Internal light-focusing solar photoelectric and light-heat composite pipe

A solar cell and solar energy technology, applied in the directions of solar thermal energy, solar thermal power generation, solar thermal collectors, etc., can solve the problems of high cost of non-concentrating flat-panel solar cells and inability to generate electricity, and achieve low production costs and lower operating temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

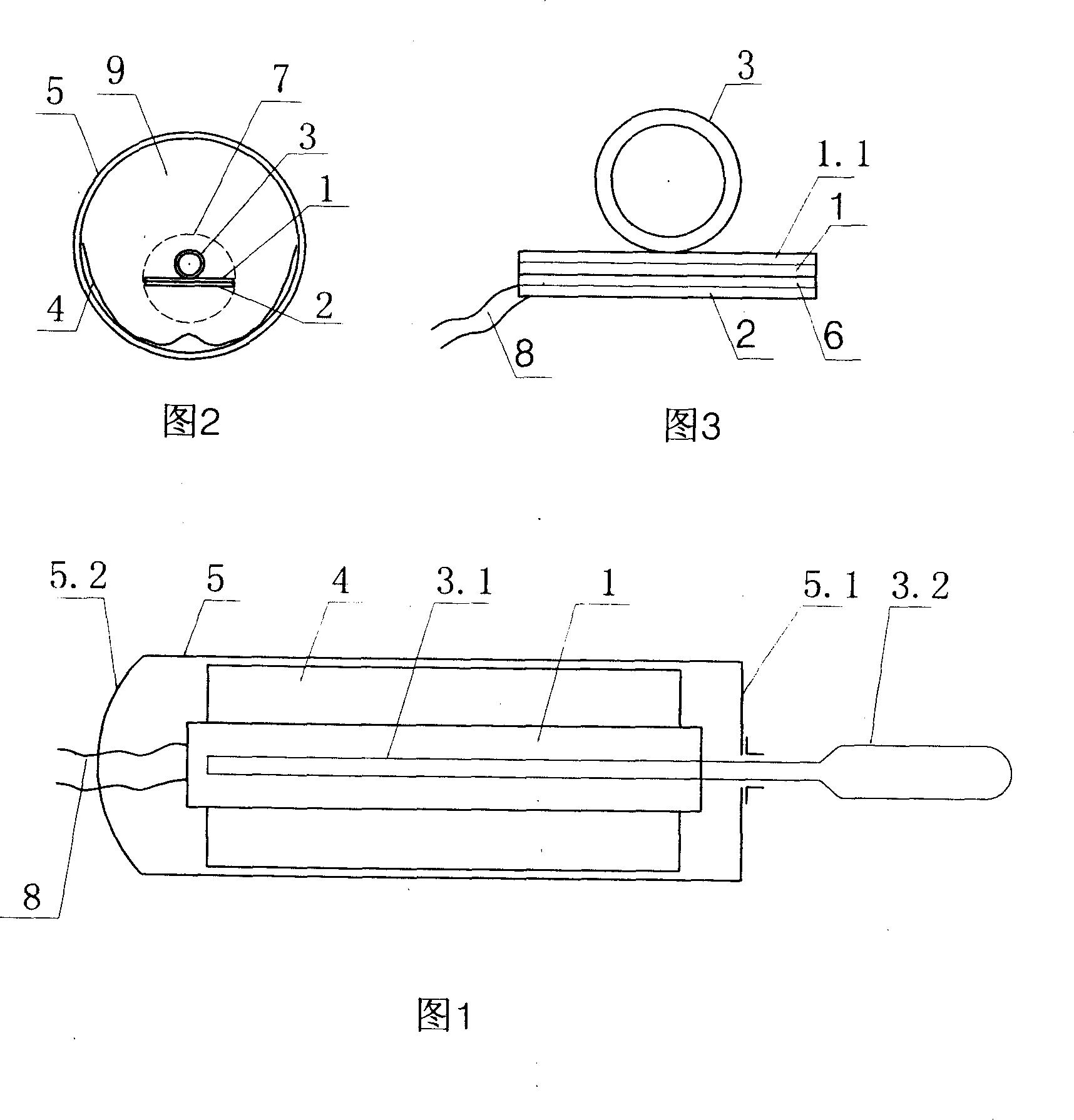

[0023] Embodiment 1: As shown in Fig. 1 and Fig. 2, the inner concentrating solar photoelectric photothermal composite tube. By bonding the polycrystalline silicon solar cell 2 on the metal heat collecting strip 1, the copper welded on the metal strip 1 The heat pipe 3, the trough-shaped reflective concentrator 4 and the encapsulated transparent glass tube 5 are composed. The trough-shaped reflective concentrator 4 gathers the incident sunlight to the polycrystalline silicon solar cells 2 on the front and back of the metal heat-collecting strip 1.

[0024] The metal strip 1 shown in Figure 3 is an aluminum strip with good thermal conductivity, which is used as a heat sink for solar cells and should be bonded with the polysilicon battery sheet 2 through an insulating heat-conducting adhesive 6. The other side of the aluminum strip 1 Deposition of solar selective heat collecting coating 1.1.

