Patents

Literature

30results about How to "Production can be scaled" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

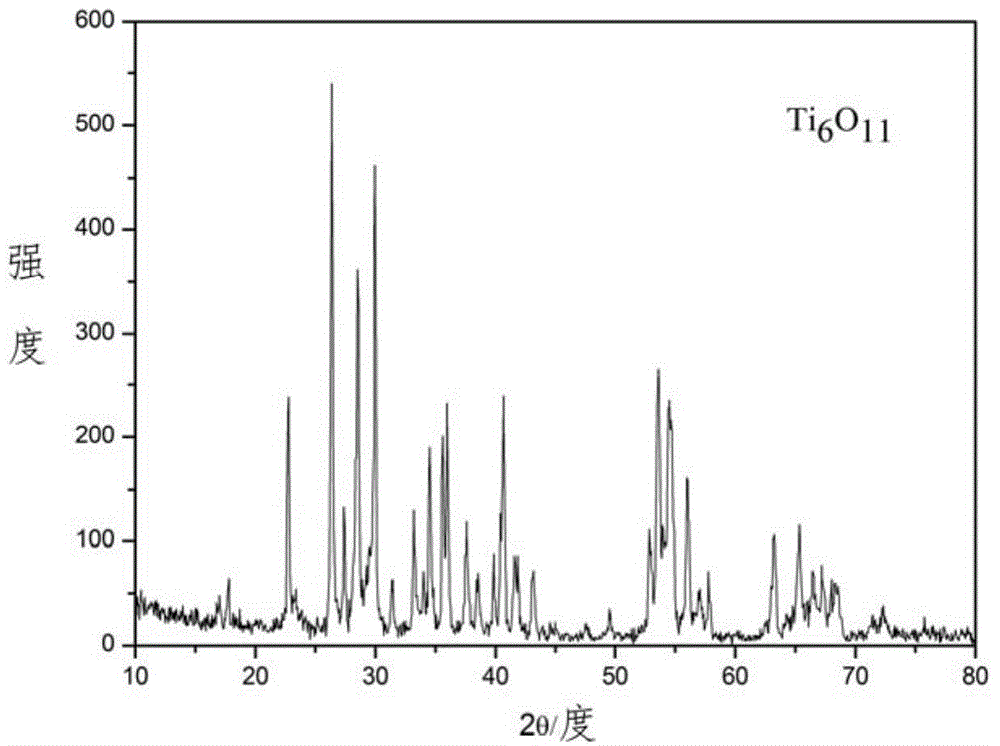

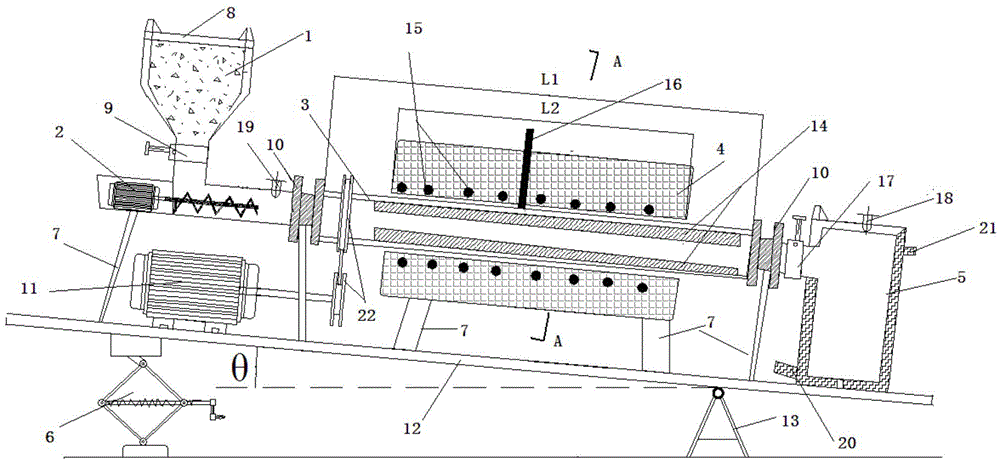

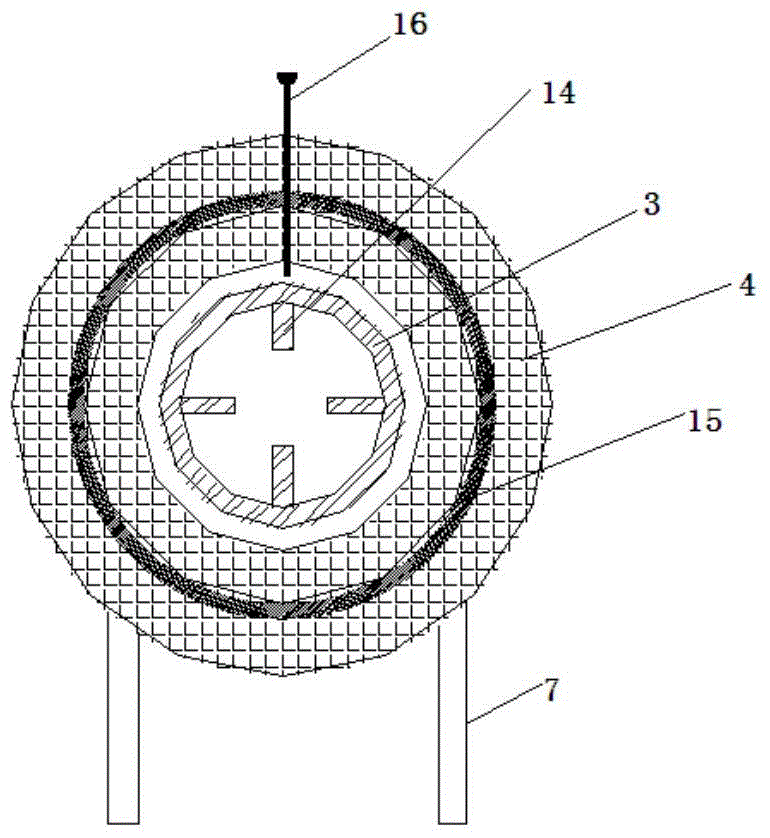

Rotary dynamic continuous preparation method for titanium black powder

InactiveCN104925857AEvenly heatedGuaranteed uniformityTitanium oxides/hydroxidesReaction temperatureTitanium

The invention provides a rotary dynamic continuous preparation method for titanium black powder. The titanium black powder is TiO powder, Ti3O5 powder, Ti4O7 powder, Ti5O9 powder, Ti6O11 powder, Ti7O13 powder, Ti8O15 powder or Ti9O17 powder. The push-type dynamic continuous preparation method comprises the following process steps: (1) preparing raw materials; using Ti and O compound powder and a reducing agent as the raw materials; (2) mixing and drying; (3) sintering: under an open system or a closed system or negative pressure, heating a furnace tube when the furnace tube is at an inclined state with a discharging opening lower than a feeding opening, and is at a rotary state, continuously feeding the mixed powder obtained in the step (2) into the furnace tube when the temperature in the furnace tube reaches the reaction temperature, and enabling the mixed powder, which enters the furnace tube, to pass a furnace tube heating area in a spiral movement manner to complete reaction so as to form a reaction product to fall into a collection chamber. Through the adoption of the preparation method, titanium black powder of which the single phase or the purity is higher than 70% can be obtained, and continuous mass production can be realized.

Owner:SICHUAN UNIV

PVC foaming architectural decoration material and preparation technique thereof

The invention relates to a PVC foaming construction decorative material and a preparation technique thereof. The preparation technique comprises the following steps: PVC plastics which are waste and are screened and ground, calcium carbonate, a stabilizer, an antioxidant, a lubricant, a foaming agent, a modifier, a foaming modifier, a dispersing agent, a colorant and the like are added into a high mixing machine according to the weight in sequence, mixed for 5 to 10 minutes, then placed into a low-temperature mixing machine for 5 to 10 minutes when being heated to be 120 to 125 DEG C; discharging is carried out when the temperature is 35 to 45 DEG C; the obtained materials are extruded by a parallel conical twin-screw extruder, molded, cooled in vacuum, pulled, film-stuck, cut and inspected and then the finished product of foaming plastic product is obtained. The invention is applicable to families, hotels, offices and entertainments, is the most ideal home decorative material with environment protection and is also the most practical home floor material.

Owner:胡大忠

Process for producing superfine high-purity quartz glass pipe for high-temperature sensor

ActiveCN101805116AWith superfineHigh temperature resistanceRadiation pyrometryGlass shaping apparatusOperabilityPerformance index

The invention relates to a process for producing a superfine high-purity quartz glass pipe for a high-temperature sensor, which is characterized by comprising the following steps of: finely selecting quartz blocks as raw materials, wherein the particle size of the quartz blocks is 20-30 mm, and the content of SiO2 is above 99%; sequentially carrying out soaking in hydrochloric acid, roasting, water quenching, mechanical pulverization, iron removal, soaking in mixed acid, high-temperature stirring and washing and high-temperature chloridization on the raw materials to obtain high-purity quartz sand; then throwing the high-purity quartz sand in a quartz furnace for smelting, pulling into a quartz glass pipe, and then scouring, cutting, trimming, ultrasonic cleaning and dehydroxylating so that a finished product is obtained. The quartz glass pipe produced and prepared by the process has the superfine and ultrathin features, has the characteristics of high-temperature resistance, molten steel and glass liquid-washing resistance, corrosive resistance, high heat transfer speed, good soaking performance, large strength, long service life, no bursting under shock heating and cooling condition, strong process operability, scale production and the like, and completely accords with the requirements of various performance indexes of the quartz glass pipe used as an outer protective pipe of the high-temperature sensor.

