Patents

Literature

32results about How to "Avoid the risk of oil spills" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

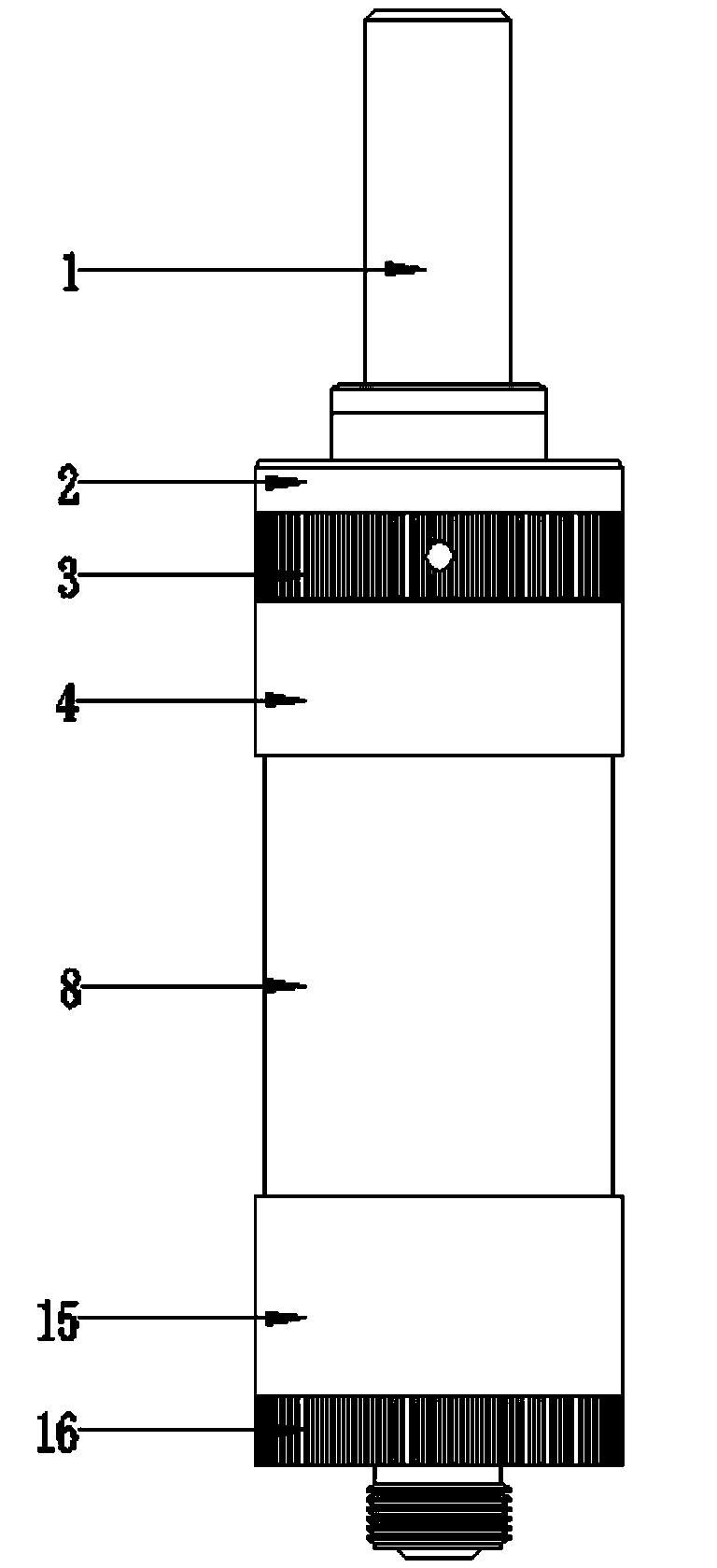

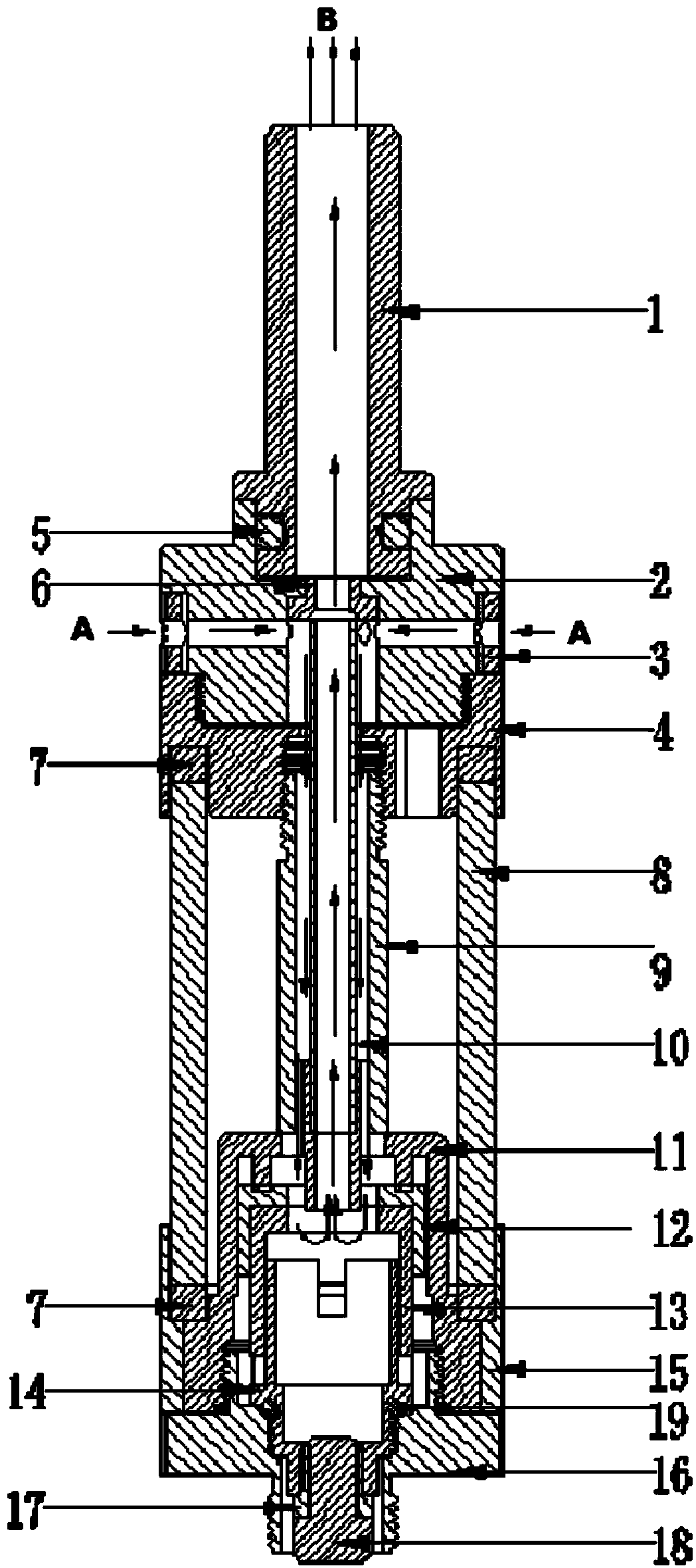

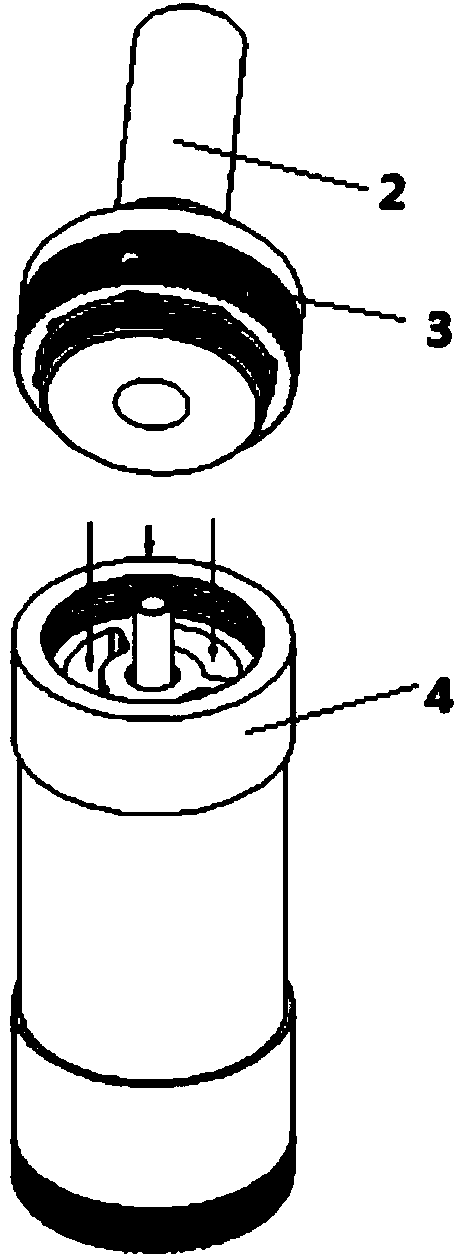

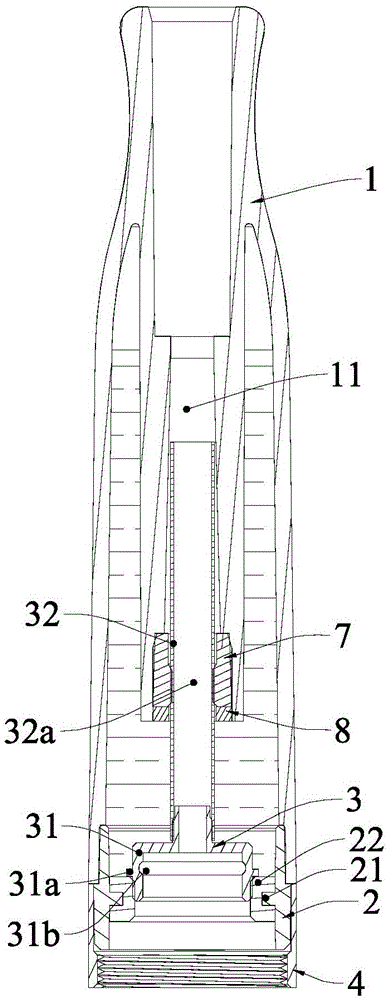

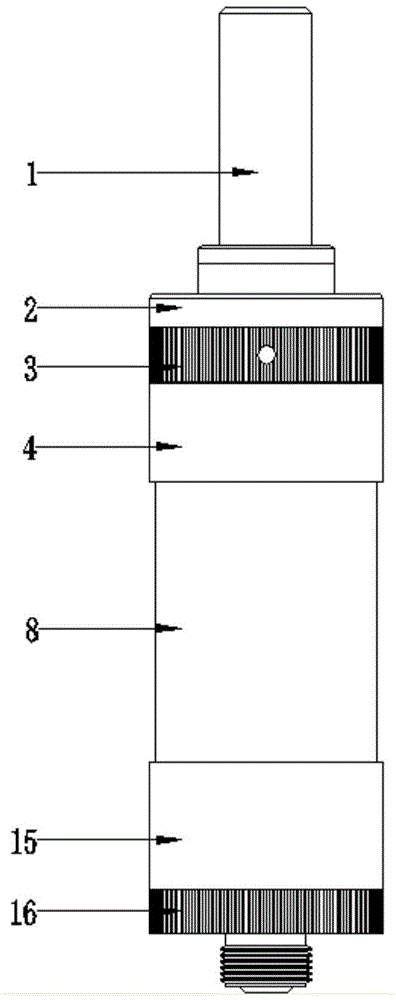

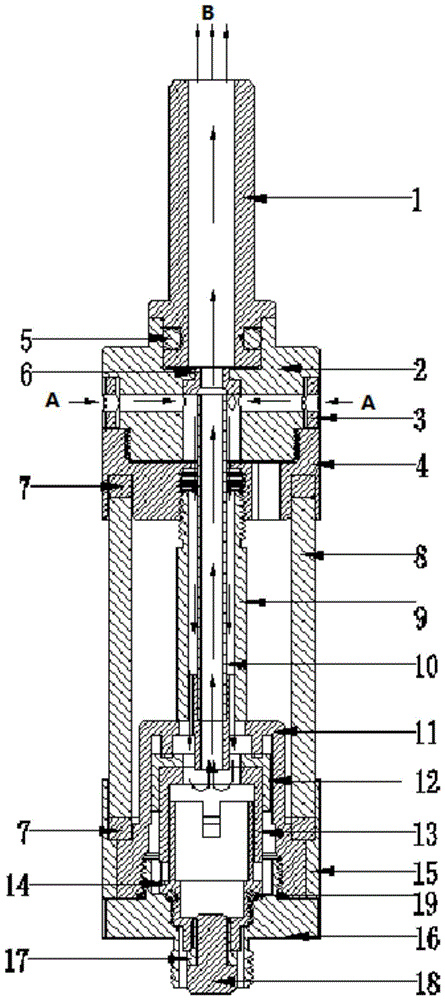

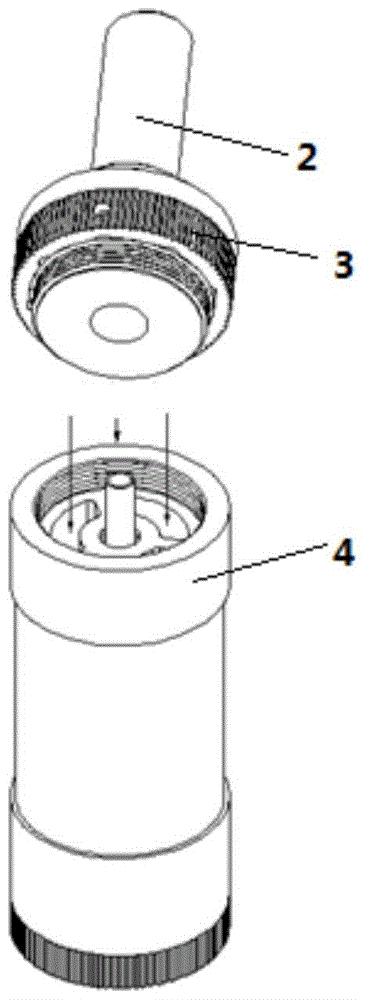

Return airflow atomizer and electronic cigarette comprising atomizer

ActiveCN104207330AAvoid the risk of oil spillsMedical devicesTobacco devicesElectronic cigaretteWaste management