[0025] As shown in Figure 1 and Figure 2, the evaporation section 3.1 of the copper he...

Embodiment 2

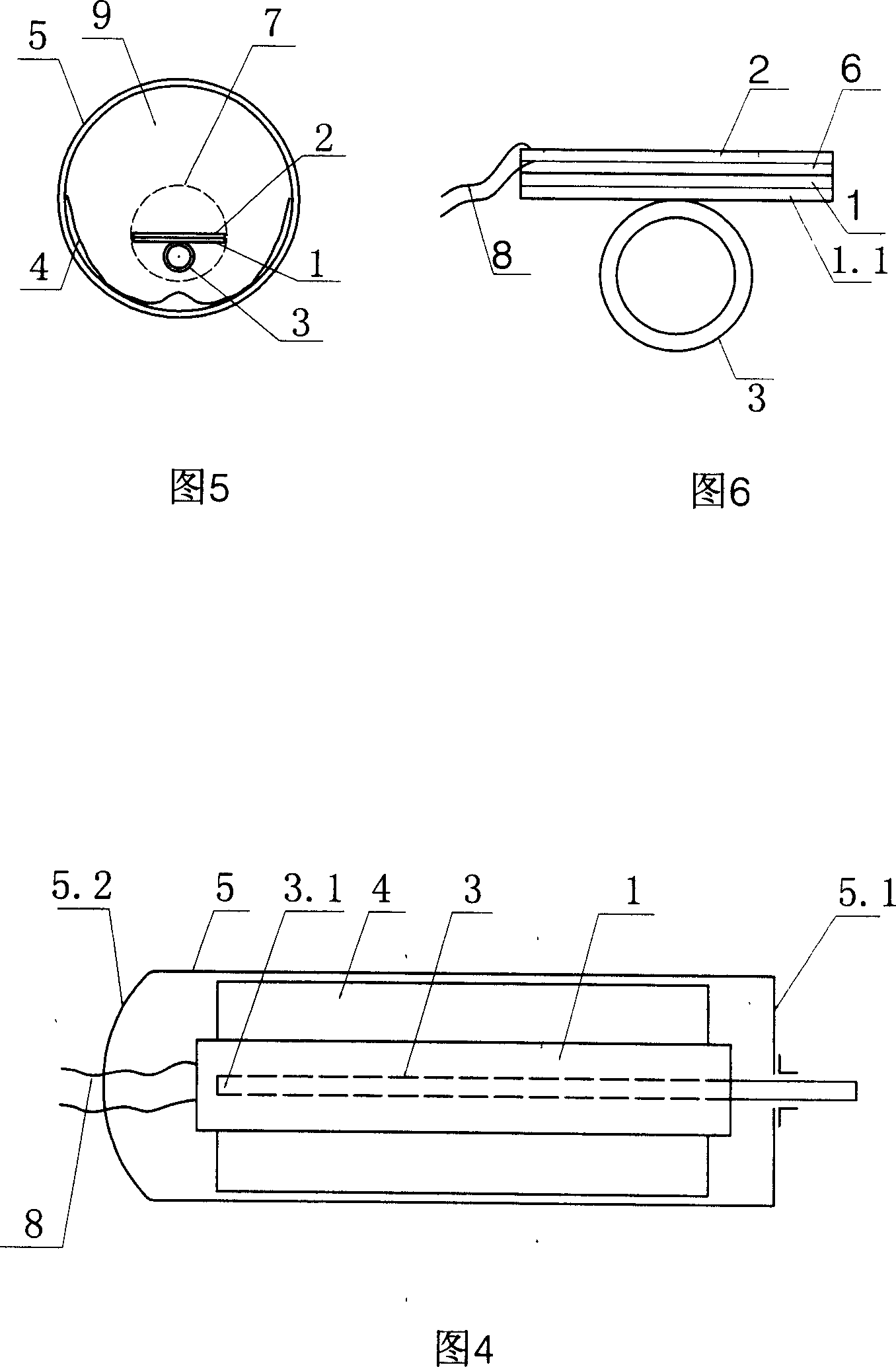

[0032] Embodiment 2: as Fig. 4, Fig. 5, shown in Fig. 6, present embodiment and embodiment 1 are basically the same. Only following two points are different:

[0033] 1. The copper heat pipe 3 in Fig. 1 of embodiment 1 is changed to the copper pipe 3 in Fig. 5 and Fig. 4 of this embodiment, and is closed at one end 3.1. The heat generated by the inner concentrating solar photoelectric photothermal composite pipe can pass through the copper pipe The working medium of the inner circulation is delivered to the user.

[0034] 2. As shown in Figure 5 and Figure 6, the side of the polycrystalline silicon solar cell 2 faces upwards and directly absorbs the incident sunlight. The solar selective heat-collecting coating 1.1 deposited on the aluminum strip 1 faces downwards and absorbs the trough-shaped reflection and concentration Sunlight reflected by device 4.

[0035] The foregoing embodiments are only two implementations of the present invention, and are only used to illustrate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com