Process for preparing soybean isoflavone aglycon by microorganism enzyme method

A technology for isoflavone aglycone and soybean isoflavone, which is applied in the field of preparation of soybean isoflavone aglycone from β-glucosidase by microbial enzymatic method, and can solve the problem that filtration equipment and technical conditions are relatively strict, and β-glucoside There are many problems such as many enzyme raw materials and increasing filtration and refining costs, so as to achieve the effect of improving bioavailability and biological activity, filling the gaps in the preparation process, and improving bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

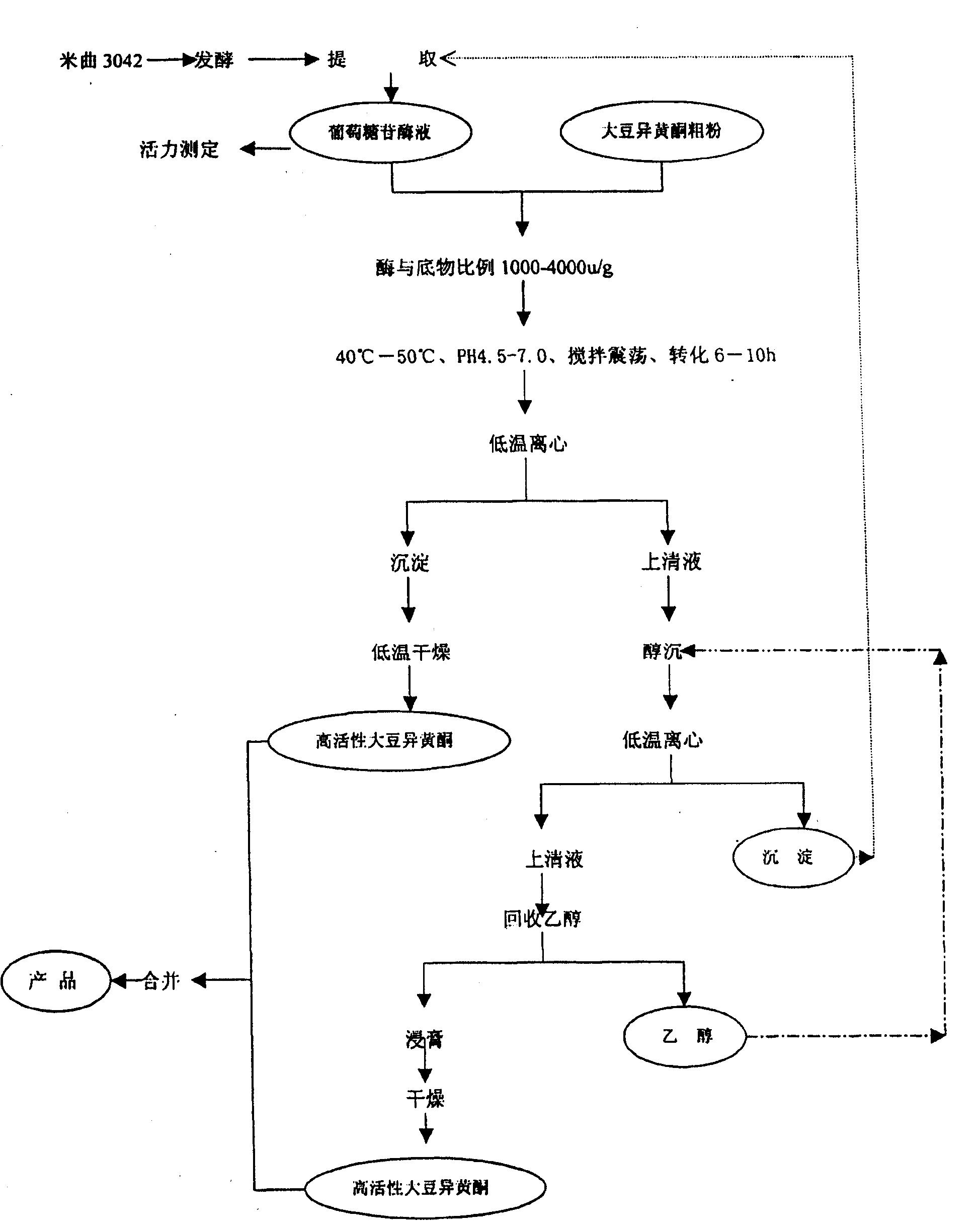

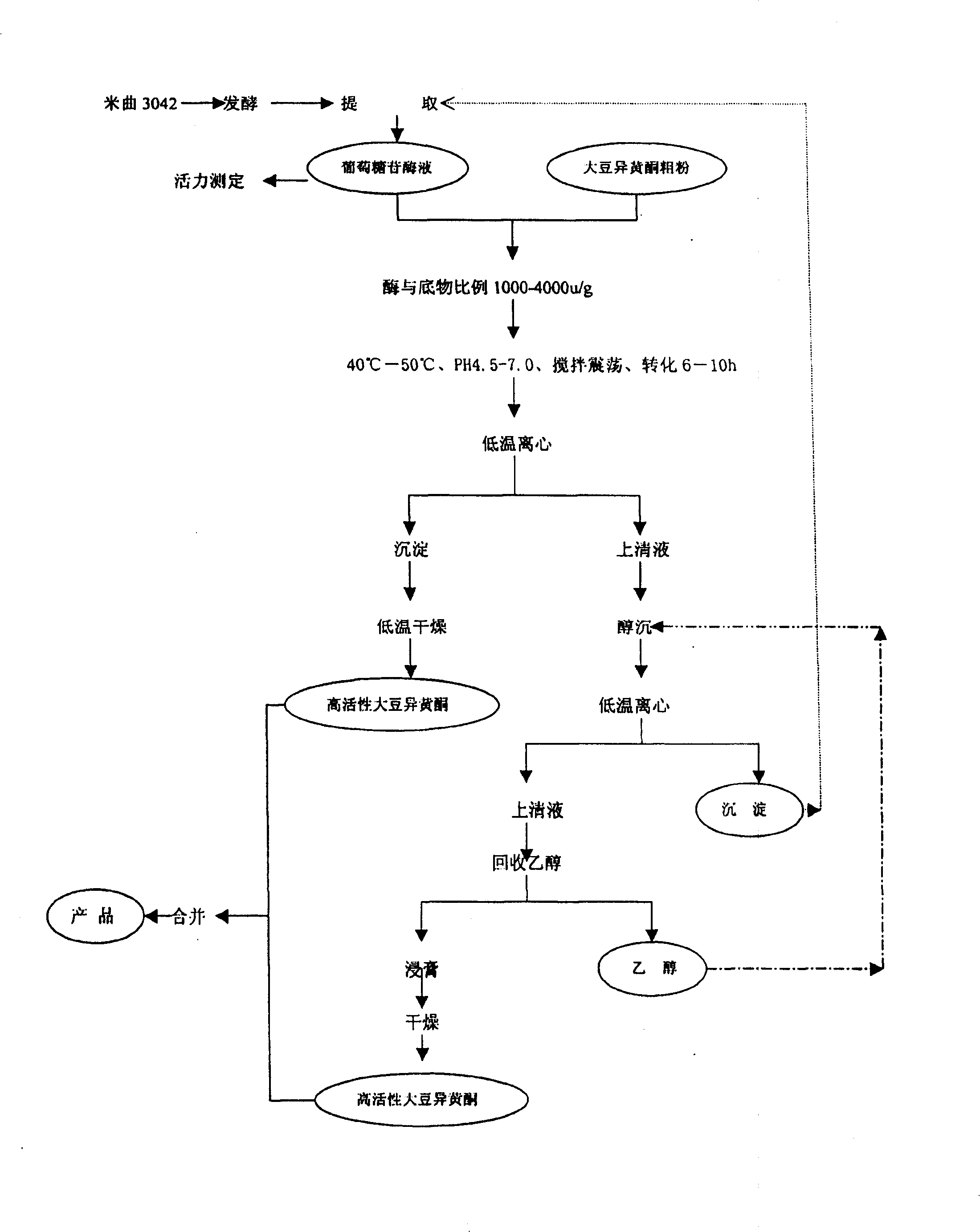

Method used

Image

Examples

Embodiment 1

[0039] Raw materials: 10% daidzein and flavone coarse powder (product of Tianjin Jianfeng Natural Products Co., Ltd.)

[0040] Strain: Aspergillus oryzae 3042 Shanghai Brewing Research Institute

[0041] The preparation method of the slant subculture medium of the strain: PDA medium preparation

[0042] 1. Preparation of β-glucosidase by solid fermentation method and determination of enzyme activity

[0043] (1) Preparation of seed culture medium and strain cultivation thereof:

[0044]Accurately weigh 10.0g of soluble starch, 5.0g of glucose, 0.5g of potassium dihydrogen phosphate, 0.5g of magnesium sulfate, 2.5g of yeast extract, 1.0g of potassium nitrate, dissolve and dilute to 500ml with distilled water, pH6.5, and dispense to 500ml In Erlenmeyer flasks, 80ml per bottle, sterilized at 121°C for 15min. Aseptically operate, pick an appropriate amount of rice koji 3042 spores from the fresh slant, transfer them into the seed medium, and cultivate them at 27°C and 160r / min ...

Embodiment 2

[0064] 1. Prepare soybean isoflavone aglycone by hydrolysis of 5% soybean isoflavone powder

