Heat-conducting tobacco sheet for cigarettes and preparation method and application thereof

A technology for tobacco sheets and cigarettes, applied in the directions of tobacco, application, and preparation of tobacco, can solve the problems of difficulty in fully releasing tobacco flavor components, insufficient smoke generation, insufficient consumer satisfaction, etc., and achieves simple production process and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

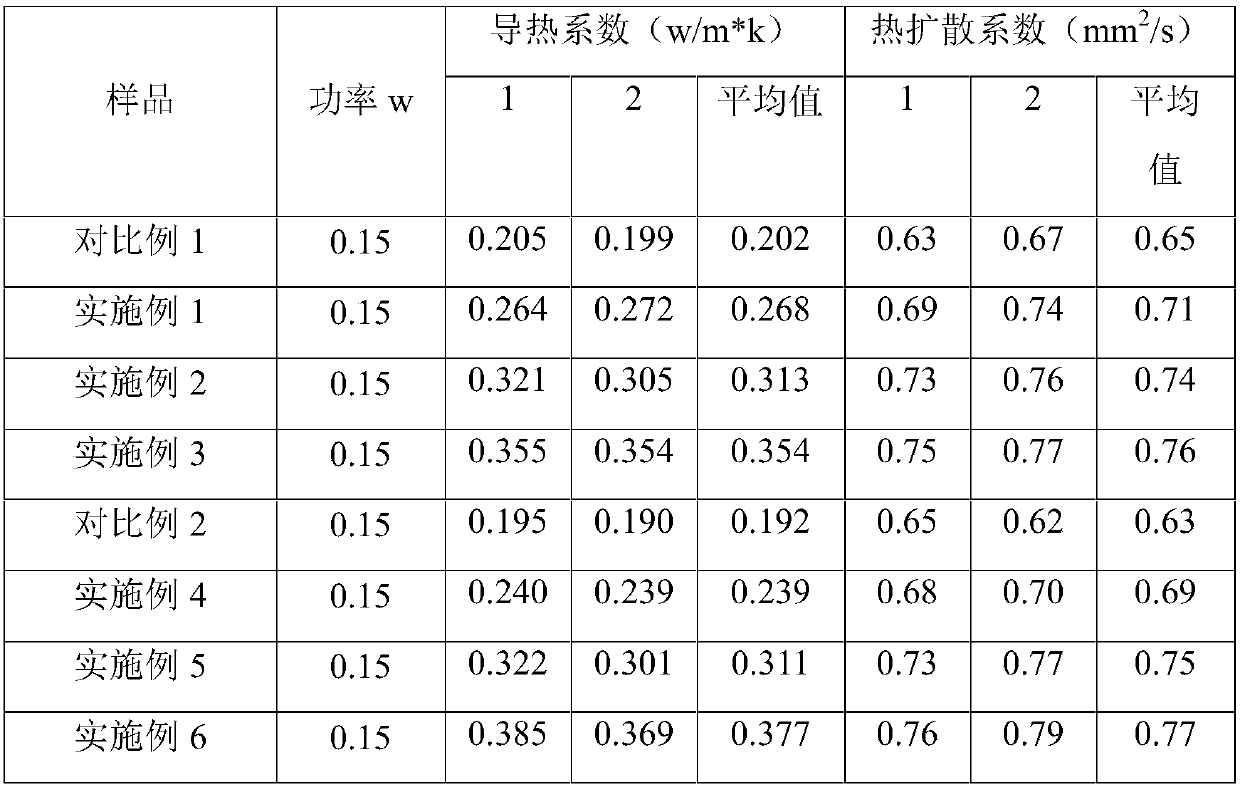

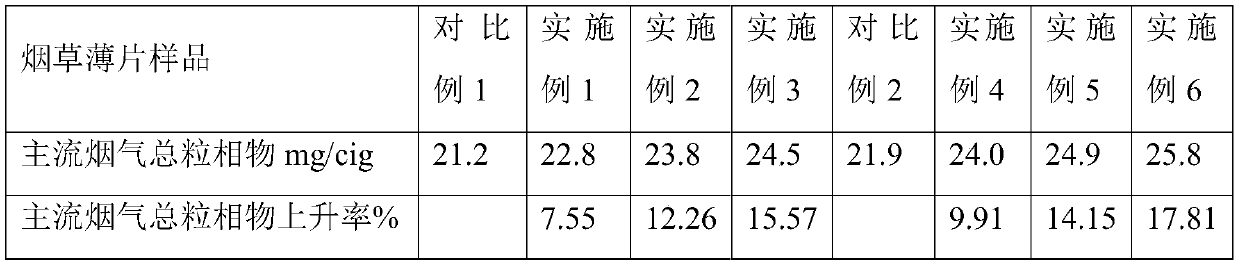

Embodiment 1

[0022] According to the method for preparing tobacco sheet by the thick slurry method described above, a heat-conducting material is added, the proportion of which accounts for 4.2% of the mass fraction of the finished heat-conducting tobacco sheet, and the heat-conducting material used is aluminum nitride powder.

Embodiment 2

[0024] According to the thick slurry method tobacco sheet preparation method described above, add heat-conducting material, its ratio accounts for 8.5% of the mass fraction of heat-conducting tobacco sheet finished product, the heat-conducting material used is aluminum nitride powder and aluminum oxide powder, and its ratio is 2: 1.

Embodiment 3

[0026] According to the thick slurry method tobacco sheet preparation method described above, add heat-conducting material, its proportion accounts for 10.8% of the mass fraction of finished heat-conducting tobacco sheet, and the heat-conducting material used is aluminum oxide powder and silicon carbide powder, and its ratio is 1:1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com