Owner:连云港市盛昌照明电器有限公司

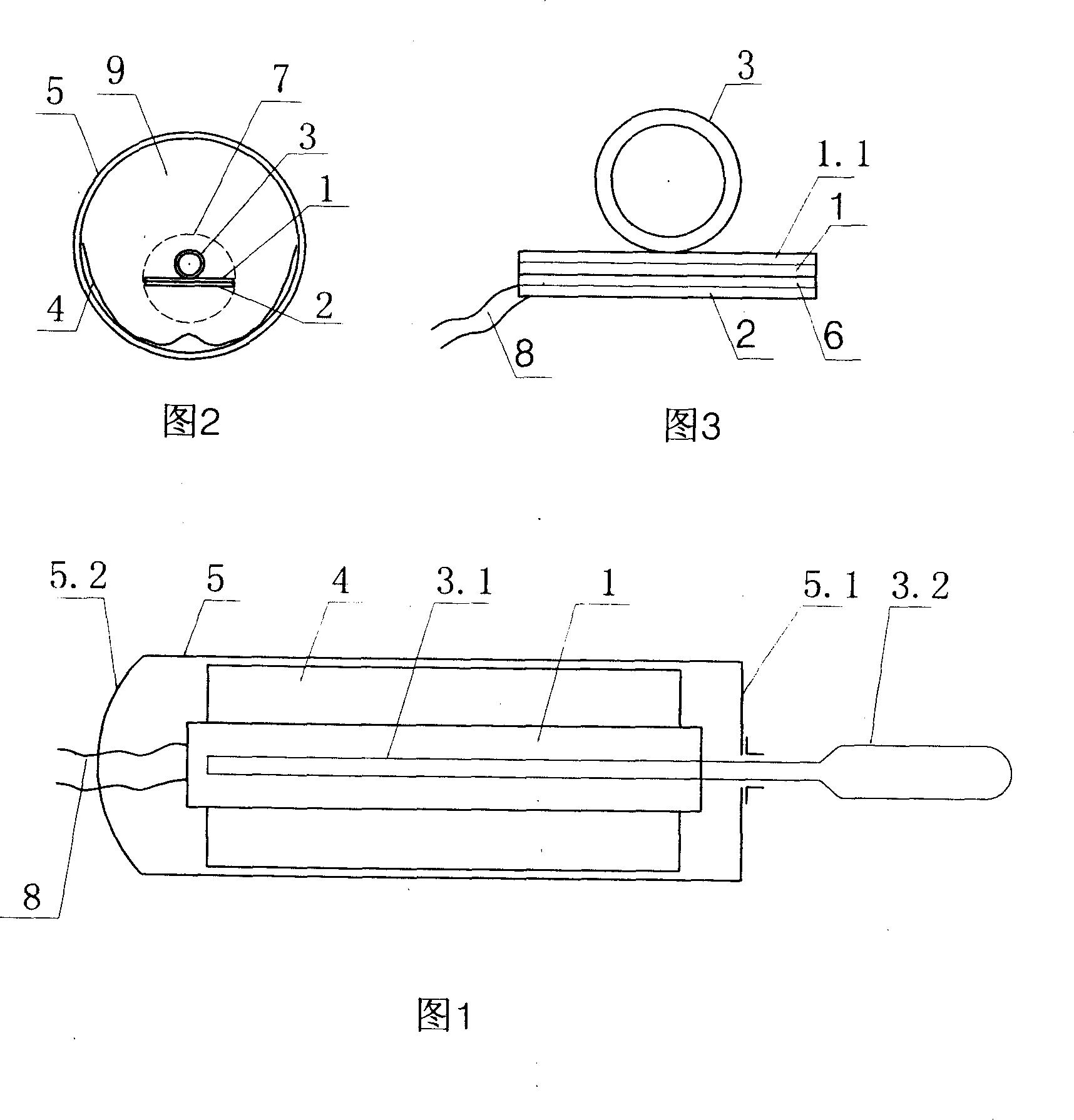

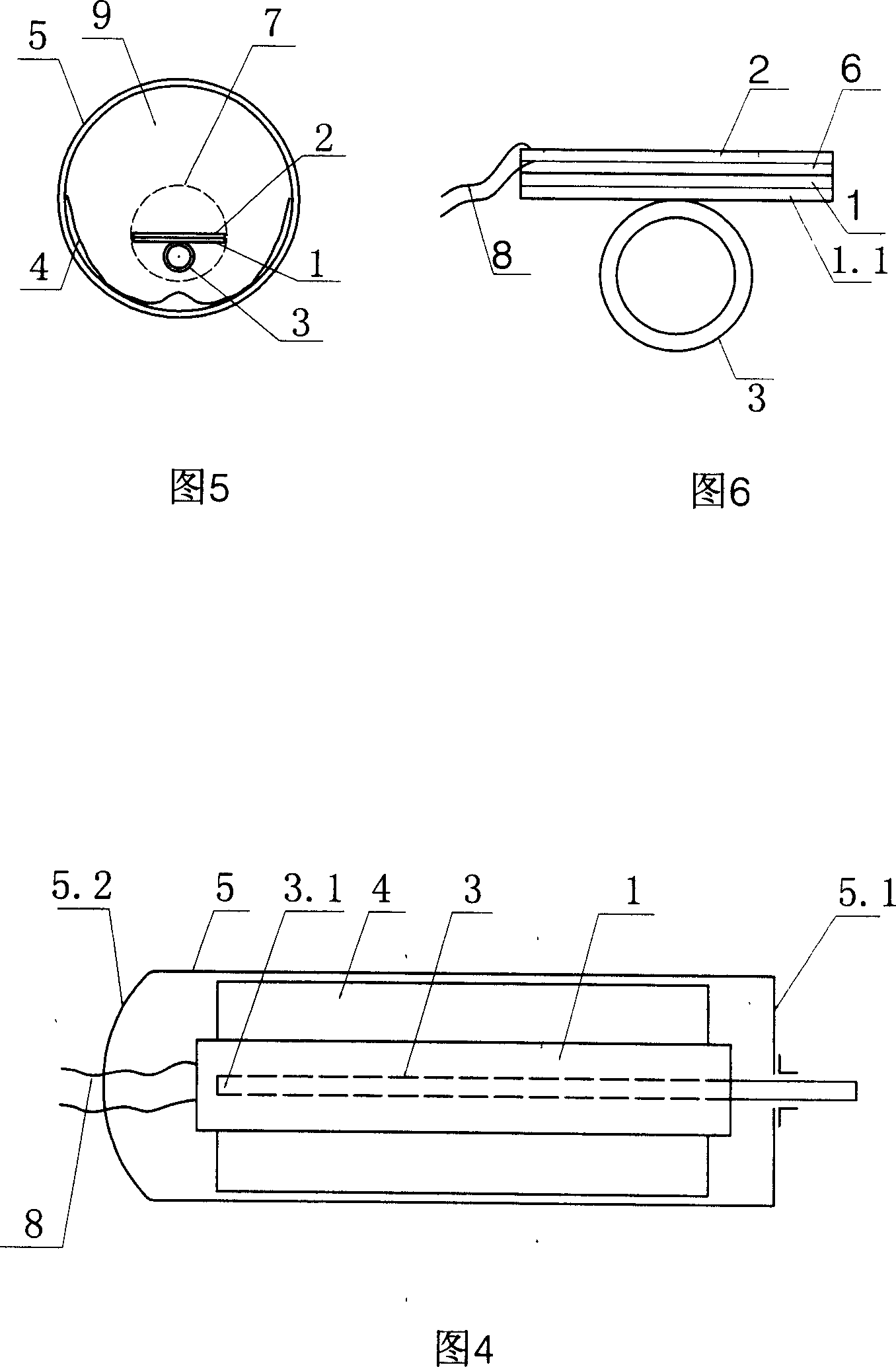

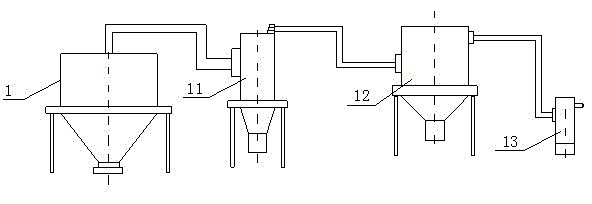

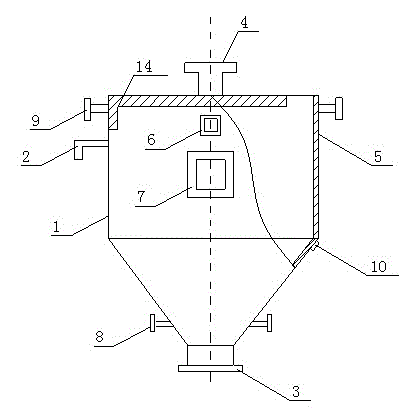

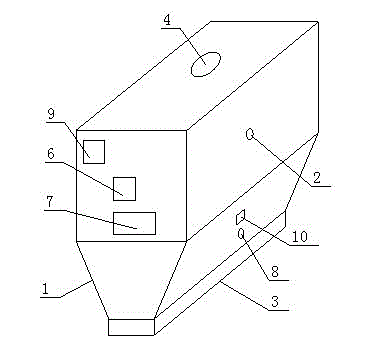

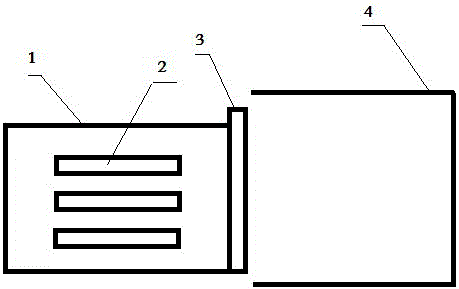

Glass microballoon manufacturing device and preparation method thereof

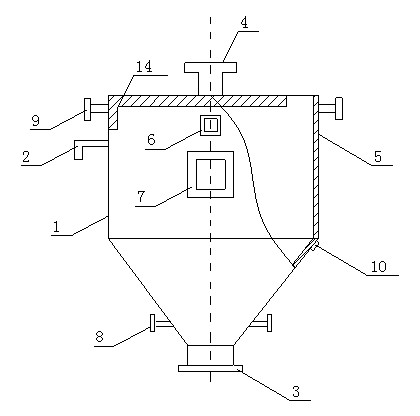

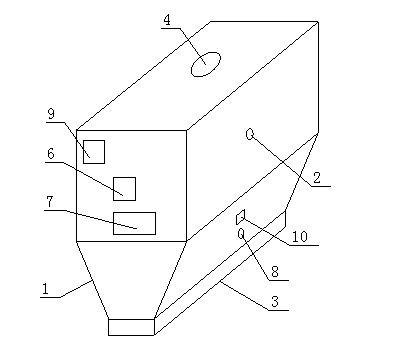

InactiveCN102417291APrevent molten buildupReduce devitrificationGlass shaping apparatusGlass productionDevitrificationCombustor

The invention discloses a glass microballoon manufacturing device comprising a furnace body (1) and a waste gas treatment device, wherein the furnace body (1) is formed by air-tight connection of an upper part and a lower part, the upper part of the furnace body is of a cubic shape, a waste gas emission port (4) is arranged at the top of the upper part, one or more injection-type burners (2) are horizontally installed on the side of the upper part, a preheating air pipe (14) is arranged in the upper part, the lower part of the furnace body is of a square conical shape, and one or more microballoon collectors (3) are arranged at the bottom of the lower part. According to the glass microballoon manufacturing device and the preparation method thereof provided by the invention, the furnace body which adopts the cubic structure enlarges the cooling space; the horizontally installed injection-type burners and the preheating air pipe arranged in the furnace body can give full play to the heat value of fuel, thus reducing energy source waste, saving energy and reducing emission; TiO2 and Al2O3 with relatively lower costs are adopted, the refractive index of the product is greater than or equal to 1.93; and the glass microballoon manufacturing device and the preparation method thereof have the advantages of reducing devitrification, improving the cooling velocity, having good product quality, improving the utilization ratio of raw material, being capable of large-scale production, and the like.

Owner:SICHUAN ZHONGKE BETTER TECH

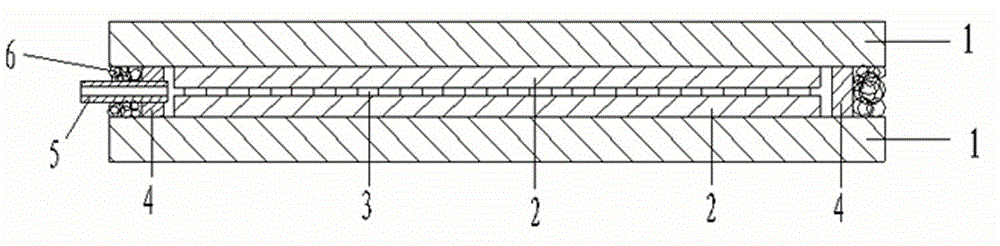

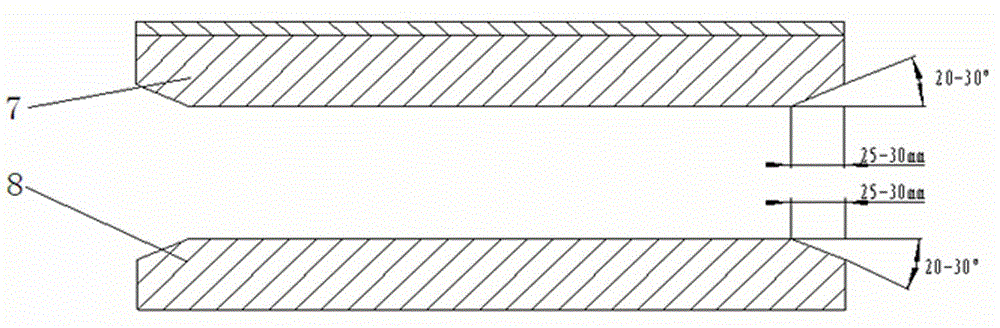

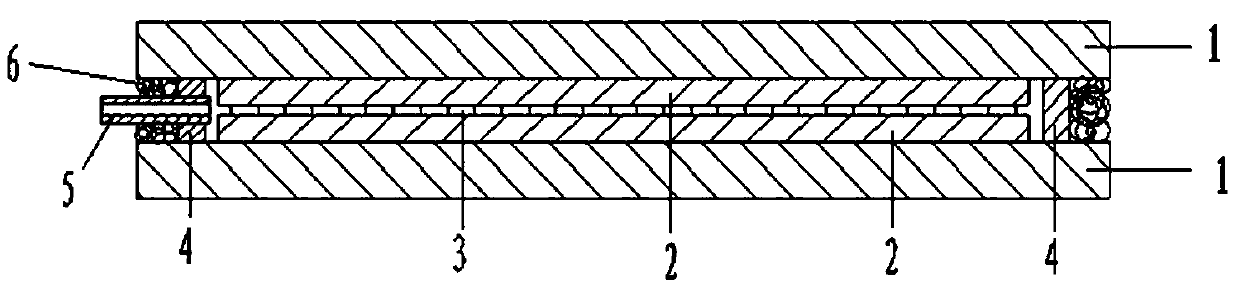

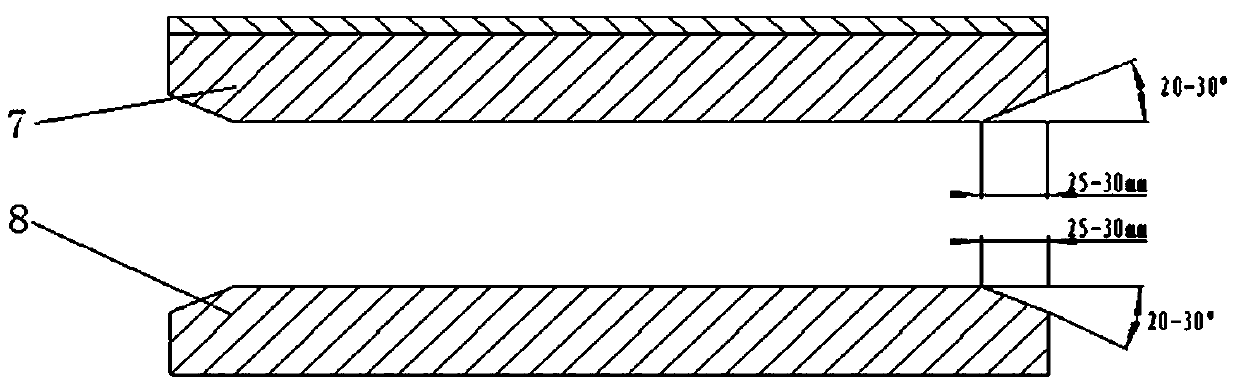

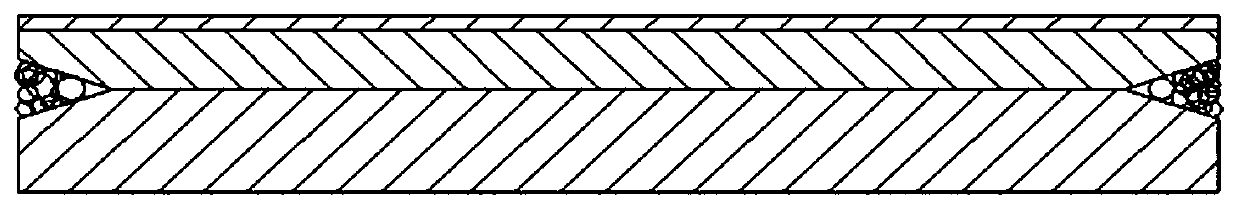

Production method for stainless steel single side composite rolls

The invention relates to a production method for rolling required stainless steel single side composite rolls through two times of manufacturing of composite billets. A base plate of carbon steel and a compound plate of stainless steel of a first composite billet are formed by welding baffle strips into a rectangular frame on a first base plate and putting a first compound plate into the rectangular frame, a second compound plate is laid after the first compound plate is coated with separant, a second base plate is laid on the second compound plate, the second base plate is welded to baffle strips, a hole is drilled between the base plates to install a vacuumized tube, rolling is carried out after leakage detecting and vacuumizing, the four edges of a rolled piece are cut off, and a single side composite plate is obtained for standby; in second billet compositing process, a carbon steel plate identical with the single side composite plate is manufactured, end bevels are formed in the carbon steel plate, pressure is exerted on a pressure platform to attach the carbon steel plate to the single side composite plate, full-length welding, drilling, vacuumized tube installing, leakage detecting, vacuumizing and rolling are carried out after steel wire rods are stuffed into the end bevels between the carbon steel plate and the single side composite plate, so far hot rolling of a stainless steel single side composite roll is finished, the thickness of the stainless steel single side composite roll is increased to 20 mm from 10 mm, guarantee is provided for a large diameter spiral welded pipe, the surfaces of compound layers are more compact and smoother, the product quality is improved, and the bonding strength and the mechanical property of a compound interface are improved.

Owner:河南盛荣金属复合新材料有限公司

Environment-friendly water-based metal printing ink and preparation method thereof

The invention relates to the technical field of printing ink, and particularly relates to environment-friendly water-based metal printing ink and a preparation method thereof. The environment-friendly water-based metal printing ink comprises 40-60 parts of water-based ink binder, 5-10 parts of dispersing agent, 0.1-1.5 parts of defoaming agent, 5-20 parts of metallic pigment, 0.5-5 parts of surface active agent, 1-5 parts of adhesion promoter and 5-20 parts of solvent. The environment-friendly water-based metal printing ink does not contain volatile poisonous solvents, has a good printing effect on plastic films, no damage to the health of printers and no pollution to atmospheric environments and is relatively low in cost and relatively good in product quality. The preparation method is high in production efficiency and used for producing the environment-friendly water-based metal printing ink on a large scale.

