Method and device for dehydrating and rectifying dichloromethane in production of acesulfame potassium

A technology of acesulfame potassium and dichloromethane, which is applied in chemical instruments and methods, preparation of halogenated hydrocarbons, disproportionation separation/purification of halogenated hydrocarbons, etc., can solve problems that are difficult to meet industrial production, low purity of dichloromethane, Color deepening and other issues, to achieve the effect of high degree of automation, large processing capacity, and light color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

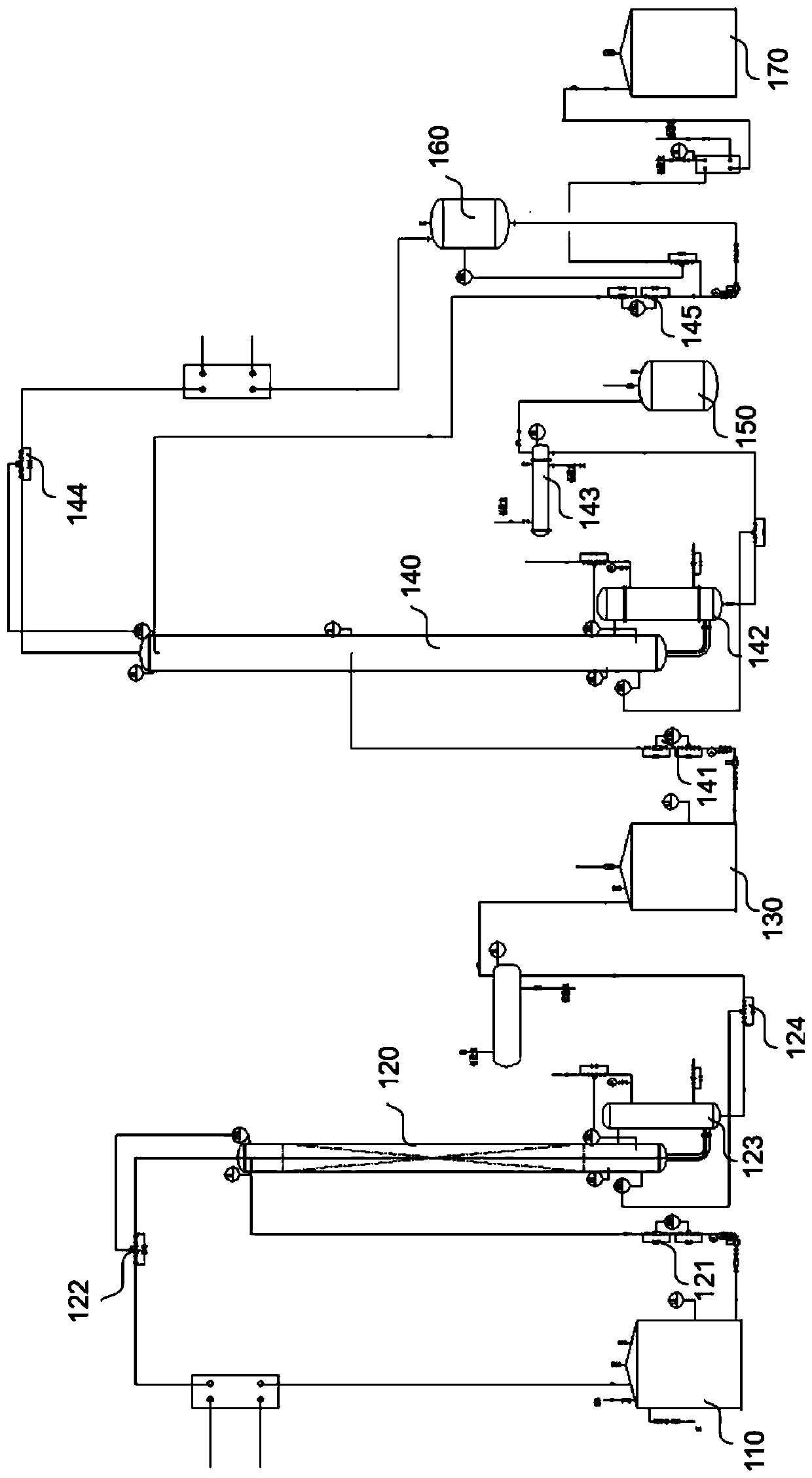

Image

Examples

Embodiment

[0031] 1. Open the discharge valve of the raw material storage tank, start the methylene chloride feed pump, feed the material into the dehydration tower to about 2 / 3 of the liquid level gauge at the bottom of the tower, and the feed flowmeter controls the opening of the feed valve.

[0032] 2. A temperature control instrument is installed at the bottom of the dehydration tower, and the bottom temperature is set to be controlled at 45-65°C. The signal of the temperature control instrument is sent to the opening of the steam inlet regulating valve of the reboiler at the bottom of the dehydration tower, and the inlet steam pressure is 0.05-0.2Mpa, so that The column is maintained at a constant temperature.

[0033]3. The dichloromethane and water at the bottom of the tower are vaporized and moved up to the top of the tower under the action of steam, and exchange heat with the top dichloromethane raw material. The mixed gas is cooled by the gas phase outlet at the top of the dehyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com