A kind of production method of stainless steel single-sided composite roll

A production method and stainless steel technology, applied in the field of stainless steel single-sided composite coils, can solve the problems of unsatisfactory stainless steel surface smoothness, stainless steel surface quality not meeting requirements, and coil thickness difficult to meet requirements, etc., to achieve economic benefits and Significant social benefits, improved mechanical properties, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The invention discloses a production method of a stainless steel single-sided composite roll, which is carried out according to the following steps:

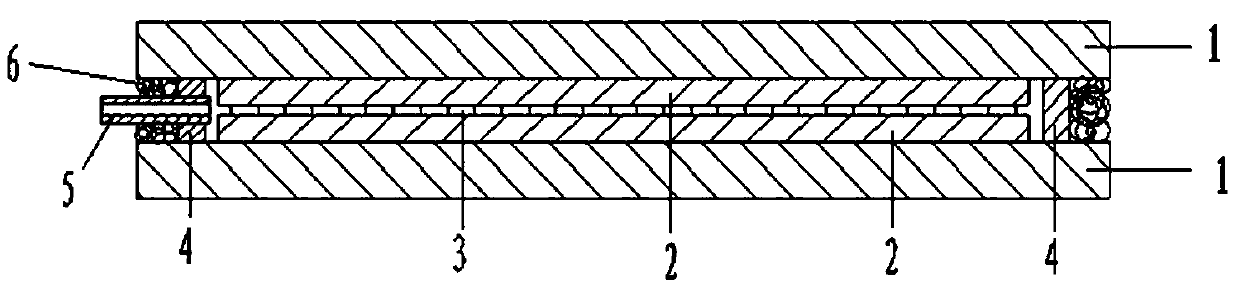

[0044] Step 1: First, make a composite billet, such as figure 1 As shown in the figure, 1—substrate, 2—complex

[0045] Plate, 3—isolating agent, 4—gear bar, 5—vacuumizing tube, 6—welding meat, the specific steps are as follows:

[0046] Step 1-1) Treat the surface of the base plate using carbon steel as material and the double plate using stainless steel as material. The method of treating the surface of the base plate, doubler board and rail is to use a combination of pickling, sandblasting, grinding and shot blasting, or one of these methods to clean the oxide layer on the surface of the raw material; Clean the oxide layer on the surface of the raw material of the substrate and double board, showing a metallic luster;

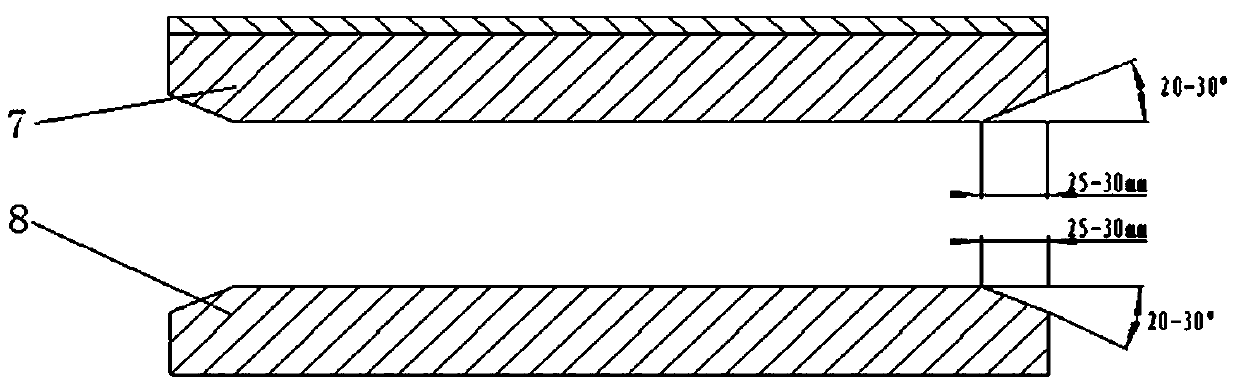

[0047] Step 1-2) Strip preparation: Cut carbon steel (such as Q235B) with a thickness of 12-20mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com