A nitrogen-doped graphene-confined Pt nanocomposite material and its preparation method and application

A technology of nitrogen-doped graphene and nanocomposite materials, applied in separation methods, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as fuel cell electrode poisoning, achieve increased electron density, simple preparation methods, The effect of mature production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

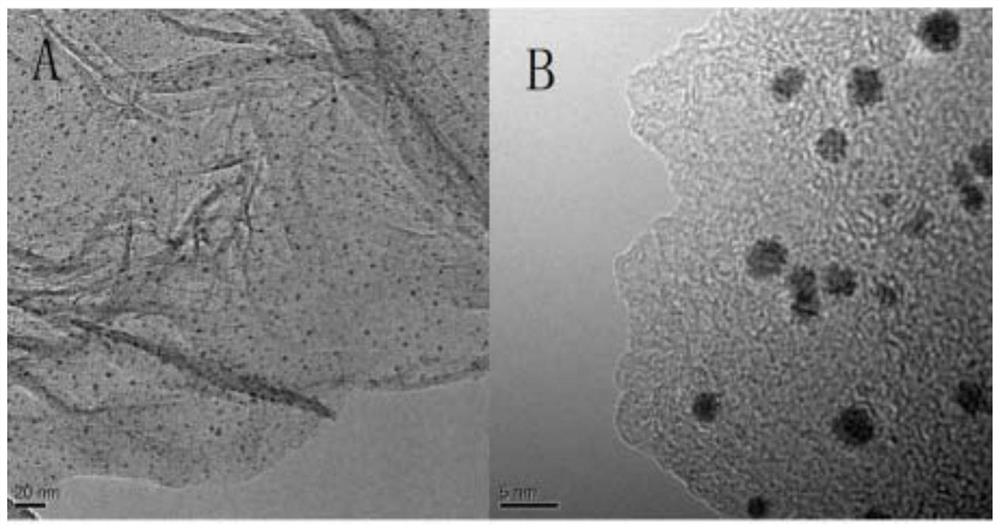

[0026] Example 1 Preparation of a nitrogen-doped graphene-confined Pt nanocomposite CN@Pt / GO

[0027] (1) The preparation method is as follows:

[0028] 1. Preparation of Pt / GO

[0029] Weigh 200mg of graphene, put it into 40mL of ethylene glycol solution, and ultrasonicate for 3-10min to make the graphene evenly dispersed. Then add 1.325mL chloroplatinic acid solution, adjust the pH of the mixed solution to 12, react at a constant temperature of 130°C for 3h, cool to room temperature after the reaction, adjust the pH of the mixed solution to 3, filter the precipitate and wash it with deionized water, and place it in 60- Dry overnight in an oven at 70°C to obtain graphene-supported Pt nanoparticle composites, denoted as Pt / GO.

[0030] 2. Preparation of CN@Pt / GO

[0031] 1) Put 50mg Pt / GO in the alumina crucible, put 0.5mL acetonitrile in the porcelain boat, put Pt / GO and acetonitrile into two tube furnaces at the same time, and the two tube furnaces are connected by quartz...

Embodiment 2

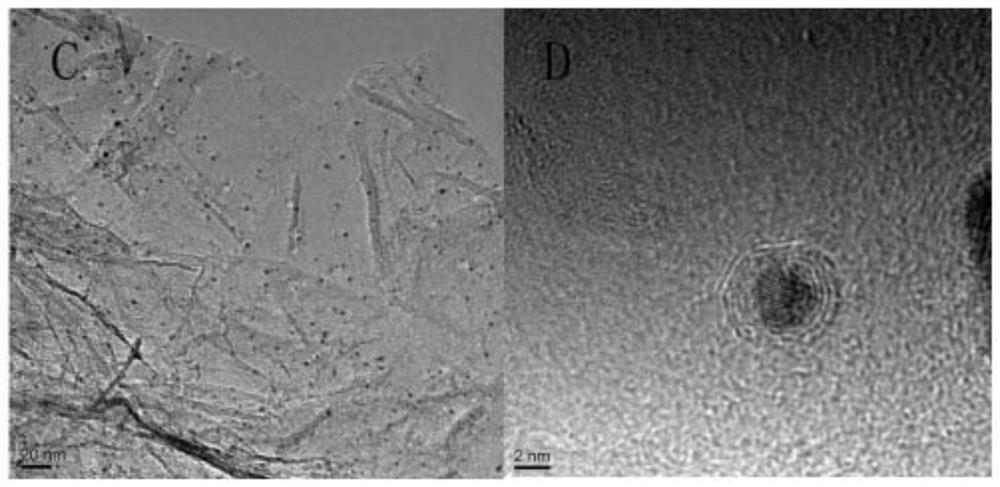

[0035] Example 2 Application of CN@Pt / GO in catalytic CO oxidation reaction

[0036] Methods as below:

[0037] 1) Place CN@Pt / GO in H 2 atmosphere, H 2 The flow rate is 30mL / min, and the in-situ reduction is performed at 200°C for 1h.

[0038] 2) In the reaction vessel, 50 mg of CN@Pt / GO after in situ reduction treatment was added as a catalyst, and the process was carried out in a temperature-programmed manner under ambient pressure with a heating rate of 2°C / min. With He as the balance gas, the gas reactant contains 1vol% CO and 1vol% O 2 , passed into the reaction vessel containing the catalyst at a flow rate of 15mL / min, and catalyzed the oxidation of CO to CO at a temperature of 30-200°C under ambient pressure 2 . As a comparison, Pt / GO is added as a catalyst in another reaction vessel, the method is the same as above, and the oxidation of CO to CO is catalyzed. 2 .

[0039] 3) Detection, reactants and products were analyzed online by gas chromatography (Agilent 789...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com