Production process for producing tricholoma matsutake mycelium from corn powder fermentation

A production process, corn flour technology, applied in horticulture, application, botanical equipment and methods, etc., to achieve the effects of low cost, increased dry weight of mycelium, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

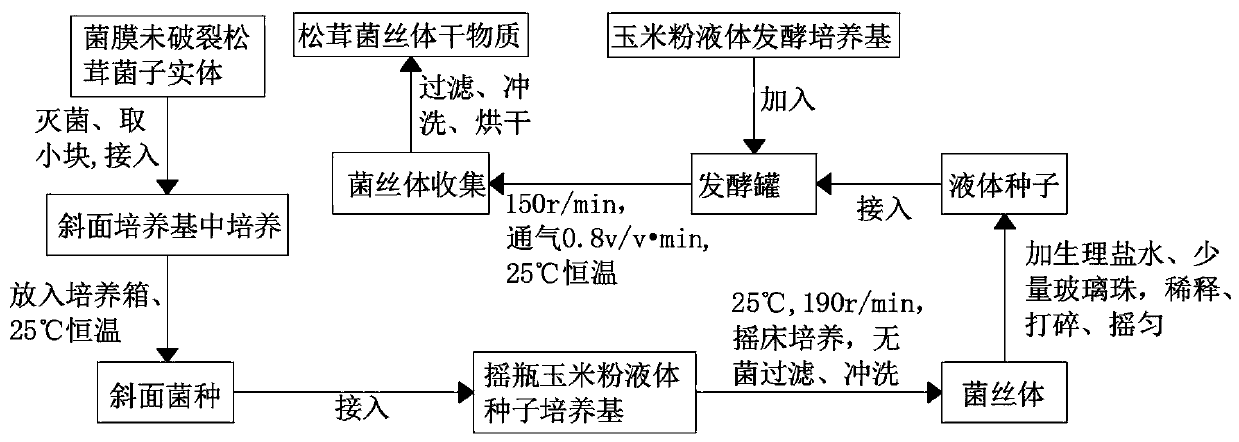

[0034] see figure 1 , a production process utilizing corn flour fermentation to produce matsutake mycelium, comprising the following steps:

[0035] 1. Strain cultivation on slant: Take matsutake sporocarp that has not broken the bacterium film, and after repeated surface sterilization with 70% ethanol by mass, remove a small piece with sterile tweezers and a knife, and insert it into the slant medium Seal it well, put it in an incubator, and cultivate it under a constant temperature condition of 25°C. After the mycelium grows all over the slope, it will be transferred to the next step of cultivation;

[0036] 2. Liquid seed culture: insert the slant bacterial classification cultivated in step 1 into the corn flour liquid seed medium in a shaker bottle, cultivate it on a shaker at 25° C. for 8 days at 190 r / min, filter aseptically to obtain mycelium, and use Rinse with sterile water, add four times the volume of normal saline and a small amount of glass beads to dilute, smash...