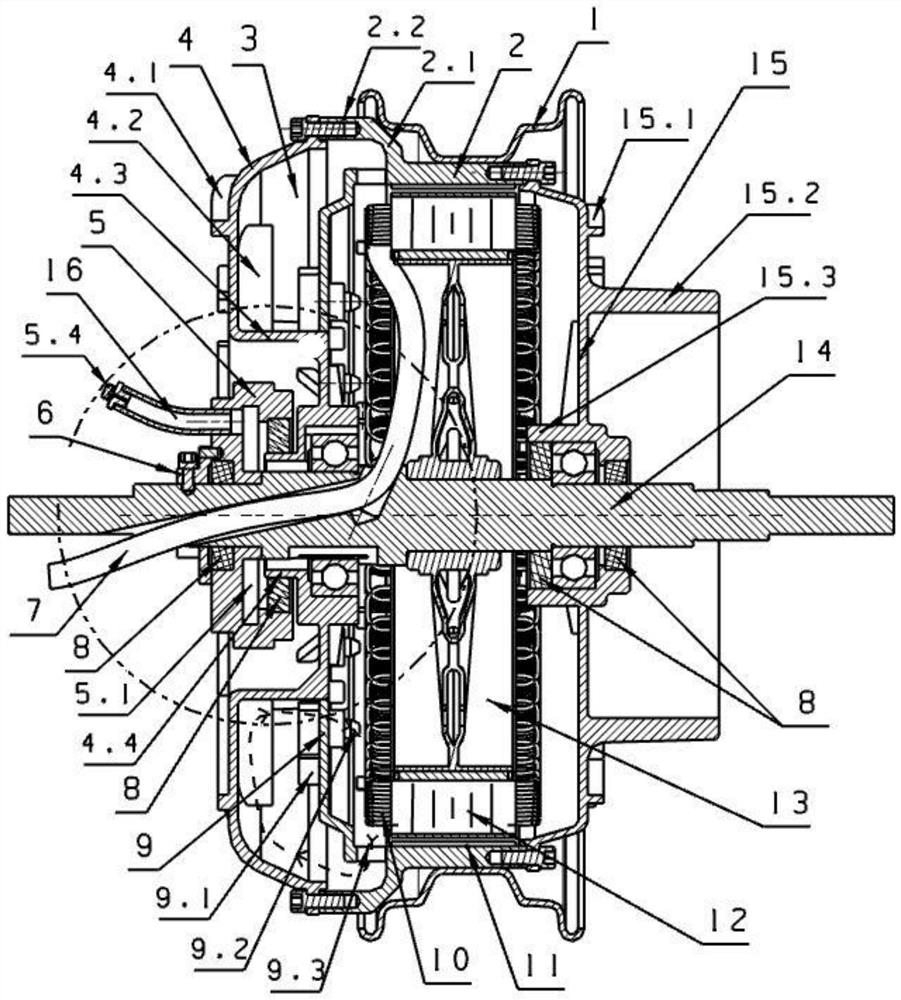

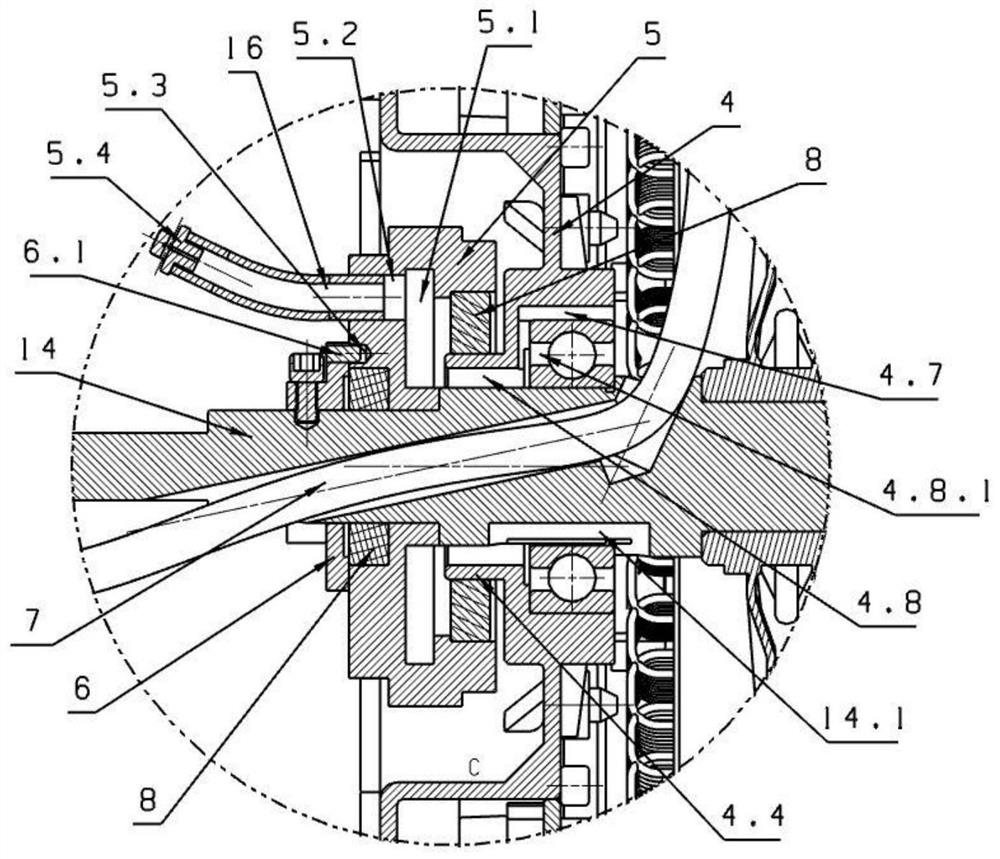

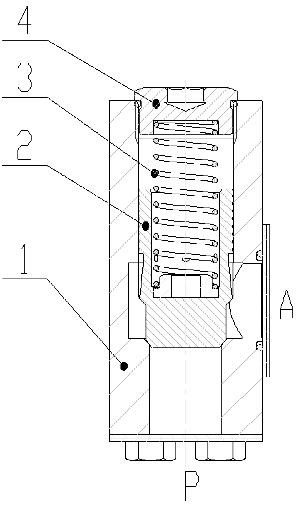

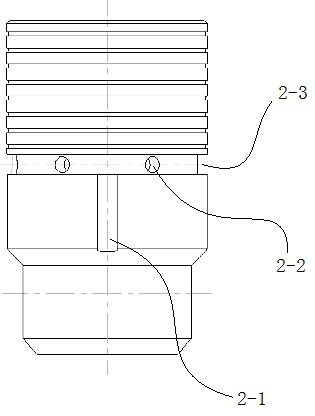

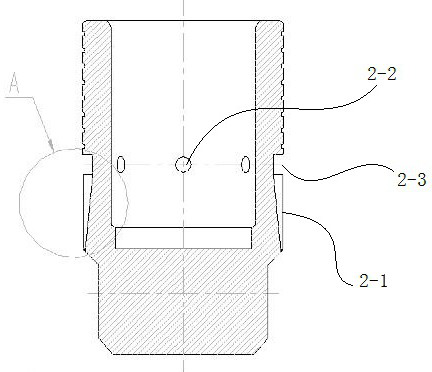

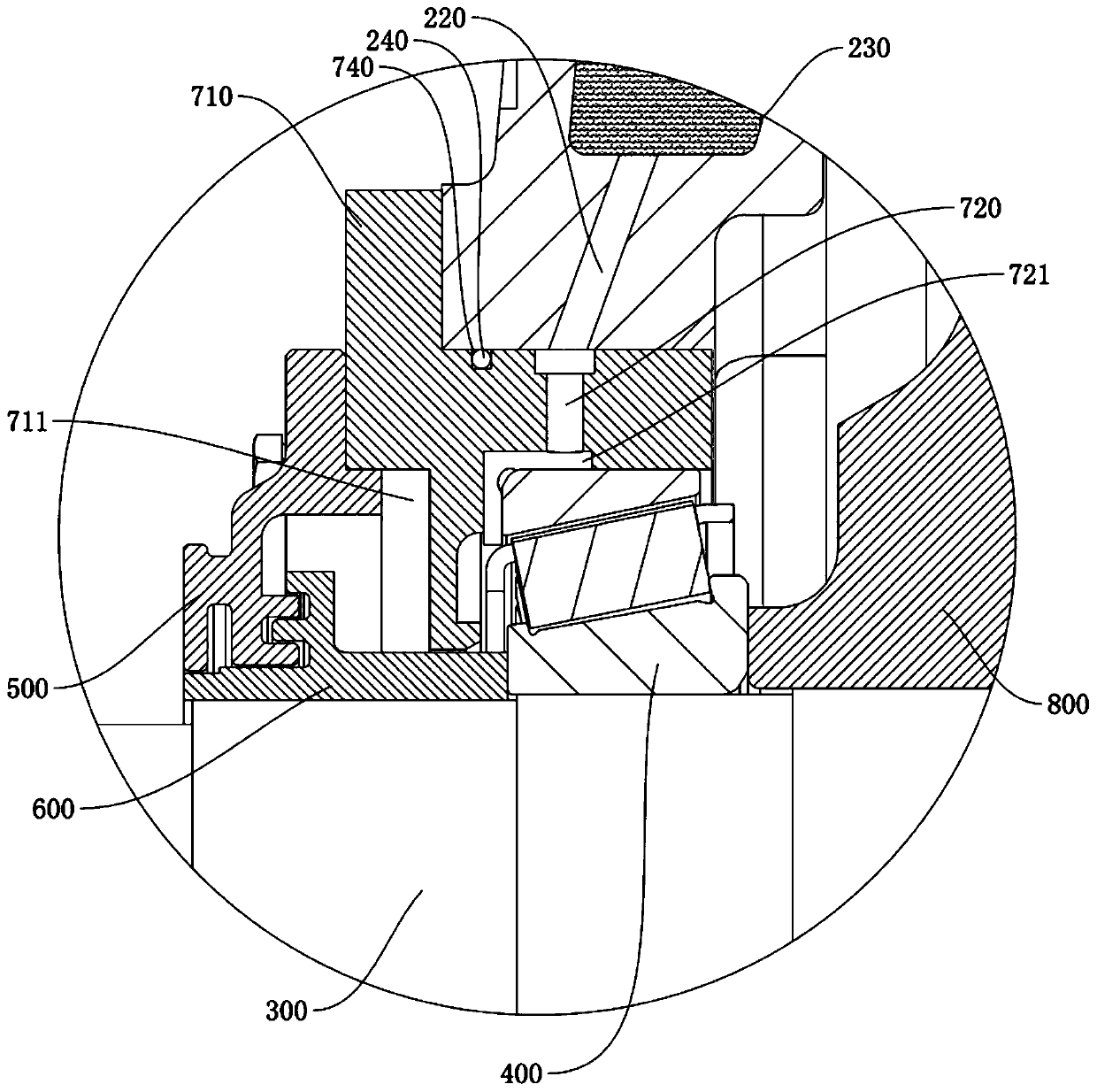

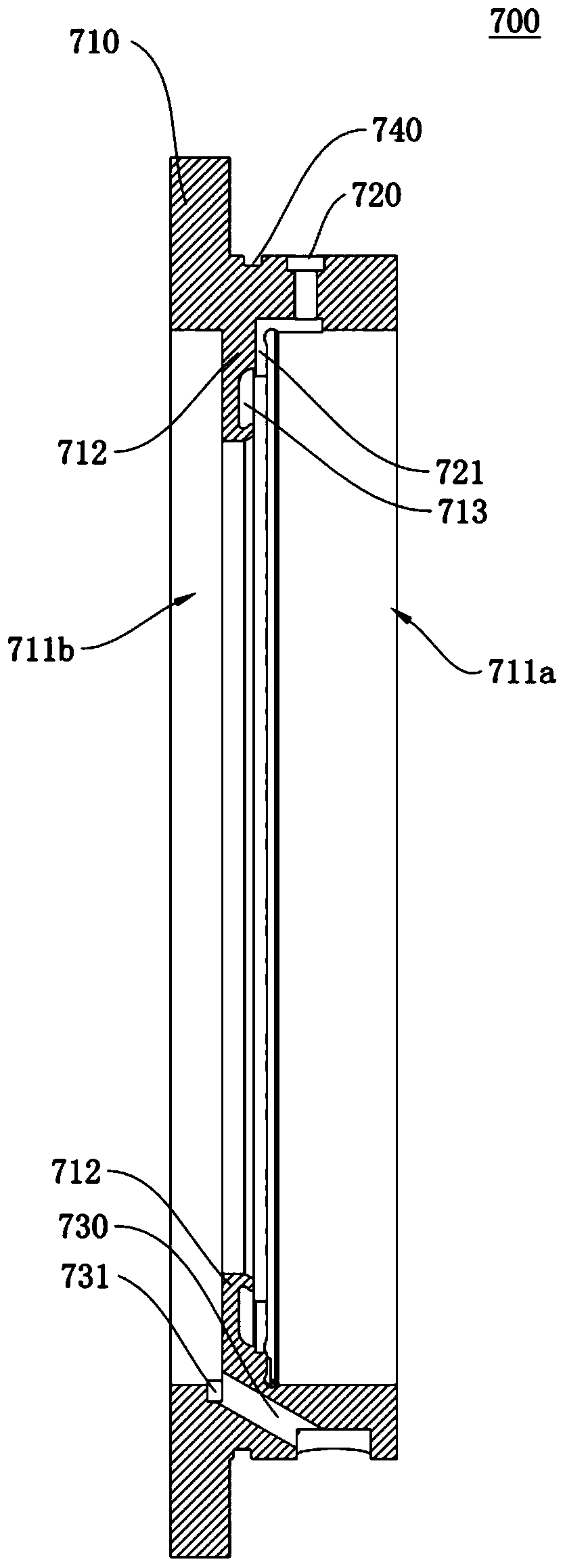

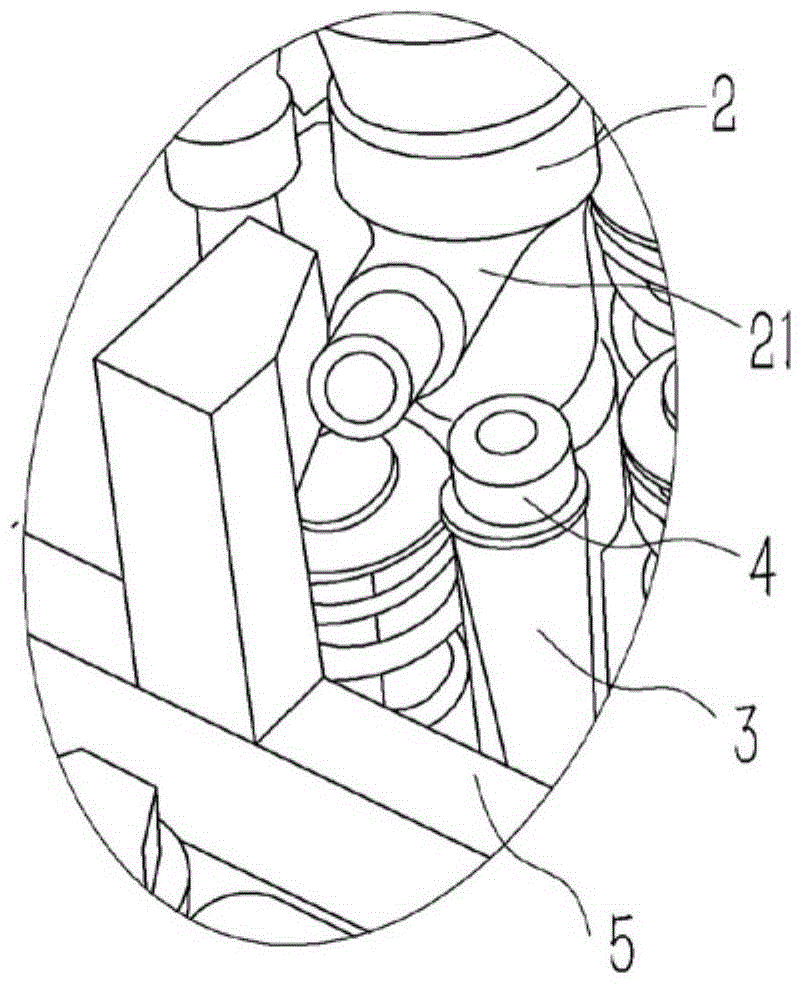

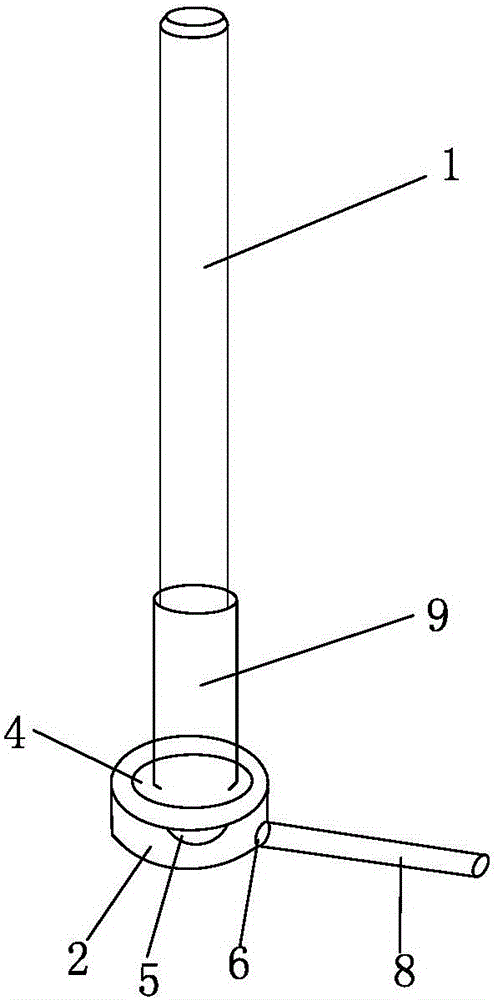

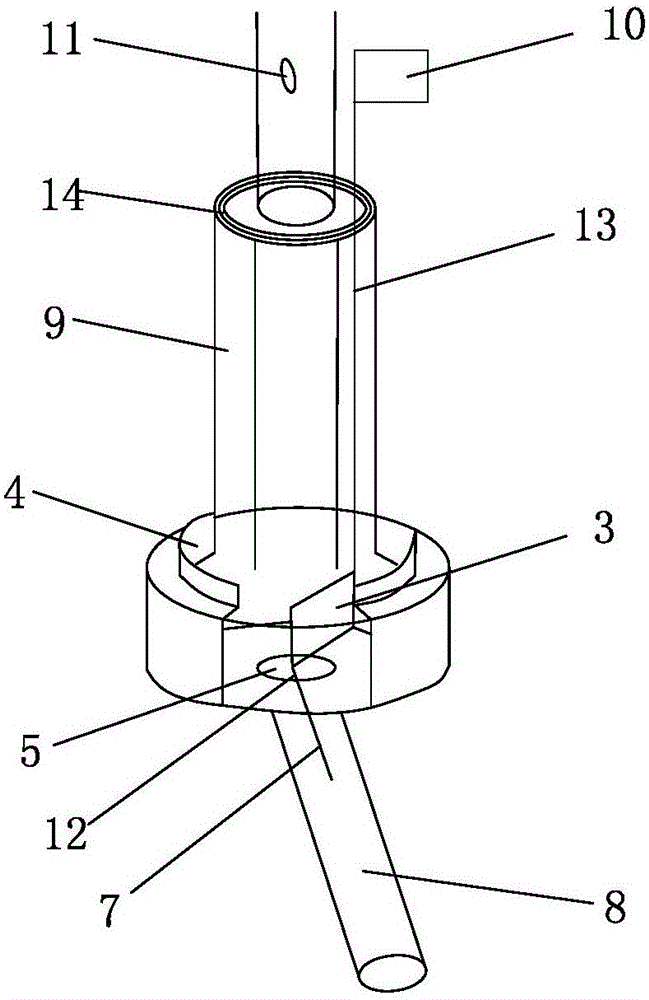

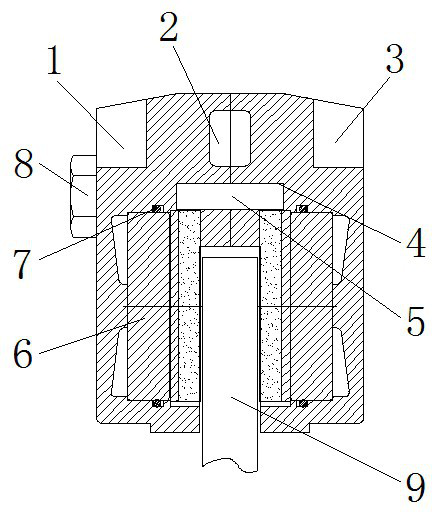

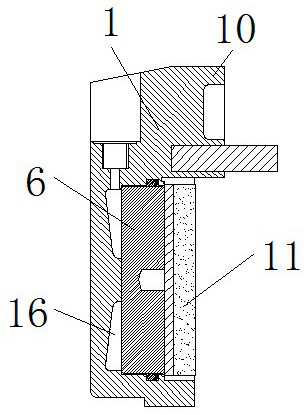

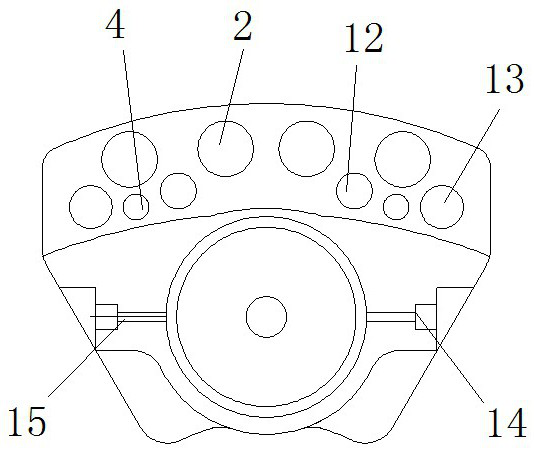

The invention provides a return airflow atomizer and an electronic cigarette. The return airflow atomizer comprises a sucker, a top external thread, a ventilating valve, a ventilating thread, a damping ring, an air guide pipe, a ventilating pipe, a bottom internal thread, springs and steel positioning balls, wherein the top external thread is connected with the ventilating thread; the springs are arranged in the top external thread; the steel positioning balls are arranged outside the springs; the ventilating valve is used for fixing the springs and the steel positioning balls; a plurality of ventilating holes are formed in the ventilating valve, and the ventilating valve sleeves the outer wall of the top external thread in a clamping manner; when rotating left and right by 360 degrees, the ventilating valve is positioned by the springs and the steel positioning balls; when the ventilating holes in the ventilating valve are communicated with air holes formed in the top external thread, airflow enters the ventilating thread. The electronic cigarette comprises the return airflow atomizer. Compared with the conventional atomizer in which the airflow enters from the bottom and leaves from the top, the return airflow atomizer disclosed by the invention is an atomizer which works by virtue of a top air inlet mode and a top air outlet mode under internal airflow circulation.