Owner:王金海

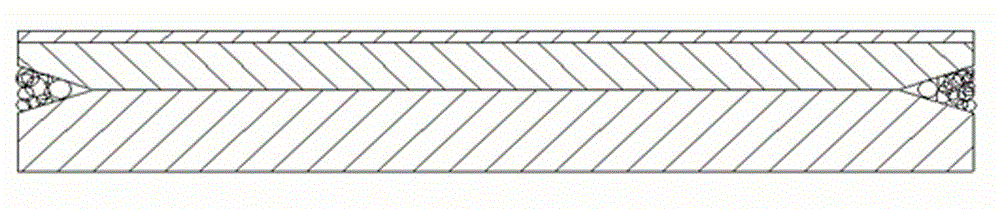

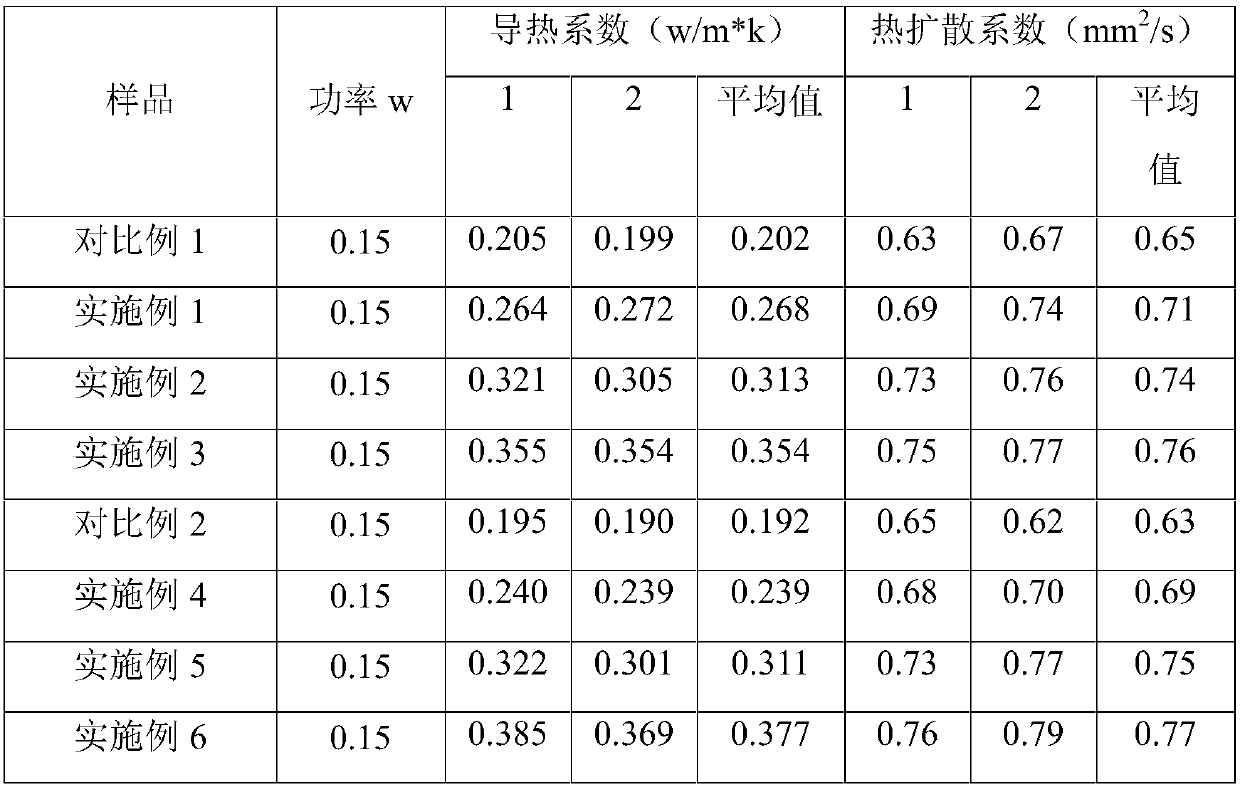

Heat-conducting tobacco sheet for cigarettes and preparation method and application thereof

InactiveCN110623296AImprove thermal conductivityFacilitated releaseTobacco preparationTobacco treatmentHeat conductingSlurry

The invention discloses a heat-conducting tobacco sheet for cigarettes and a preparation method and application thereof. The preparation method comprises the steps of preparing the heat-conducting tobacco sheet by using a thick pulp method, adding a binder, tobacco powder and heat-conducting materials into tobacco sheet paper pulp prepared by using the thick pulp method, stirring to form slurry, and drying to prepare the heat-conducting tobacco sheet. The heat-conducting tobacco sheet prepared by the invention has the outstanding characteristics that an existing tobacco sheet is used as a carrier, the heat-conducting materials are added in the production process of the tobacco sheet, the process flow is not required to be added, or the heat-conducting materials are added through existing coating or spraying equipment, the production process is simple, the cost is low, and the heat-conducting tobacco sheet can be produced in a large scale.

Owner:CHINA TOBACCO HUNAN INDAL CORP

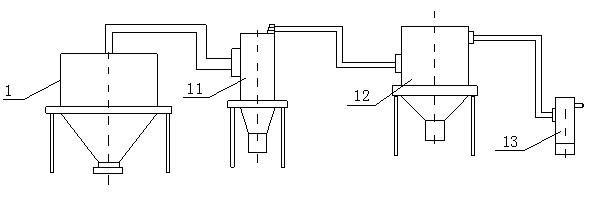

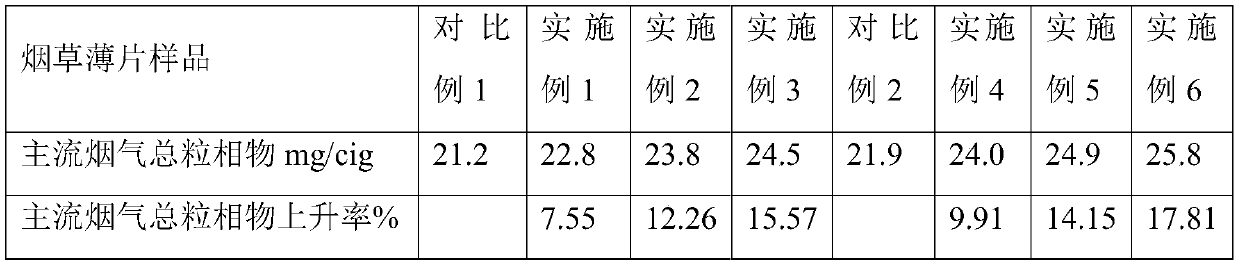

Method and device for dehydrating and rectifying dichloromethane in production of acesulfame potassium

PendingCN109776257AHigh purityLight colorHalogenated hydrocarbon separation/purificationPotassiumLiquid tank

The invention relates to a method and device for dehydrating and rectifying dichloromethane in the production of acesulfame potassium. The device comprises a crude dichloromethane product tank, a dehydration tower, an intermediate dichloromethane product tank, a rectifying tower, a residual liquid tank, a reflux tank and a finished product tank; the crude dichloromethane product tank, the dehydration tower, the intermediate dichloromethane product tank, the rectifying tower, the residual liquid tank and the reflux tank are sequentially communicated with the finished product tank. According tothe device for dehydrating and rectifying dichloromethane in the production of acesulfame potassium, recovered dichloromethane is high in purity, light in color and good in quality; the treatment capacity is large, and large-scale production can be achieved. The device has the advantages of being high in automation degree, capable of achieving DCS remote control and high in safety.

Owner:山东亚邦化工科技有限公司

Lily coffee and production process thereof

InactiveCN103283908APreserve natural nutrientsRich life needsRoasted coffee treatmentSucroseAdditive ingredient

The invention relates to lily coffee and a production process thereof. The lily coffee contains lily instant powder, coffee full powder, soybean protein and cane sugar. The production process comprises the following three steps: (1) adding water into well-chosen fresh lily and grinding; carrying out slurry-residue separation, sedimentation, atomization and drying to obtain lily raw powder; (2) frying the lily raw powder for the second time and cooling; carrying out ultramicro treatment on the lily powder to obtain the lily instant powder; (3) adding coffee powder and soybean protein powder into the lily instant powder to be mixed, and then drying and cooling; then adding the cane sugar, agitating and mixing to obtain the lily coffee. The lily coffee disclosed by the invention keeps natural nutritional ingredients of the lily, has the taste of the coffee, has the effect of removing heat from the liver and lubricating the intestine and has the characteristic of convenience and rapidness for eating, so as to add one nutritious food for a market.

Owner:侯兆乾

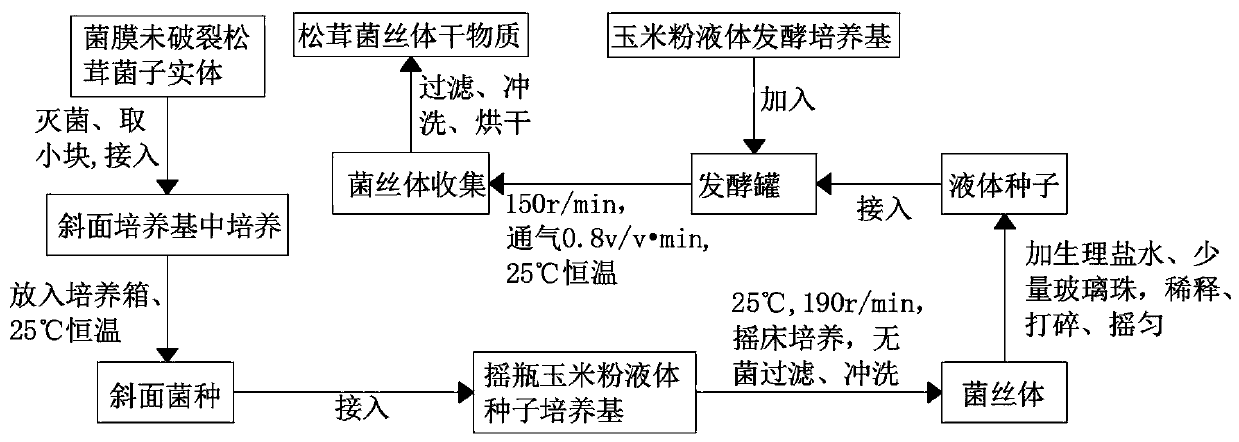

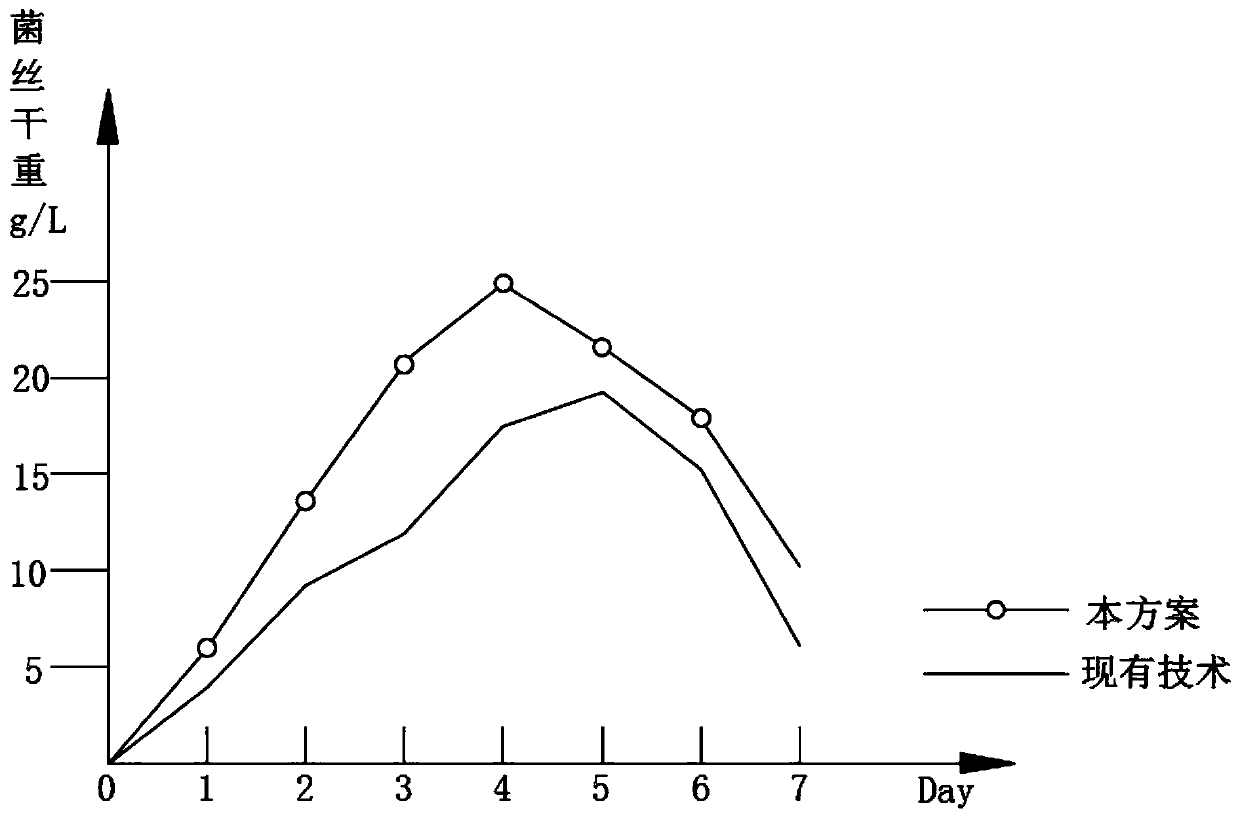

Production process for producing tricholoma matsutake mycelium from corn powder fermentation

InactiveCN110199778AImprove dry matter yieldSimple processCultivating equipmentsMushroom cultivationDry weightTricholoma matsutake

The invention discloses a production process for producing tricholoma matsutake mycelium from corn powder fermentation and belongs to the field of production of tricholoma matsutake mycelium. The production process includes the steps of 1, culture of inclined bacterial; 2, culture of liquid seeds; 3, fermentation culture; 4, dry weight of the mycelium. The experimental results show that the highest yield of dry matter fermentation of the mycelium produced by the process is above 24.82g / L while the dry matter yield of the mycelium is only about 18g / L in the existing technology, so that comparedwith the prior art, the production process for producing the tricholoma matsutake mycelium has the advantage of significant improvement; the production process is suitable for fermentation and culture of the tricholoma matsutake, the dry material yield of the mycelium is stable and high in yield, large-scale production can be achieved, and the production process is worth popularizing.

Owner:LINYI XINBANG BIOTECH CO LTD

Printing ink

InactiveCN105315776ALong storage timeReduce coefficient of frictionInksFrictional coefficientPrinting ink

The invention discloses printing ink which is prepared from the following raw materials in parts by weight: 20-40 parts of polyamide resin, 40-60 parts of a solvent, 5-10 parts of pigment, 1-5 parts of a viscosity conditioning agent, 0-1.5 parts of vinyl chloride-vinyl acetate resin, 1-3 parts of a printing ink reinforcing agent, 1-5 parts of a wear-resisting auxiliary, 1-3 parts of active monomer, 1-3 parts of hollow glass bead, 1-3 parts of an antifoaming agent and 5-10 parts of a diluent. According to the printing ink, the active monomer is added, so that the surface tension of the prepared printing ink is equal to or less than that of the printed surface; the wear-resisting auxiliary is added, so that the printed printing ink layer has a very small frictional coefficient, and the wear resistance of the printing ink is greatly improved; the printing ink contains no volatile toxic solvent, is good in printing effect, strong in adhesion fastness, incombustible, unexplosive and nontoxic, cannot damage health of printing workers, has no environmental pollution on atmosphere, and is lower in cost; an ink layer is high in adhesion fastness, namely adhesive force, rub-resistant, scratch-resistant, high in glossiness, good in wear resistance, quick in drying rate and good in product quality.

