Insertion piece for wind turbine blade root

A technology of wind turbines and wind blades, which is applied in the field of inserts, can solve the problem of no effect on material consumption, and achieve the effects of reducing raw material costs, automating production processes, and reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The invention will now be described in detail with reference to the accompanying drawings showing an embodiment of a root insert according to the invention and an embodiment of a wind turbine blade root comprising a plurality of such root inserts of the invention.

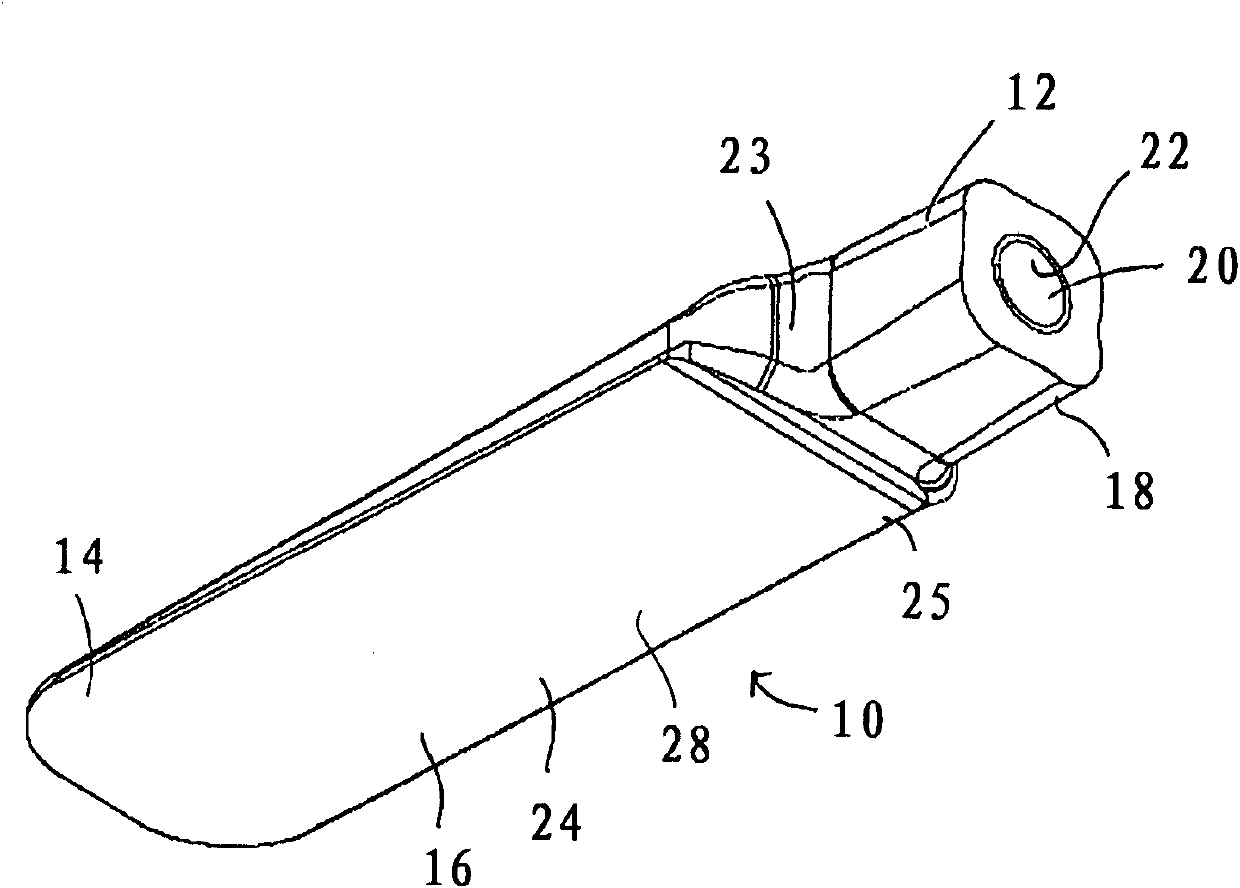

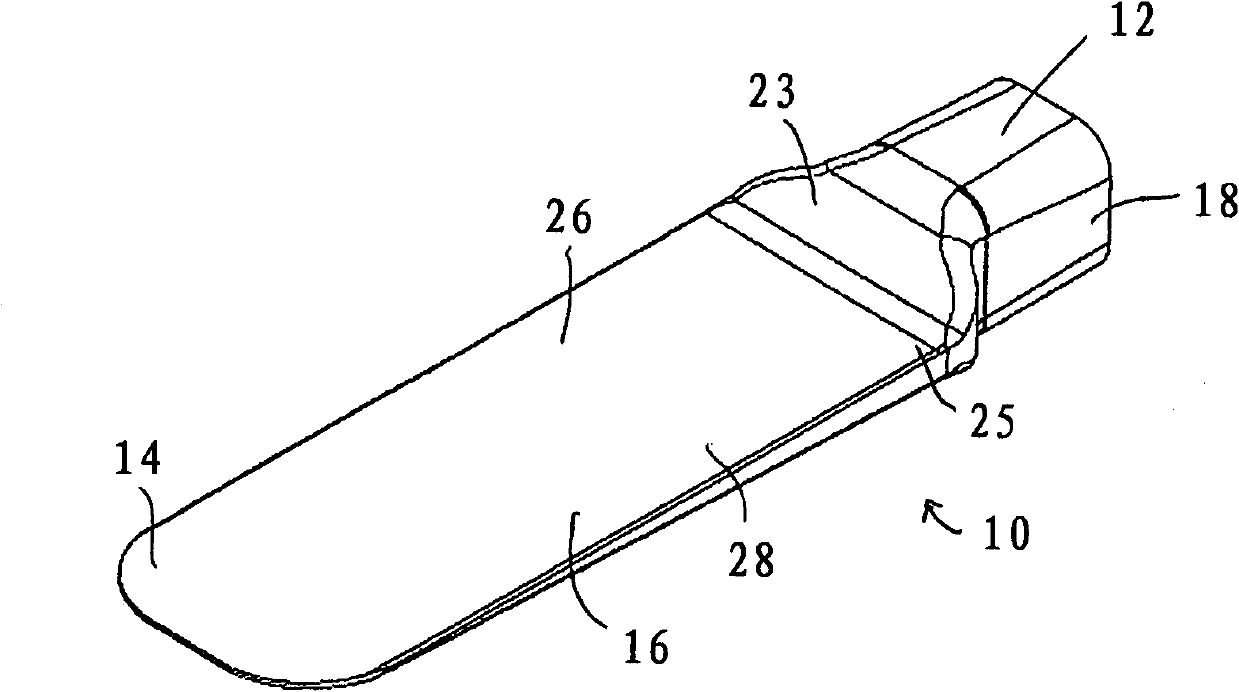

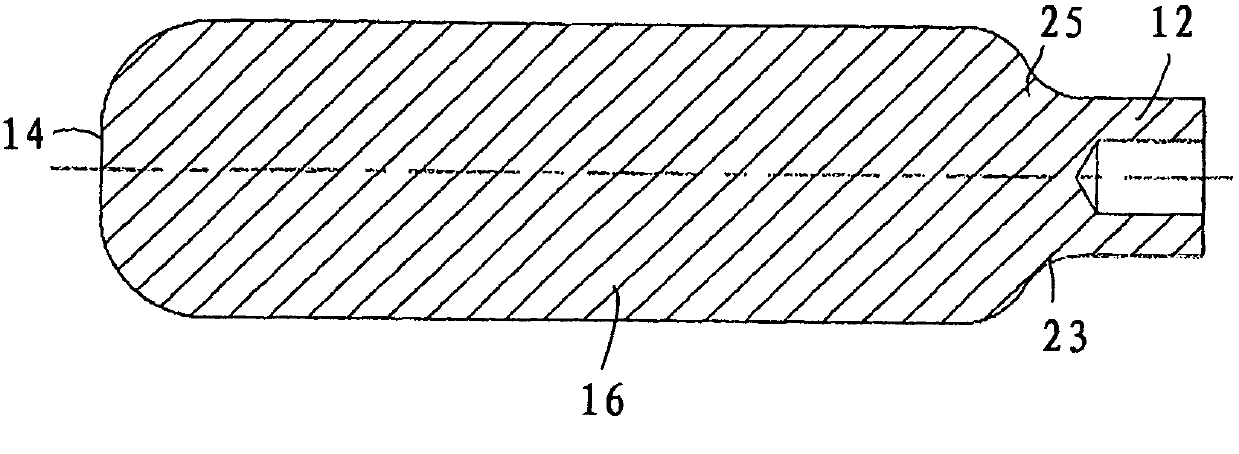

[0051] First, refer to figure 1 and figure 2 , which show a perspective view of a root insert 10 for a wind turbine blade root from two opposite sides and two opposite ends respectively, image 3 and Figure 4 show respectively figure 1 Two mutually perpendicular cross-sectional views of the insert.

[0052] The root insert 10 includes an enlarged connecting portion 12 at a proximal end 18 of the root insert 10 and a flattened wedge portion 16 at a distal end 14 of the root insert 10 . The enlarged connecting portion 12 extends transversely with respect to a longitudinal axis extending between the proximal end 18 and the distal end 14 to provide a substantial width in a direction perpendicular to the long...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com