Owner:SHENZHEN DORTEAM TECH LTD

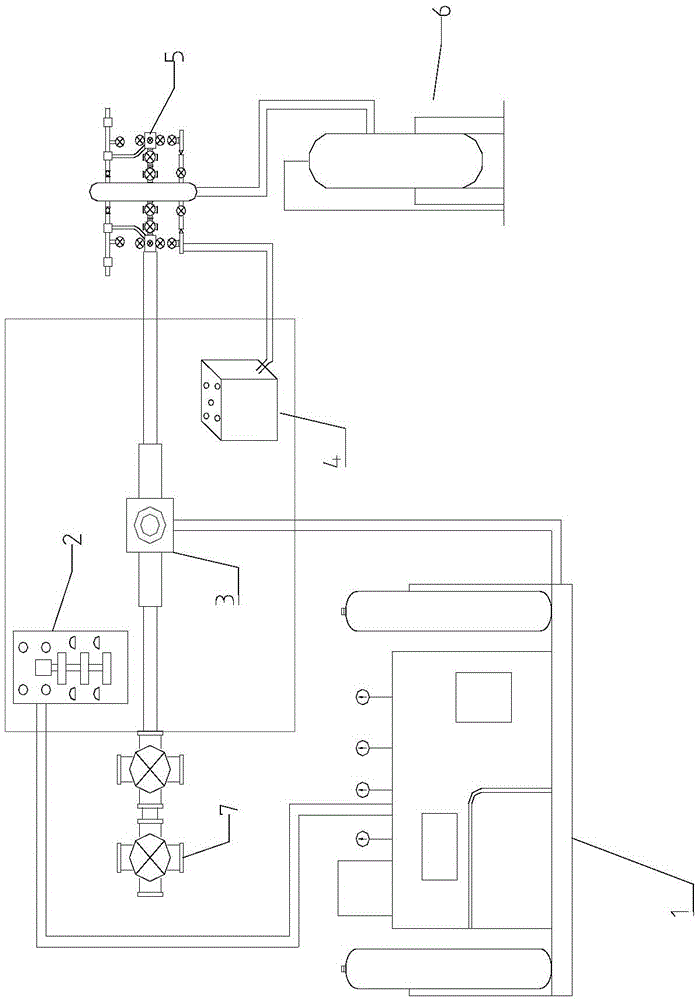

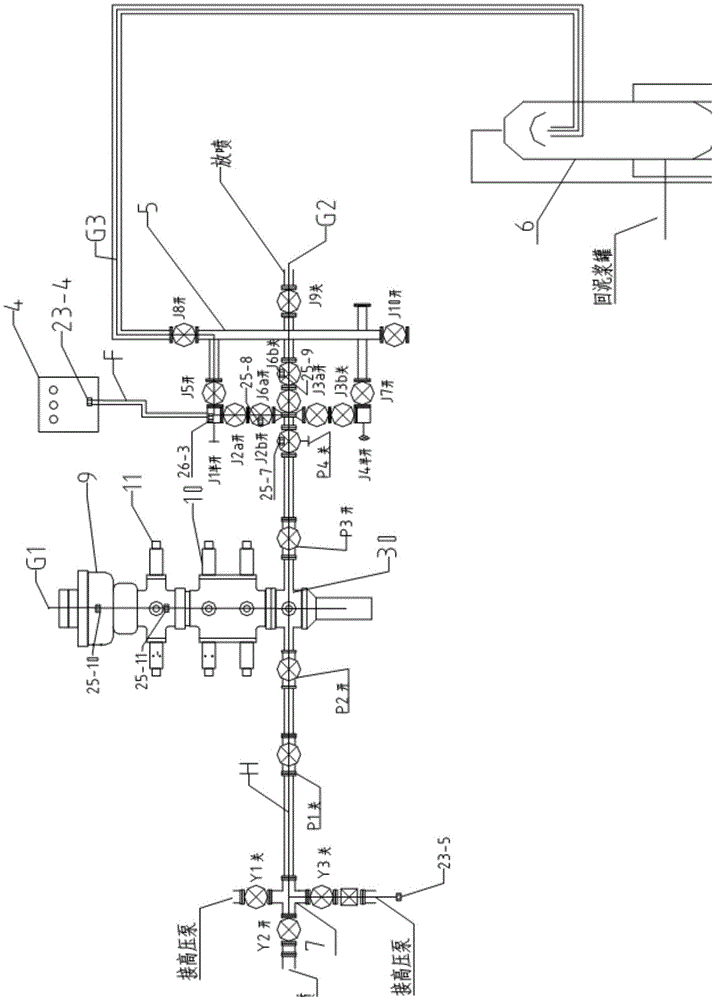

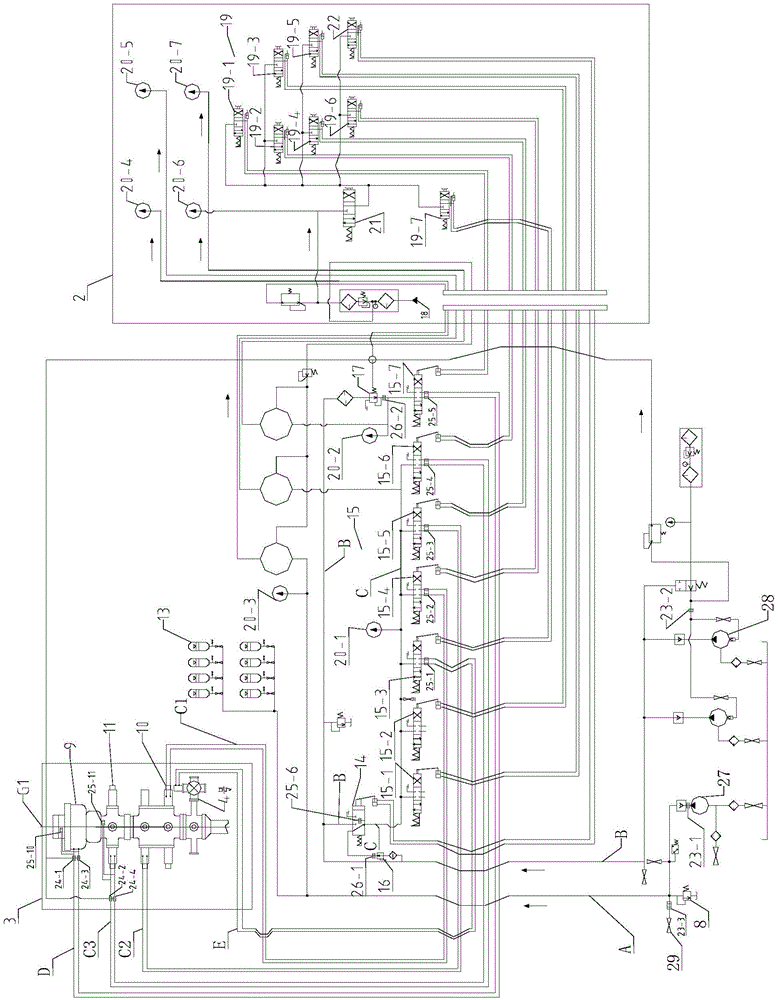

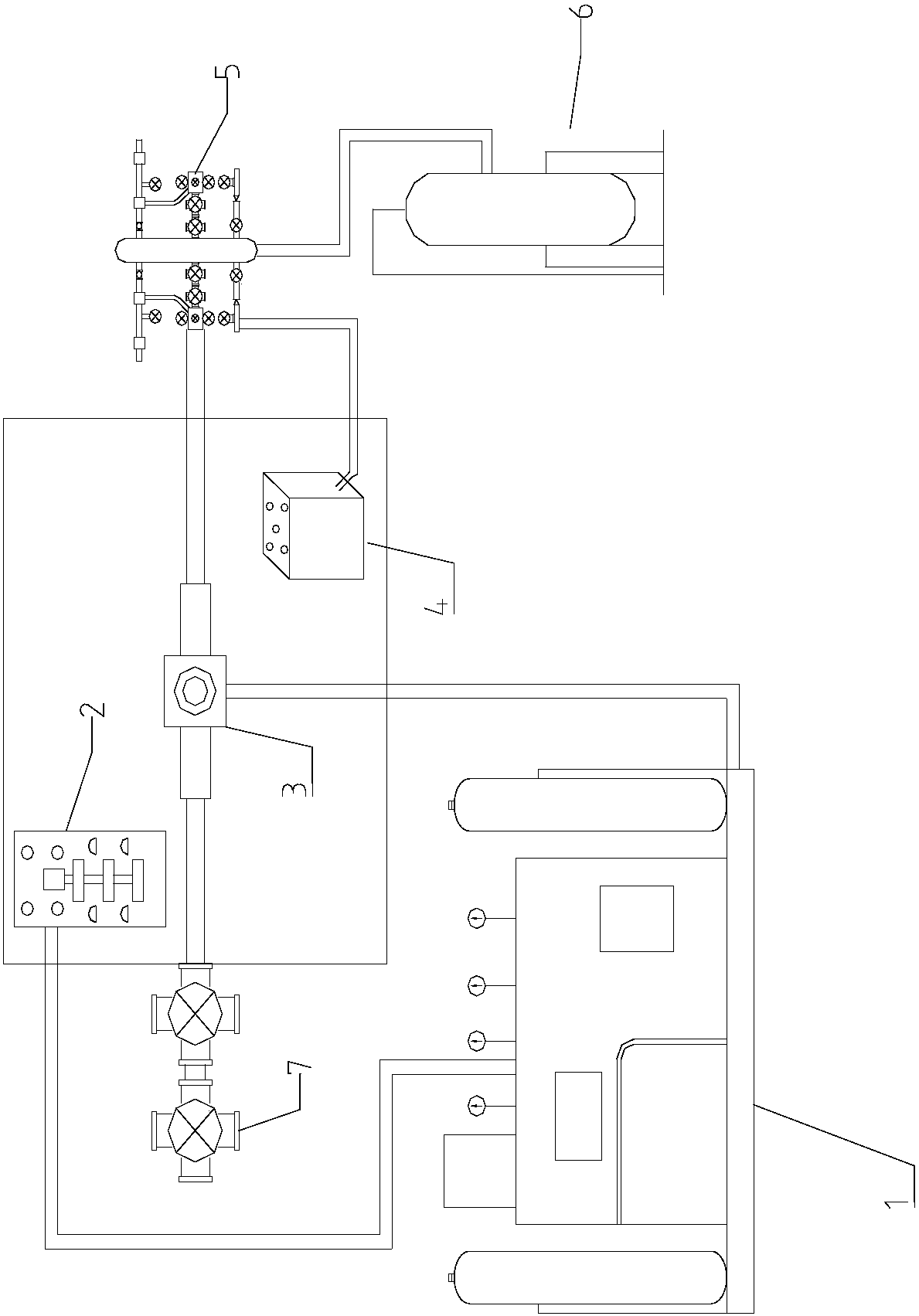

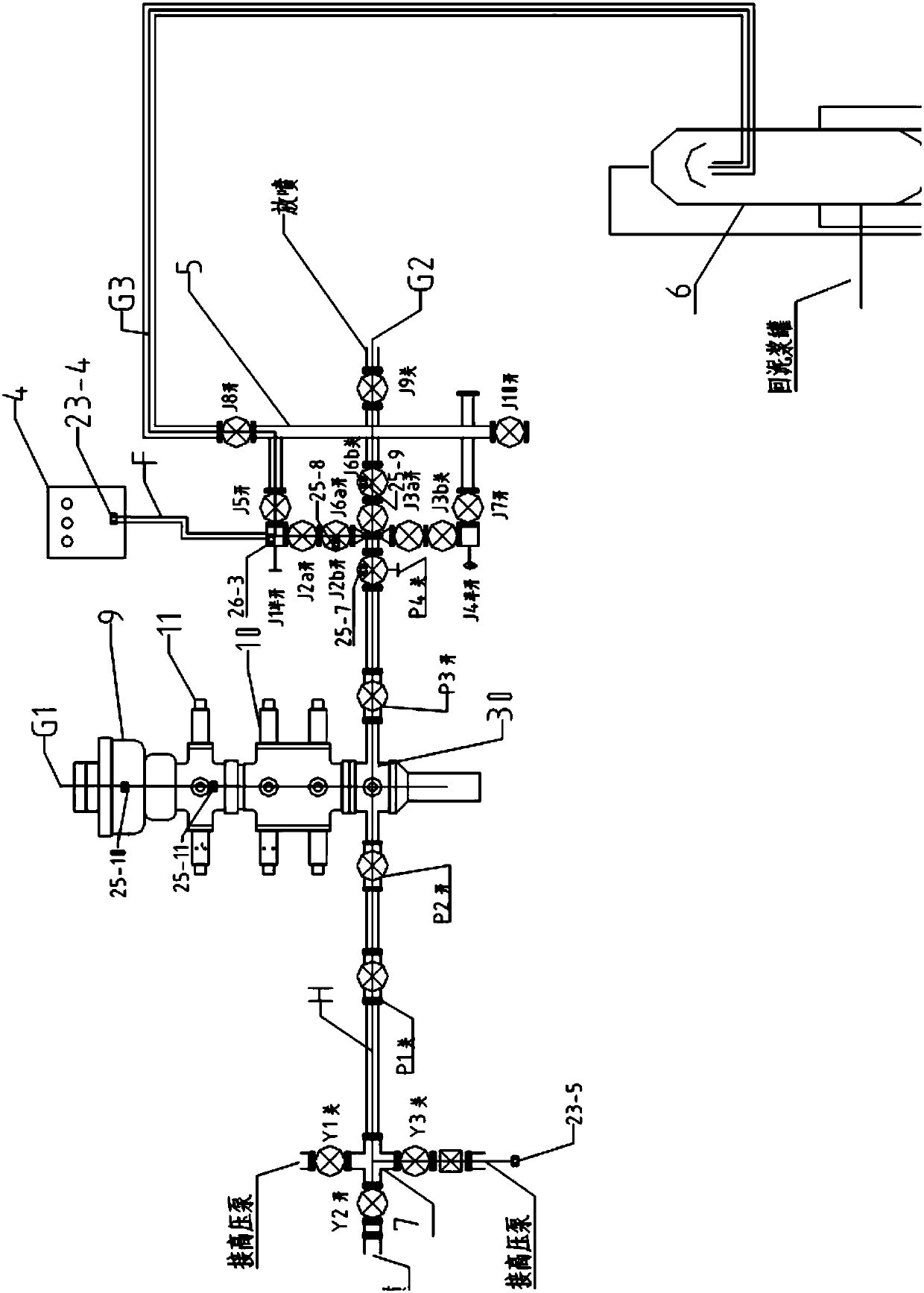

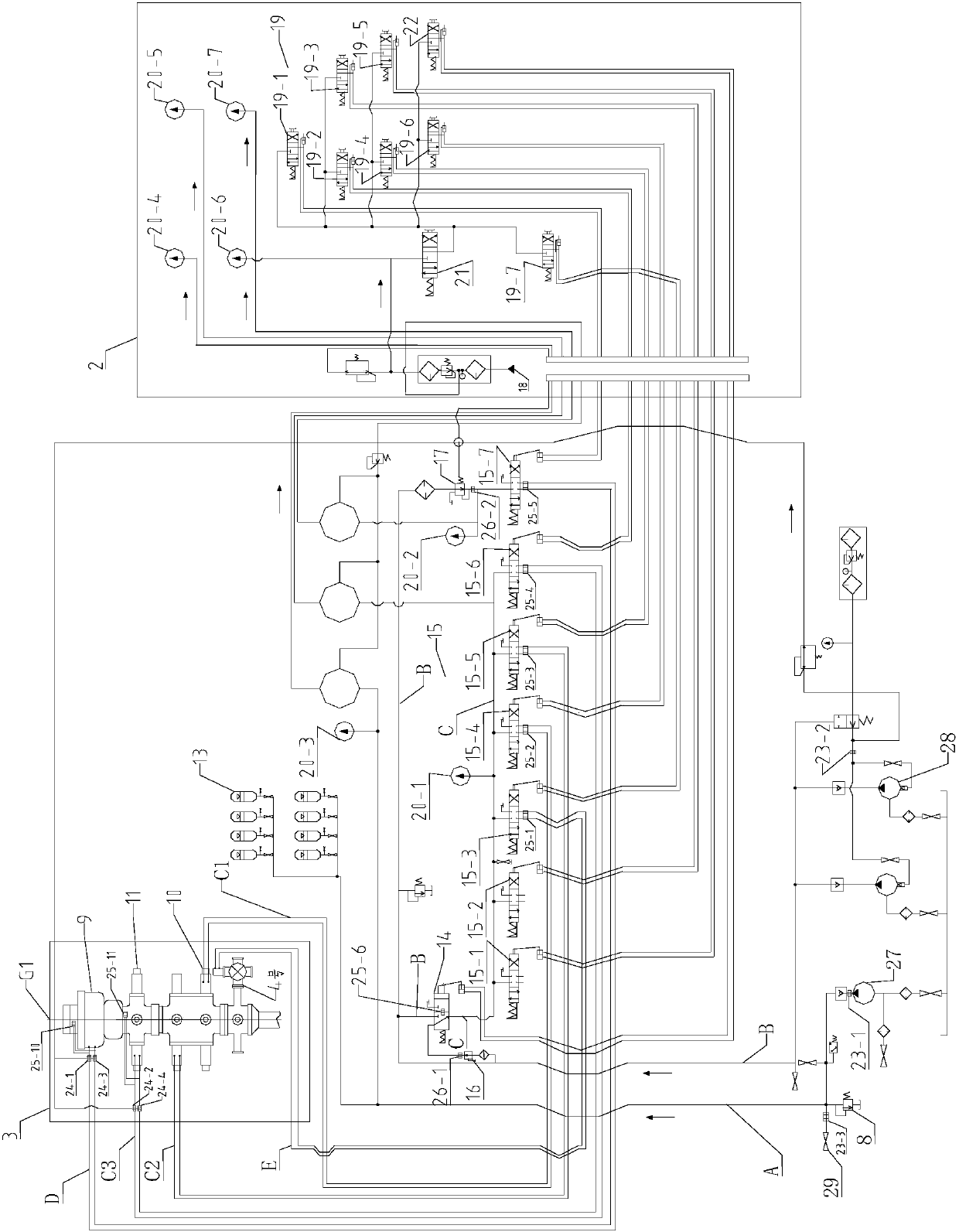

Dynamic demonstration model of petroleum drilling well control device

ActiveCN105632321AAvoid the risk of oil spillsEasy maintenanceEducational modelsWell drillingRotary valve

The present invention discloses a dynamic demonstration model of a petroleum drilling well control device. The dynamic demonstration model of the petroleum drilling well control device comprises a driller's console, a remote console, a throttle manifold control cabinet, and a liquid-gas separator, a throttle manifold, a blowout preventer stack and a kill manifold which are connected in order; the throttle manifold, the blowout preventer stack and the kill manifold are respectively installed at different interfaces of a drilling spool; the driller's console is connected with the remote console; the remote console is connected with the blowout preventer stack through a transparent pipeline, and the blowout preventer stack is internally provided with a light band G1; the throttle manifold control cabinet is connected with the throttle manifold; the three-position four-way air rotary valve and the two-position four-way slide valve of the driller's console are able to pass through the three-position four-way change valves of an air control remote console to control the switch of the blowout preventer stack; the lamp strip is arranged in the associated line of the remote console and the blowout preventer stack; and proximity switches are arranged in the three-position four-way change valves to control the switching of the lamp strip. The dynamic demonstration model of a petroleum drilling well control device is able to visually demonstrate the actual running condition of the device in different work states and improve the operation safety.

