Stitchless seam arrangement of sportsball and manufacturing method thereof

a manufacturing method and sportsball technology, applied in the field of sportsball, can solve the problems of inherently two different components, inability to produce sportsballs in large quantities in a relatively short period of time, and high cost of final assembling operation of sportsball, so as to reduce the time-consuming manufacturing procedure of sportsball and simplify the final assembling operation. , the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

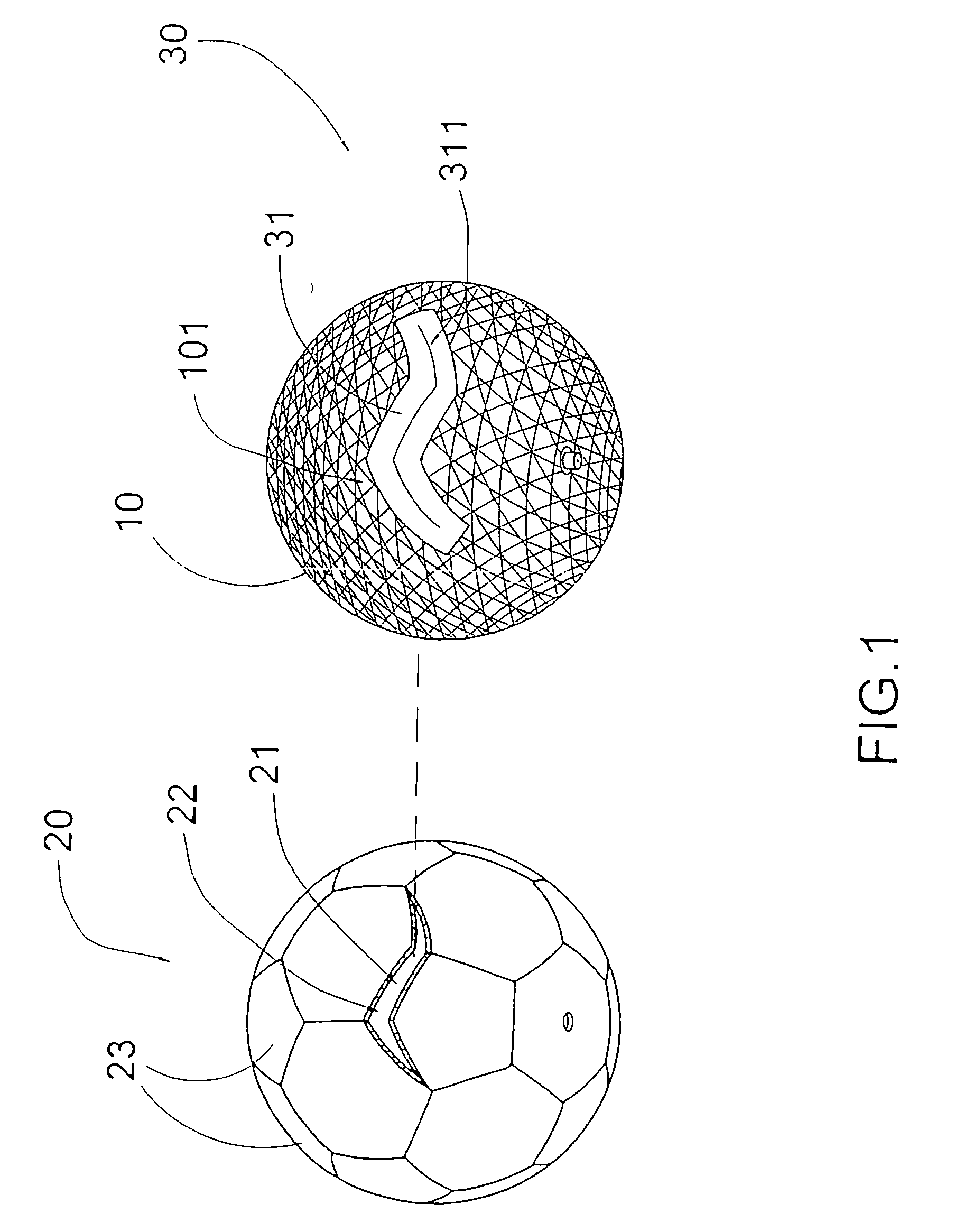

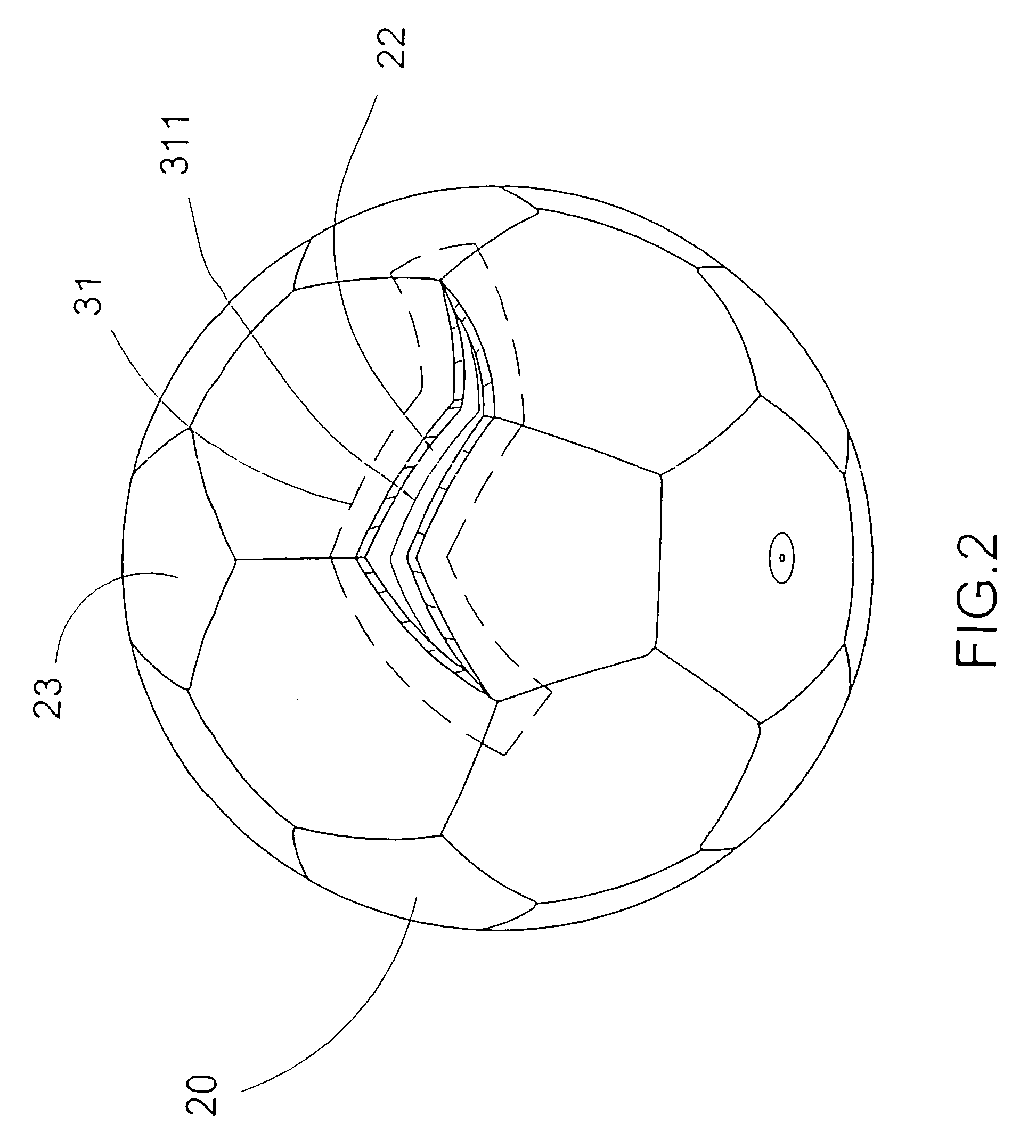

[0037]Referring to FIGS. 1 to 4 of the drawings, a sportsball and its manufacturing method according to the present invention are illustrates, wherein the sportsball, such as a soccer ball, is a stitching type sportsball and comprises an inflatable ball body 10, and a ball carcass 20 having a ball cavity 21 and an opening 22.

[0038]The ball body 10 is disposed in the ball cavity 21 through the opening 22 for propping up the ball carcass 20 after inflation. As shown in FIGS. 1 and 3, the ball body 10 comprises an inflatable bladder 11 for being popped by air inflation via a valve stem and an exterior web layer 12, which is integrally attached on an outer surface of the lo inflatable bladder 11, comprises at least an elongated winding thread 121 evenly wound around the outer surface of the inflatable bladder 11 such that the web layer 12 embraces the inflatable bladder 11 for resisting stress and impact force applied to the inflatable bladder 11. Accordingly, the purpose of the thread ...

