Automatic lifting and separating device for floor panels

An automatic lifting and separating device technology, which is applied in the direction of transportation and packaging, unstacking of objects, conveyors, etc., can solve problems such as difficult to take out alone, short length and width, and difficult floor boards, so as to reduce labor intensity and manufacture The effect of low cost and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

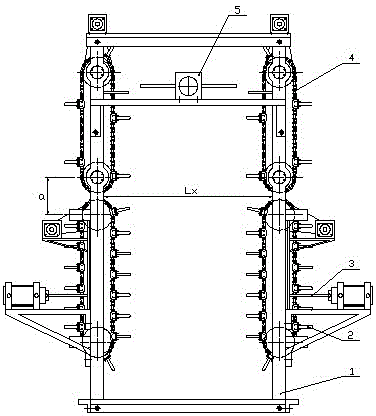

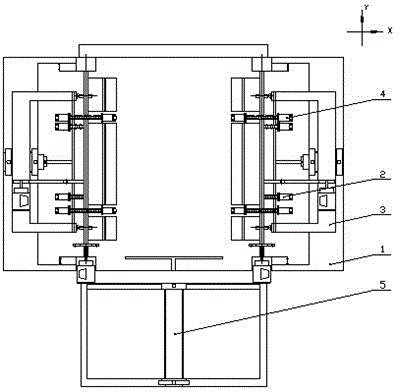

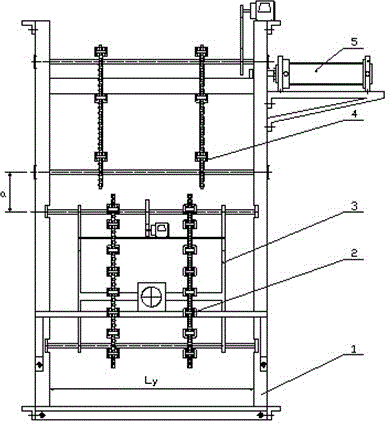

[0076] An automatic lifting and separating device for platform boards. In this embodiment: the platform board 55 is as Figure 21 and Figure 22 As shown, length × width × height = 1200 × 1000 × 150mm; the distance L between the inner sides of the two columns 8 adjacent to each other on the base frame 1 x =1700mm, the distance L between the inner sides of the two columns 8 adjacent to the left and right of the base frame 1 y =1400mm.

[0077] The automatic lifting separation device such as figure 1 , figure 2 and image 3 As shown, it consists of a base frame 1, 2 first lifting devices 2, 2 position control devices 3, 2 second lifting devices 4 and a pushing device 5. The first lifting device 2 is symmetrically installed on the left and right sides of the lower part of the base frame 1. The upper ends of the two position control devices 3 are flexibly connected with the first lifting drive shafts 28 of the corresponding two first lifting devices 2. The two position cont...

Embodiment 2

[0130] An automatic lifting and separating device for platform boards. Except following technical parameter, all the other are with embodiment 1:

[0131] In this embodiment: the length × width × height of the platform plate = 1000 × 800 × 130mm; the distance L between the inner sides of the two columns 8 adjacent to the left and right of the base frame 1 x =1600mm, the distance L between the inner sides of the two columns 8 adjacent to the left and right of the base frame 1 y =1200mm.

[0132] The center distance a of the first hoisting driving wheel of the first hoisting device 2 and the second hoisting driven wheel of the second hoisting device 4 in side projection is:

[0133] a=(0.7~0.8)(L x -L 0 ) (1)

[0134] In formula (1): L x Indicates the distance between the insides of the left and right adjacent columns 8;

[0135]L 0 Indicates the length of the floor plate.

[0136] Will L x = 1600mm and L 0 =1000mm into formula (1), get:

[0137] a=420-480mm.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com