Rotary dynamic continuous preparation method for titanium black powder

A rotary dynamic, titanium oxide technology, applied in the direction of titanium oxide/hydroxide, etc., can solve the problems of large temperature influence of upper and lower products, hindering reaction speed, and uneven reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

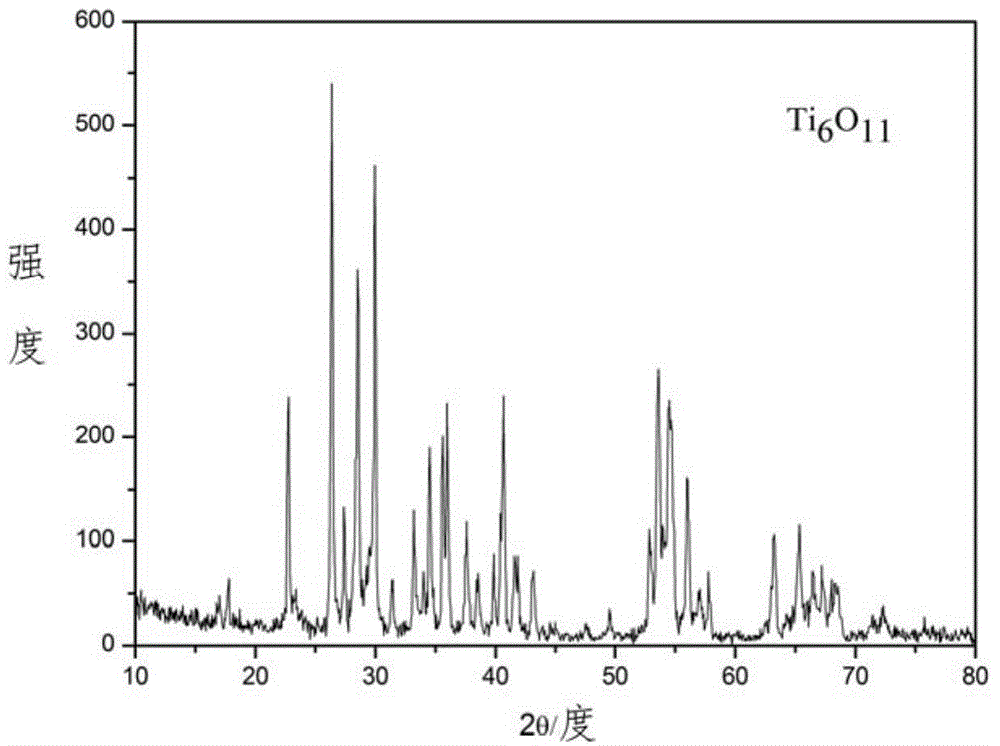

Embodiment 1

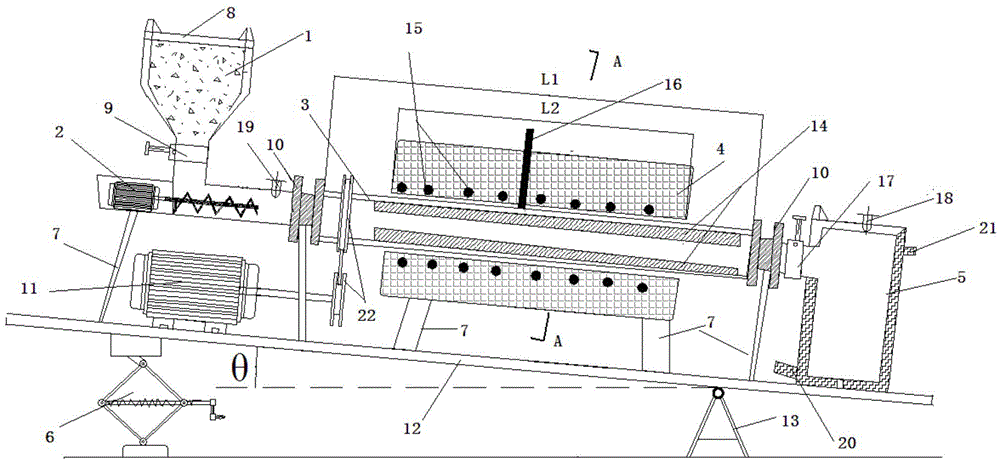

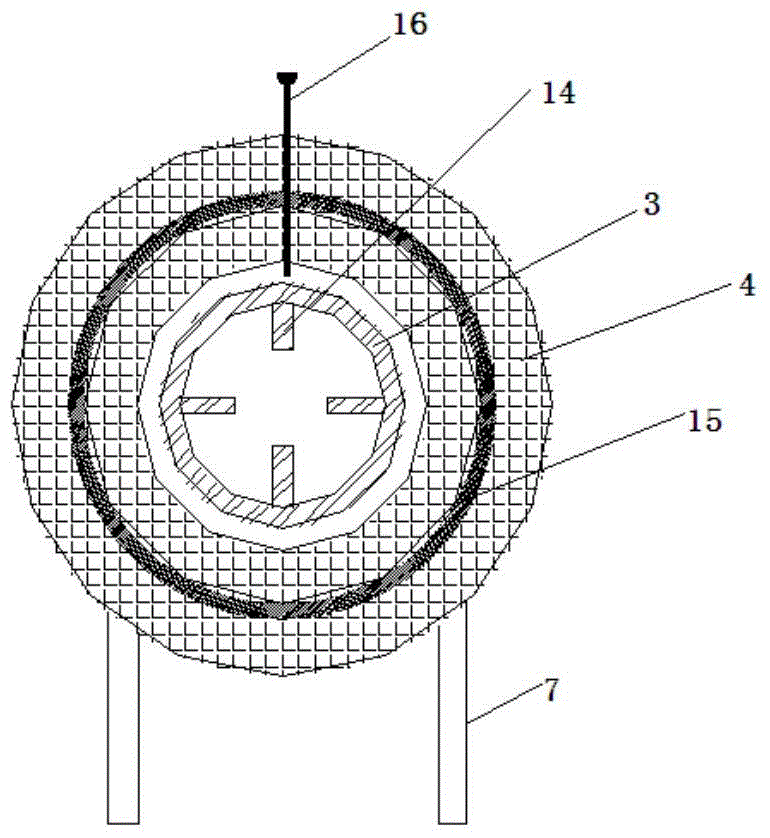

[0085] In this embodiment, the rotary dynamic continuous sintering device such as figure 1 , figure 2 As shown, it consists of a material storage chamber 1, a screw feeder 2, a furnace tube 3, a furnace tube drive mechanism, a heating furnace 4, a collection chamber 5, a support frame, a threaded lifter 6 and a bracket 7. The discharge end of the screw feeder is provided with an air inlet valve 19, the top of the storage chamber is provided with a sealing cover 8, the lower part is provided with a discharge control valve 9, and the discharge port at the bottom is connected with the screw feeder. The heating furnace is provided with a resistance heating device heating device 15 and a thermocouple 16 . The collection chamber is provided with an air outlet valve 18 and a material intake port equipped with a sealing cover, and a feed control valve 17 is provided at the inlet of the collection chamber. The chamber wall of the collection chamber 5 is a sandwich structure, and the...

Embodiment 2

[0100] The difference between the rotary dynamic continuous sintering device used in this embodiment and embodiment 1 is that the length of the furnace tube is 3m, and the length L2 of the heating zone of the heating furnace is 2m; the heating device of the heating furnace is an induction heating device, such as image 3 shown.

