Method for preparing clutch facing blanks by adopting glue squeezing device

A clutch surface and rubber technology, applied in the direction of coating, etc., can solve the problems affecting product quality, loose combination of rubber and skeleton fiber bundles, etc., to avoid the use of rubber solvents, stable product quality, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

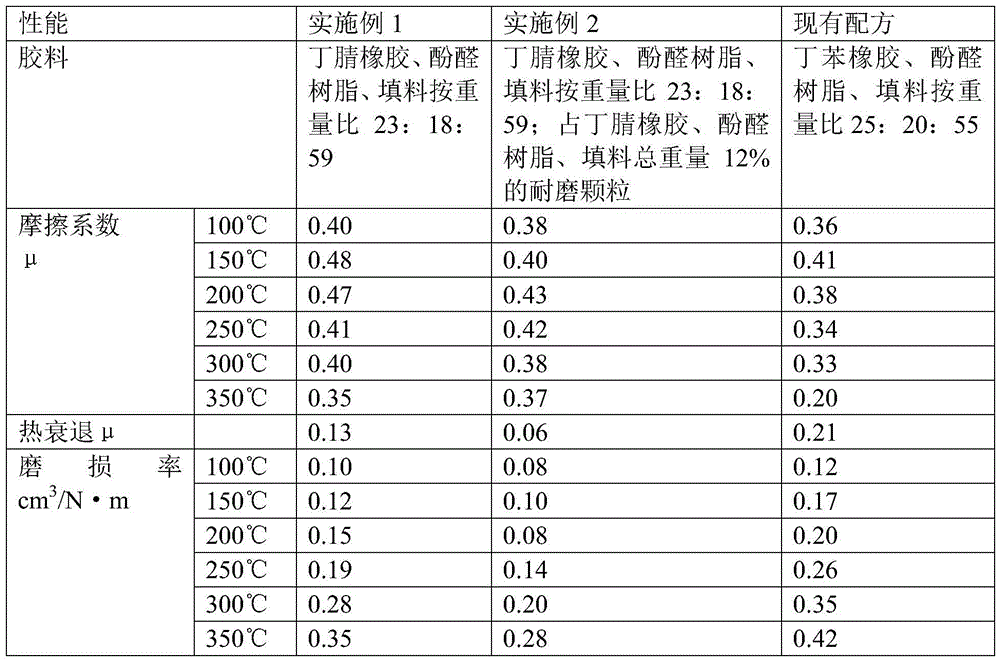

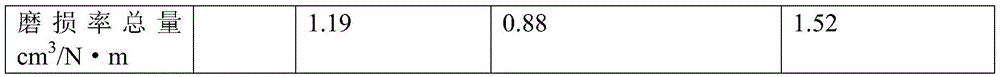

Embodiment 1

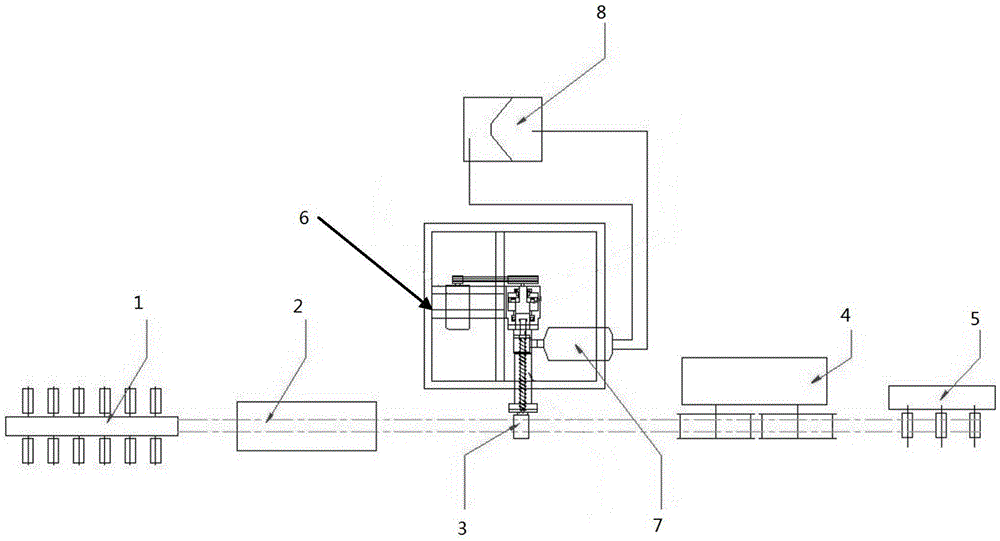

[0030] A device for continuously producing clutch face blanks, such as figure 1 As shown, the device includes a skeleton fiber bundle pay-off frame 1, a tight flow line and a wire splitting wheel 2, a glue extruder 6, a tractor 4 and a winder 5 placed in sequence, and an extrusion head is installed on the glue extruder 3. The extrusion head of the extruder is provided with 3-5 extrusion holes, and the skeleton fiber bundles used to produce the clutch face are installed on the skeleton fiber bundle pay-off frame, and the free ends of the skeleton fiber bundles are passed through the tight flow The wire series and the splitting wheel pass through the extrusion head of the rubber extruder, and then are tightened by the tractor, and finally fixed on the winder; a hopper 7 is installed on the rubber extruder, and the rubber material is placed in the rubber particle storage box in advance , transported to the hopper via the rubber conveyor 8.

[0031] A method for preparing a clutc...

Embodiment 2

[0037] A method for preparing a clutch face blank by using the above-mentioned device, the specific process is the same as in Example 1, the difference is that: wear-resistant particles are added to the basic formula of the rubber, and the wear-resistant particles account for nitrile rubber, phenolic resin, filler 12% of three kinds of raw material gross weights, the formula of wear-resistant particle is as follows (mass fraction): the formula of shown wear-resistant particle is magnesium oxide 5%, zirconium dioxide 3%, rice husk charcoal powder 20%, fly ash 45% %, boron carbide 1.5%, antimony sulfide 5%, liquid rosin resin 3.5%, carboxylated nitrile latex 17%, total 100%. The production method of rice husk charcoal powder is as follows: put the clean rice husk at 280°C and slowly raise the temperature to 560°C at a heating rate of 5°C / min, and accelerate the heating at 560°C to 680°C at a heating rate of 10°C / min. Incubate at 680°C for 1-1.2 hours.

[0038] The preparation m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com