Owner:桐城市人和包装有限公司

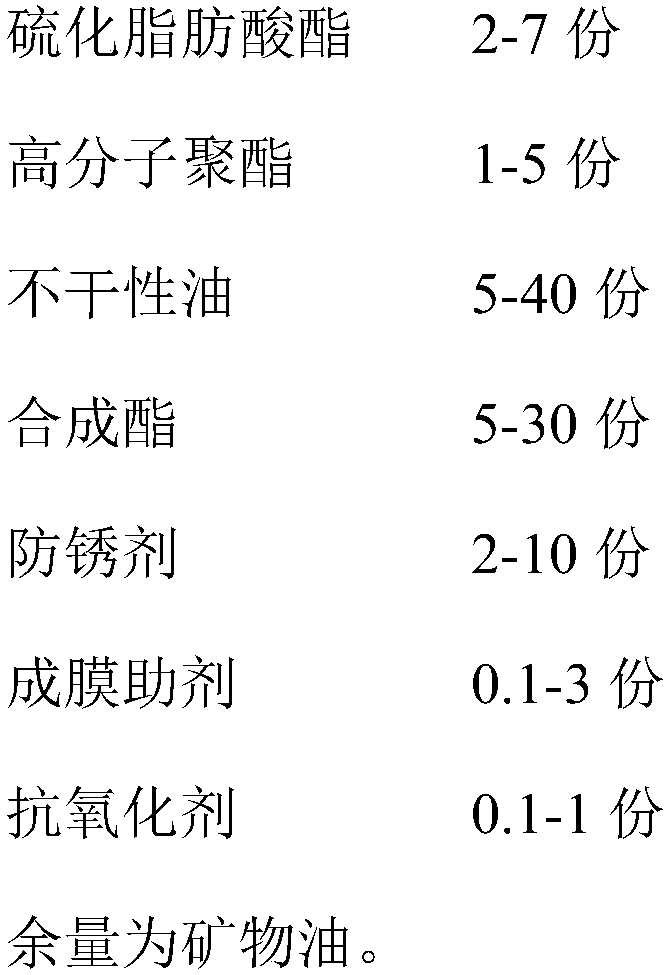

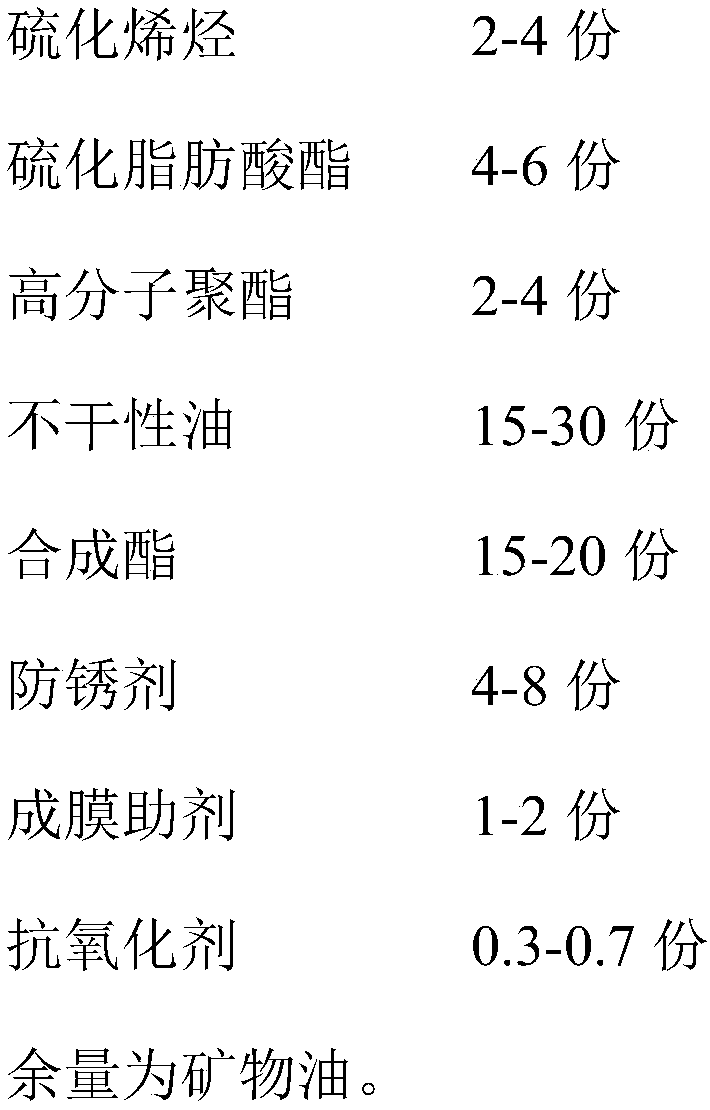

Medium-period and long-period antirust type cutting oil and preparation method thereof

InactiveCN109111977ALubricity does not affectImprove the lubrication effectAdditivesPolyesterMetal machining

The invention relates to the technical field of metal machining oil, in particular to medium-period and long-period antirust type cutting oil and a preparation method thereof. The medium-period and long-period antirust type cutting oil is prepared from 0.5 to 5 parts of sulfurized olefin, 2 to 7 parts of sulfurized fatty acid ester, 1 to 5 parts of high molecular polyester, 5 to 40 parts of non-drying oil, 5 to 30 parts of synthetic ester, 2 to 10 parts of an antirust agent, 0.1 to 3 parts of a film forming auxiliary agent, 0.1 to 1 part of an antioxidant and the balance of mineral oil. The preparation method of the medium-period and long-period antirust type cutting oil comprises the following preparation steps: 1) adding the mineral oil, the high molecular polyester, the antirust agent,the film forming auxiliary agent and the antioxidant, and heating to 55 to 70 DEG C; stirring for 15 to 25min and uniformly mixing; 2) stopping heating; adding the sulfurized olefin, the sulfurized fatty acid ester, the non-drying oil and the synthetic ester and continually stirring for 25 to 35min; uniformly blending to prepare a finished product. The medium-period and long-period antirust type cutting oil provided by the invention has good lubricating performance and also has a medium-period and long-period antirust function.

Owner:AMER TECH CO LTD

Internal light-focusing solar photoelectric and light-heat composite pipe

InactiveCN1983640ALower working temperatureImprove photoelectric conversion efficiencySolar heating energySolar heat devicesWorking temperatureSilicon solar cell

The invention is concerned with photovoltaic and photo-thermal multiple tube of concentrated solar energy. It relates to crystal silicon solar cell felted on the metal heat collector bar, metal pipe felted on this metal bar, echo concentrator in groove shape and encapsulation transparent glass pipe. The echo concentrator in groove shape collects the incident sun's rays to metal heat collector bar and the crystal silicon solar cell on the other face. The glass pipe is vacuum or filled with nitrogen and the solar energy cell is closed in it to avoid oxidation, damp and erosion. A part of the absorbed solar energy changes into electricity and educes outside of glass pipe by metal lead. And a part changes into heat and carries to metal pipe by metal bar, and continues carries out of glass pipe by the matter inside it. It reduces the cell's work temperature and increases photoelectric conversion efficiency. The pipe has higher work temperature of solar cell by generate electricity and heat together.

Owner:江希年

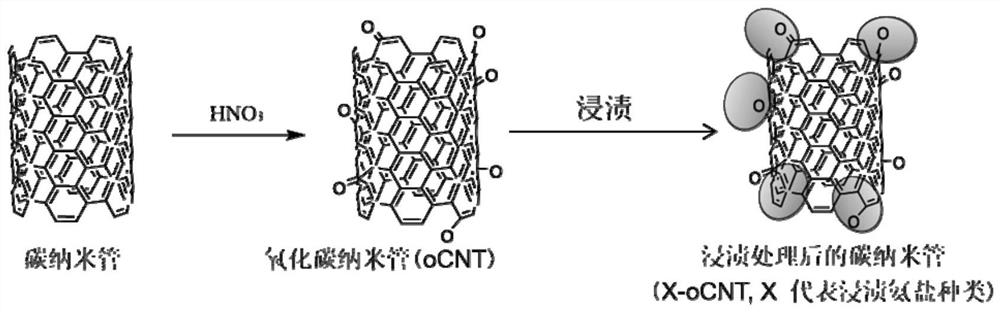

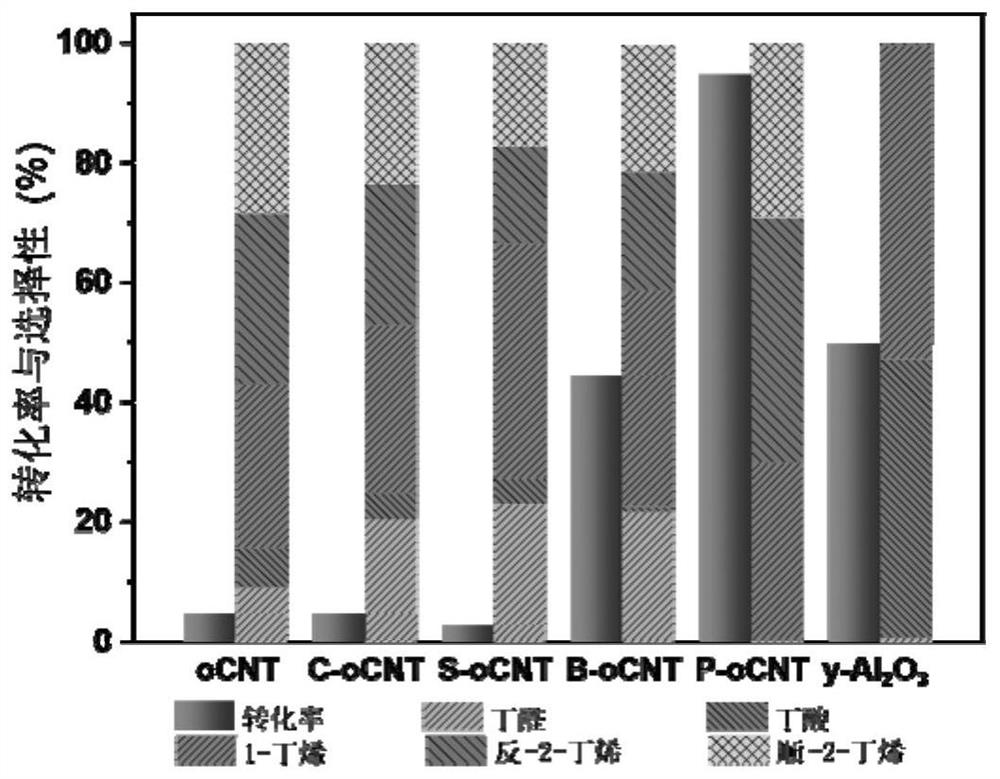

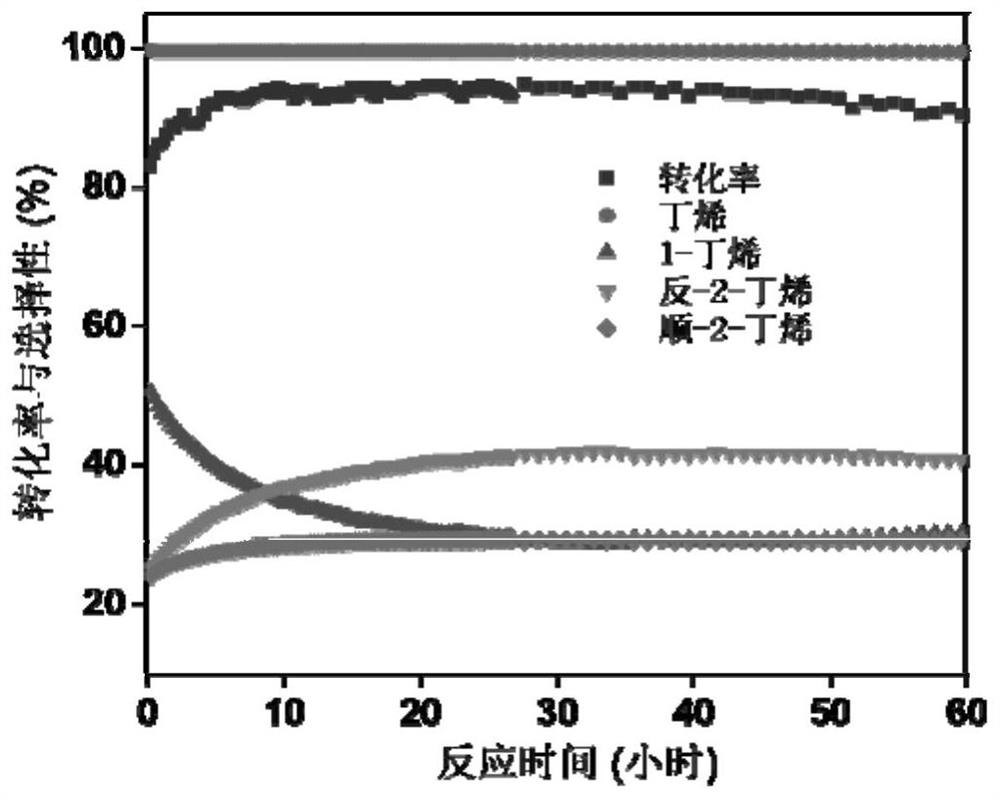

Nano-carbon solid acid catalyst, preparation thereof and application of nano-carbon solid acid catalyst in preparation of olefin by catalytic dehydration of alcohol

InactiveCN113617349AEasy to makeMaterials are readily availableCatalyst activation/preparationHydrocarbon from oxygen organic compoundsPtru catalystPhosphate

The invention discloses a nano-carbon solid acid catalyst, a preparation method thereof and application of the nano-carbon solid acid catalyst in a reaction for preparing olefin through butanol dehydration, and belongs to the technical field of nano-carbonic acid catalytic dehydration application catalysis. The nano-carbon solid acid catalyst can catalyze butanol dehydration to generate corresponding olefin products with high selectivity. The catalytic reaction condition is that the reaction temperature is 150-450 DEG C. According to the catalyst disclosed by the invention, phosphate groups are loaded on the surface of the nano-carbon material through a wet impregnation method, so that the types and the quantity of acidic groups on the surface of the nano-carbon material are regulated and controlled; and the phosphate groups can interact with a carbon substrate and can be kept stable for a long time in a catalytic reaction, so that the selectivity and conversion rate of a nano-carbon catalyzed butanol dehydration product are effectively improved. As a solid acid catalyst, the catalyst has the characteristics of convenience in preparation, low cost, high activity, long-time stability and the like, and has a good application prospect in an alcohol gas-phase dehydration reaction process.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

