Application of nano-carbon supported monatomic palladium-based catalyst in catalytic hydrogenation of nitrile compound to prepare secondary amine

A technology for catalytic hydrogenation and compounding, which is applied in the preparation of amino compounds, organic compounds, physical/chemical process catalysts, etc. It can solve the problem of low selectivity, achieve good repeatability, easy access to materials, and increase the production of secondary amines. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A single-atom palladium-based catalyst (Pd 0.1 / ND@G) 20mg was added to a 50ml pressure-resistant reaction bottle, 4mmol of ammonia borane was added, and 10ml of methanol solution containing 0.5mmol of the reaction substrate was added, and the reaction was carried out at a reaction temperature of 60°C for 8h. After the reaction, the conversion rate of benzonitrile is 55%, the selectivity of the product dibenzylamine is 98%, and the total selectivity of other by-products is 2%.

Embodiment 2

[0028] A single-atom palladium-based catalyst (Pd 0.1 / ND@G) 30mg was added to a 50ml pressure-resistant reaction bottle, 4mmol of ammonia borane was added, and 10ml of methanol solution containing 0.5mmol of the reaction substrate was added, and the reaction was carried out at a reaction temperature of 60°C for 8h. After the reaction, the conversion rate of benzonitrile is >99.9%, the selectivity of the product dibenzylamine is 98%, and the total selectivity of other by-products is 2%.

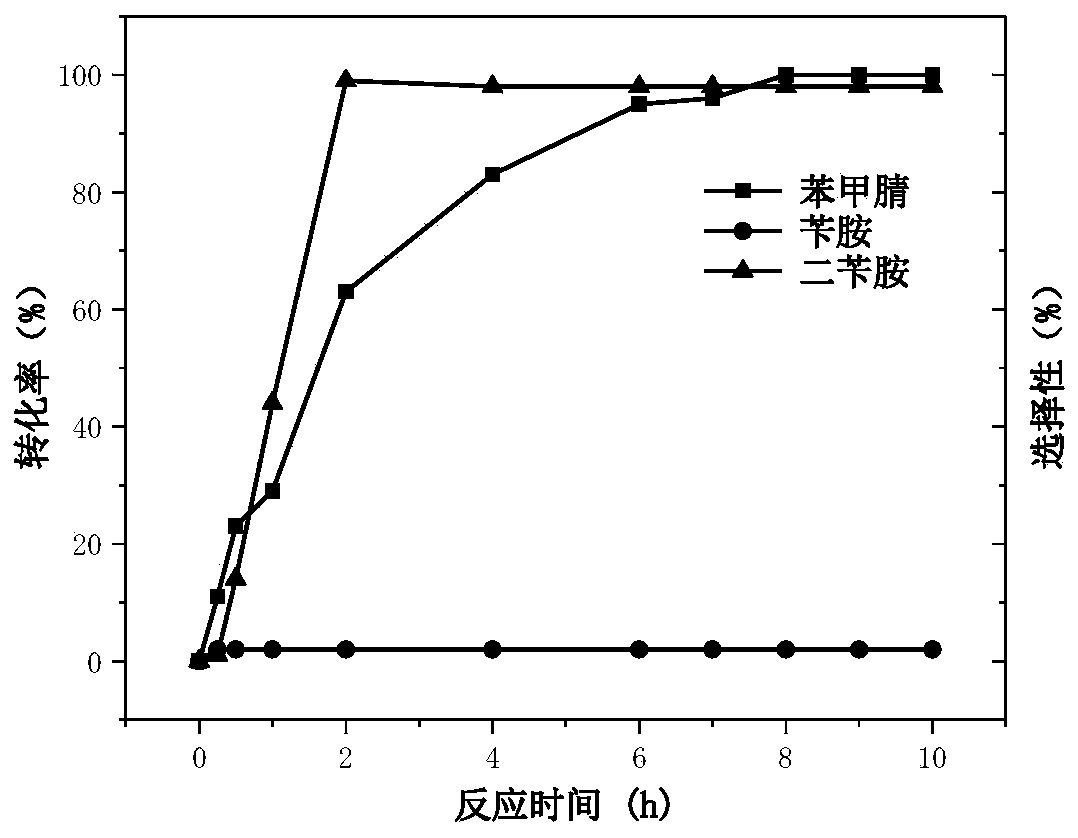

[0029] Under the condition that other conditions remain unchanged, only changing the reaction time, the activity and selectivity of the catalyst at different reaction times will change as follows: figure 2 shown.

Embodiment 3

[0033] A single-atom palladium-based catalyst (Pd 0.1 / ND@G) 30mg was added to a 50ml pressure-resistant reaction bottle, 3mmol of ammonia borane was added, and 10ml of methanol containing 0.5mmol of the reaction substrate was added, and the reaction was carried out at a reaction temperature of 60°C for 8h. After the reaction, the conversion rate of benzonitrile was 54%, the selectivity of the product dibenzylamine was 98%, and the total selectivity of other by-products was 2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com