Method for producing natural bamboo fibers

The technology of a kind of raw bamboo fiber and production method is applied in the production of fiber and the field of production of raw bamboo fiber, which can solve the problems of not forming a perfect technical system, adverse effects on health and environment, and backward productivity, so as to achieve good health and controllable production Good performance and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

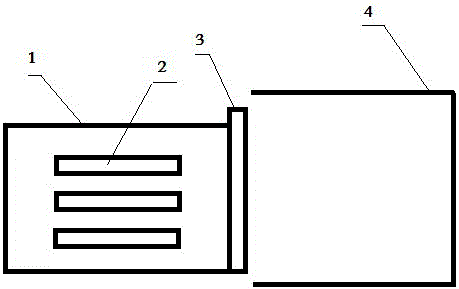

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0015] Such as figure 1 Shown, a kind of production method of raw bamboo fiber, comprises the following steps:

[0016] A. Clean the bamboo surface with running water, and then split it into bamboo pieces along the fiber direction;

[0017] B, the bamboo chips that step A is made are put into metal airtight container, add the pure water of 5% of metal airtight container volume in metal airtight container, then give metal airtight container pressurization to 2 Pa, be heated to 130 ℃, make Rapid carbonization of bamboo chips;

[0018] C. After heating and pressurizing the metal airtight container in step B for 30 minutes, quickly open the gate on the right side of the metal airtight container to release the pressure instantly, and the bamboo chips in the metal airtight container will rush out of the metal airtight container under pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com