Owner:TIANJIN LUYA SCI & TECH CO LTD

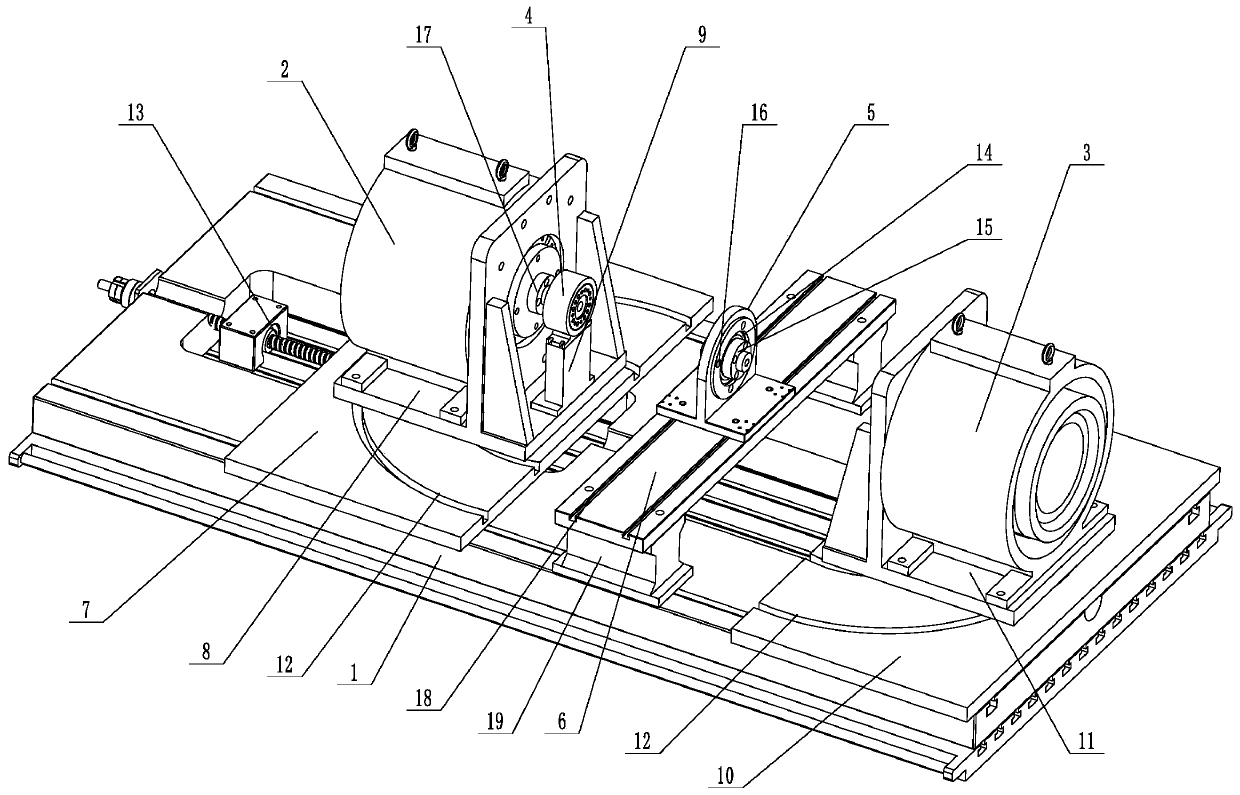

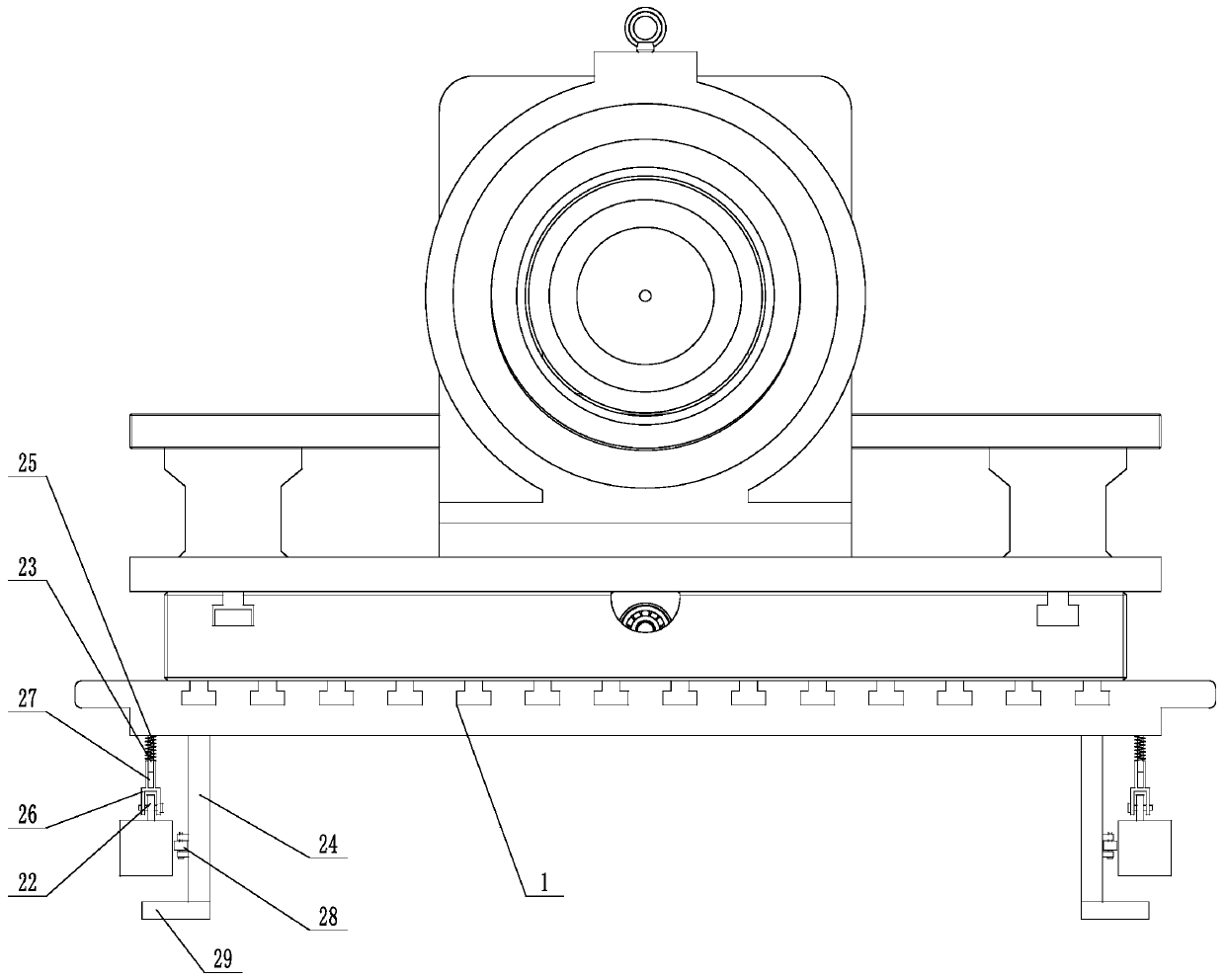

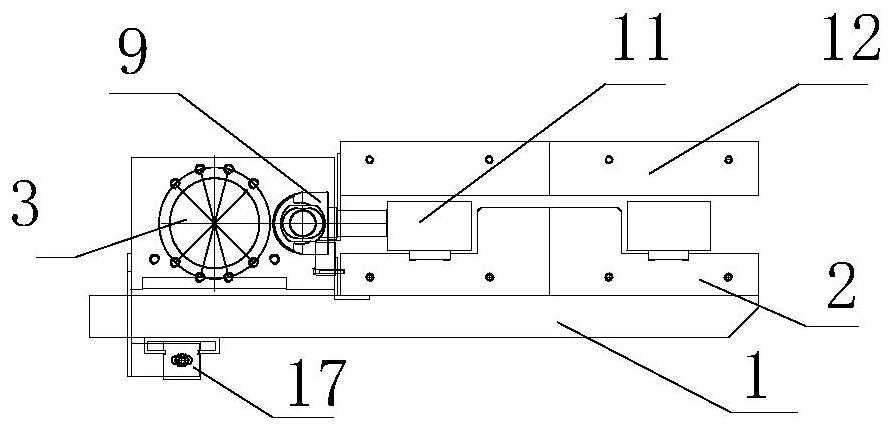

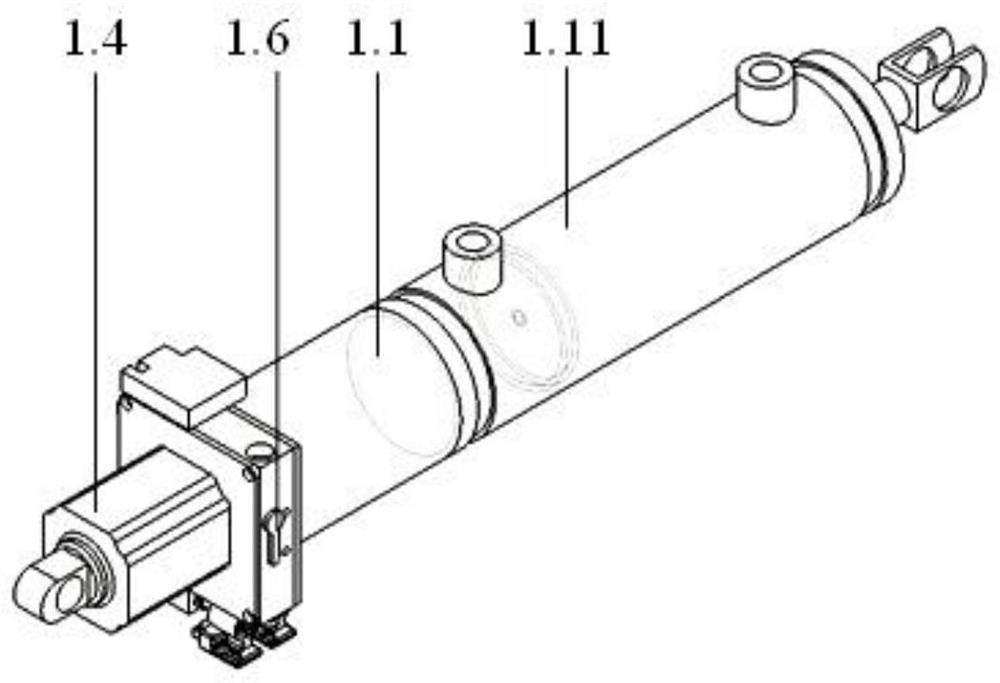

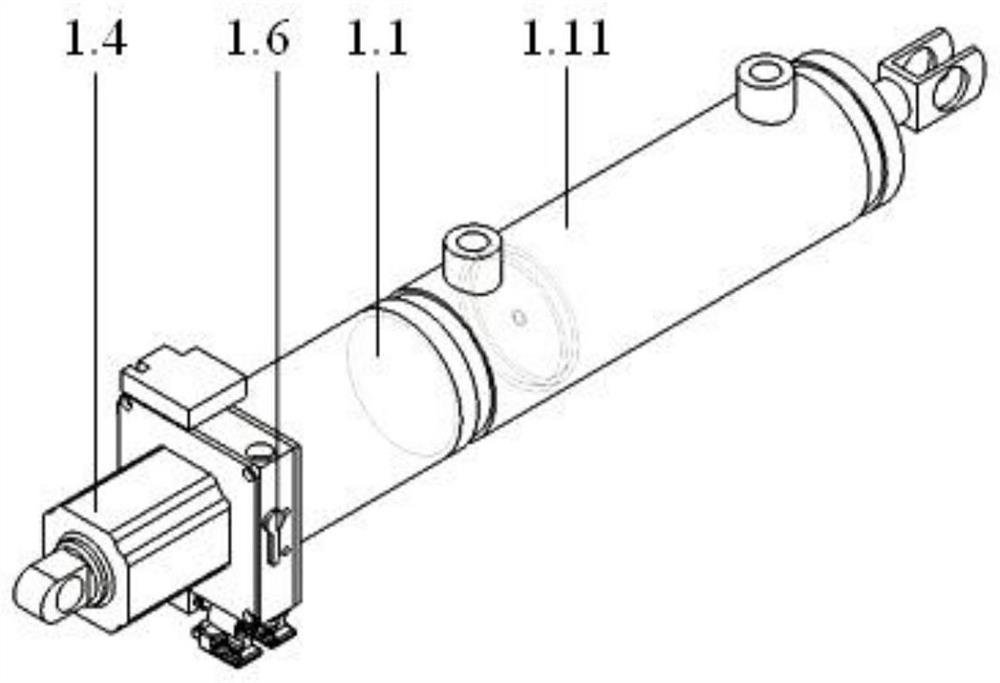

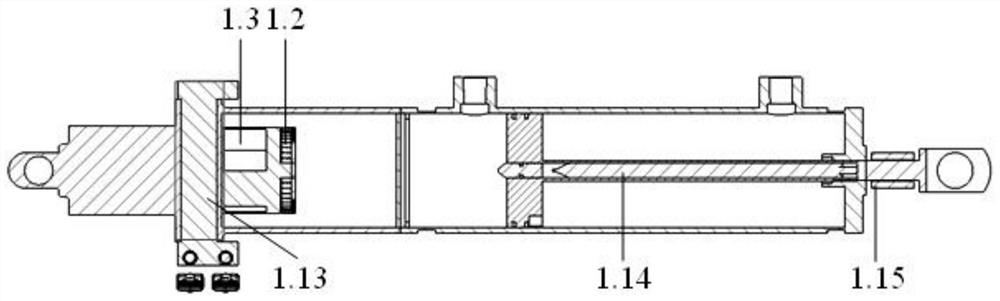

Electric direct-drive shaft torsional fatigue test device and method

ActiveCN111366357ASimple structureLow costMachine gearing/transmission testingTorsion fatigueElectric machine

The invention discloses an electric direct-drive shaft torsional fatigue test device and method, and aims to overcome defects of high cost, poor universality and oil leakage risk of an existing hydraulic fatigue test machine. The device comprises a mounting platform, a power direct-drive main motor, a power direct-drive auxiliary motor, a torque sensor and a connecting seat for clamping a test piece, wherein a movable sliding plate is mounted on the mounting platform, the power direct-drive main motor is rotatably mounted on the sliding plate, the power direct-drive auxiliary motor is rotatably mounted on the mounting platform, the connecting seat is movably mounted between the power direct-drive main motor and the power direct-drive auxiliary motor, the connecting seat is arranged betweenthe power direct-drive main motor and the power direct-drive auxiliary motor, and the torque sensor is arranged between the connecting seat and the power direct-drive main motor. The electric direct-drive shaft torsional fatigue test device is simple in structure, low in cost and good in universality, and the risk of oil leakage is avoided.

Owner:策仕(宁波)工业技术有限公司

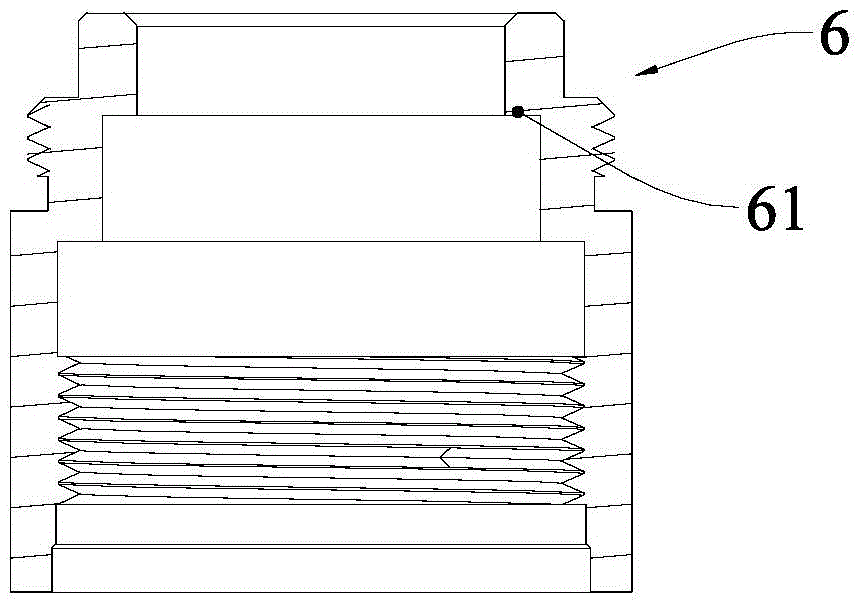

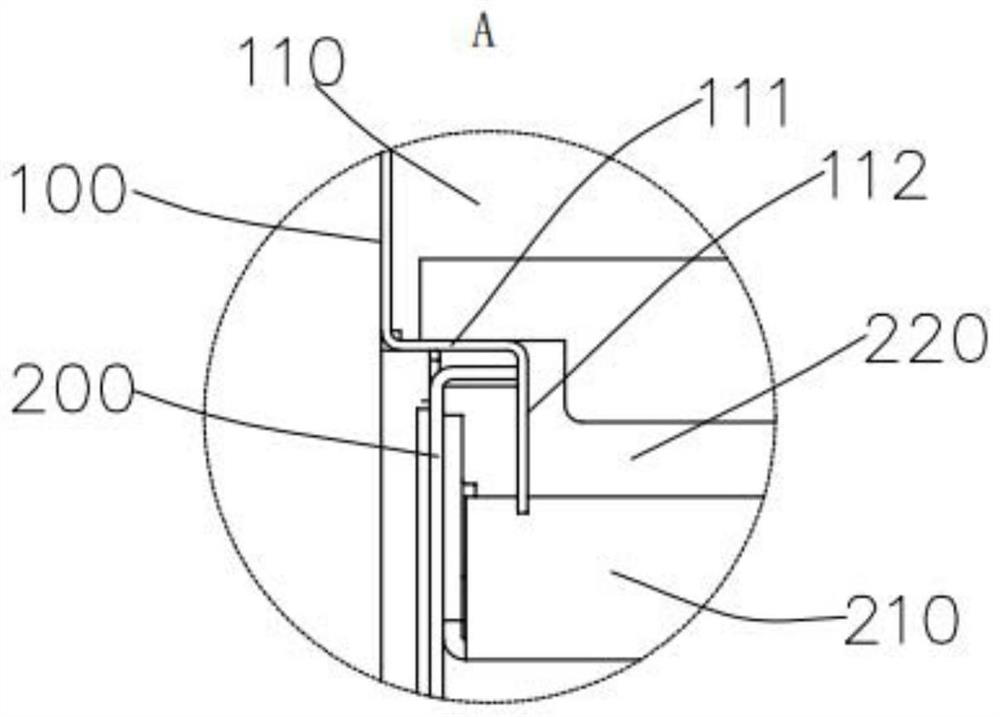

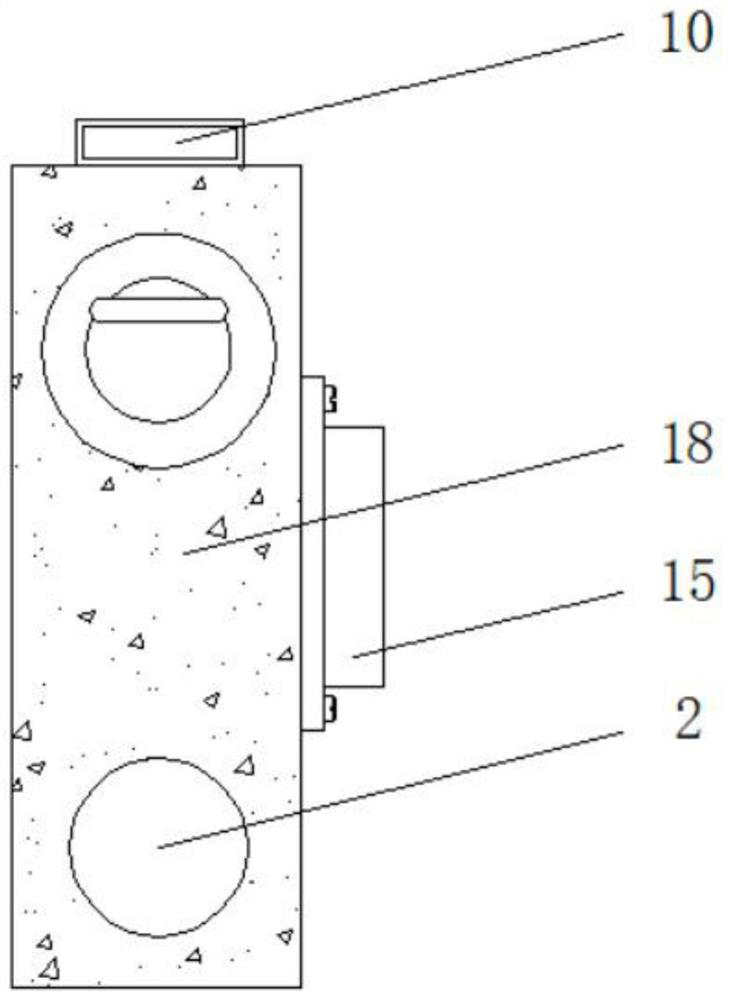

Oil leakage preventing structure of oil cup and electronic cigarette

ActiveCN105595435AAvoid contactQuality is not affectedTobacco devicesElectronic cigarettePetroleum engineering

The invention belongs to the technical field of electronic cigarettes and discloses an oil leakage preventing structure of an oil cup and an electronic cigarette. The oil leakage preventing structure of the oil cup comprises an oil cup assembly and an atomizing core; the oil cup assembly comprises an oil cup body, a locating ring arranged at the opening end of the oil cup body and an oil seal arranged in the oil cup body; a first smoke channel is formed in the oil cup body, a first annular protrusion is arranged on the inner wall of the locating ring, and a check ring made of an elastic material is arranged on the first protrusion in a sleeving manner; a second protrusion matched with the first protrusion for limiting is arranged at one end of the oil seal, a second smoke channel extending into the first smoke channel is formed in the other end of the oil seal, and sealing arrangement between the first smoke channel and the second smoke channel is realized; the atomizing core is detachably connected with the oil seal. According to the oil leakage preventing structure of the oil cup and the electronic cigarette, smoking oil in the oil cup body is always in a sealed state in a moving process of the atomizing core and the oil seal; thus, the risk of oil leakage is effectively prevented.

Owner:CHANGNING DEKANG BIOTECH SHENZHEN CO LTD

Turbocharger control method and device

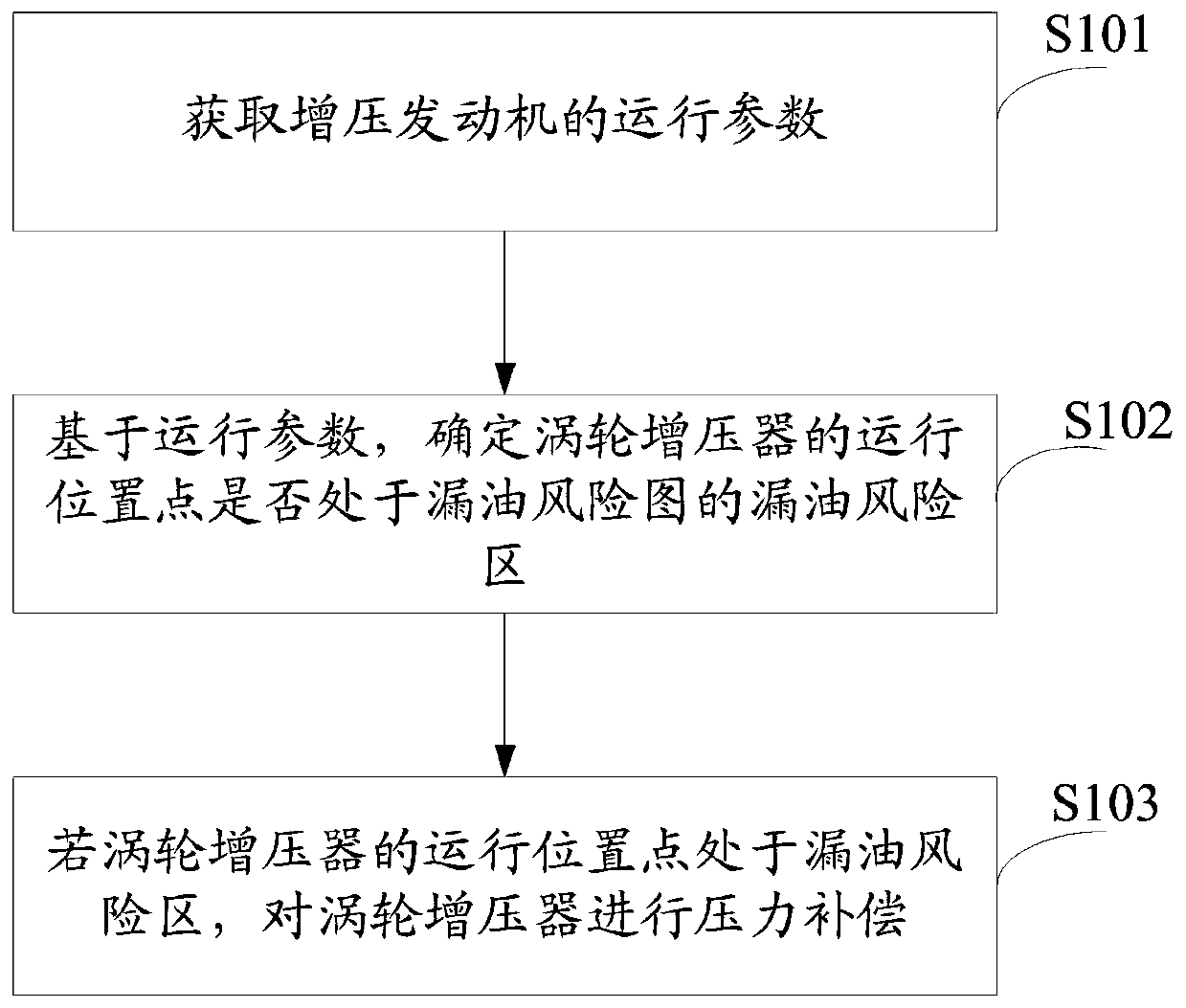

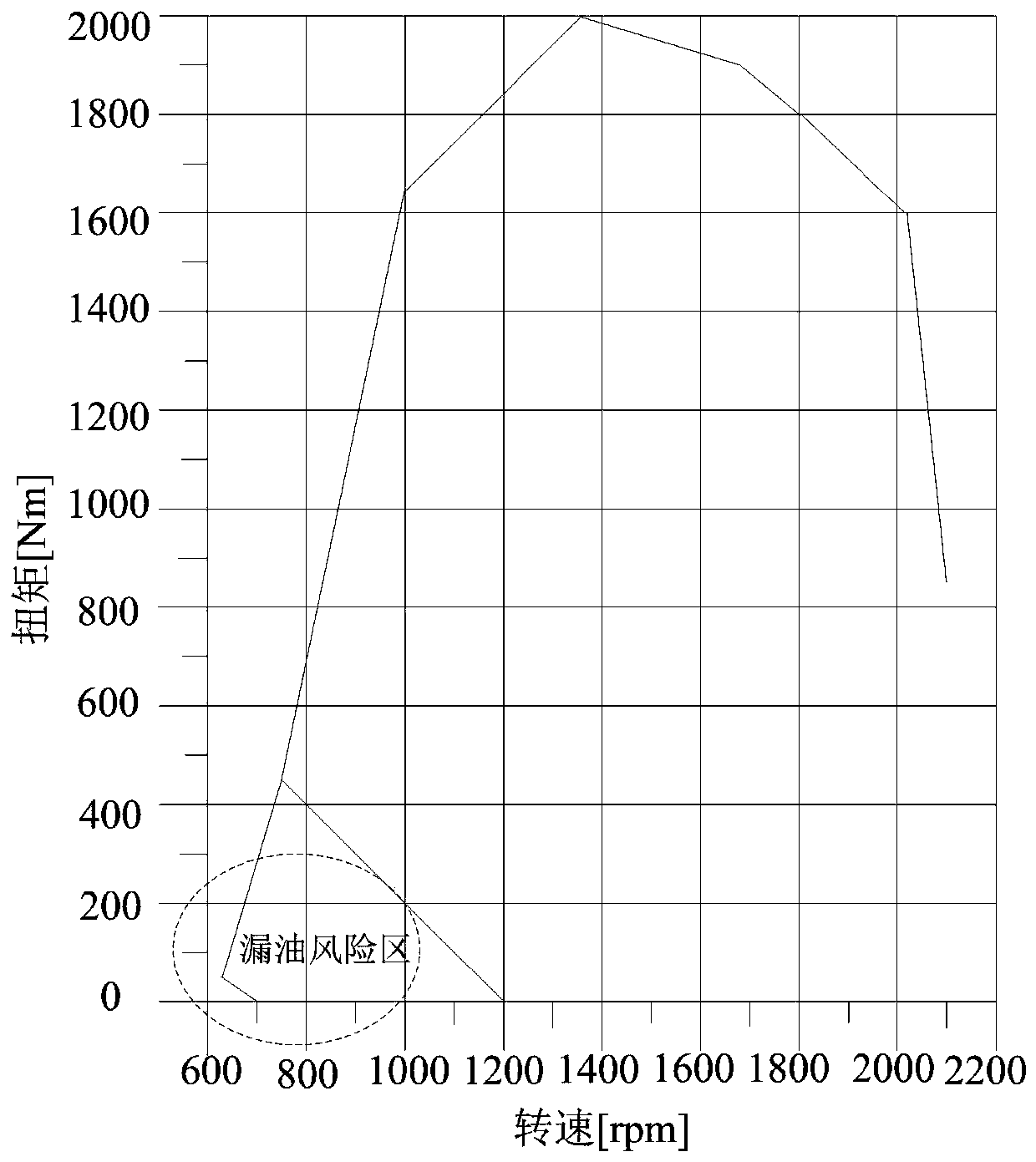

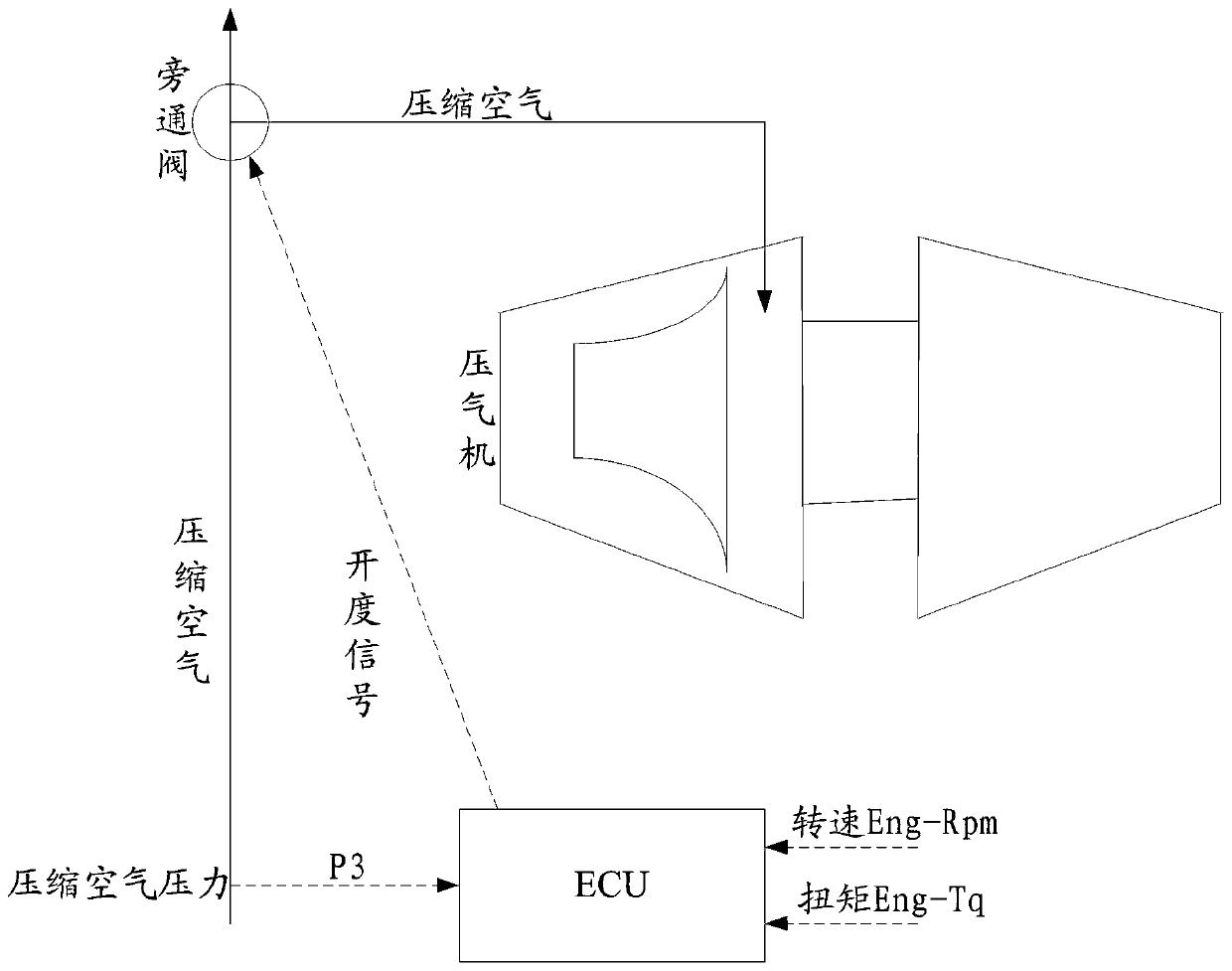

InactiveCN110529272AGuaranteed uptimePrevent oil spillsElectrical controlInternal combustion piston enginesTurbochargerRisk area

