An adjustable oil receiving plate device and control method thereof

An oil receiving plate, adjustable technology, applied in transmission parts, gear lubrication/cooling, belt/chain/gear, etc., can solve the problem of increasing the sealing pressure of the reducer, the safety hazard of normal operation of the equipment, and the poor performance of the reducer and other problems to achieve the effect of reducing sealing pressure, reducing the risk of oil leakage and ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

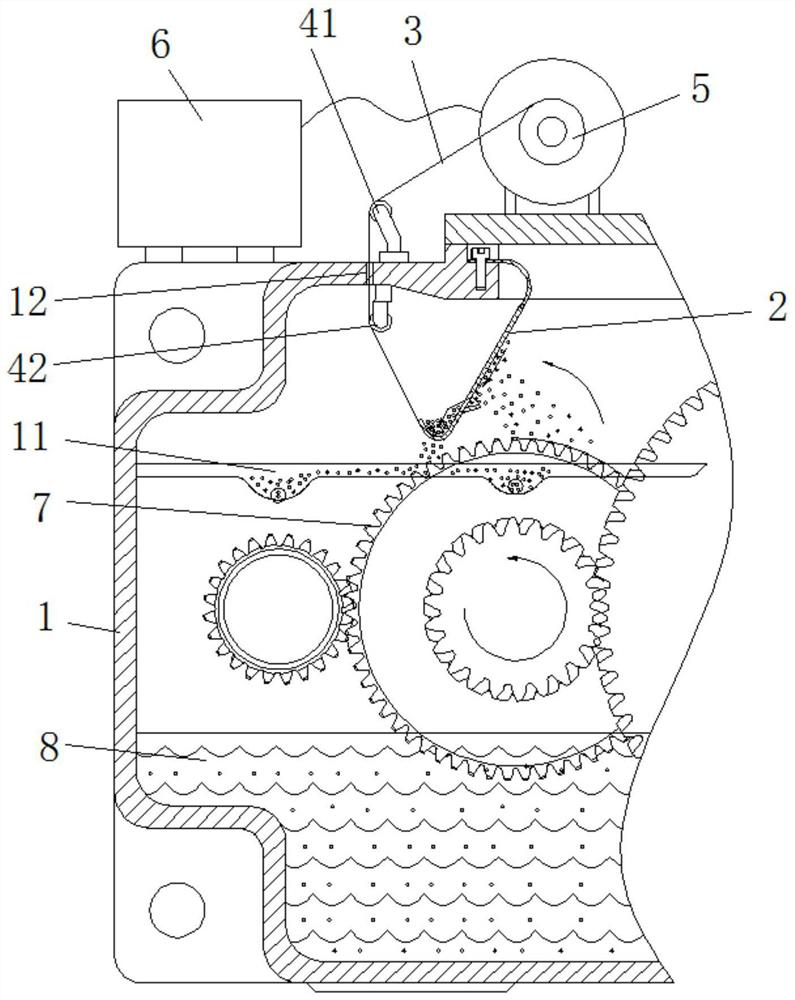

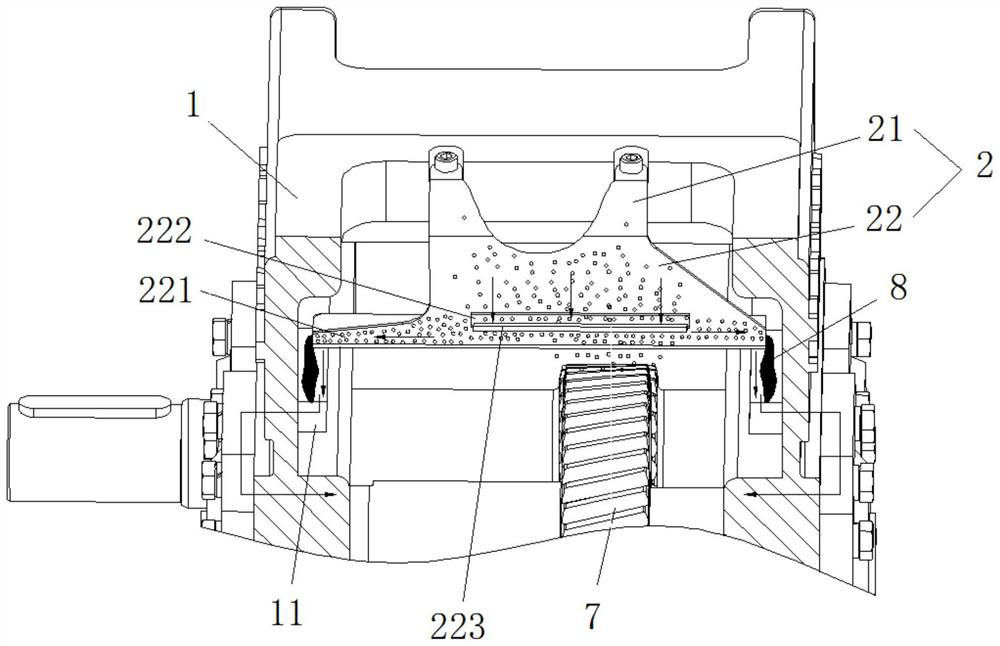

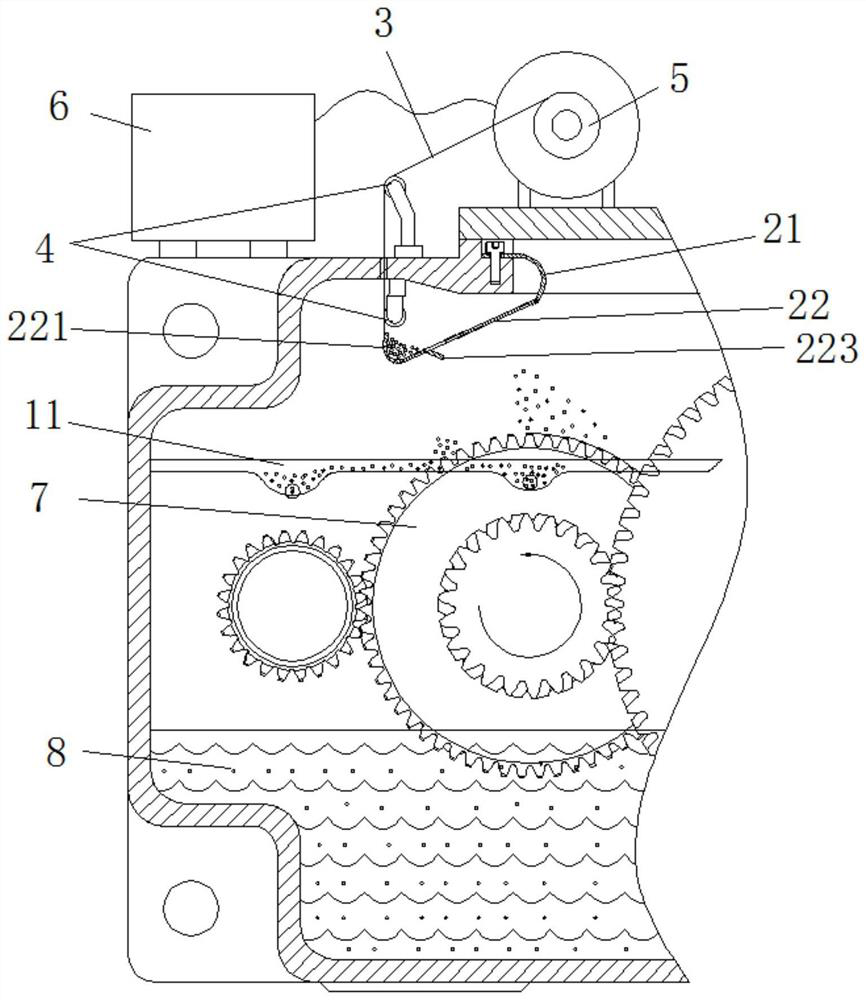

[0022] In order to make it easy to understand the technical means, creative features, goals and effects realized by the present invention, the following embodiments are combined with the appendix. figure 1 to the attached Figure 4 The technical solutions provided by the present invention are described in detail, but the following contents are not intended to limit the present invention.

[0023] The adjustable oil receiving plate device provided in this embodiment is arranged on the casing of the reducer, and both sides of the inner wall of the casing of the reducer are provided with oil grooves connected to the bearings, so that the oil in the oil grooves can Lubricate the bearings.

[0024] figure 1 It is a structural diagram of a view from one state of an adjustable oil receiving plate device of the present invention;

[0025] figure 2 It is a structural diagram of a state of an adjustable oil receiving plate device of the present invention from another perspective; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com