[0101] In this example, Ti 9 o 17 The process steps and operation method of the rotary dynamic continuous preparation method of powder are the same as in Example 1, and the process parameters in this example are as follows:

[0102] The weight percentage of each raw material in the step (1): H 2 TiO 3 Powder: (nano charcoal powder + titanium hydride powder) = 9:1.5;

[0103] The inclination angle of support plate in step (3) is 10 °; The gas flow velocity of 2L / min is charged into hydrogen in furnace tube with the gas flow velocity of 2L / min from the gas inlet valve 19 that screw feeder is provided with; The rotational speed of furnace tube is 1.2...

Embodiment 3

[0105] The difference between the rotary dynamic continuous sintering device used in this example and Example 1 is that the length of the furnace tube is 3m, and the length of the heating zone of the heating furnace is 2m.

[0106] In this example, Ti 9 o 17 The process steps and operation method of the rotary dynamic continuous preparation method of powder are the same as in Example 1, and the process parameters in this example are as follows:

[0107] The weight percentage of each raw material in the step (1): micron TiO 2 Powder: micron carbon black powder = 9:1;

[0108] The inclination angle of the support plate in step (3) is 45°; the gas flow rate of 1L / min is charged into the furnace tube with the mixed gas obtained by mixing hydrogen and nitrogen with a volume ratio of 30:70 from the inlet valve 19 provided by the screw feeder ; The rotation speed of the furnace tube is 0.05r / min; the temperature reached in the furnace tube is 900°C; the sintering time is 2 hours. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com