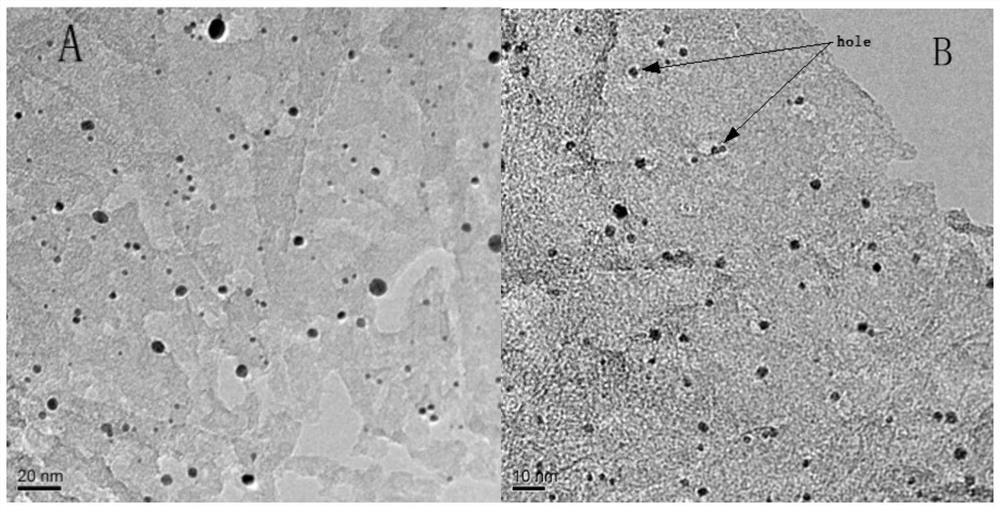

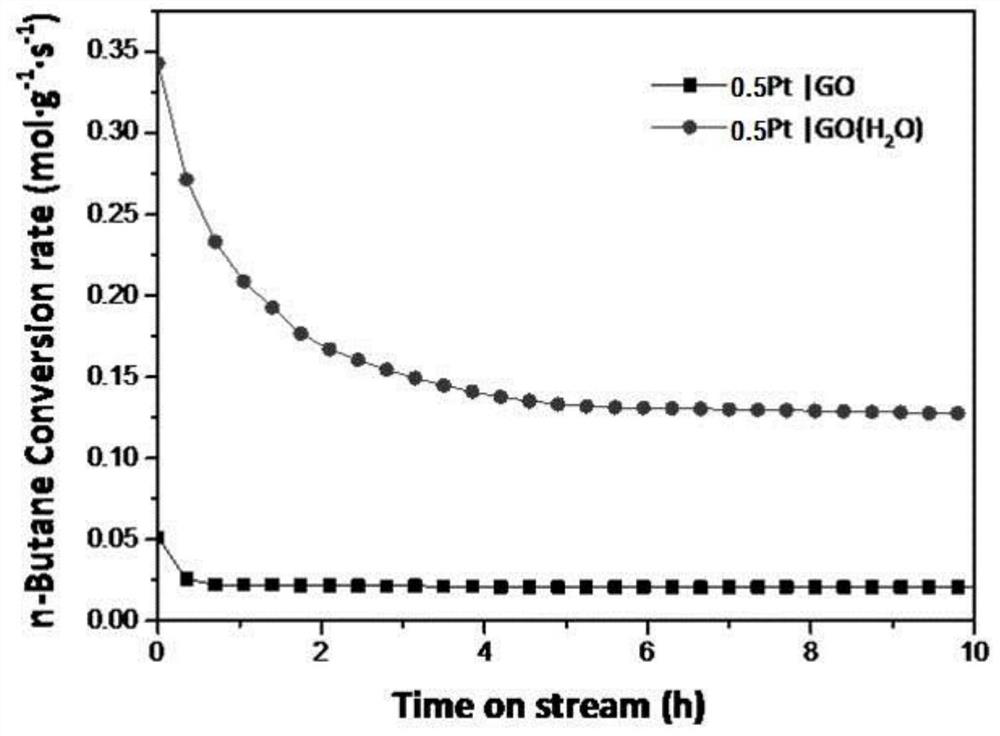

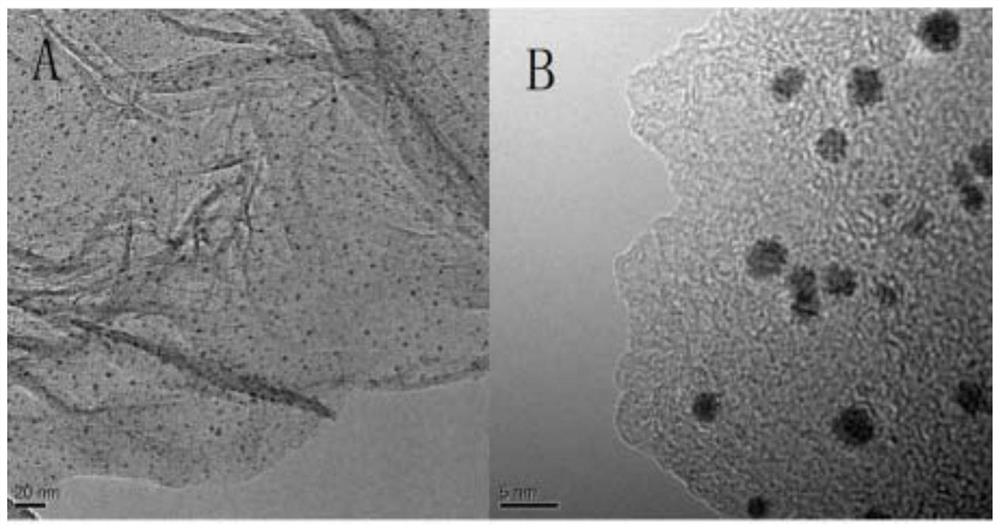

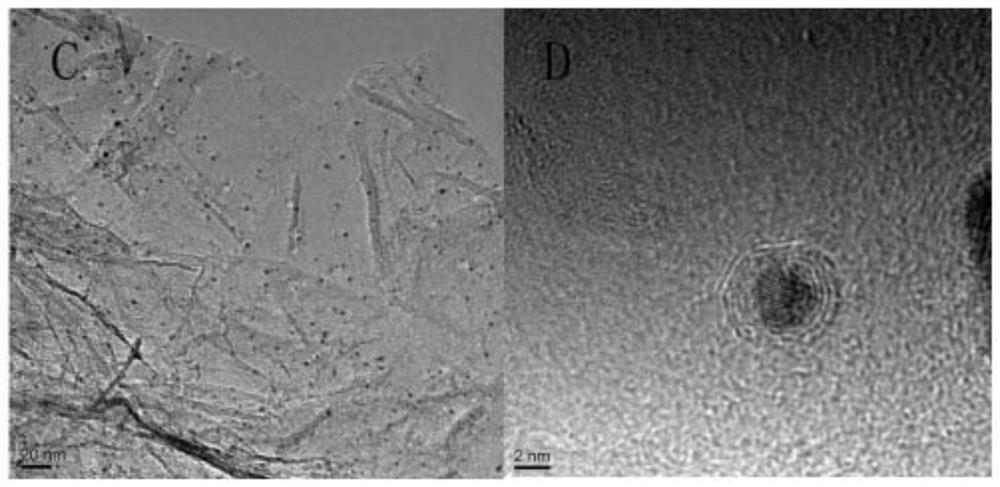

Water-etched graphene confinement Pt nano composite material, preparation method and application thereof

ActiveCN112452318AImprove catalytic performanceImprove stabilityCatalyst activation/preparationHydrocarbonsDehydrogenationGraphite

The invention discloses a preparation method and application of a water-etched graphene confinement Pt nano composite material, wherein the water-etched graphene confinement Pt nano composite materialis Pt / GO(H2O). The preparation method comprises the following steps: directly loading Pt nanoparticles onto graphene by utilizing a wet chemical reduction method to obtain Pt / GO; and then adopting aCVD method to enable vapor deposition to etch the surface layer of the graphene to prepare Pt / GO(H2O). According to the invention, the Pt / GO(H2O) prepared by the method shows good butane dehydrogenation catalytic performance; and more defects are caused to graphene through the etching effect of water to well stabilize the Pt nanoparticles, so that the Pt nanoparticles have higher conversion rate and selectivity in the selective dehydrogenation reaction of n-butane.

Owner:LIAONING UNIVERSITY

Cutting fluid for high-efficiency bearing grinding and cutting, preparation method and application method thereof

ActiveCN109054971AExcellent anti-rustImprove the lubrication effectLubricant compositionMonoisopropanolamineCarboxylic acid

The invention relates to the technical field of cutting fluids, in particular to a cutting fluid for high-efficiency bearing grinding and cutting, a preparation method and an application method thereof. The cutting fluid comprises 10-20 parts of water-soluble alcoholamine, 3-12 parts of a preservative of a dicarboxylate-based composite, 2-10 parts of an emulsifier, 2-8 parts of synthetic resin, 2-8 parts of a film-forming agent, 1-3 parts of hexanediol, 0.1-1 part of benzotriazole, 1-3 parts of a pH adjuster, 15-25 parts of base oil, and 30-40 parts of deionized water. The preparation steps ofthe invention are as follows: first, heating sebacic acid, dodecane dibasic acid, methyl benzotriazole, neodecanoic acid, isopropanolamine and water to 55-65 DEG C to completely dissolve into a transparent liquid, adding water-soluble alcohol amine, base oil, benzotriazole, deionized water and a pH adjuster to stir to be even and transparent, finally adding the emulsifier, the synthetic resin, the film-forming agent, and hexanediol, and stirring to be transparent. The cutting fluid for high-efficiency bearing grinding and cutting facilitates workshop management and the appearance of rust anddark spots can be avoided.

Owner:苏州安美润滑科技有限公司

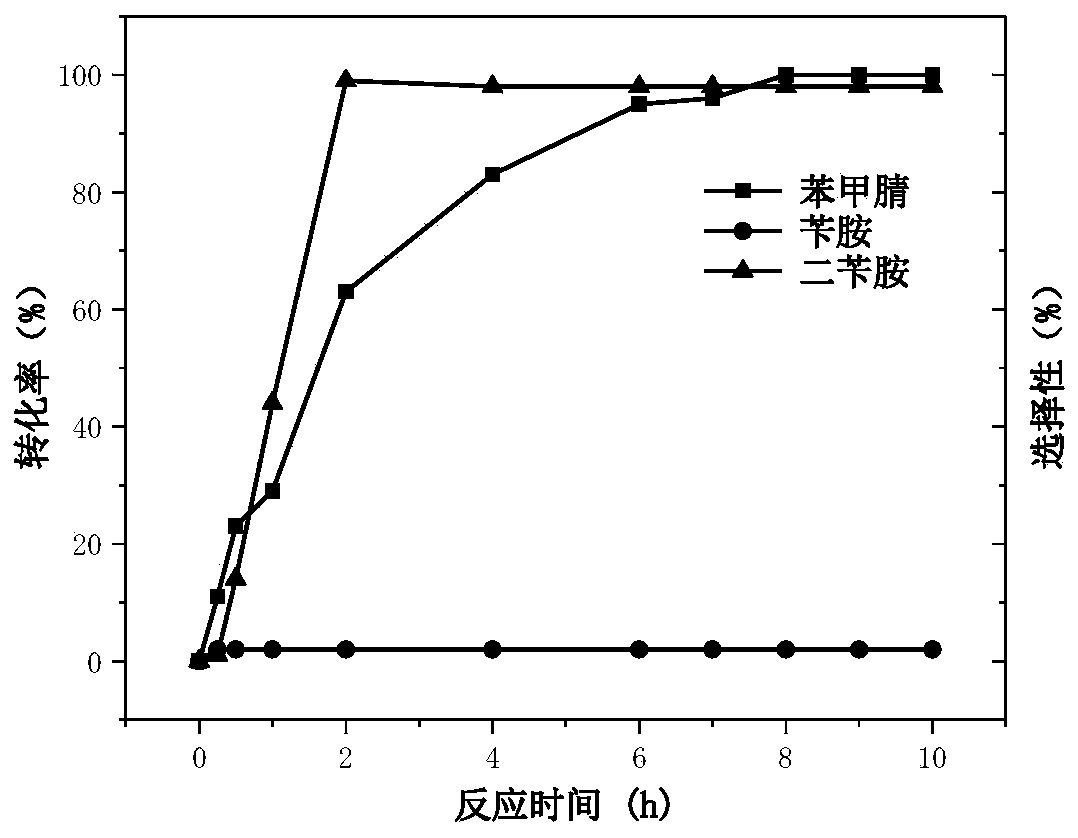

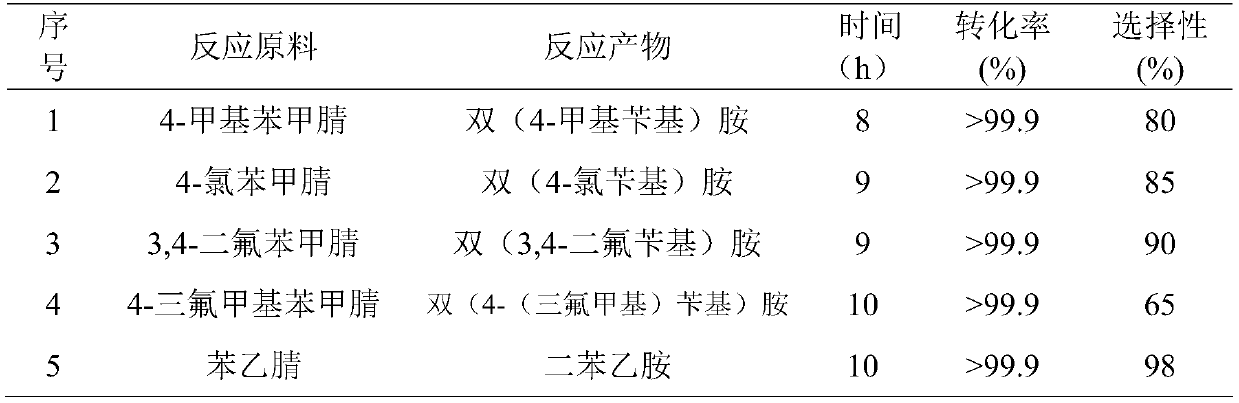

Application of nano-carbon supported monatomic palladium-based catalyst in catalytic hydrogenation of nitrile compound to prepare secondary amine

ActiveCN110790669AMaterials are readily availableLow costOrganic compound preparationAmino compound preparationPtru catalystFluid phase

The invention discloses application of a nano-carbon supported monatomic palladium-based catalyst in catalytic hydrogenation of a nitrile compound to prepare a secondary amine and belongs to the technical field of catalysts with application of catalytic hydrogenation of liquid-phase nitrile compounds. By adopting the monatomically dispersed palladium-based catalyst, a corresponding secondary aminecompound is generated with high selectivity under a mild condition, and the catalysis reaction conditions are that the reaction temperature is 45-90 DEG C and ammonia borane is adopted as a hydrogensource. In the catalyst disclosed by the invention, metals exist in a monatomic dispersion state, so that the utilization efficiency of the metals can be effectively improved, and the activity and theselectivity of the nitrile compound can be remarkably improved. In addition, the monatomically dispersed catalyst is convenient to prepare and low in cost, and has very good application prospects incatalytic hydrogenation of the nitrile compound to prepare the secondary amine.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Glass microballoon manufacturing device and preparation method thereof

InactiveCN102417291BPrevent molten buildupReduce devitrificationGlass shaping apparatusGlass productionDevitrificationCombustor

The invention discloses a glass microballoon manufacturing device comprising a furnace body (1) and a waste gas treatment device, wherein the furnace body (1) is formed by air-tight connection of an upper part and a lower part, the upper part of the furnace body is of a cubic shape, a waste gas emission port (4) is arranged at the top of the upper part, one or more injection-type burners (2) are horizontally installed on the side of the upper part, a preheating air pipe (14) is arranged in the upper part, the lower part of the furnace body is of a square conical shape, and one or more microballoon collectors (3) are arranged at the bottom of the lower part. According to the glass microballoon manufacturing device and the preparation method thereof provided by the invention, the furnace body which adopts the cubic structure enlarges the cooling space; the horizontally installed injection-type burners and the preheating air pipe arranged in the furnace body can give full play to the heat value of fuel, thus reducing energy source waste, saving energy and reducing emission; TiO2 and Al2O3 with relatively lower costs are adopted, the refractive index of the product is greater than or equal to 1.93; and the glass microballoon manufacturing device and the preparation method thereof have the advantages of reducing devitrification, improving the cooling velocity, having good product quality, improving the utilization ratio of raw material, being capable of large-scale production, and the like.

