Assembly machine for venting cap of disposable cell culture flask

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

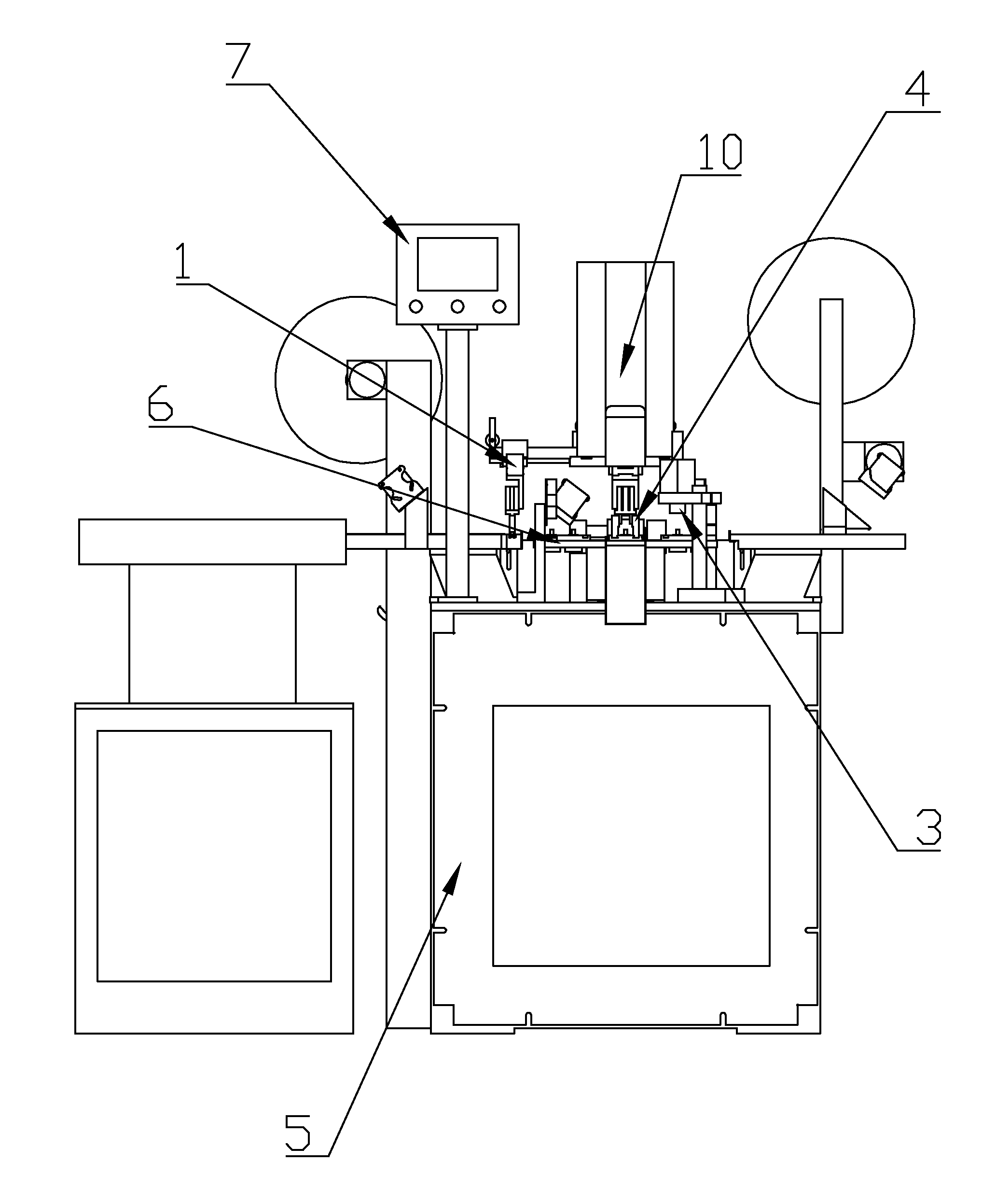

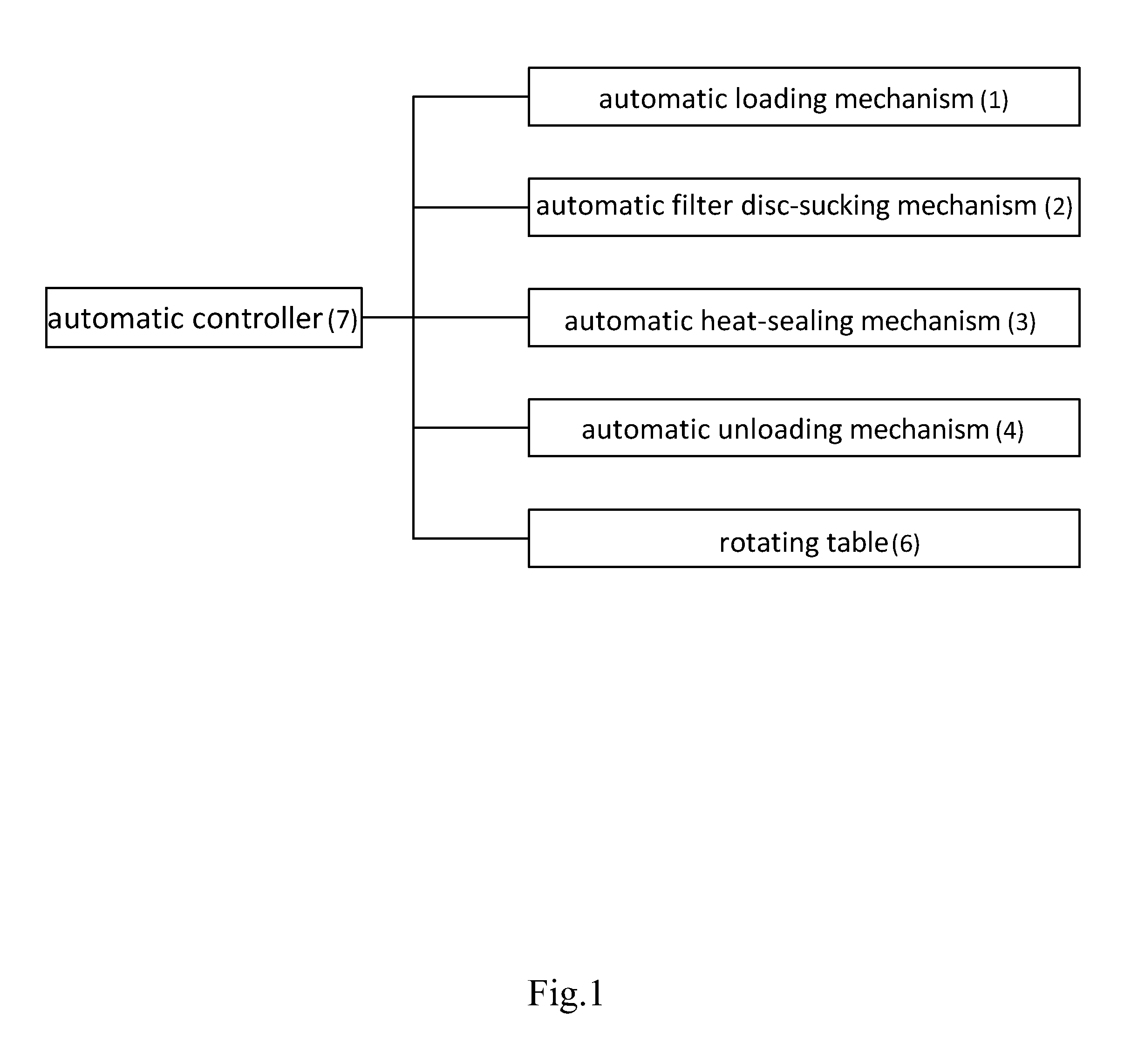

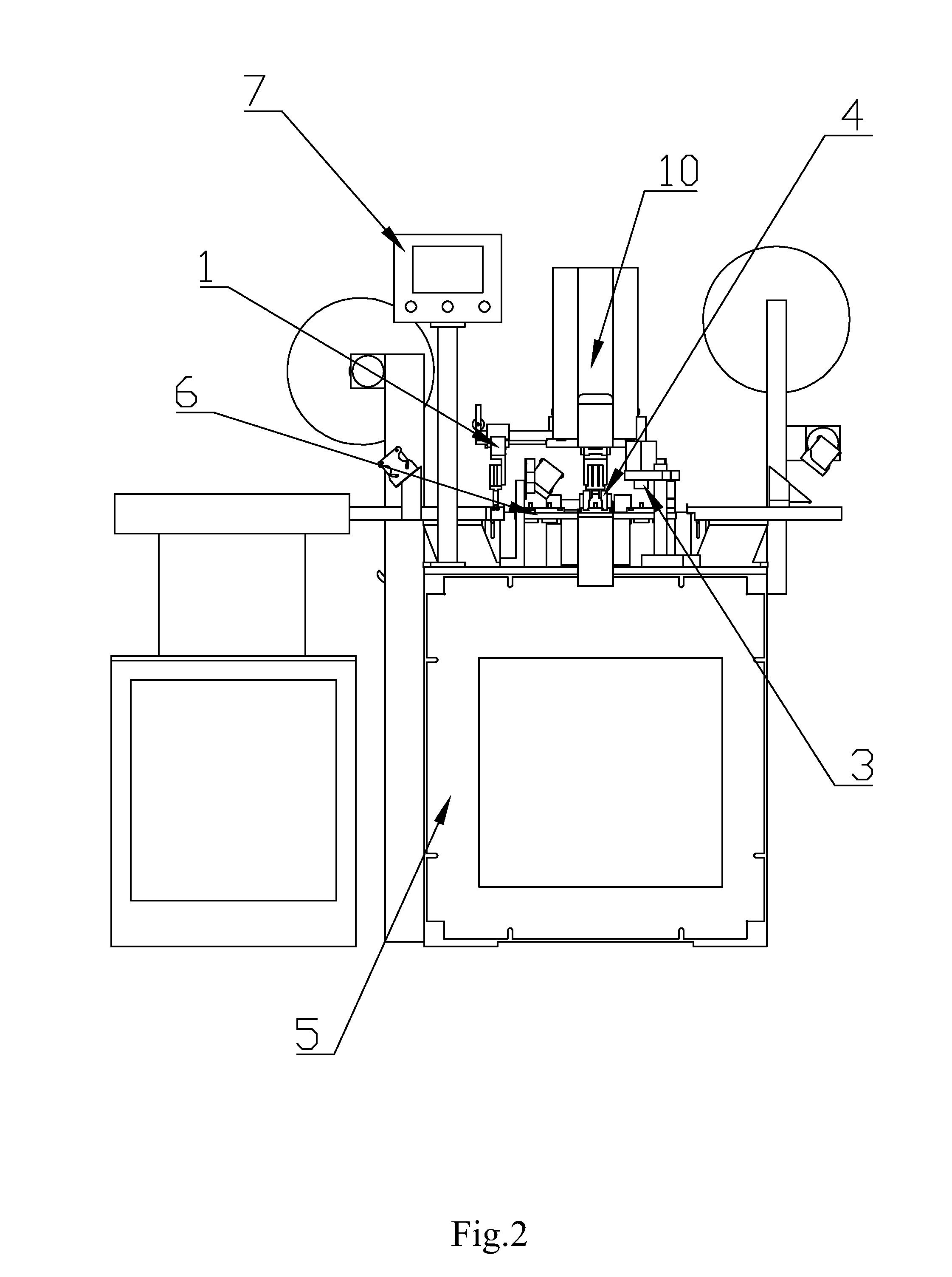

[0024]Referring to FIG. 1 to FIG. 8, an assembly machine for venting cap of disposable cell culture flask, comprising a rack 5, an automatic controller 7 and a rotating table 6 arranged on the rack 5, wherein an automatic loading mechanism 1, an automatic filter disc-sucking mechanism 2, an automatic heat-sealing mechanism 3, and an automatic unloading mechanism 4 are arranged above the rotating table 6; and the automatic controller 7 is electrically connected with the rotating table 6, the automatic loading mechanism 1, the automatic filter disc-sucking mechanism 2, the automatic heat-sealing mechanism 3, and the automatic unloading mechanism 4.

[0025]By means of the automatic loading mechanism 1, the automatic filter disc-sucking mechanism 2, the automatic heat-sealing mechanism 3 and the automatic unloading mechanism 4 as well as the automatic controller 7 and related control circuit adapted thereto, and with the control of automatic controller 7 to the automatic loading mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com