The invention provides a turbocharger control method and device. The method comprises the steps that operating parameters of a supercharged engine are obtained; based on the operation parameters, whether the operation position point of the turbocharger is located in an oil leakage risk area of the oil leakage risk graph or not is determined; and if the operation position point of the turbochargeris located in the oil leakage risk area, pressure compensation is conducted on the turbocharger. According to the scheme, the oil leakage risk graph containing the oil leakage risk area is constructedin advance with the operating parameters as the coordinate axis, and the operating parameters of the supercharged engine are collected in the operating process of the supercharged engine. According to the operation parameters of the supercharged engine, whether the operation position point of the turbocharger is located in an oil leakage risk area or not is determined in combination with the oilleakage risk graph. If the operation position point is located in the oil leakage risk area, pressure compensation is conducted on the turbocharger, oil leakage of the turbocharger is prevented, and stable operation of the supercharged engine is guaranteed.

Owner:WEICHAI POWER CO LTD

Oil-gas double-cooling motor

PendingCN113794331ANo emissionsPrevent leakageCooling/ventillation arrangementThermal dilatationSteam pressure

The invention discloses an oil-gas double-cooling motor, belongs to the technical field of wheel power transmission, and particularly relates to wheel power transmission of electric motorcycles and electric bicycles. The motor comprises a motor shaft, a stator, a rotor and a hub steel ring, and is characterized in that the motor is further provided with a motor working chamber, an oil storage and circulation cooling chamber, a cooling oil heat dissipation circulation system, a cooling oil separation system and a motor cavity internal and external pressure difference balance system, and the motor cavity internal and external pressure difference balance system comprises an oil vapor recovery chamber, a vent hole, a waterproof ventilation valve and the like. The motor has the advantages that the device can isolate and move residual oil, gasoline and liquid in the motor working chamber into the oil vapor recovery chamber through a ventilation isolation oil discharge duct for full vaporization and secondary recovery, so that the steam pressure in the motor cavity is kept balanced, smooth exhaust is realized, the cooling liquid is prevented from gushing out of the motor and leaking, and oil-free discharge is realized. And the problem that oil leaks and leaks from a power line and a sealing port due to thermal expansion of oil, which cannot be solved by an oil cooling motor in the prior art, is thoroughly solved.

Owner:李绵军

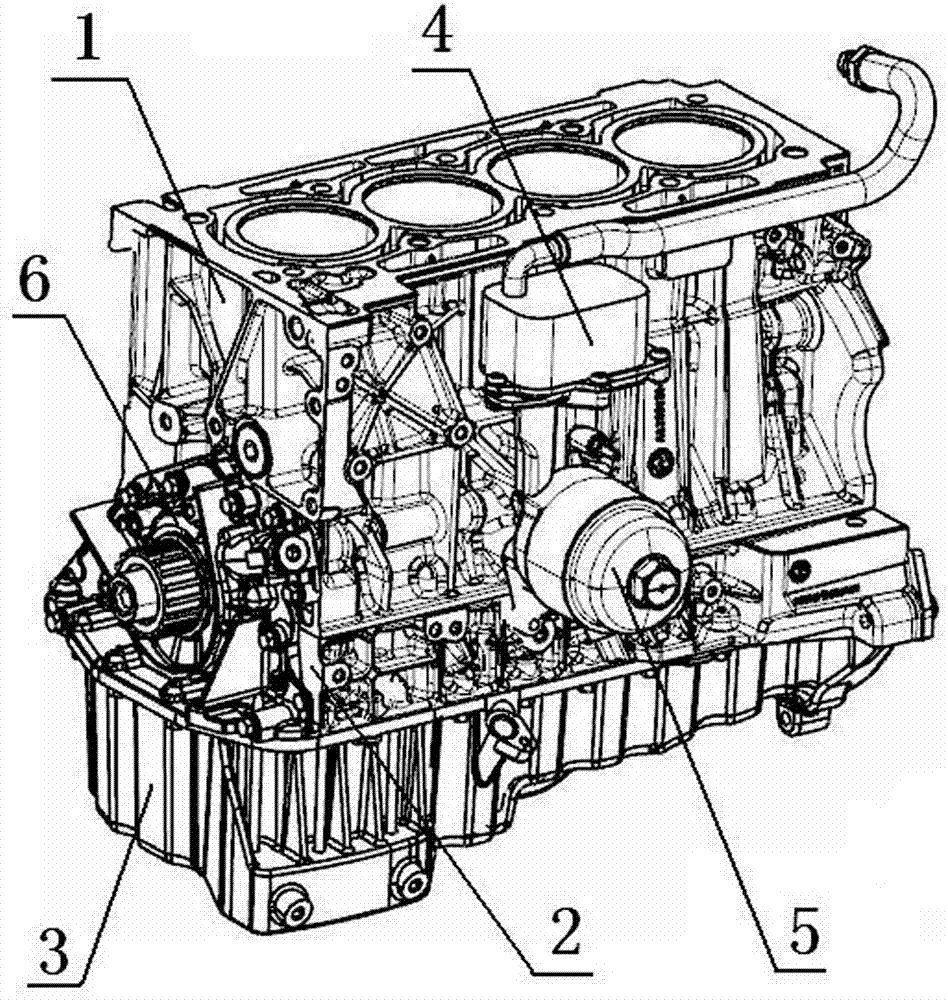

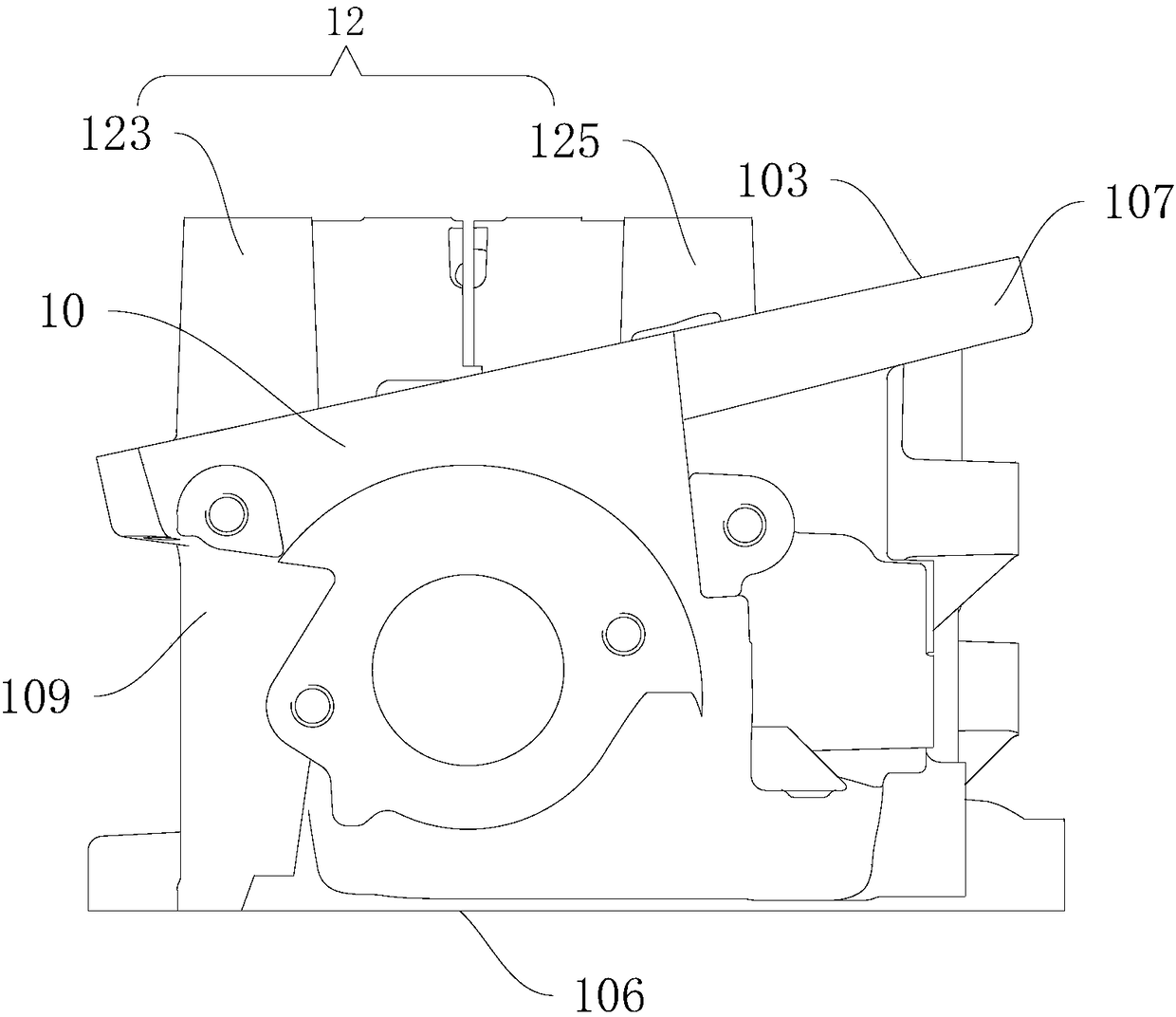

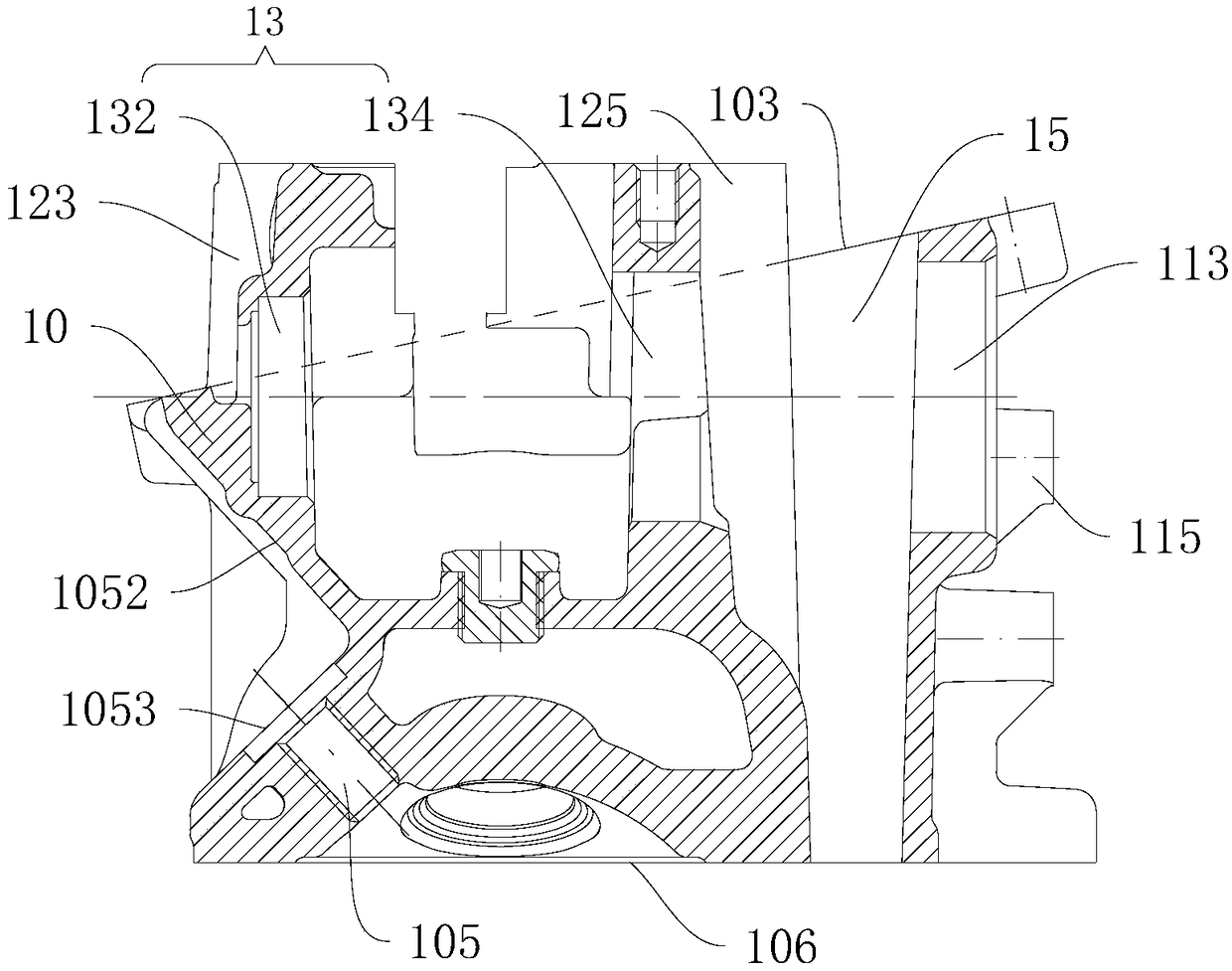

Engine lubricating cooling oil line assembly

InactiveCN107965360AImprove maintenance efficiencyAvoid the risk of oil spillsCylinder headsCylindersCylinder blockMotor oil

The invention discloses an engine lubricating cooling oil line assembly, and relates to the technical field of automobile manufacturing. The engine lubricating cooling oil circuit assembly comprises acylinder body, wherein the cylinder body is composed of an upper cylinder body and a lower cylinder body connected with the upper cylinder body; an oil sump is connected below the lower cylinder body, and an engine oil pump is arranged in the oil sump; an engine oil cooler is arranged on the air inlet side of the upper cylinder body, and the engine oil pump communicates with a first oil way arranged on the engine oil cooler; an engine oil filter is arranged on the oil sump, and an oil inlet line and an oil return line are arranged between the engine oil filter and the engine oil cooler; and the oil return line communicates with a main oil line of the cylinder body. According to the engine lubricating cooling oil line assembly, the problems that an existing engine cylinder body assembly oil line arrangement is unreasonable, the engine is inconvenient to maintain, and the engine oil filter is inconvenient to disassemble and assemble are solved.