[0065] The enzyme liquid used for hydrolysis is the same as 10% soybean isoflavone powder hydrolysis test: raw material 5% soybean isoflavones (the 10% soybean isoflavone powder that North China Pharmaceutical Co., Ltd. Prepared from defatted soybean flour) Before conversion, the content of daidzein is 3.37%, the content of genistin is 1.12%, the content of daidzein is 1.21%, the content of daidzein is 0.25%, the content of genistein is 0.02%, and the content of glycitein is 0.04%.

[0066] (1) Weigh 100g of 5% soy isoflavones, add 192ml of crude enzyme solution according to the ratio of enzyme to substrate 2300U / g, add distilled water to 1000 (substrate concentration is 0.1g / ml), pH is natural, at a temperature of 45 Under the condition of stirring speed of 180 rpm at ℃, the conversion was carried out for 8 hours, and the reaction was terminated. The enzyme conversion liquid was cent...

Embodiment 3

[0072] 1. Prepare soybean isoflavone aglycone by hydrolysis of 20% soybean isoflavone powder

[0073] The enzyme liquid used for hydrolysis is the same as 10% soybean isoflavone powder hydrolysis test: the raw materials used are 7.98% daidzin content in 20% soybean isoflavone powder (Tianjin Jianfeng Natural Products Co., Ltd.), 9.51% genistin content, soybean Glycoside 2.62%, daidzein 0.72%, genistein 0.61%, glycitein 0.19%.

[0074] (1) Weigh 100g of 20% soy isoflavones, add 250ml of crude enzyme solution according to the ratio of enzyme to substrate 3000U / g, add distilled water to 1000 (substrate concentration is 0.1g / ml), pH is natural, at a temperature of 45 Under the condition of stirring speed of 180 rpm at ℃, the conversion was carried out for 8 hours, and the reaction was terminated. The enzyme conversion liquid was centrifuged at 10000 r / min at 4 °C, and the precipitate was collected at 70 °C. Drying under reduced pressure under the condition of -0.1Mpa, and pulveri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com