Owner:SICHUAN ZHONGKE BETTER TECH

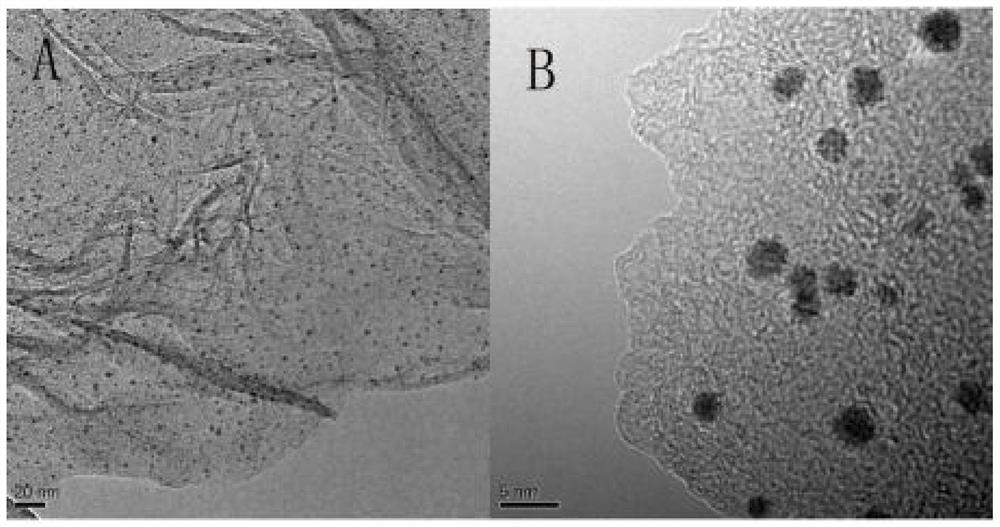

A nitrogen-doped graphene-confined Pt nanocomposite material and its preparation method and application

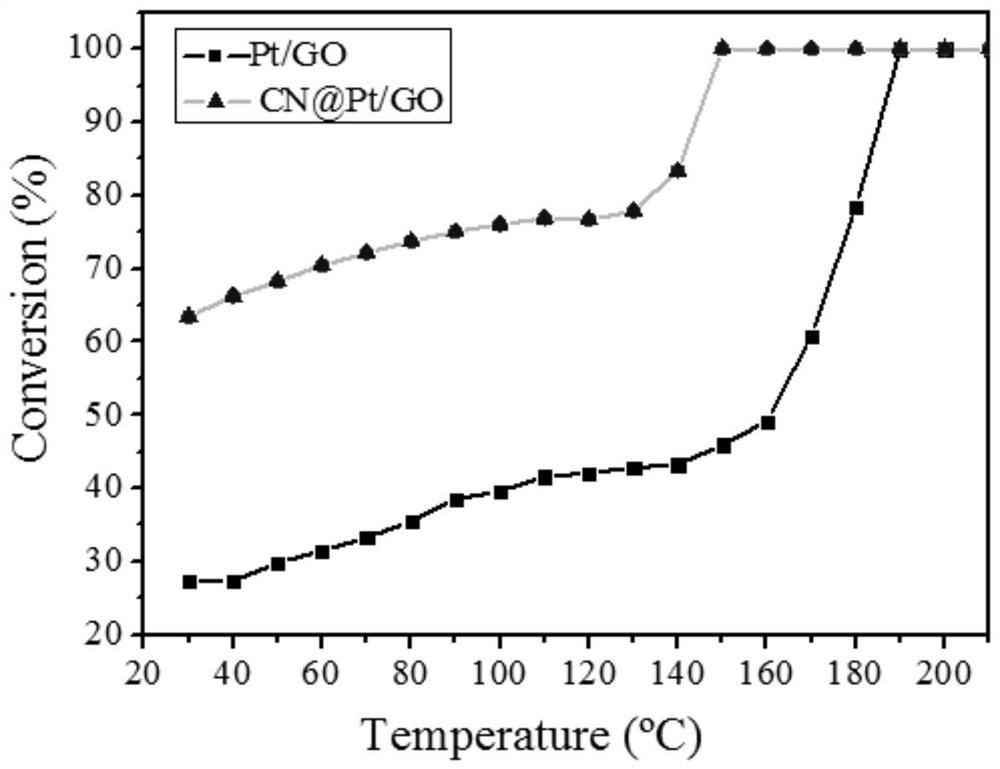

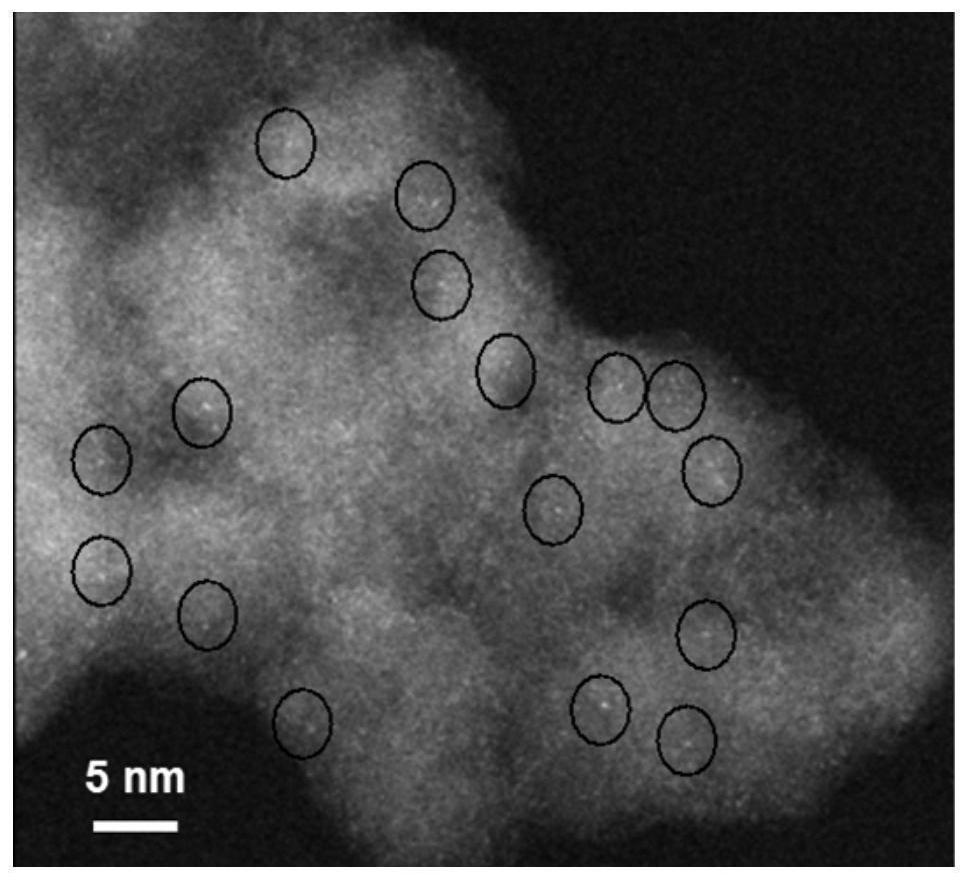

ActiveCN110038611BImprove CO low-temperature catalytic performanceFacilitate desorptionGas treatmentPhysical/chemical process catalystsDoped graphenePtru catalyst

The invention discloses a nitrogen-doped graphene-confined Pt nanocomposite material, a preparation method and an application thereof. The nitrogen-doped graphene-confined Pt nanocomposite is CN@Pt / GO; firstly, Pt nanoparticles are directly loaded on graphene by wet chemical reduction method to obtain Pt / GO; then, by CVD method, the Pt / GO prepared by rapidly depositing a nitrogen-doped graphene layer on the surface of Pt nanoparticles. The CN@Pt / GO prepared by the present invention exhibits better catalytic performance for low-temperature oxidation of CO. Due to the confinement of Pt nanoparticles and graphene and nitrogen-doped graphene, the electron density of supported Pt nanoparticles is increased, and the desorption of CO is enhanced, so that the low-temperature catalytic performance of CN@Pt / GO for CO is better than that of Pt / GO. Thus, the CO low-temperature catalytic performance of the CN@Pt / GO catalyst was improved.

Owner:LIAONING UNIVERSITY

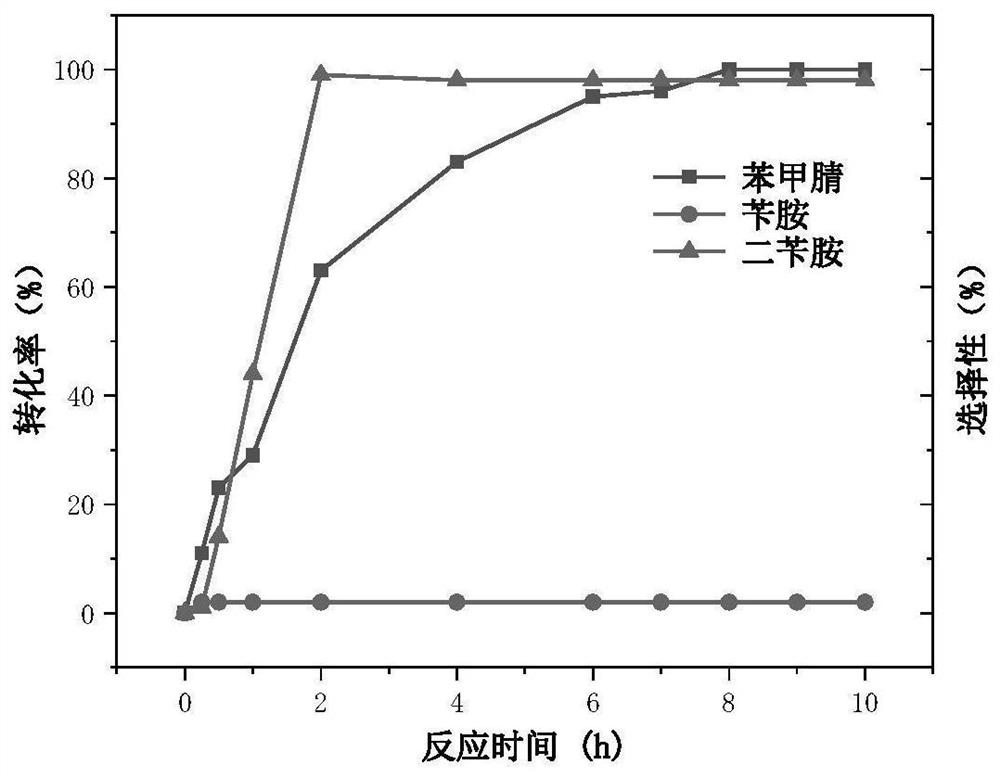

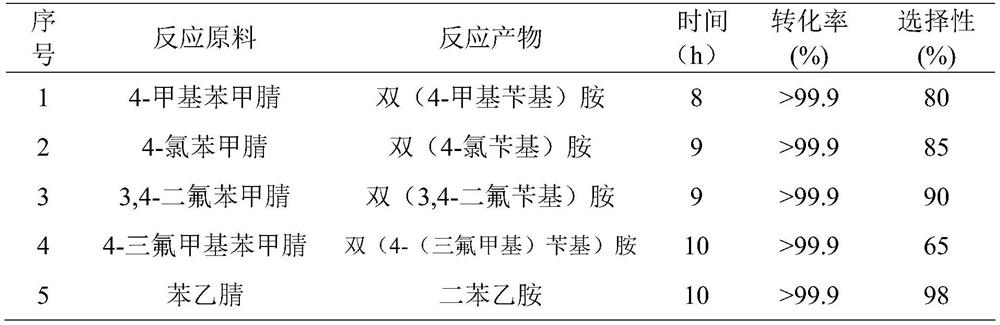

Application of nanocarbon-supported single-atom palladium-based catalysts in the catalytic hydrogenation of nitrile compounds to prepare secondary amines

ActiveCN110790669BMaterials are readily availableLow costOrganic compound preparationAmino compound preparationPtru catalystReaction temperature

The invention discloses the application of a nano-carbon-supported single-atom palladium-based catalyst in the catalytic hydrogenation of nitrile compounds to prepare secondary amines, and belongs to the technical field of catalysts for catalytic hydrogenation of liquid-phase nitrile compounds. The monoatomically dispersed palladium-based catalyst can generate corresponding secondary amine compounds with high selectivity under mild conditions; the catalytic reaction conditions are: reaction temperature 45-90°C, hydrogen source is ammonia borane. In the catalyst of the present invention, the metal exists in a dispersed state of single atoms, which more effectively improves the utilization efficiency of the metal, so that the activity and selectivity of hydrogenation of nitrile compounds are obviously improved. Moreover, the atomically dispersed catalyst is easy to prepare and low in cost, and has good application prospects in the hydrogenation of nitrile compounds to prepare secondary amines.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A kind of production method of stainless steel single-sided composite roll

The invention relates to a production method for rolling required stainless steel single side composite rolls through two times of manufacturing of composite billets. A base plate of carbon steel and a compound plate of stainless steel of a first composite billet are formed by welding baffle strips into a rectangular frame on a first base plate and putting a first compound plate into the rectangular frame, a second compound plate is laid after the first compound plate is coated with separant, a second base plate is laid on the second compound plate, the second base plate is welded to baffle strips, a hole is drilled between the base plates to install a vacuumized tube, rolling is carried out after leakage detecting and vacuumizing, the four edges of a rolled piece are cut off, and a single side composite plate is obtained for standby; in second billet compositing process, a carbon steel plate identical with the single side composite plate is manufactured, end bevels are formed in the carbon steel plate, pressure is exerted on a pressure platform to attach the carbon steel plate to the single side composite plate, full-length welding, drilling, vacuumized tube installing, leakage detecting, vacuumizing and rolling are carried out after steel wire rods are stuffed into the end bevels between the carbon steel plate and the single side composite plate, so far hot rolling of a stainless steel single side composite roll is finished, the thickness of the stainless steel single side composite roll is increased to 20 mm from 10 mm, guarantee is provided for a large diameter spiral welded pipe, the surfaces of compound layers are more compact and smoother, the product quality is improved, and the bonding strength and the mechanical property of a compound interface are improved.