Owner:DONGFENG LIUZHOU MOTOR

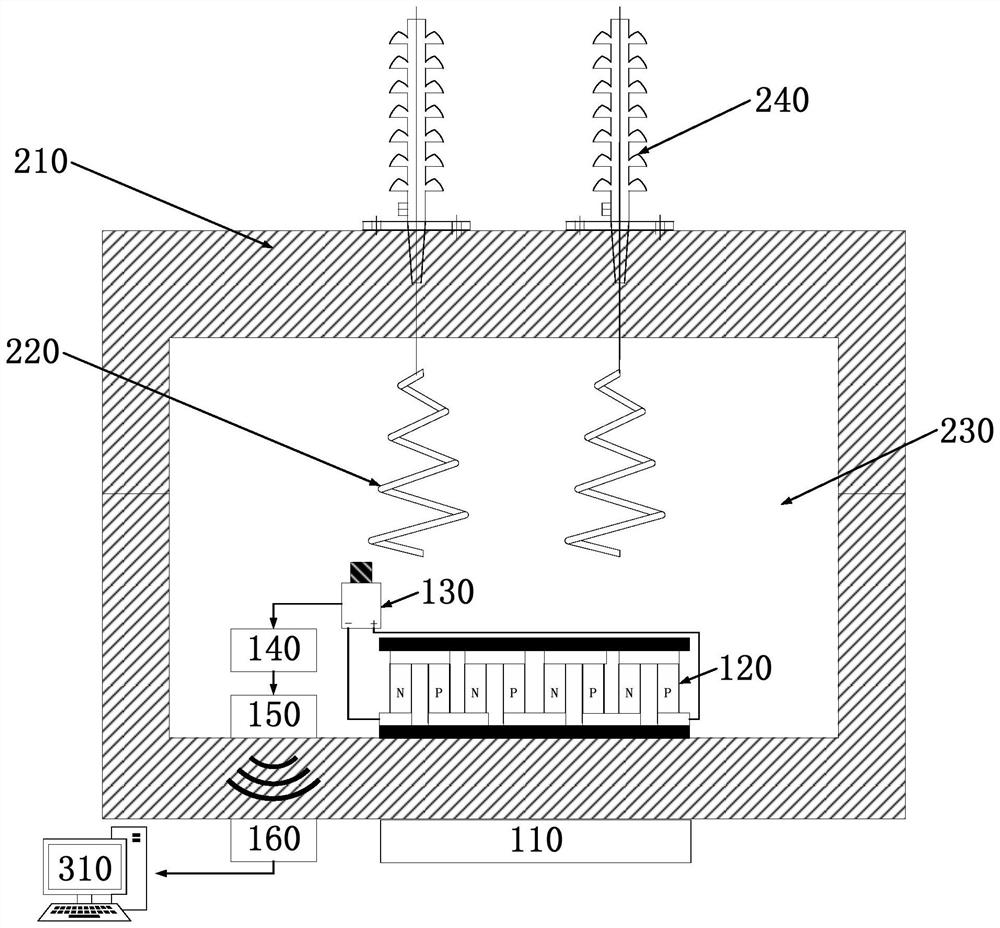

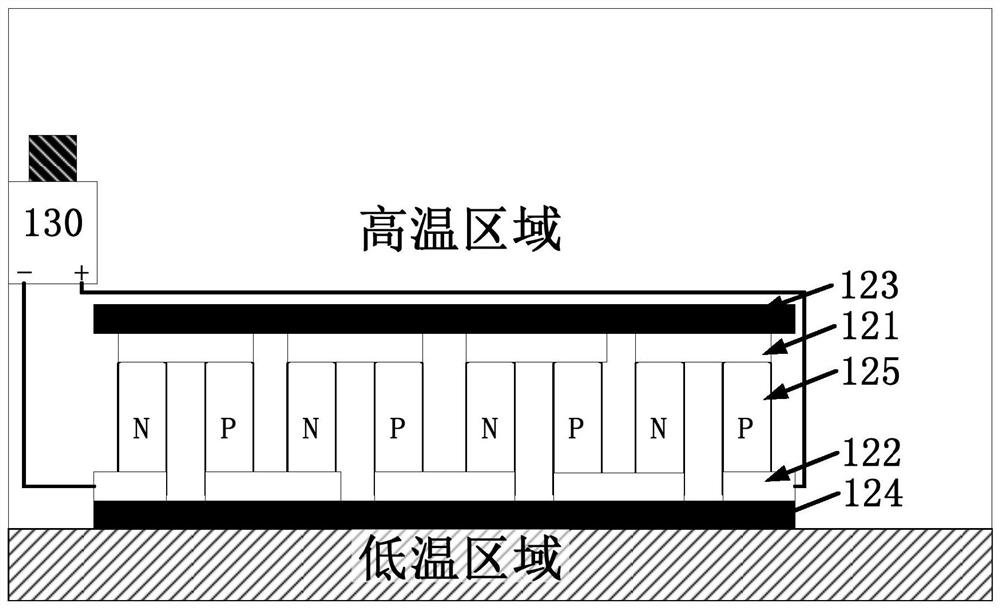

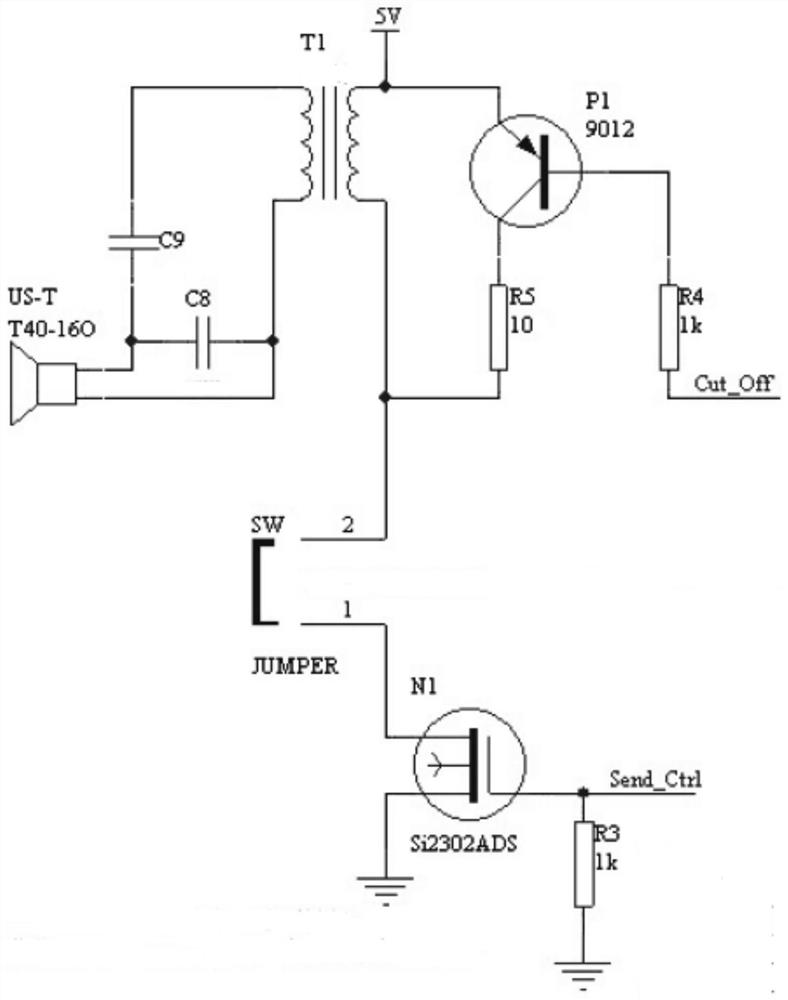

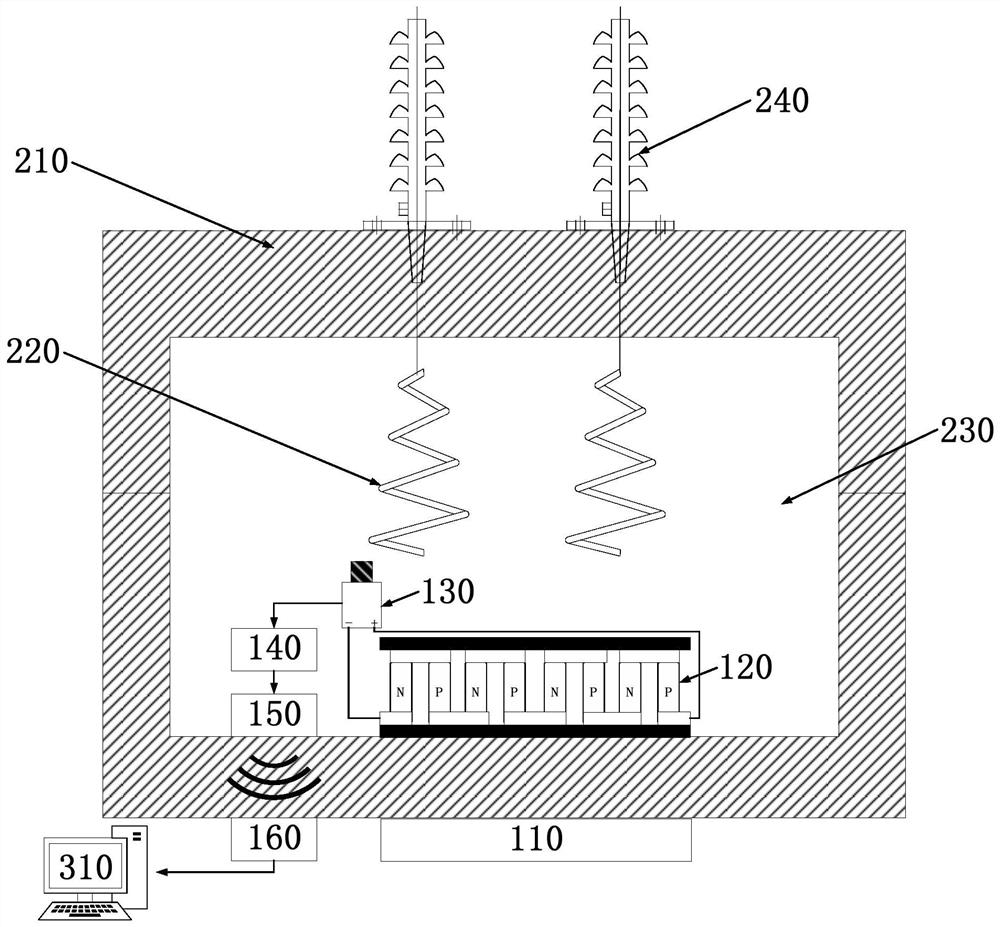

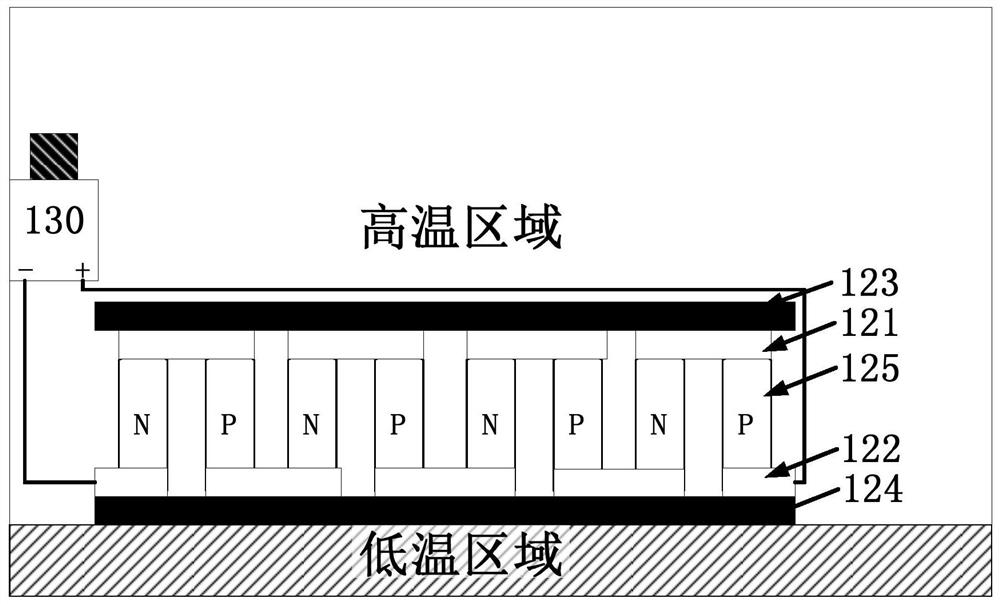

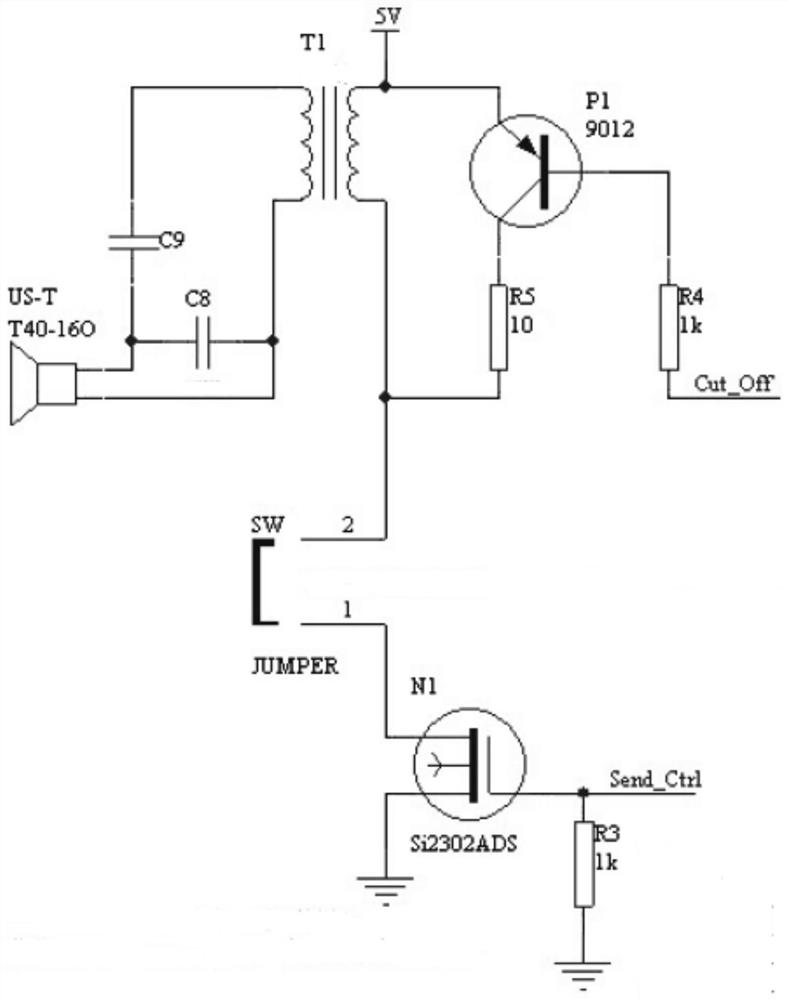

Online detection device and method for faults in transformer shell

PendingCN113376461ARealize online detectionReduce security risksVibration measurement in solidsNon-electrical signal transmission systemsTransformerProcess engineering

The invention provides an online detection device and method for faults in a transformer shell, wherein the device comprises a refrigeration sheet, a temperature difference power generation unit, a vibration sensor and an ultrasonic unvarnished transmission module; the refrigeration sheet is disposed at the outer side of the shell of a transformer, is used for reducing the temperature of the shell and forms a temperature difference with insulating oil in the transformer; the temperature difference power generation unit is mounted on the inner side of the shell of the transformer, is opposite to the refrigeration sheet in position and is used for generating and outputting temperature difference voltage; the vibration sensor is mounted in the transformer, is connected with the temperature difference power generation unit, supplies power through the temperature difference power generation unit, and is used for detecting the vibration condition in the transformer; and the ultrasonic unvarnished transmission module is used for sending the vibration condition in the transformer to a terminal outside the transformer. The device is simple in structure, the method is convenient to operate, external power supply is not needed, potential safety hazards of transformer operation are reduced, and online detection of faults in the transformer shell is achieved.

Owner:DALI BUREAU OF ULTRA HIGH VOLTAGE TRANSMISSION CO CHINA SOUTHERN POWER GRID CO LTD

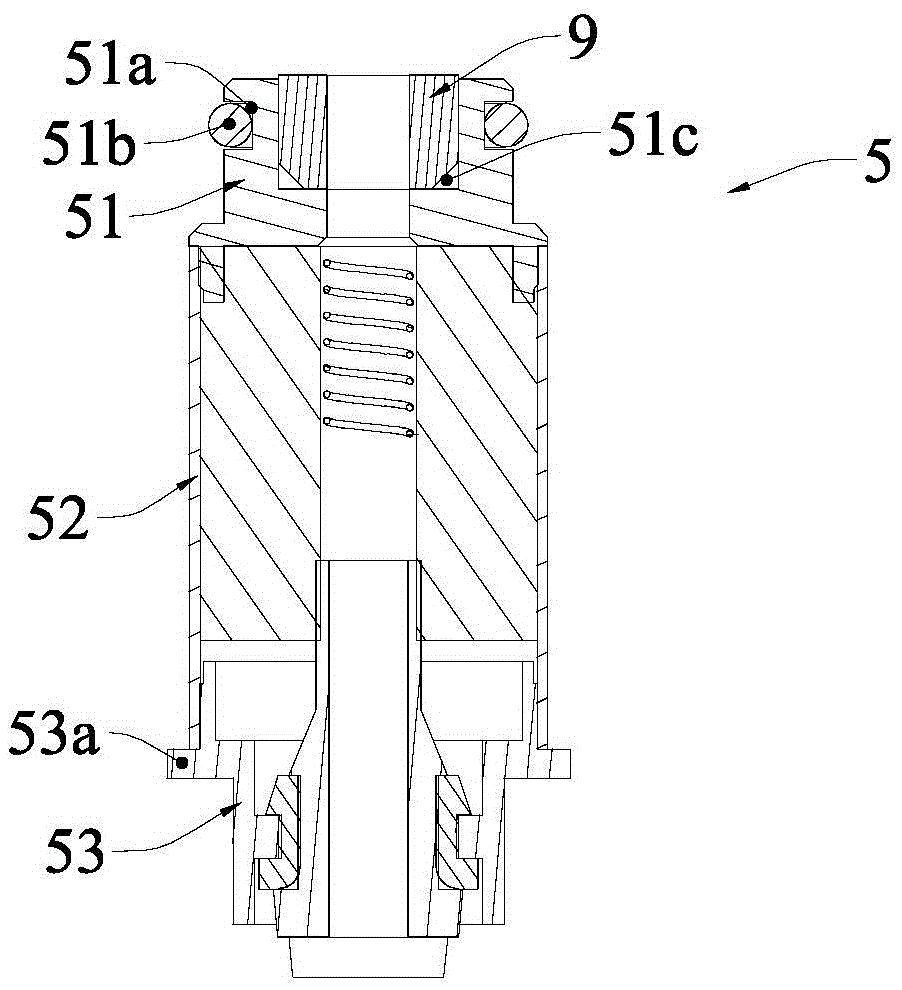

Novel one-way valve buffer structure

PendingCN113323935ADoes not affect response speedReduce shockServomotor componentsCheck valvesEngineeringMechanical engineering

The invention discloses a novel one-way valve buffer structure, and belongs to the technical field of hydraulic valves. The lower end of a valve element hole of a valve body is an oil port P, and the upper end of the valve body valve element hole is a spring cavity; a screw plug is arranged at the end of the spring cavity, a valve element is arranged in the spring cavity in a sliding mode, and a spring is arranged between the valve element and the screw plug; the lower end of the valve element abuts against the inner wall of the valve element hole of the valve body in a matched mode; an axial conical oil channel is formed in the circumferential face of the lower end of the valve element, the sectional area of the conical oil channel is gradually reduced from top to bottom, and the upper portion of the conical oil channel communicates with the spring cavity through an oil through hole; an oil port A is formed in one side of the valve body and communicates with the valve element hole of the valve body, and the conical oil channel is opposite to the oil port A in the radial direction of the valve element hole of the valve body. An oil way is simple and compact in structure, easy to machine and operate and high in practicability, the impact force of opening of the one-way valve on the screw plug is reduced, the risk of oil leakage at the screw plug is eradicated, and the response speed of the one-way valve is not affected.

Owner:徐州阿马凯液压技术有限公司

Bearing lining and gear box

PendingCN110905926AAchieve lubricationExtended service lifeGear lubrication/coolingBearing unit rigid supportOil canGear wheel

The invention discloses a bearing lining and a gear box and relates to the technical field of gear transmission equipment. The lining comprises a lining body, an oil inlet hole and an oil return hole,wherein the lining body is provided with a through hole, the oil inlet hole is formed in the lining body, is communicated with the through hole and is formed in the radial direction of the through hole, and the oil return hole is formed in the lining body and is communicated with the through hole. The lining is advantaged in that the lubricating oil in a box shell is led into the through hole through the oil inlet hole formed in the bearing lining, the lubricating oil can be guided back into the box shell through an oil return hole formed in the bearing lining, so lubrication of a bearing isachieved, the service life of the bearing is prolonged, maintenance cost is reduced, the oil inlet hole is formed in the radial direction of the through hole, an oil inlet groove can be directly communicated with the oil inlet hole of the lining, the oil leakage risk is avoided, the oil inlet hole can be an unthreaded hole, the machining process is simplified, and production cost is reduced.

Owner:南京高精轨道交通设备有限公司

Stop valve

Owner:GREE ELECTRIC APPLIANCES INC

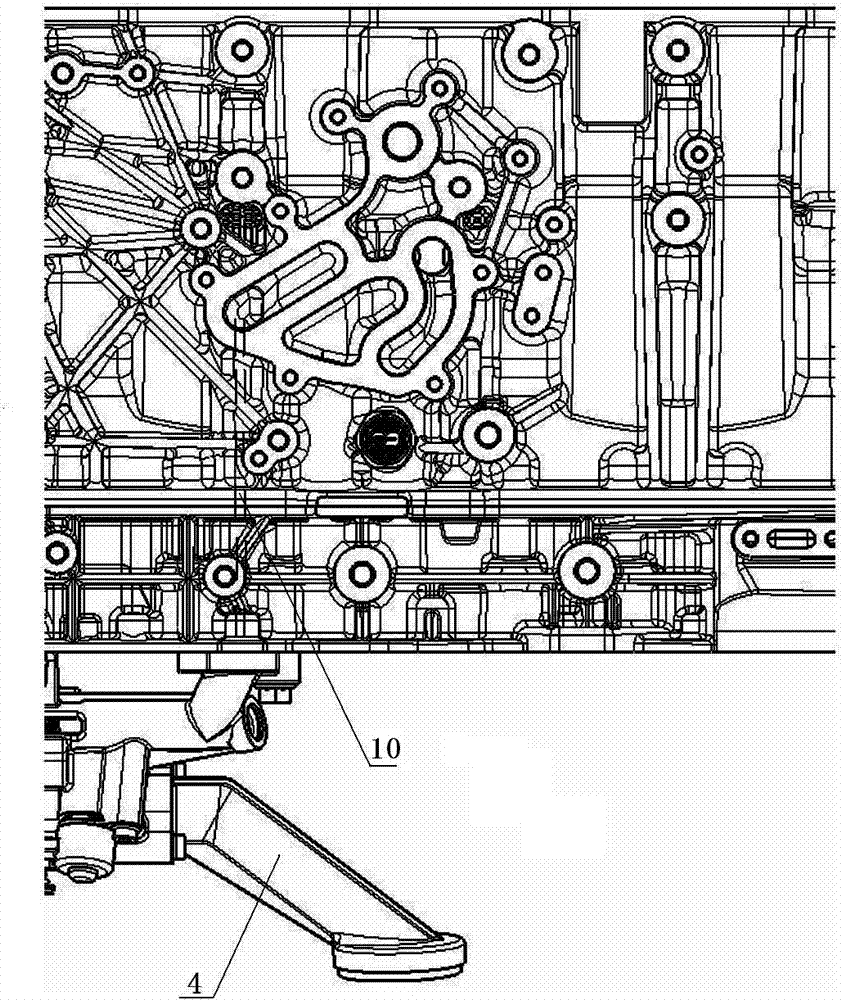

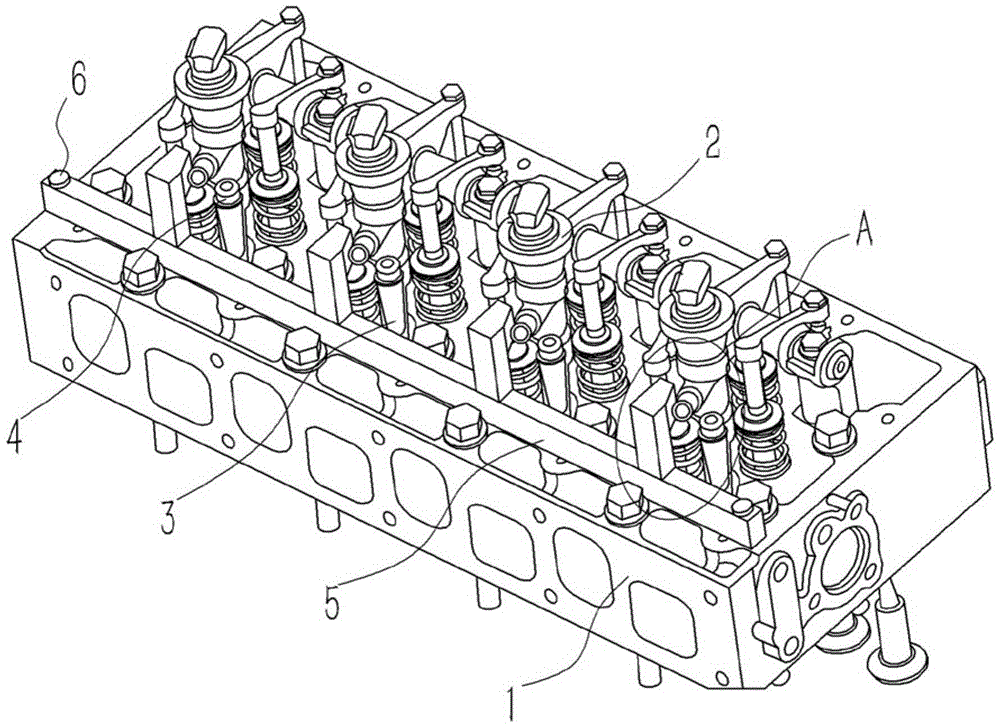

A positioning device for installing a fuel injector on a diesel engine

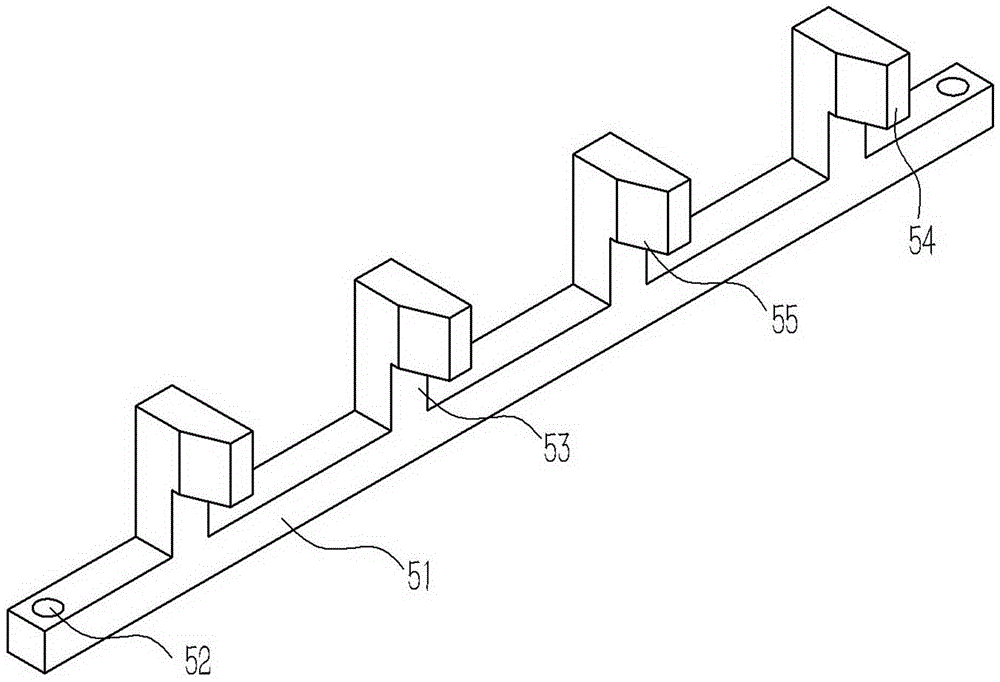

ActiveCN104265535BEasy to installAvoid the risk of oil spillsCylinder headsCylindersCylinder headEngineering

A positioning device for installing a fuel injector on a diesel engine, including a cylinder head installed on a cylinder, a number of fuel injectors are arranged on the cylinder head, an oil inlet arm is formed on the fuel injector, and a positioning baffle is arranged on the cylinder head , the positioning baffle is composed of a cross bar, a vertical rod and a stopper. A number of vertical rods are formed on the crossbar. The top of the vertical rod is formed with a stopper extending to the side of the crossbar. The side wall of the stopper is formed with a slope , the oil inlet arm of the injector leans against the slope of the positioning baffle, pin holes are formed at both ends of the cross bar, and the positioning pins pass through the pin holes of the cross bar and are plugged into the cylinder head; The fuel injector is fixed on the cylinder head through the injector pressure plate and the fuel injector pressure plate bolts. It uses a new type of positioning device to position the fuel injector and then fasten it, so that the installation angle of the fuel injector can be accurately positioned, which facilitates the installation of the cylinder head cover, and also solves the problem of sealing rings in the four holes on the side of the cylinder head cover risk of oil spills.

