Starch production technology

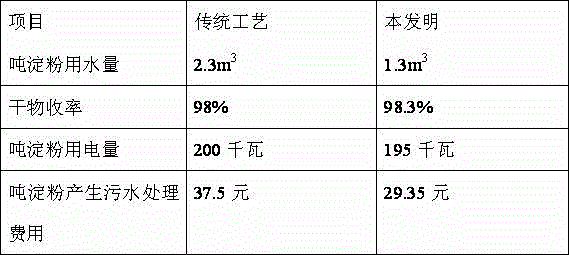

A production process and starch technology, applied in the field of food processing, can solve the problems of increased power consumption, water consumption, large amount of production, burden on sewage treatment plants, etc., and achieve the effect of reducing power distribution power load, lightening load and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with specific embodiment, further illustrate the present invention.

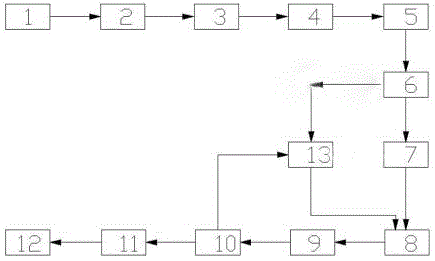

[0016] A starch production process, with purification, soaking, crushing, germ separation, fine grinding, fiber separation, protein separation, starch washing, refining, dehydration, drying, packaging, recycling, raw corn is sent to corn drum sieve for purification and impurity removal, The purified raw corn is put into the corn mixing box and mixed with dilute corn steep liquor, and then sent to the soaking tank for soaking. Crushing, germ separation, the thin corn steep liquor obtained after crushing, after fine grinding, is sent to the pressure curved sieve, and the fiber separation and coarse starch milk separation are carried out through the pressure curved sieve, and the remaining fine corn steep liquor is obtained by evaporating and concentrating Concentrated corn steep liquor is sold, and steam is condensed to obtain corn steep liquor soda, which is sent to the recycling s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com