Owner:河南盛荣金属复合新材料有限公司

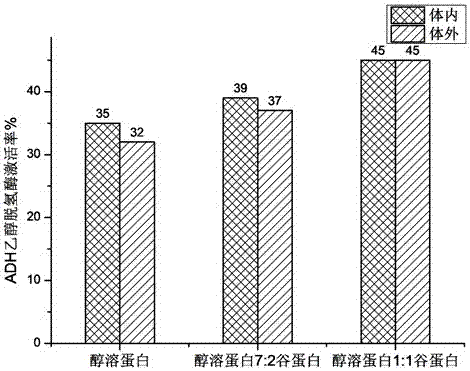

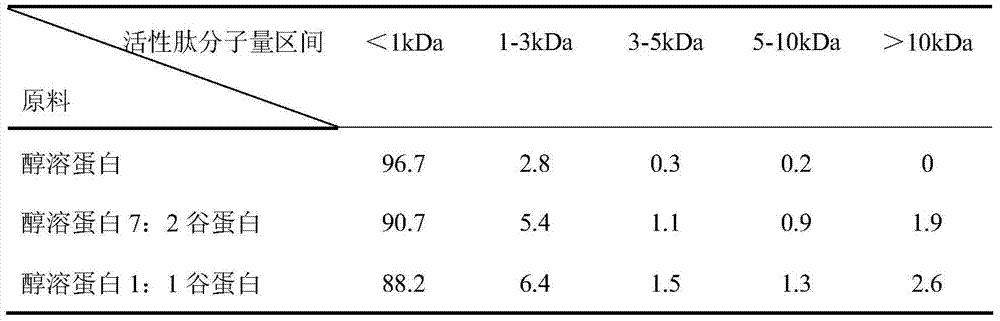

Preparation method of a novel corn protein source ethanol metabolism-promoting polypeptide

ActiveCN104313092BConducive to further explain the mechanism of sobering upGreat contributionFermentationEthanol dehydrogenaseAdditive ingredient

The invention discloses a novel method for preparing ethanol metabolism-promoting polypeptide derived from corn protein. The method comprises: pretreatment of corn yellow powder raw material to remove starch; extraction of prolamin and glutenin; mixed enzymatic hydrolysis product of prolamin and glutenin preparation; the supernatant enzymatic hydrolyzate was freeze-dried to obtain the ethanol metabolism-promoting polypeptide derived from corn protein. The obtained product is used as the main functional component of the ethanol metabolism-promoting health-care product to reduce the damage of ethanol to the human body. The active peptide has been verified by the alcohol dehydrogenase (ADH) kit and the police alcohol blowing tester, and it is confirmed that the activity of alcohol dehydrogenase can be increased by 32%~45%. Compared with the peptide obtained from a single gliadin enzymatic hydrolysis product, increasing the proportion of gluten in the enzymatic hydrolysis raw material within a certain range can make the obtained crude polypeptide have a greater activation effect on alcohol dehydrogenase ADH and a faster metabolism of ethanol. The molecular weight of the target active peptide was generally lower than 1kDa as determined by gel chromatography analysis.

Owner:SOUTH CHINA UNIV OF TECH

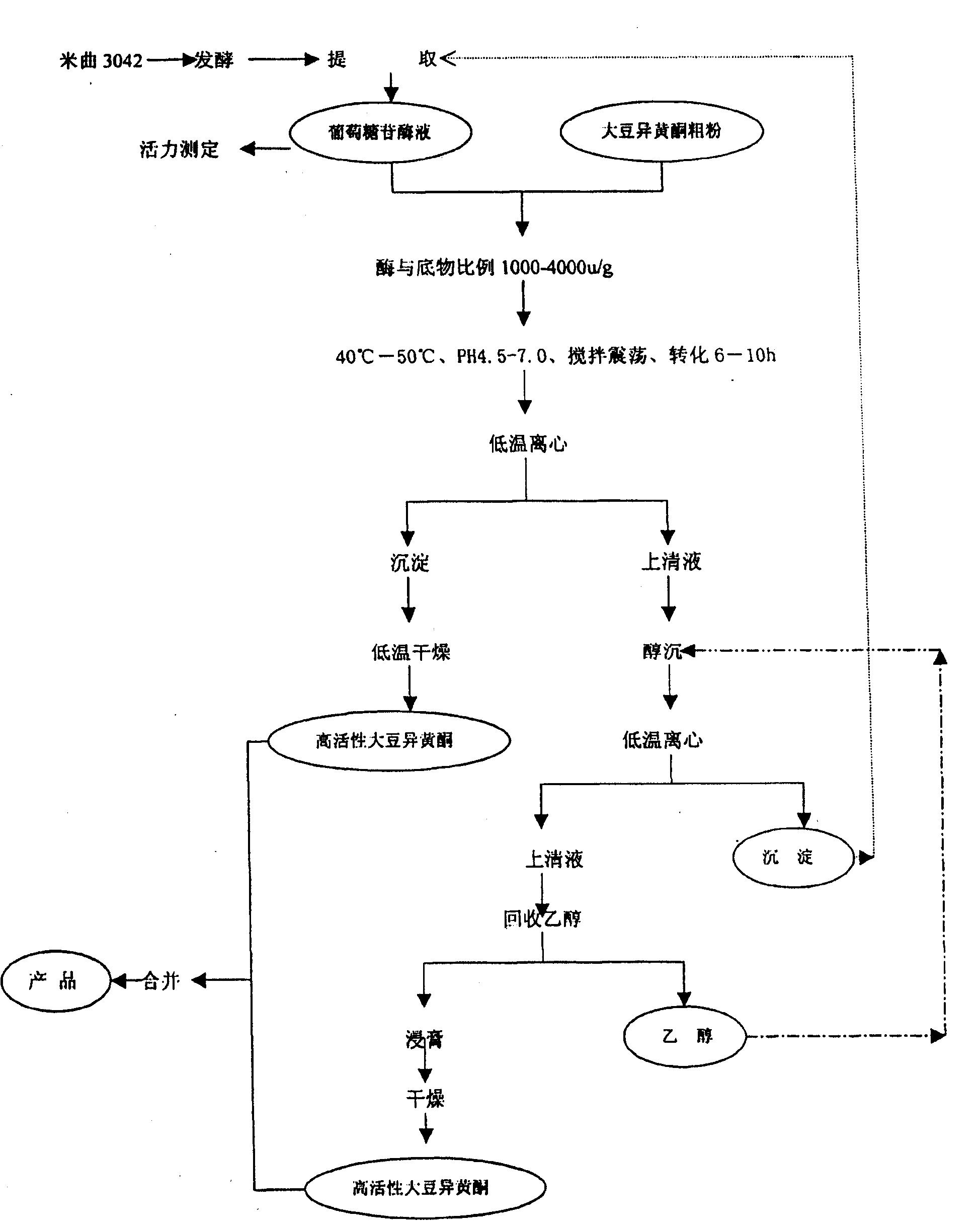

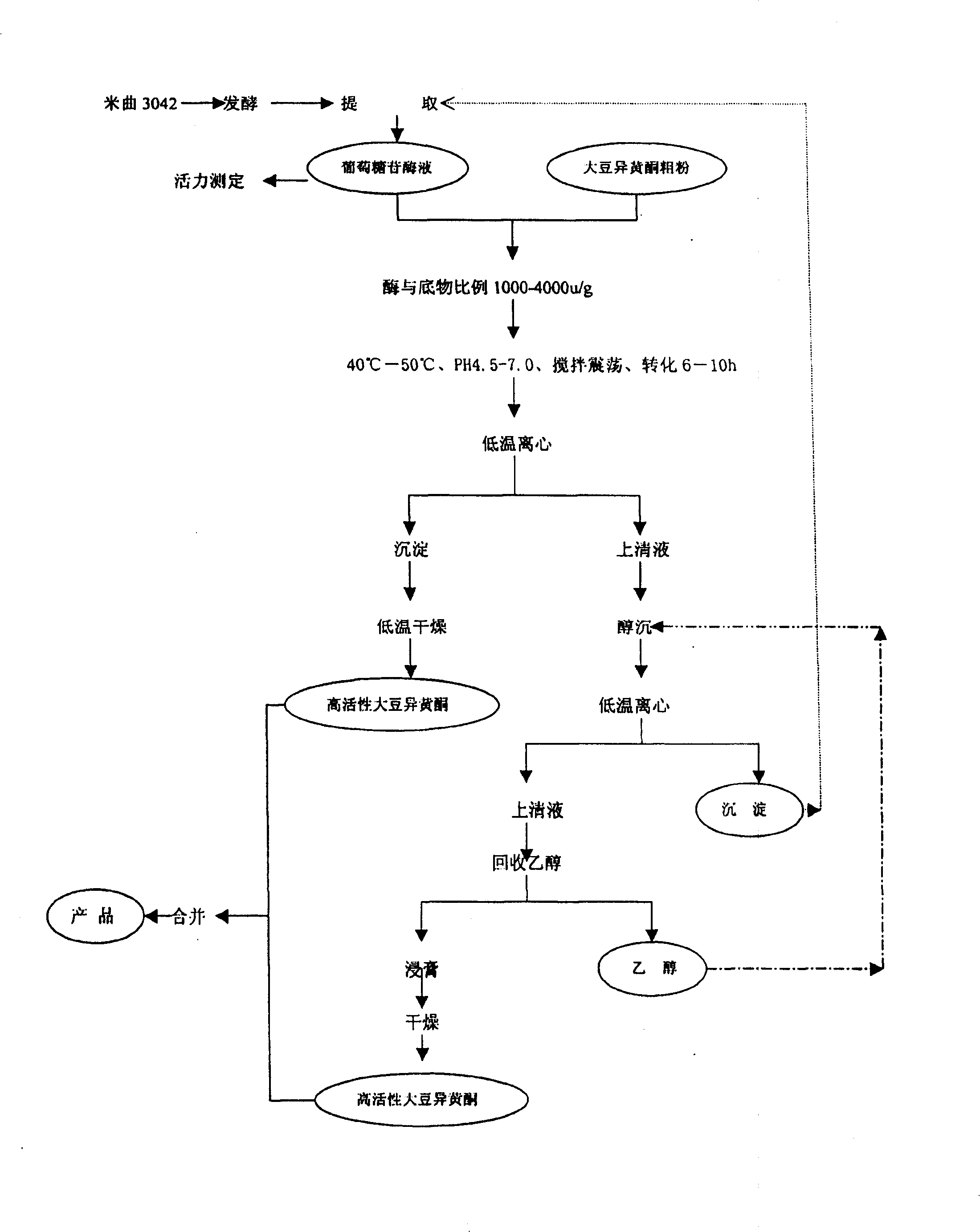

Process for preparing soybean isoflavone aglycon by microorganism enzyme method

InactiveCN1966705BShort processLower conversion costsMicroorganism based processesFermentationMicroorganismAlglucerase

The invention discloses a method for producing soybean isoflavone aglycone through microbe's enzyme method, and is culturing Aspergillus oryzae with soybean isoflavone powder as raw materials for fermentation to produce beta-glucosidase, and converting soybean isoflavone to soybean isoflavone aglycone. The method is characterized in comprising the following preparation steps: the said raw materials are 2-90% soybean isoflavone powder, the said strain is Aspergillus oryzae 3042, preparing seed culture liquid with the strain, preparing solid fermentation medium, fermenting to obtain fermenting product containing beta-glucosidase, adding soybean isoflavone powder for preparing enzyme converting solution, centrifuging for separation to obtain deposit, drying at low temperature to obtain soybean isoflavone aglycone. The invention avoids the restriction of the raw materials purity, converting rata can reach to over 90%. The invention has the advantages of short procedure, low cost, high bioavailability.

Owner:辽宁省微生物科学研究院

Process for producing superfine high-purity quartz glass pipe for high-temperature sensor

ActiveCN101805116BEfficient removalEasily brokenRadiation pyrometryGlass shaping apparatusPerformance indexOperability

Owner:连云港市盛昌照明电器有限公司

A cutting fluid for high-efficiency bearing grinding and cutting, its preparation method and use method

ActiveCN109054971BExcellent anti-rustImprove the lubrication effectLubricant compositionSebacic acidMethyl palmoxirate

The invention relates to the technical field of cutting fluids, in particular to a cutting fluid for high-efficiency bearing grinding and cutting, a preparation method and an application method thereof. The cutting fluid comprises 10-20 parts of water-soluble alcoholamine, 3-12 parts of a preservative of a dicarboxylate-based composite, 2-10 parts of an emulsifier, 2-8 parts of synthetic resin, 2-8 parts of a film-forming agent, 1-3 parts of hexanediol, 0.1-1 part of benzotriazole, 1-3 parts of a pH adjuster, 15-25 parts of base oil, and 30-40 parts of deionized water. The preparation steps ofthe invention are as follows: first, heating sebacic acid, dodecane dibasic acid, methyl benzotriazole, neodecanoic acid, isopropanolamine and water to 55-65 DEG C to completely dissolve into a transparent liquid, adding water-soluble alcohol amine, base oil, benzotriazole, deionized water and a pH adjuster to stir to be even and transparent, finally adding the emulsifier, the synthetic resin, the film-forming agent, and hexanediol, and stirring to be transparent. The cutting fluid for high-efficiency bearing grinding and cutting facilitates workshop management and the appearance of rust anddark spots can be avoided.