Owner:ZHEJIANG XINCHAI

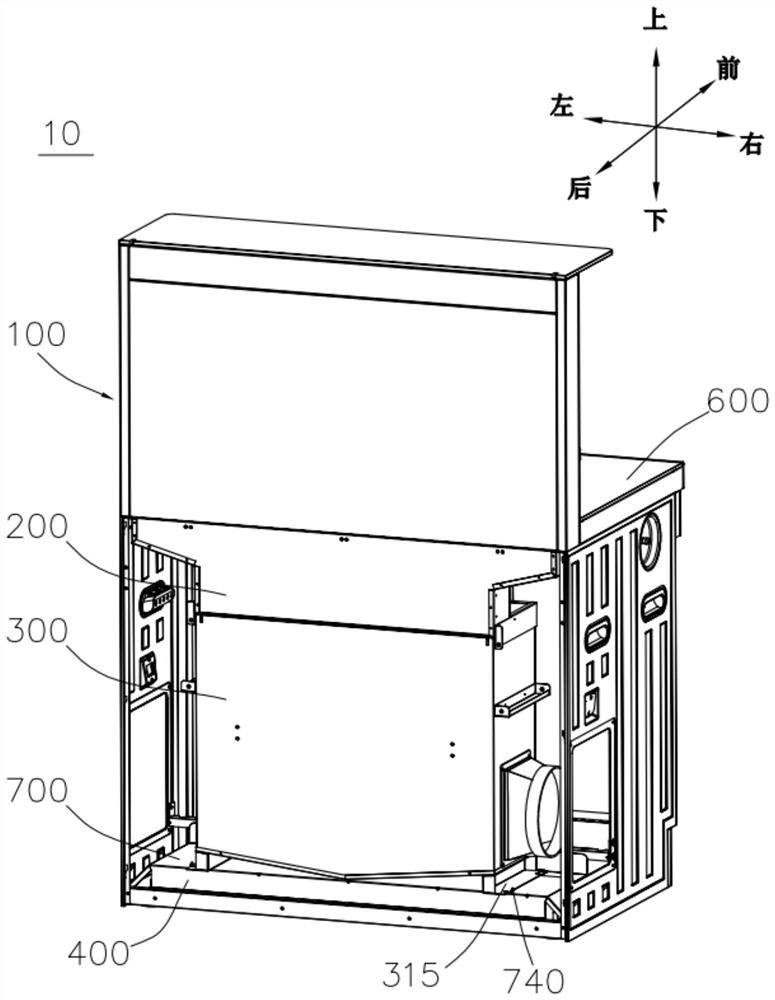

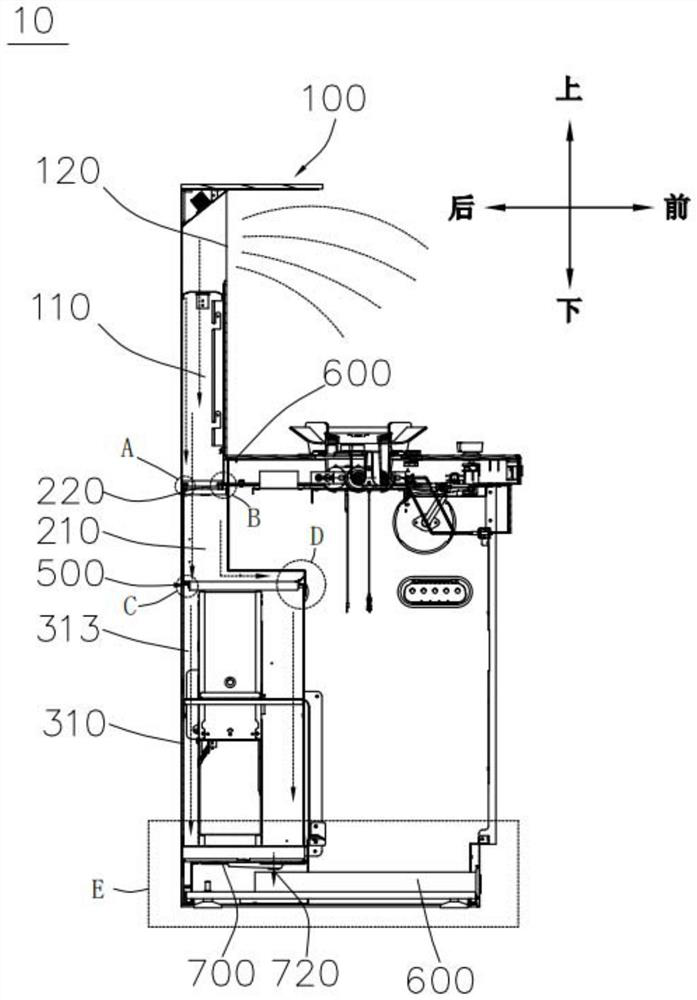

Integrated cooker

PendingCN112664990ASimplify the flue structureGuaranteed performanceDomestic stoves or rangesLighting and heating apparatusThermodynamicsFlue

The invention discloses an integrated cooker. The integrated cooker comprises a shell, an oil fume channel is formed in the shell, and an oil fume suction port is formed in the shell and communicates with the oil fume channel; a flow guide box is arranged in the shell, the flow guide box is provided with a flow guide cavity, an oil fume inlet and an oil fume outlet, the flow guide cavity communicates with the oil fume inlet and the oil fume outlet, and the periphery of one end of the oil fume channel and the flow guide box are allocated to be suitable for guiding oil in the oil fume channel into the flow guide cavity; an air bellow assembly comprises an air bellow, the air bellow is detachably arranged in the shell, the air bellow is provided with an air cavity and an oil passing hole, the oil passing hole is communicated with the air cavity, the flow guide box is detachably connected with the air bellow, and an oil guide structure suitable for guiding oil into the air cavity is arranged at the periphery of the oil smoke outlet; and an oil collecting box is arranged in the shell and used for receiving the oil flowing out of the oil passing hole. According to the integrated cooker, due to the fact that the air bellow assembly is detachably connected with the flow guide box and the shell, the air bellow assembly is detachable, an oil way of the integrated cooker is reliable, the risk of oil leakage is avoided, and the flue structure of the integrated cooker is simplified.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD

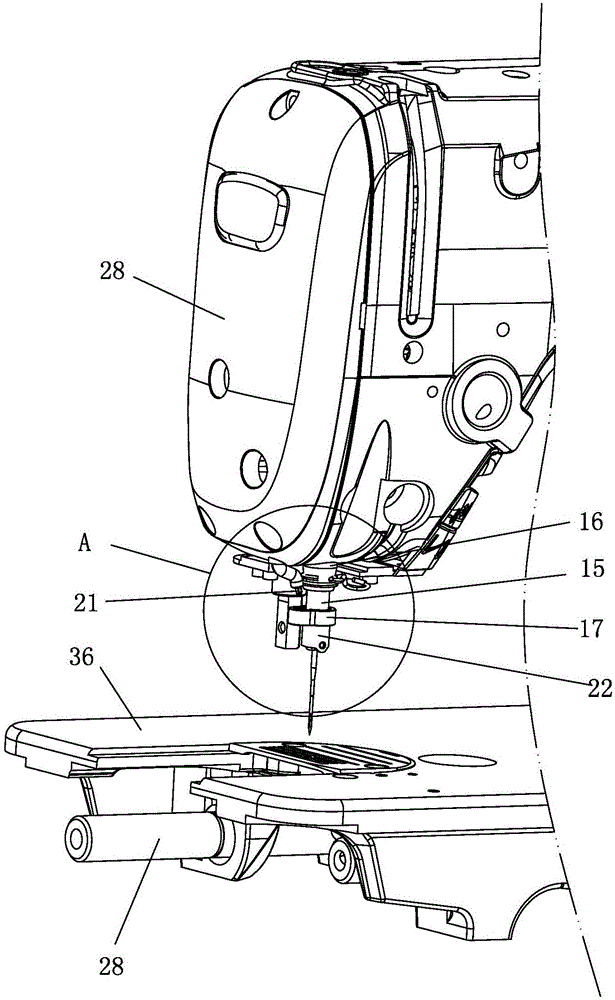

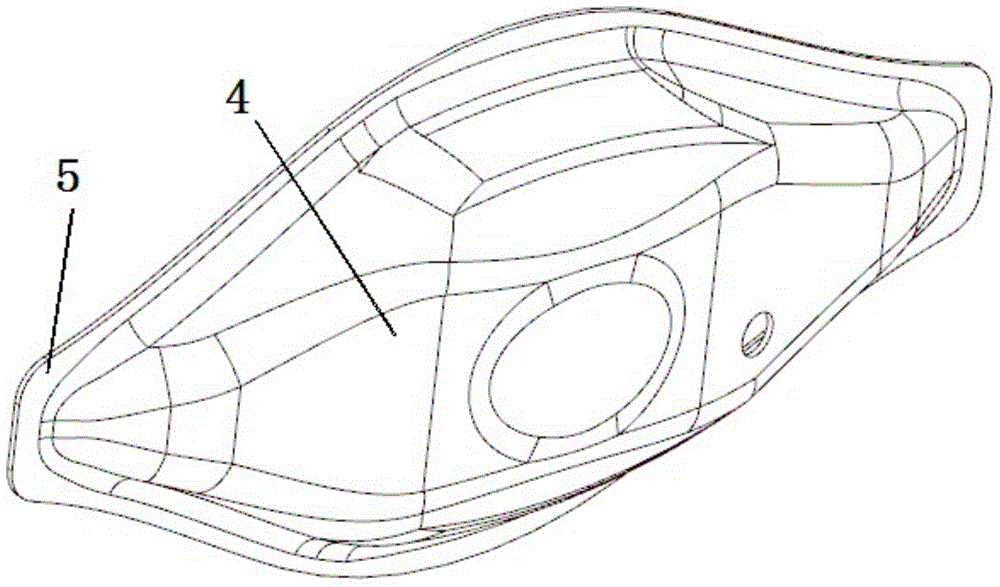

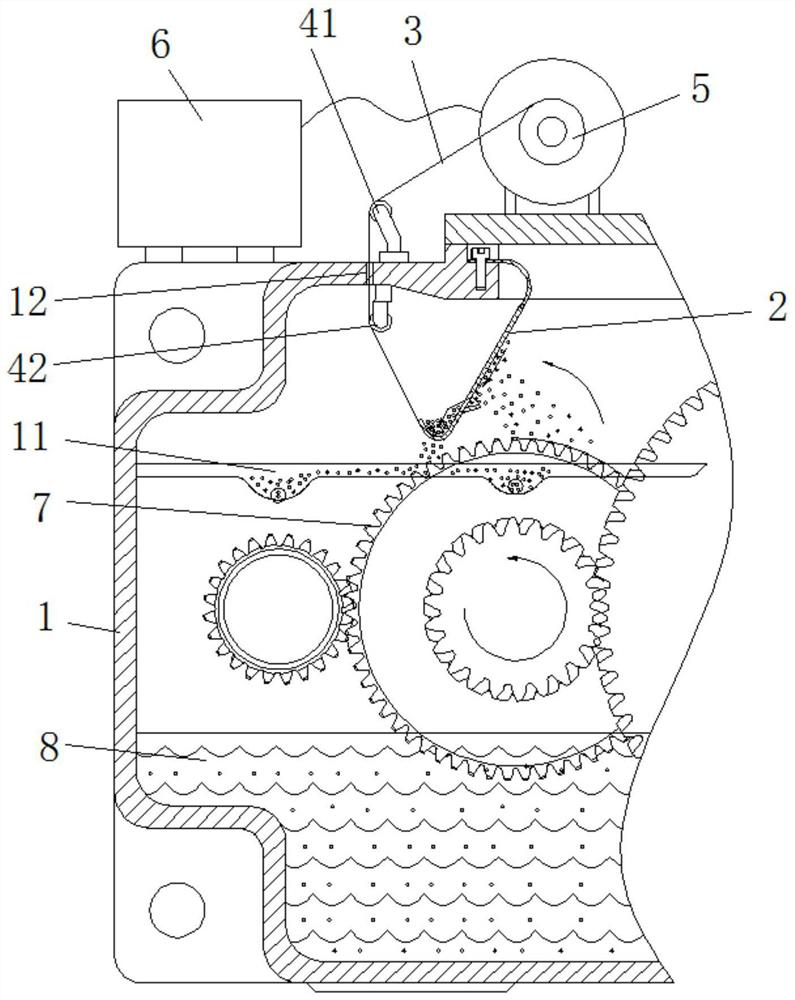

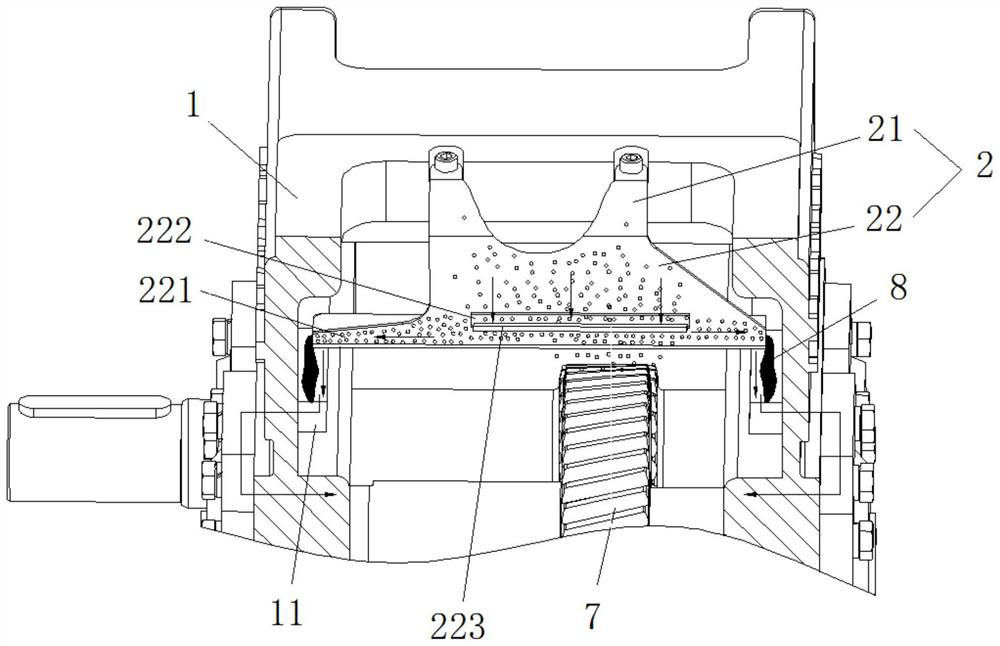

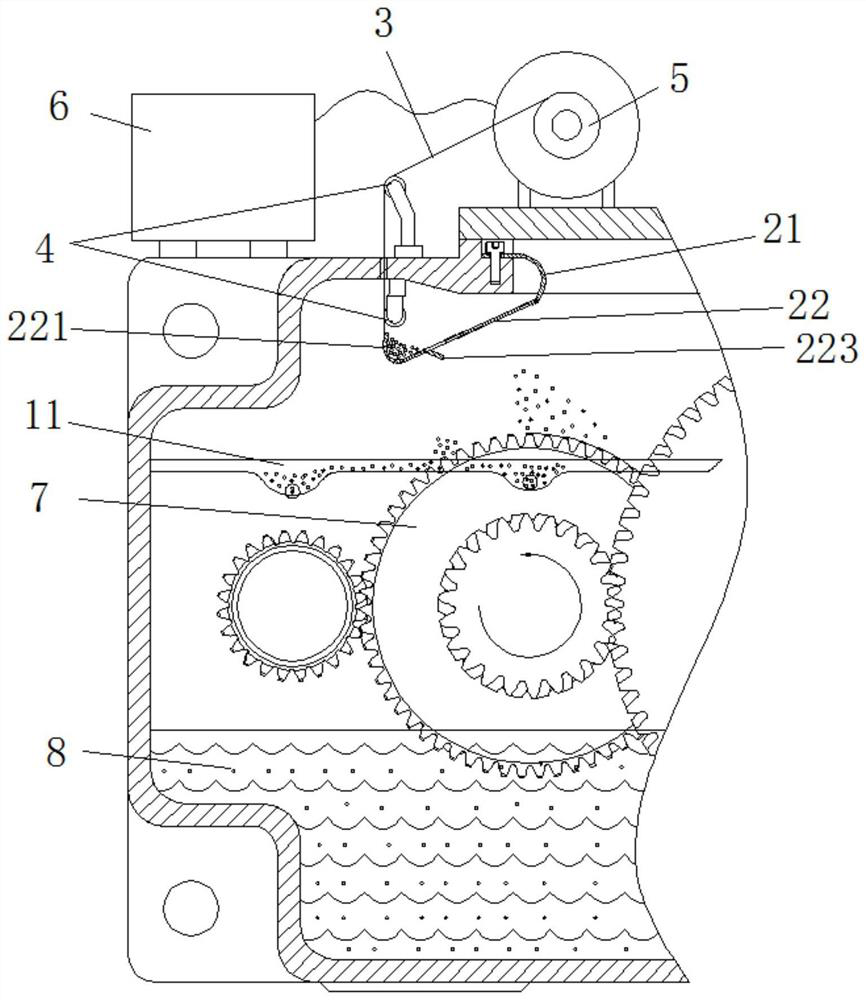

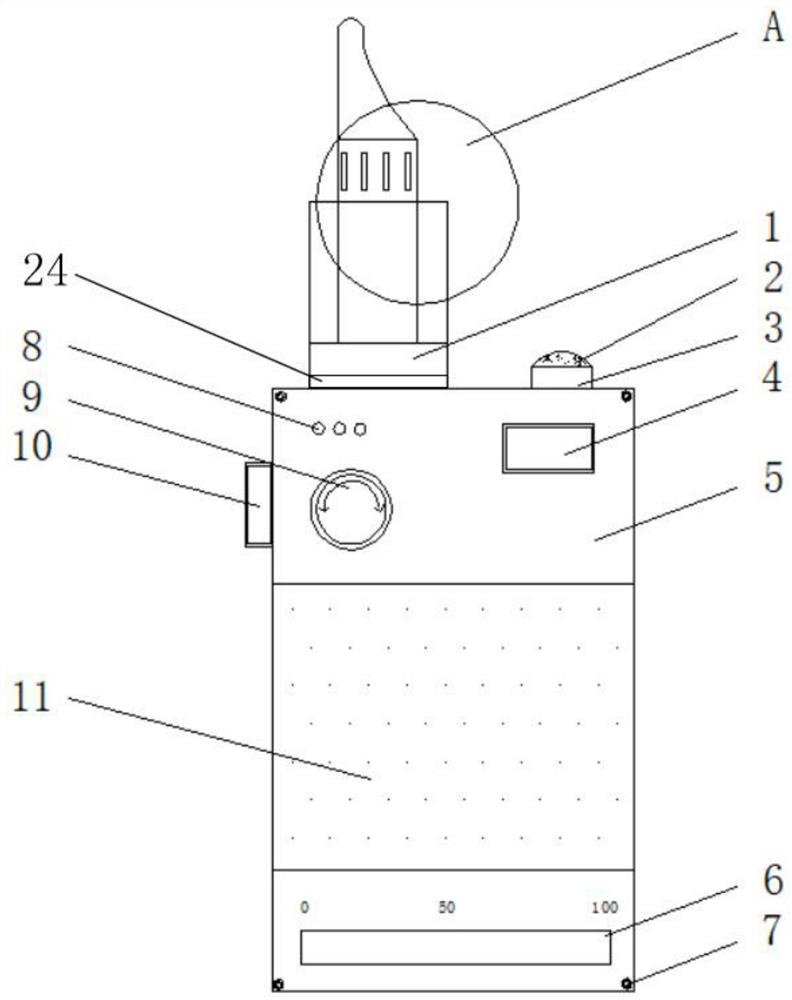

Oil-proof device for sewing machine needle bar

ActiveCN105970510ASolve the problem of poor anti-oil effectEliminate the risk of oil spillsLubrication/cooling devicesVertical motionSewing machine

The invention belongs to the technical field of sewing machines, and particularly relates to an oil-proof device for a sewing machine needle bar. The oil-proof device comprises the needle bar, a return oil storing device capable of collecting lubricating oil leaking between the needle bar and a needle bar lower bush is arranged on the needle bar, a return oil pipe is arranged at one side of the needle bar, the oil sucking end of the return oil pipe is located above the return oil storing device, and the return oil pipe is connected with the return oil device; in the vertical motion process, the needle bar drives the return oil storing device to move vertically, the return oil storing device moves to make contact with the oil sucking end of the return oil pipe, and the return oil pipe adsorbs lubricating oil in the return oil storing device through the return oil device and returns the oil. By means of oil return of the return oil pipe, the problem of leaked oil on the needle bar contaminates a sewing material is solved fundamentally, and the technical problem that fabric is contaminated due to lubricating oil leakage is avoided.