second embodiment

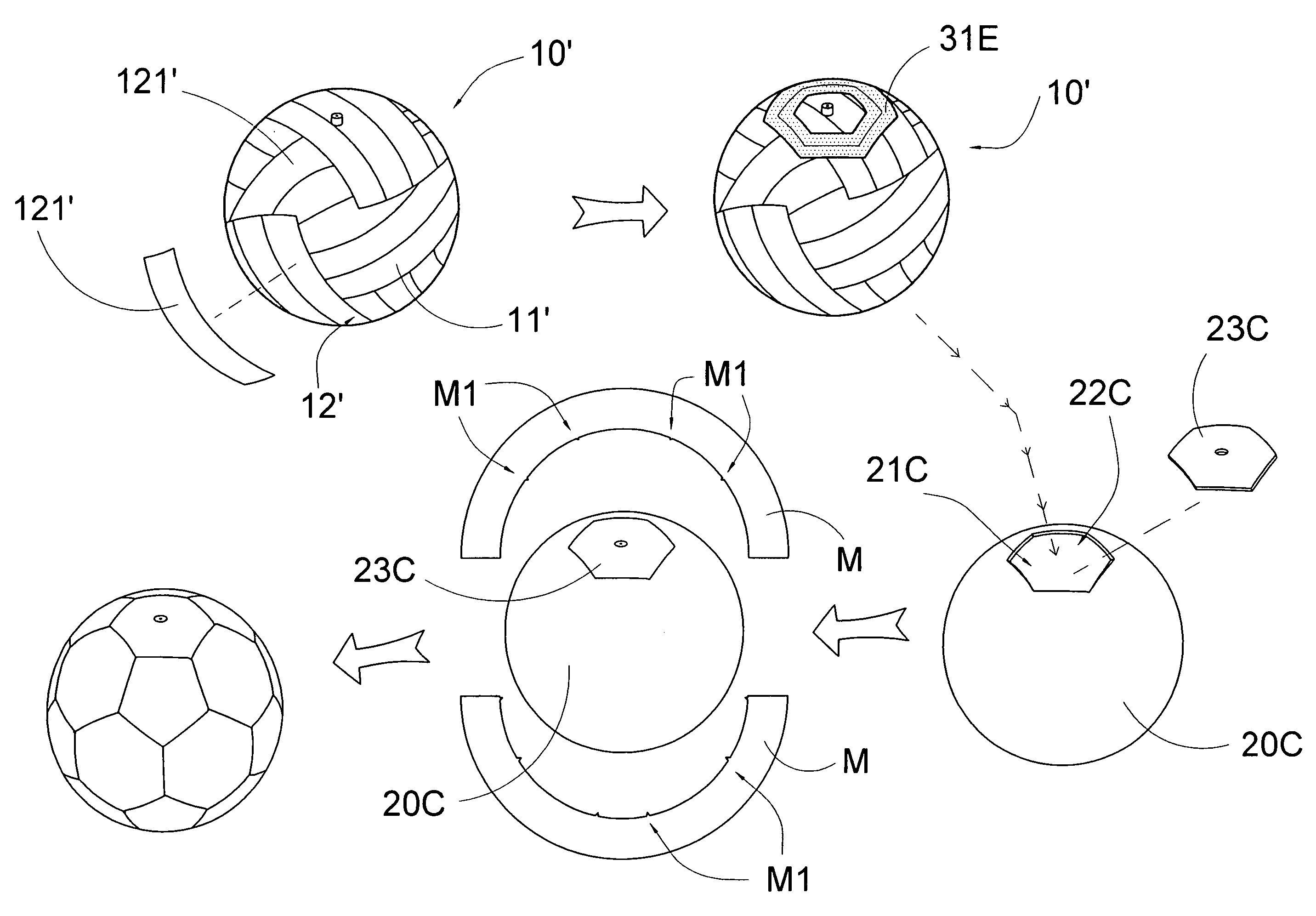

[0074] the adhesive layer 31′ is provided at a closing area 101′ of the ball body 10′, wherein the closing area 101′ is an area on the outer surface of the ball body 10′ that when the ball body 10′ is disposed in the ball carcass 20′, the closing area 101′ is facing towards the opening 22′ of the ball carcass 20′. In particularly, the adhesive layer 31′ is a rubber strip pre-applied on the outer surface of the ball body 10′ to form a hexagonal contour matching with the hexagonal contour of the opening 22′. After the ball body 10′ is disposed in the ball carcass 20′, the adhesive layer 31′ is aligned with the opening 22′ of the ball carcass 20′. Therefore, the edge portions of the opening 22′ are adhered on the outer surface of the ball body 10′ through the rubber strip after heat treatment.

[0075]It is appreciated that the adhesive layer 31′ is extended throughout the entire ball body 10′, as shown in FIG. 5, wherein the adhesive layer 31′ is provided on the ball body 10′ along the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com