Owner:苏州安美润滑科技有限公司

Bi2S3-doped PbS thermoelectric material and preparation method thereof

InactiveCN106558647AIncrease thermoelectric figure of merit ZTEasy to operateThermoelectric device junction materialsMaterials scienceSpark plasma sintering

The invention relates to a Bi2S3-doped PbS thermoelectric material and a preparation method thereof. The Bi2S3 doping proportion in the thermoelectric material is 1-5.5wt%. The preparation method is that a hydrothermal method is used for synthesizing Bi2S3-doped PbS powder, and the thermoelectric material is obtained through spark plasma sintering (SPS). The thermoelectric material obtained by the preparation method is characterized in that the seebeck coefficient absolute value is reduced, the conductivity is increased, the thermal conductivity is reduced, the thermoelectric figure of merit ZT is increased, and the thermoelectric property is effectively improved.

Owner:涂艳丽

Preparation method of photosynthetic bacterium solid medium

The invention relates to a preparation method of a photosynthetic bacterium solid medium, and belongs to the technical field of medium preparation. The preparation method mainly includes the steps that mistletoe leaves are pretreated, stir-fried and ground, and mistletoe leaf powder is obtained; then, the mistletoe leaf powder, Prunus persica (L.) Batsch and liquid supernatant in a biogas digester are stirred, mixed and fermented, and mixed fermentation liquor is obtained; then, the mixed fermentation liquor and substances such as sodium acetate and ammonium chloride are stirred and mixed, the mixture is sterilized, and the photosynthetic bacterium solid medium is obtained. According to the preparation method, the mistletoe leaves are fully utilized for fermentation, so that the photosynthetic bacterium solid medium is loose and porous, and the problems that the production process is difficult to control and large-scale production is difficult to achieve in a shallow-layer or thin-layer fermentation process are avoided; besides, transportation is convenient, packaging is easy, and cost is lowered.

Owner:郭舒洋

Method for producing natural bamboo fibers

The invention discloses an article for daily use, discloses a method for producing natural bamboo fibers, and belongs to the technical field of textile industry. The method includes thoroughly cleaning the surfaces of bamboo by the aid of running water; chopping the bamboo along the directions of fibers to obtain bamboo strips; placing the bamboo strips in a metal sealed container; adding an appropriate quantity of purified water into the metal sealed container; pressurizing and heating the metal sealed container to quickly carbonize the bamboo strips and optionally appropriately adjusting the temperatures and the pressures according to the tenderness of the bamboo; quickly opening a gate on the right side of the metal sealed container and instantly releasing the pressures; bursting the bamboo strips in the metal sealed container out of the metal sealed container under the effect of the pressures and directly bursting the bamboo strips into a recycling device. The pressures are suddenly decreased, so that volumes of the bamboo strips are quickly expanded, and the bamboo strips are broken and are decomposed into small and slender natural bamboo fiber yarns in the shape of cotton. The method has the advantages that working procedures are simple, the natural bamboo fibers are convenient to produce and free of optional chemical reagents, are environmentally friendly, are hygienic, are beneficial to the physical health of people and can be produced on a large scale, and the method is easy to popularize, good in production controllability and high in production efficiency.

Owner:杨朝军

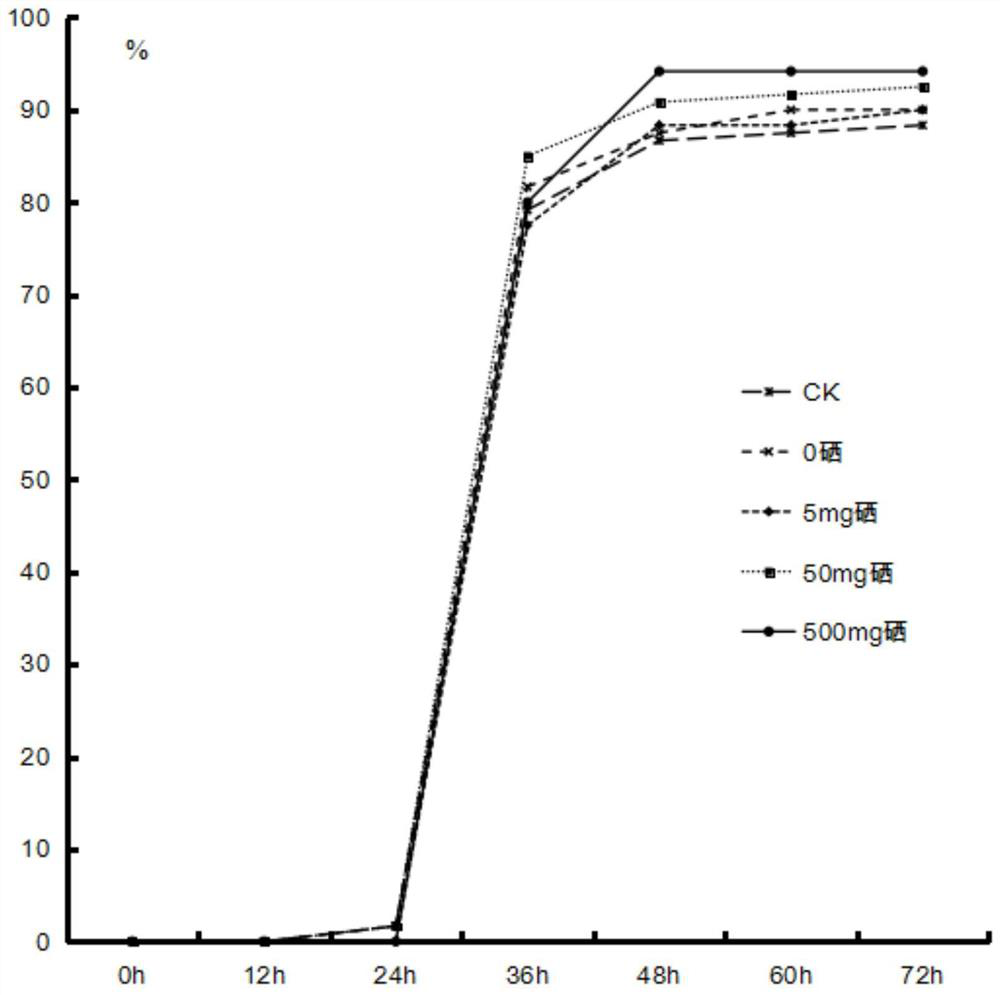

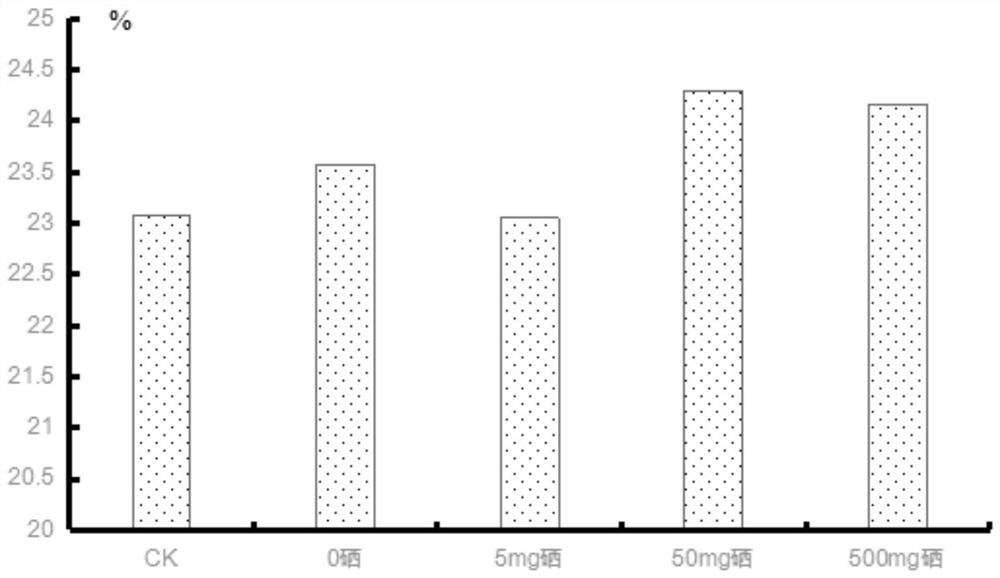

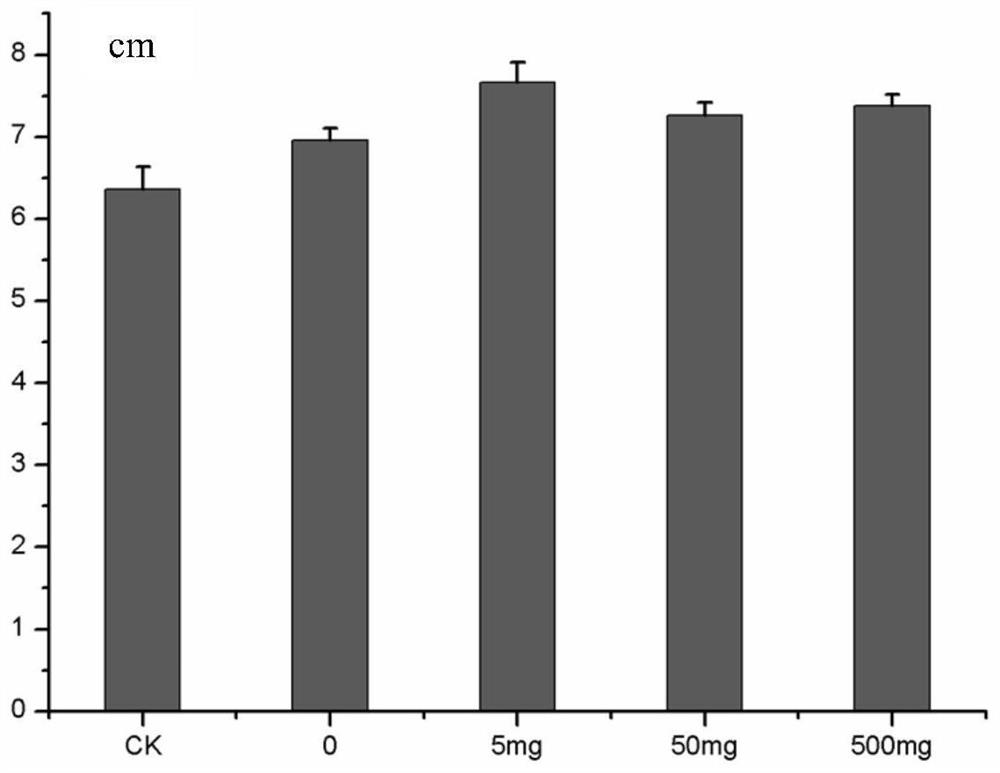

Composite organic selenium nutrient solution, application thereof and sprouting vegetable cultivation method

PendingCN111869558AEasy to makeImprove germination rateAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersCarrageenanVitamin C

The invention discloses a composite organic selenium nutrient solution, application thereof and a sprouting vegetable cultivation method. The composite organic selenium nutrient solution is formed bymixing selenized carrageenan, urea, monopotassium phosphate and water, the concentration of the selenized carrageenan in the nutrient solution is 5-500 mg / L, the concentration of the urea in the nutrient solution is 2 g / L, and the concentration of the monopotassium phosphate in the nutrient solution is 1 g / L. The composite organic selenium nutrient solution can be applied to the fields of promoting germination of double-low rape seeds and cultivating selenium-rich sprouting vegetables, has a remarkable promoting effect on the germination rate, germination potential, bud length and bud thickness of seed germination, can promote vitamin C accumulation in crops, and can improve the selenium content in the sprouting vegetables.

Owner:孝昌县乡香太子米专业合作社联合社

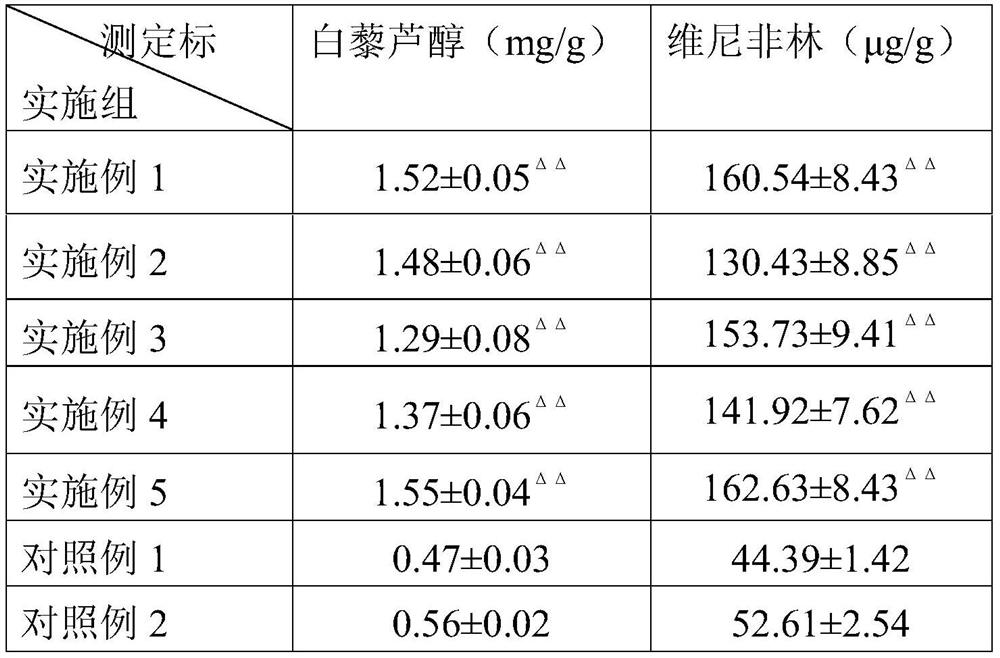

A kind of preparation method of edible fungus fermentation product rich in stilbene compounds

ActiveCN108103113BImprove protectionImprove absorption and utilizationMicroorganism based processesFermentationBiotechnologyPhellinus igniarius

The invention discloses a preparation method of an edible and medicinal fungus fermentation product containing rich stilbene compounds. The preparation method comprises the following steps: inoculating phellinus igniarius seed liquid into a solid culture medium added with an exogenous substance and culturing; after drying and crushing a cultured product, obtaining an exogenous substance solid fermentation culture substance, wherein the exogenous substance is selected from one or more than two of peanut, mulberry fruit, grape, radix polygoni multiflori and radix et rhizoma rhei; inoculating thephellinus igniarius seed liquid into a liquid fermentation culture medium added with the exogenous substance solid fermentation culture substance and culturing for a period of time; adding cold shockprotein and then continually culturing for a period of time; then stopping fermentation to obtain the edible and medicinal fungus fermentation product containing the rich stilbene compounds. According to the preparation method disclosed by the invention, the exogenous substance contains less resveratrol and is combined with characteristic of a stilbene compound anabolism way, and phellinus igniarius solid fermentation and liquid fermentation technologies are carried out; the cold shock protein is added at a specific fermentation phase, so that the amount of the biologically synthesized stilbene compounds can be effectively increased and a new way is provided for the product containing the rich stilbene compounds.

Owner:ZHEJIANG FORESTRY ACAD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com