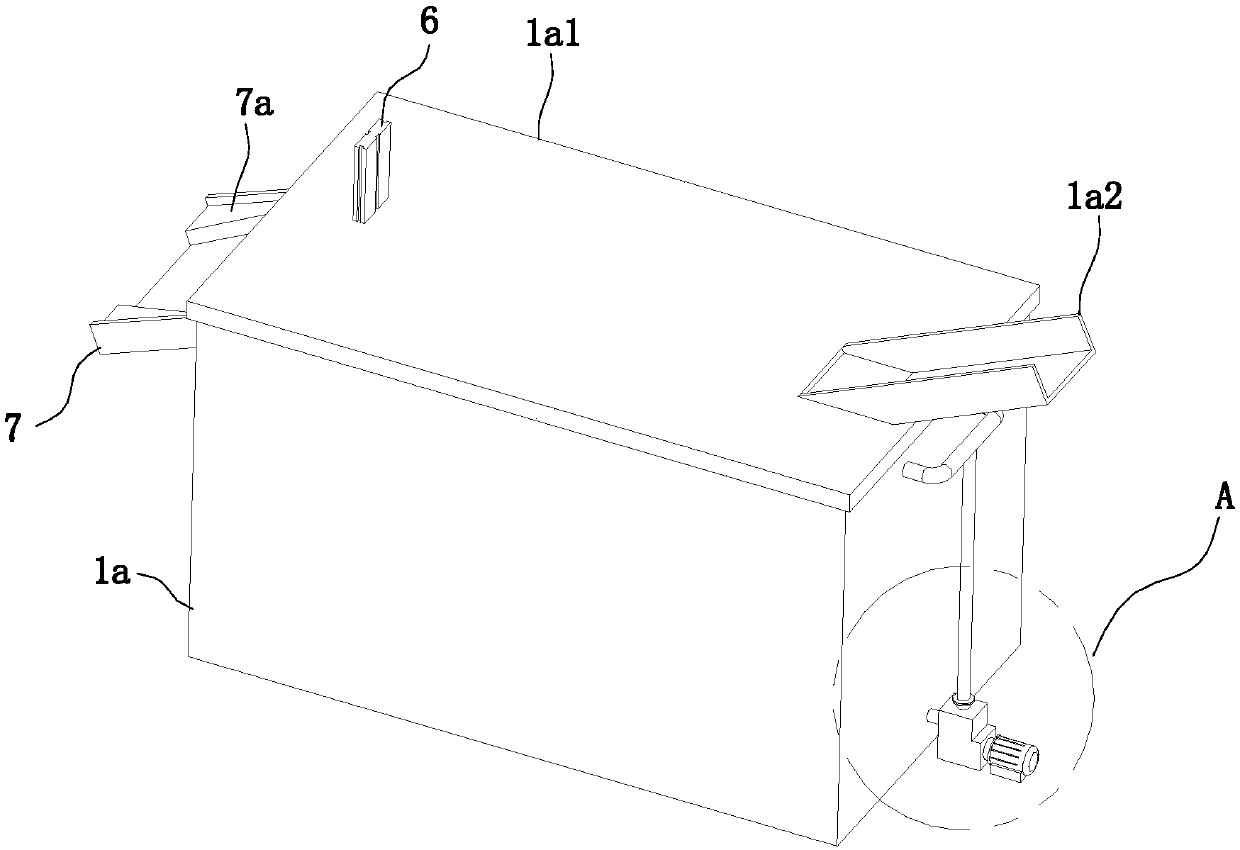

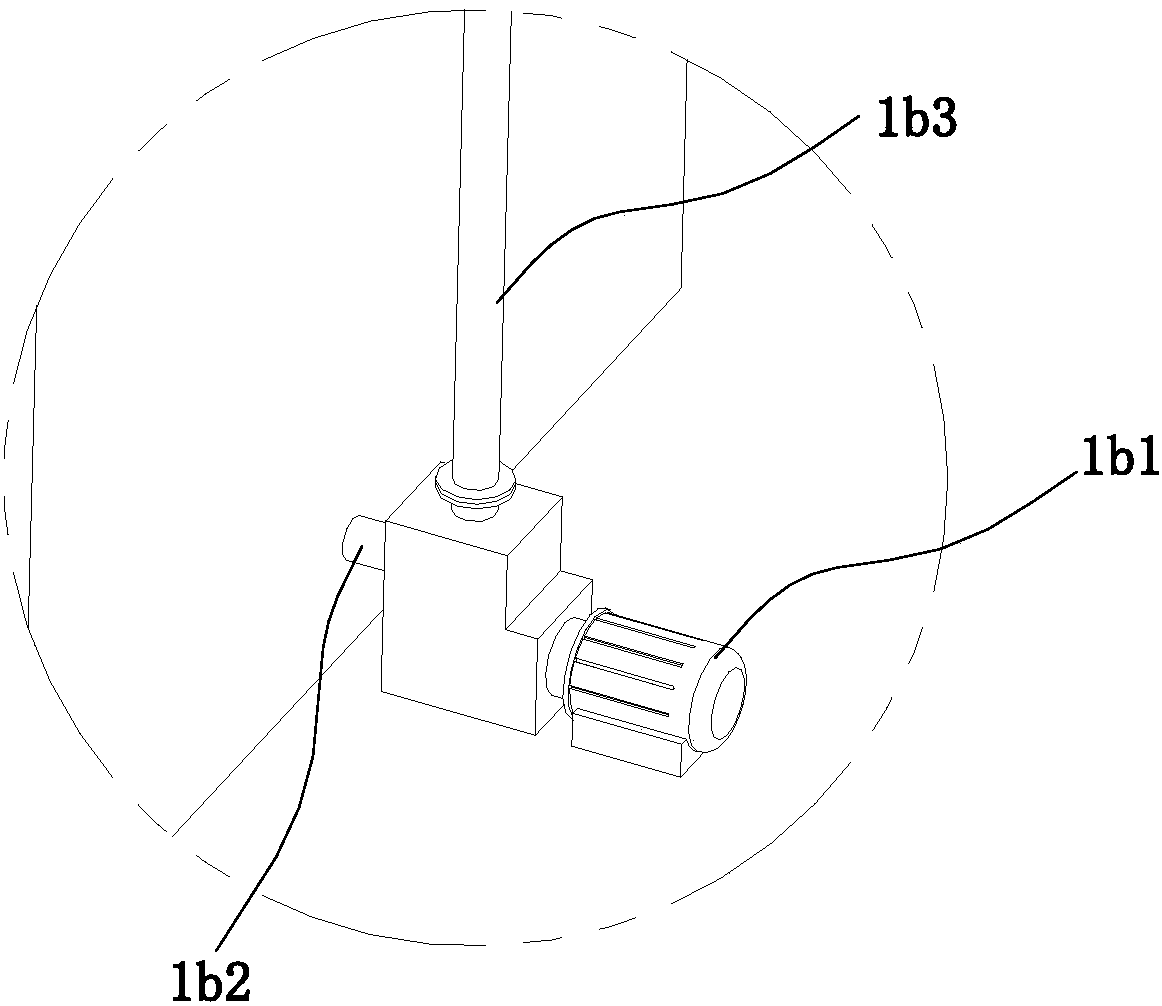

[0030] refer to Figures 1 to 12 A kind of crushing and beating machine for tomatoes shown includes a cleaning device 1, a crushing device 2, a conveyor belt 3 and an air-drying device 4, the conveyor belt 3 is located between the cleaning device 1 and the crushing device 2 and the input end of the conveyor belt 3 is connected to the cleaning device 1 connected, the output end of the conveyor belt 3 is connected with the crushing device 2, and the air-drying device 4 is erected on the conveyor belt 3 for air-drying the tomatoes transported on the conveyor belt 3, and the air-drying device 4 is provided for drying the conveyor belt 3 separately. The dry drying assembly 4a, when working, puts the tomatoes in the cleaning device 1 for cleaning, and then transfers the cleaned tomatoes to the action area of the air dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com