Clamping unit for containers on container handling machines

一种处理装置、容器的技术,应用在标记非刚性容器、包装、运输和包装等方向,能够解决竖直位置依赖等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

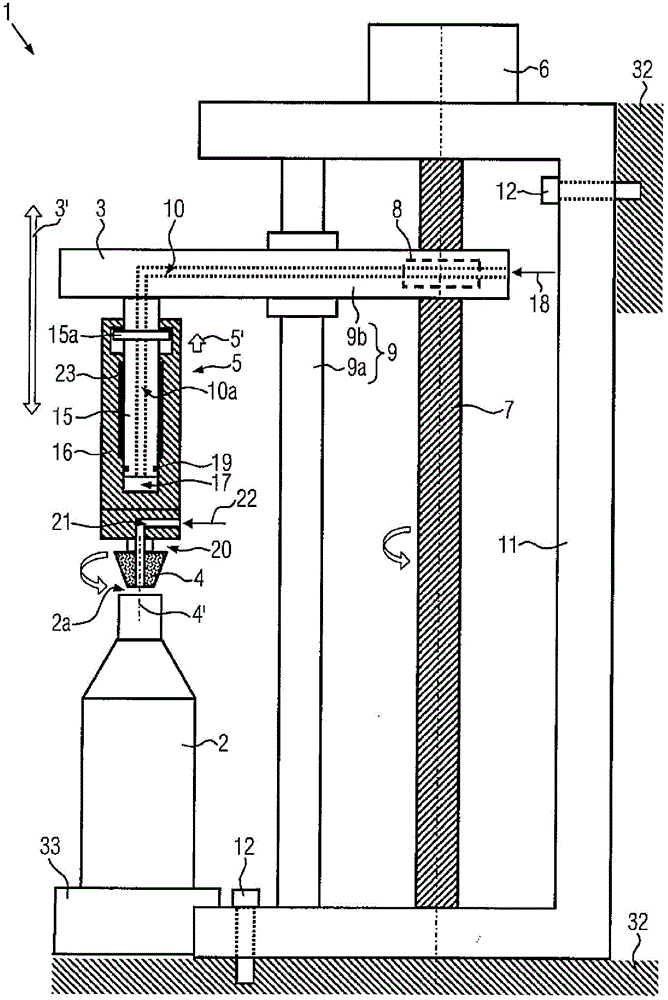

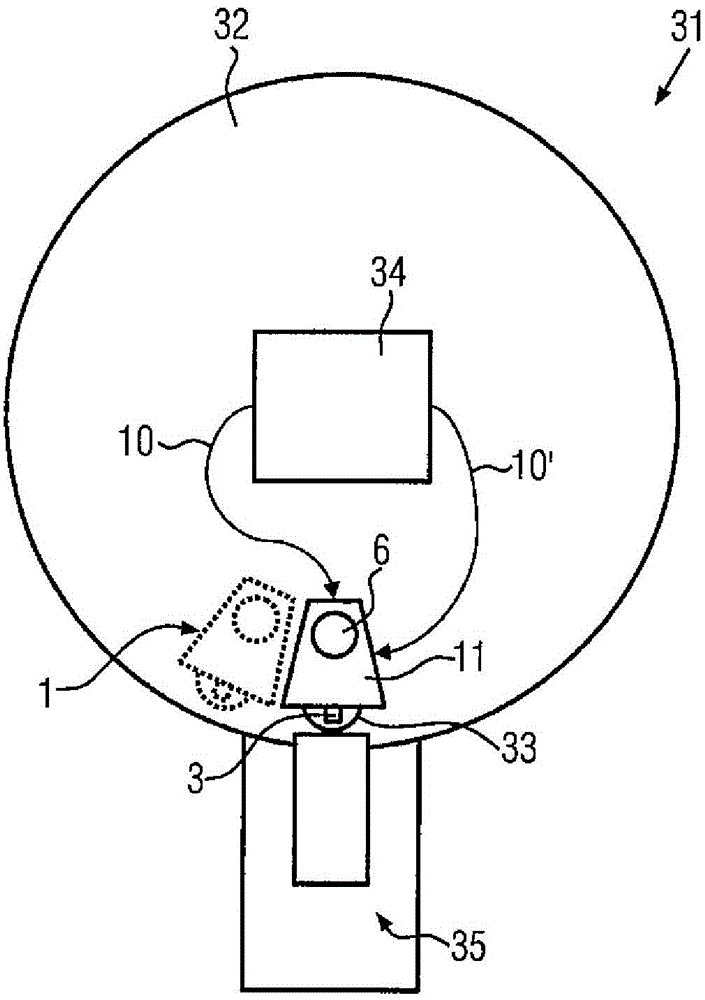

[0024] Such as figure 1 As shown, a preferred embodiment of the gripping unit 1 of the invention for a container 2 comprises a lifting arm 3 which is displaceable in a vertical direction 3', in particular linearly in a vertical direction 3', The lifting arm 3 carries a centering support 4 , which preferably rotates about an axis 4 ′, by means of which the container 2 can be gripped from above. For example, the centering support 4 cooperates with the mouth area 2 a of the container 2 . The centering support 4 may also have a bell-like design in order to grip a closed container from above by holding it from the outside (not shown).

[0025] The centering support 4 is elastically mounted at the lifting arm 3 in the vertical direction by means of a pneumatic spring 5 . From figure 1 From the shown rest position of the centering support 4 not in contact with the container 2 , the centering support 4 can perform a relative movement upwards relative to the lifting arm 3 against th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com