experiment example 1

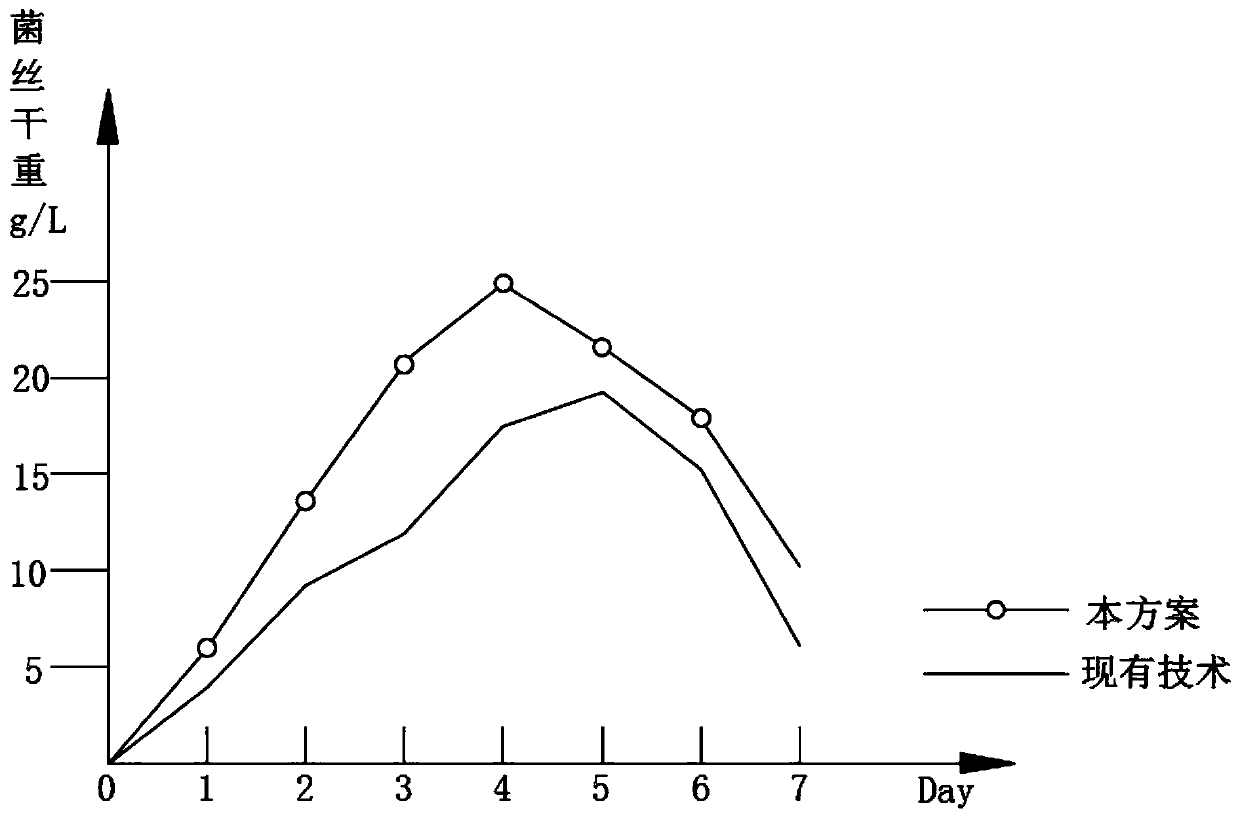

[0049] Experimental example one: according to the mycelia fermentation method in the embodiment one of this program and the mycelia fermentation method in the prior art, get the matsutake mycelia of one week and carry out mycelium dry weight experiment contrast, obtain figure 2 middle data;

[0050] Depend on figure 2 It can be seen that after 1 day of fermentation in this scheme, the dry weight of mycelia in this scheme tends to increase in the first four days, and the dry weight of mycelium in this scheme reaches the highest value on the 4th day, and the dry weight of mycelia at this time is 24.88g / L, after the 6th day of fermentation, the dry weight of the mycelium began to decrease significantly. From this, it can be seen that matsutake bacteria began to grow in several phases on the second day of fermentation, and all indicators increased rapidly, and the metabolism was very active. After reaching the maximum value, matsutake bacteria The growth and metabolism are rel...

experiment example 2

[0053] Experimental example 2, take the same size about 2cm 2 5 pieces of bacterium block, respectively numbered as A, B, C, D, E, cultivate respectively by the method for embodiment one, and get the mycelia of the 4th day and carry out dry matter weight measurement, the result is as follows:

[0054] Experimental example A B C D E Mycelium dry matter yield (g / L) 25.03 24.82 24.95 24.91 24.97

[0055] It can be seen from the above table that the highest yield of mycelium dry matter fermentation produced by this process is above 24.82g / L, while the dry matter yield of mycelium in the prior art is only about 18g / L, so compared with the existing The production process of mycelium dry matter of the technology has been significantly improved. It can be seen that the present invention is suitable for the fermentation and cultivation of matsutake fungus. The yield of mycelium dry matter is stable and the output is high, and it can be produced on a large s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com