Medium-period and long-period antirust type cutting oil and preparation method thereof

A medium-to-long-term, cutting oil technology, which is applied in the field of medium-to-long-term anti-rust cutting oil and its preparation, can solve difficult problems such as rust resistance, and achieve the effects of cost saving, high production efficiency, and reduced operating process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

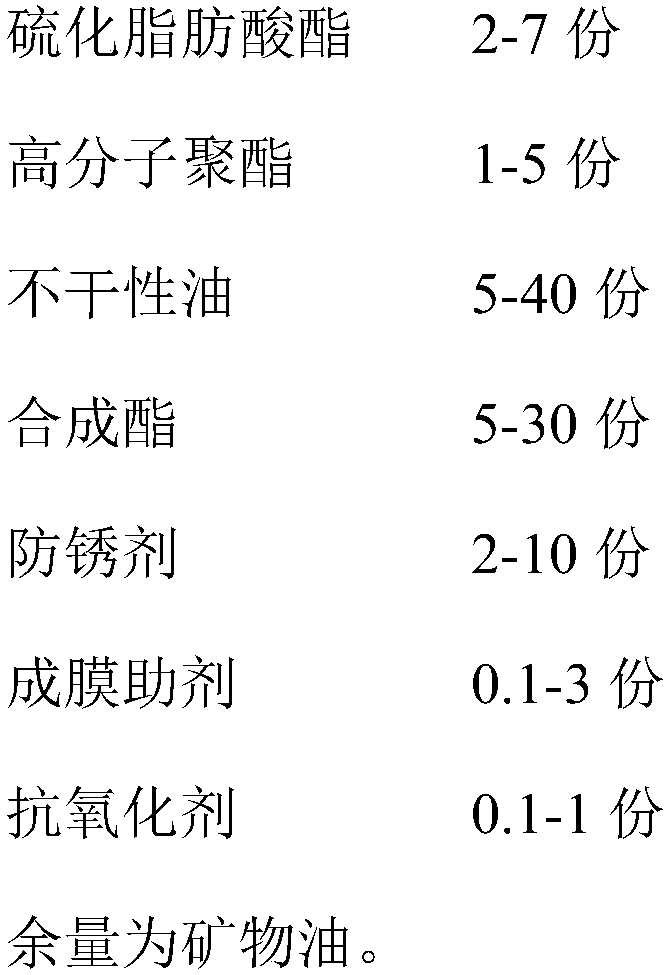

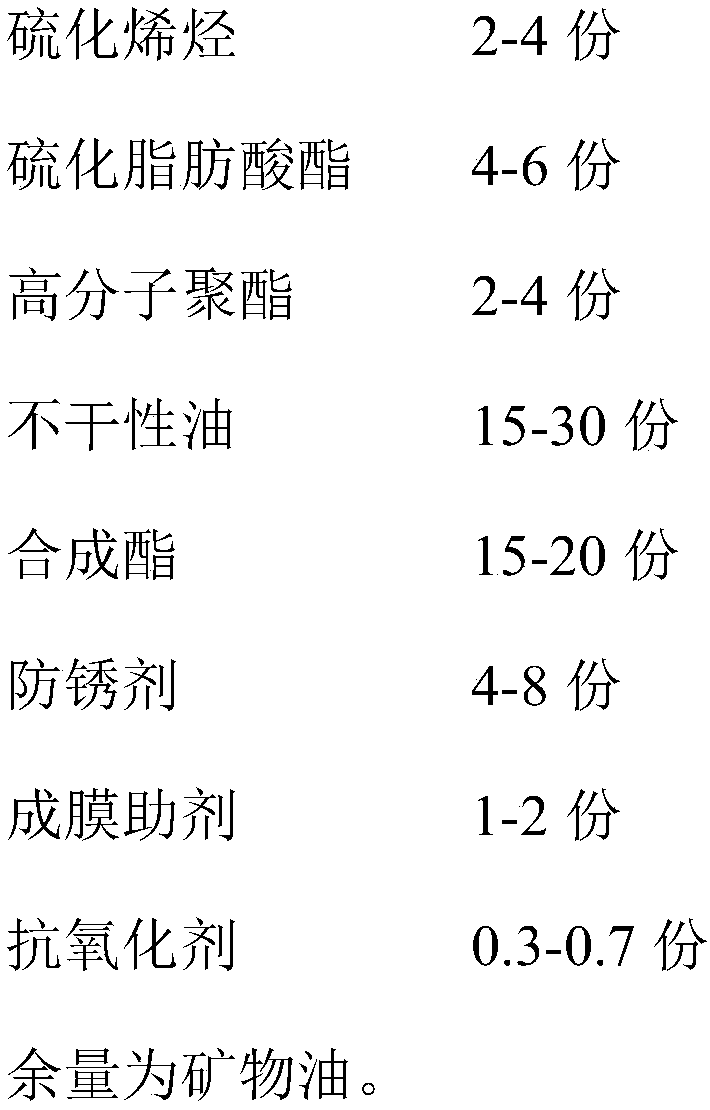

Method used

Image

Examples

Embodiment 1

[0027] A kind of medium and long-term anti-rust type cutting oil of the present embodiment, it comprises following preparation steps:

[0028] 1) Add 36.5 parts of mineral oil, 5 parts of polymer polyester, 2 parts of calcium sulfonate, 3 parts of lanolin, and 1 part of alkylphenol antioxidant, heat to 60°C, stir for 20 minutes and mix well;

[0029] 2) Stop heating, add 0.5 parts of sulfurized olefin, 7 parts of sulfurized fatty acid ester, 20 parts of palm oil, 20 parts of castor oil, 2 parts of monoester and 3 parts of diester, continue stirring for 30 minutes, and mix well to obtain the finished product.

Embodiment 2

[0031] A kind of medium and long-term anti-rust type cutting oil of the present embodiment, it comprises following preparation steps:

[0032] 1) Add 46.2 parts of mineral oil, 1 part of polymer polyester, 10 parts of zinc naphthenate, 0.5 part of lanolin magnesium soap, and 0.3 part of alkylphenol antioxidant, heat to 65°C, stir for 20 minutes and mix well;

[0033] 2) Stop heating, add 5 parts of sulfurized olefin, 2 parts of sulfurized fatty acid ester, 5 parts of olive oil, 10 parts of monoester, 10 parts of diester, and 10 parts of polyol ester, continue stirring for 30 minutes, and mix well to obtain the finished product.

Embodiment 3

[0035] A kind of medium and long-term anti-rust type cutting oil of the present embodiment, it comprises following preparation steps:

[0036] 1) Add 36.3 parts of mineral oil, 4 parts of polymer polyester, 4 parts of phosphoric acid ester, 1 part of lanolin magnesium soap, 1 part of oxidized paraffin wax, 0.7 part of alkylphenol antioxidant, heat to 55 ° C, stir for 125 minutes and mix well ;

[0037] 2) Stop heating, add 2 parts of sulfurized olefin, 6 parts of sulfurized fatty acid ester, 15 parts of castor oil, 15 parts of olive oil, 7 parts of diester, and 8 parts of polyol ester, continue stirring for 35 minutes, and mix well to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com