A packing sealing mechanism for a reciprocating compressor

A packing seal and compressor technology, which is applied in the direction of engine seal, machine/engine, liquid displacement machinery, etc., can solve the problems of reduced sealing capacity and short service life of packing seal, so as to reduce packing seal pressure and prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

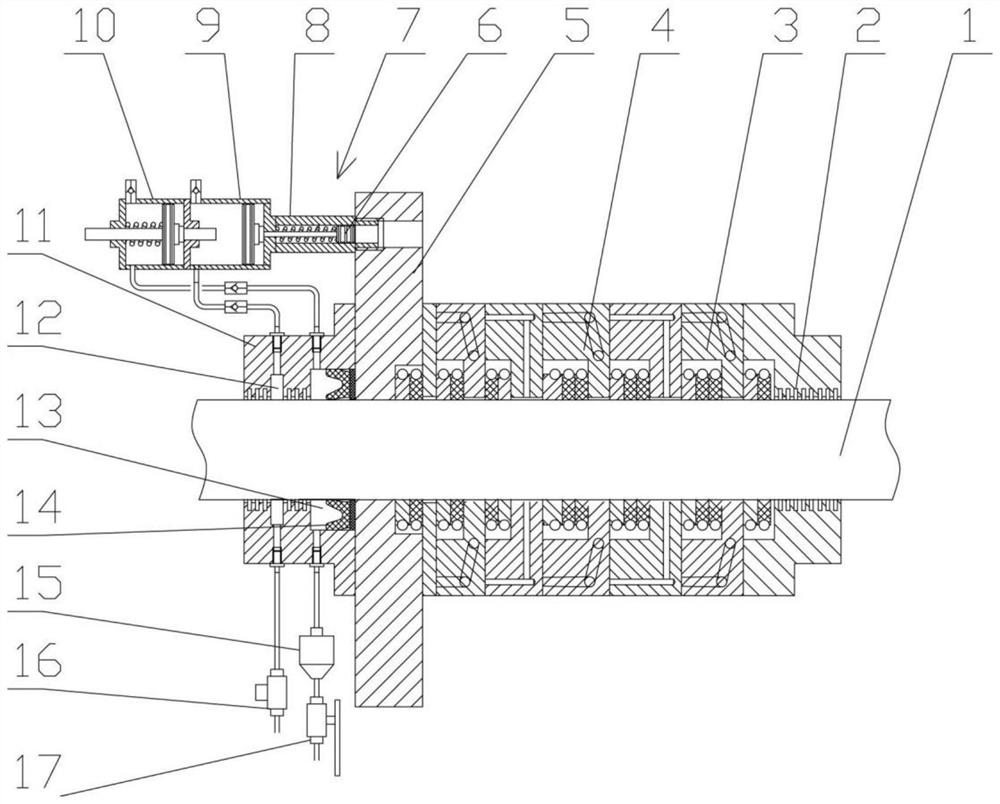

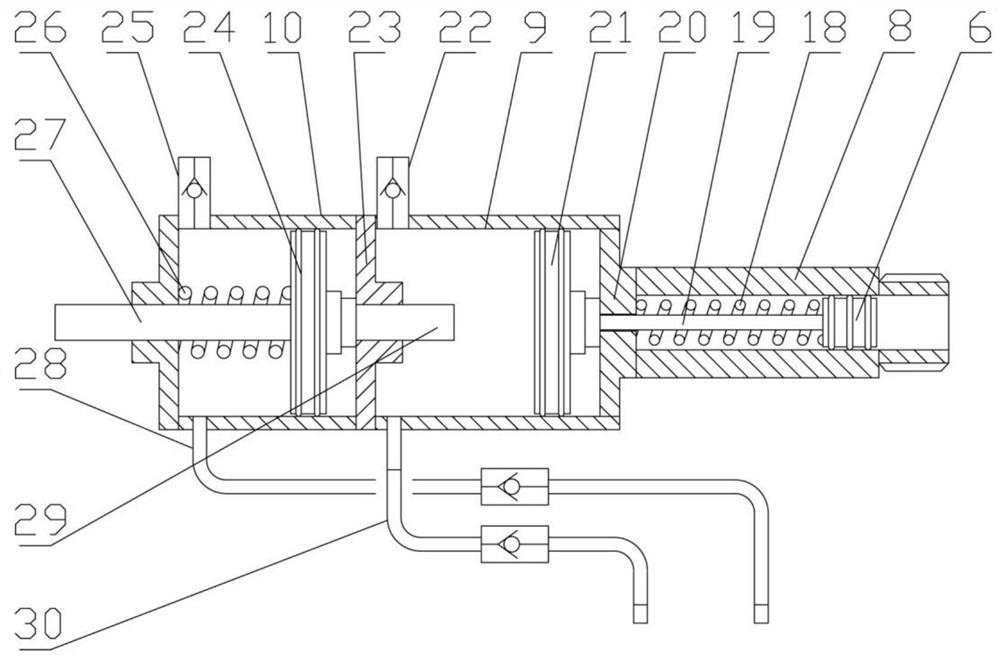

[0015] as Figure 1 and 2 As shown, a reciprocating compressor packing sealing mechanism, comprising a packing sealing ring 4 and a pressure reduction ring 3, the pressure reduction ring 3 is provided with a first labyrinth sealing ring 2 at one end. Through the first labyrinth sealing ring 2, the sealing pressure difference of the rear dynamic packing sealing ring 4 can be reduced, thereby effectively improving the sealing pressure difference capacity of the packing and improving the adaptability of the compressor to various working conditions.

[0016] In the packing sealing ring 4 at the rear end is provided with a second labyrinth sealing ring 11, the second labyrinth sealing ring 11 is provided with a groove 12, in the compressor block 5 is connected to the intake sleeve 8, the intake sleeve 8 is connected to the first supercharging sleeve 9 at one end, the inner diameter of the first supercharging sleeve 9 is greater than the inner diameter of the intake sleeve 8, the intake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com