Owner:JACK SEWING MASCH CO LTD

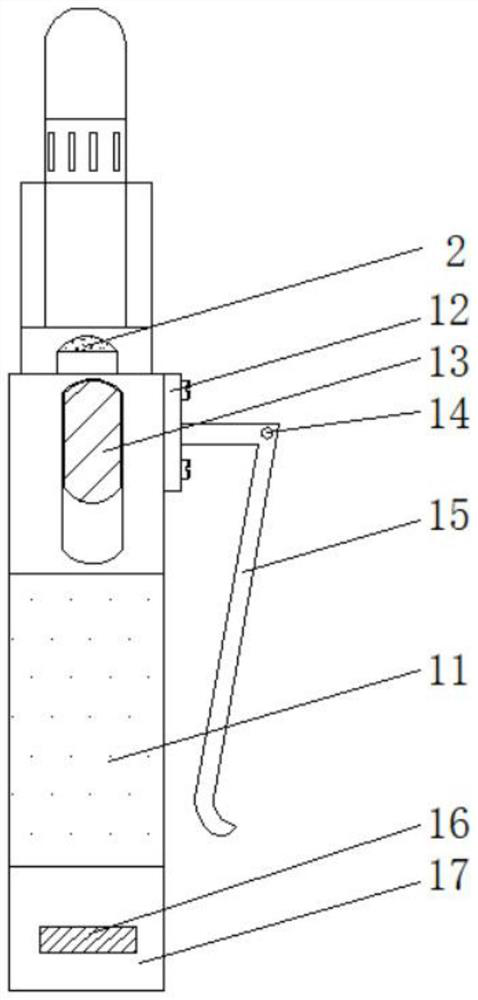

A backflow airflow atomizer and electronic cigarette including the atomizer

ActiveCN104207330BSecondary oil injection preventionSecondary oil injection will also prevent the risk of oil leakageMedical devicesTobacco devicesVentilation tubeReflux

The invention provides a backflow airflow atomizer and an electronic cigarette. The return flow atomizer includes suction nozzle, top external thread, vent valve, vent thread, damping ring, air guide tube, vent pipe, bottom internal thread, spring, positioning steel ball, top external thread is connected with vent thread, and spring is set outside the top The inside of the thread and the outside of the spring are provided with positioning steel balls. The ventilation valve is used to fix the spring and the positioning steel balls. The ventilation valve is provided with a number of ventilation holes. When the air hole of the air vent communicates with the air hole provided by the top external thread, the air flow enters the air vent thread. An electronic cigarette includes the above-mentioned backflow airflow atomizer. Different from the traditional nebulizer with bottom airflow and top airflow, this design is an atomizer that takes in air from the top, circulates the internal airflow, and at the same time exits the air at the top.

Owner:SHENZHEN DORTEAM TECH LTD

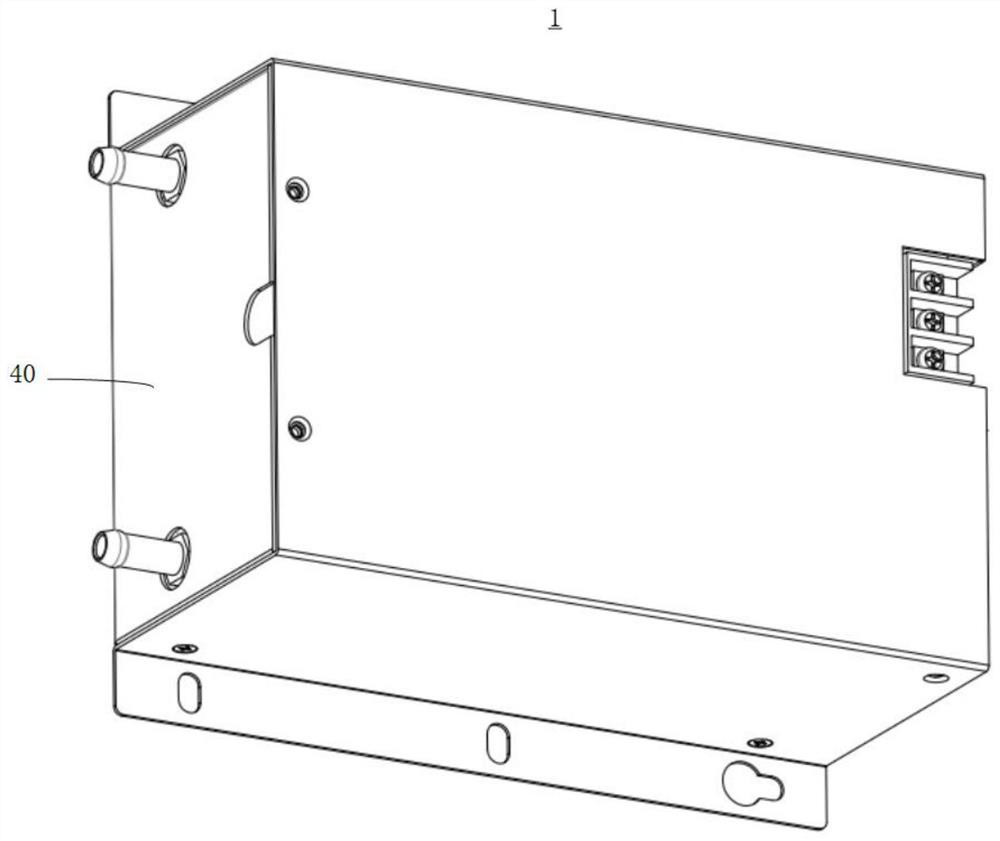

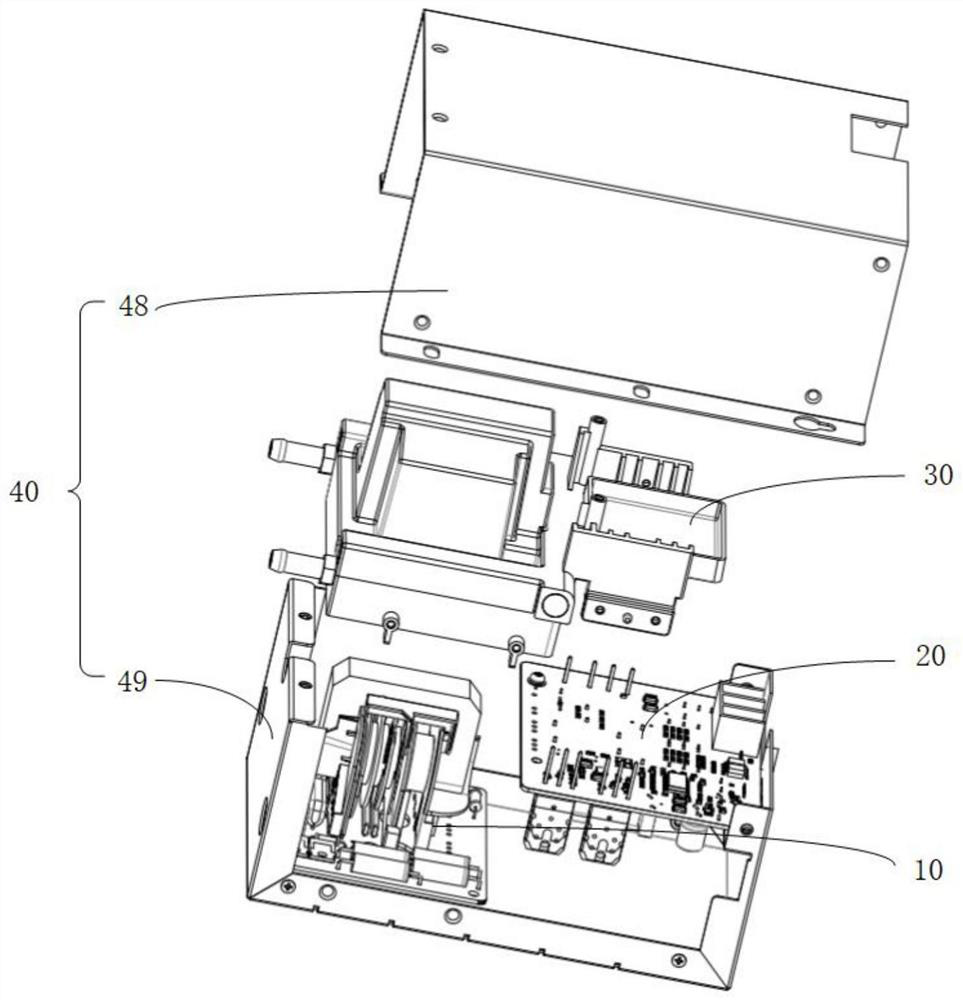

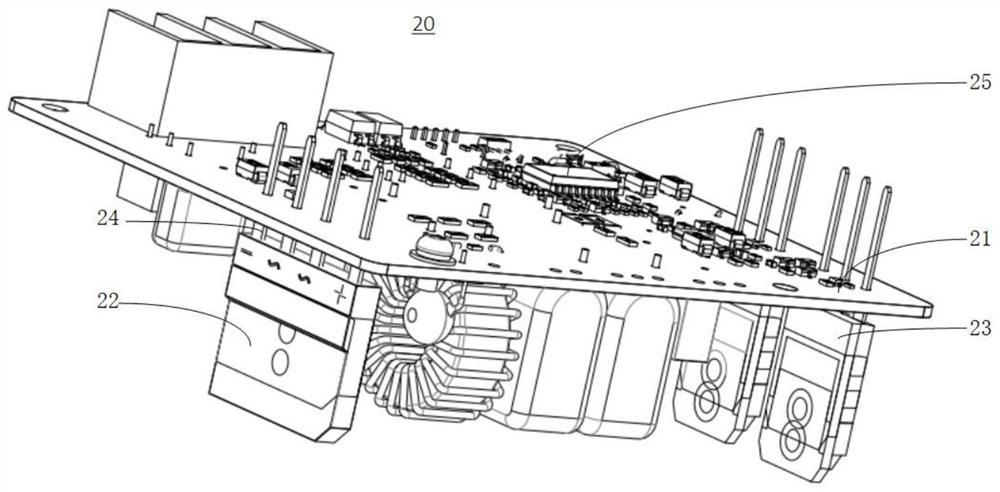

Power supply and electric equipment

PendingCN113692155AWaterproofImprove cooling effectCasings/cabinets/drawers detailsCooling/ventilation/heating modificationsOil coolingElectric equipment

The embodiment of the invention relates to the technical field of power supply heat dissipation, and particularly discloses a power supply and electric equipment. The power supply comprises a high-voltage assembly; a low-voltage assembly; a water-cooling shell which comprises a water-cooling shell body and an extension part extending from the water-cooling shell body, wherein the water-cooling shell body wraps the high-voltage assembly, the extension part accommodates part of the low-pressure assembly, the water-cooling shell body is provided with a cooling channel penetrating through the water-cooling shell body, the cooling channel is arranged around the high-voltage assembly, and cooling liquid is injected into the cooling channel; and a potting layer which wraps the water-cooling shell body and the high-voltage assembly, wherein the potting layer is formed after the water-cooling shell body is subjected to high-pressure potting by a potting material and is solidified. By means of the mode, the power source can be cooled, and the oil leakage risk caused by oil cooling and the noise trouble caused by air cooling through a fan are avoided.

Owner:SHENZHEN MEGMEET ELECTRICAL CO LTD

Automobile rear axle case

InactiveCN104309409AAvoid the risk of oil spillsImprove NVH qualityAxle unitsNoise, vibration, and harshnessPunching

The invention relates to an automobile rear axle case, which comprises an axle case assembly and a rear cover, wherein the rear cover is a whole and is in a rhombic shape, the middle part of the rear cover is outwards projected, the rear cover is connected with the axle case assembly, and a diagonal line of two smaller inner corners of the rear cover is parallel to the axial line of the axle case assembly. A round rear cover and two back reinforcing plates in the prior art are integrated into one rhombic rear cover, the rear axle part number is reduced, one punching forming element is adopted for replacing the use performance of three parts, the manufacturing work procedures are reduced, the production cost is reduced, the structure rigidity of the axle case and the X-direction bending mode are improved, the resonance frequency domain is avoided, and the NVH (noise vibration and harshness) quality of a whole automobile is improved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

An adjustable oil receiving plate device and control method thereof

ActiveCN112065969BRealize automatic storageGuaranteed uptimeGear lubrication/coolingOil canLow speed

Owner:宁波东力股份有限公司

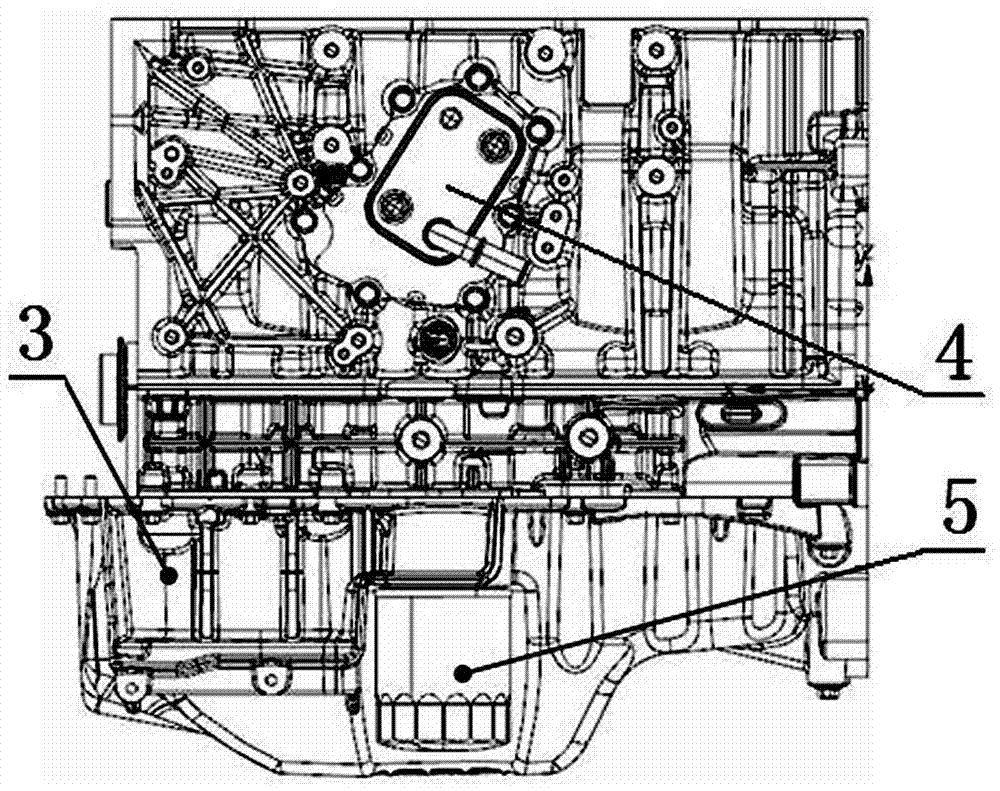

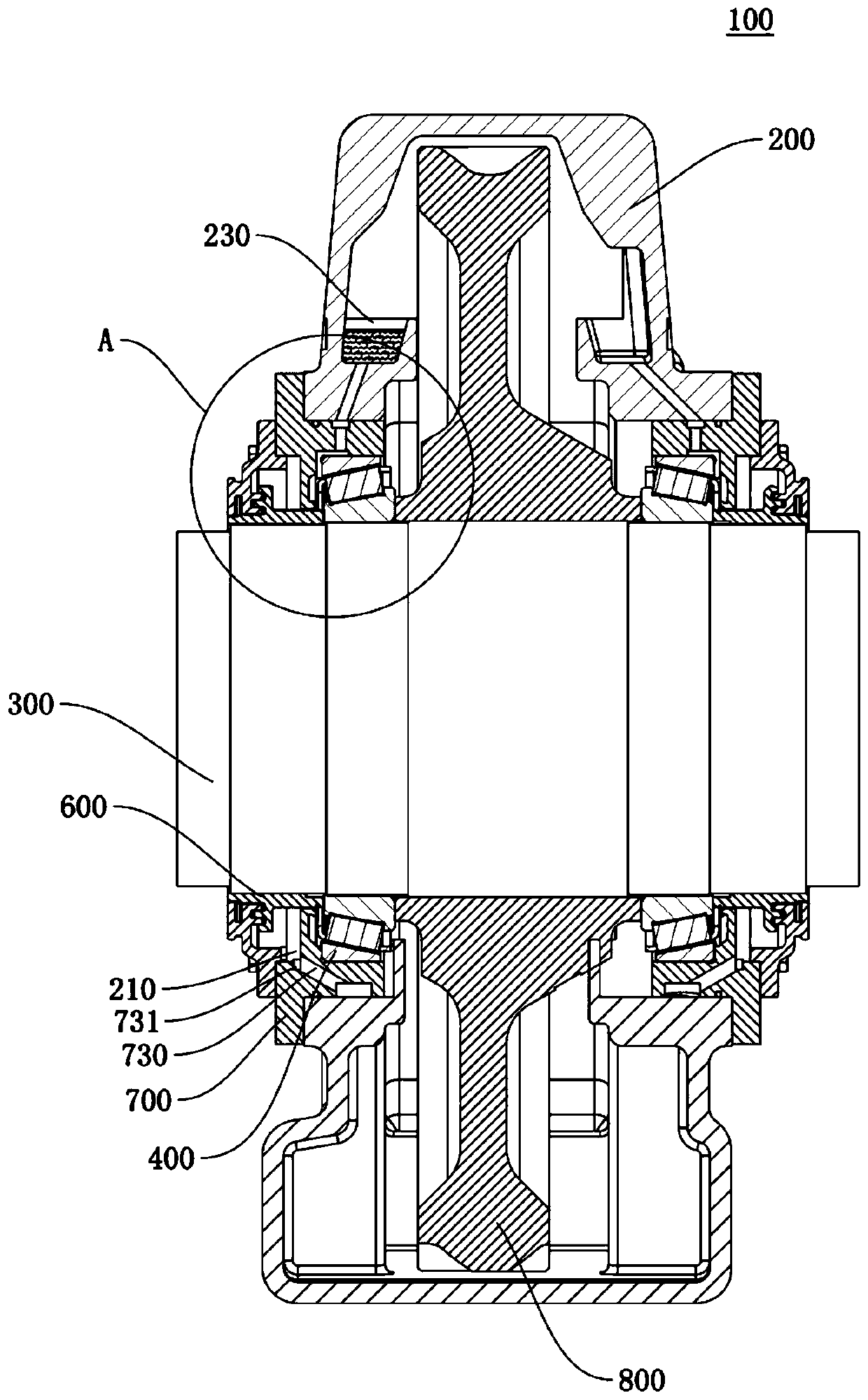

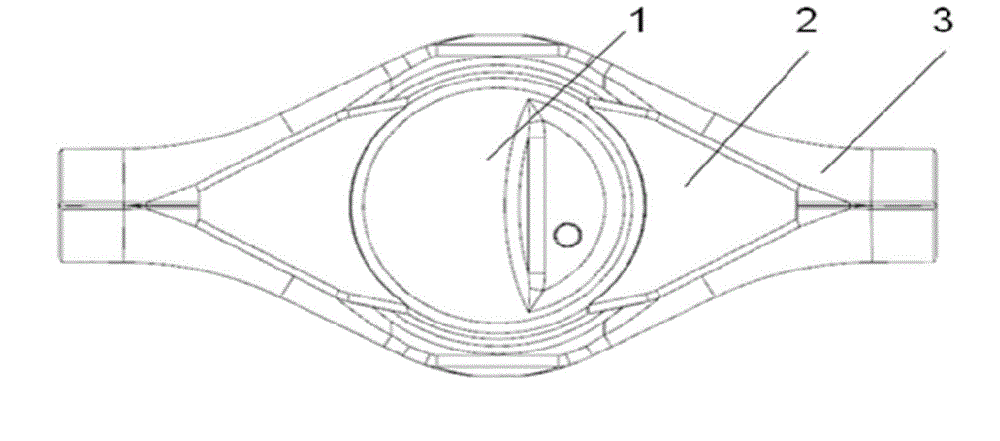

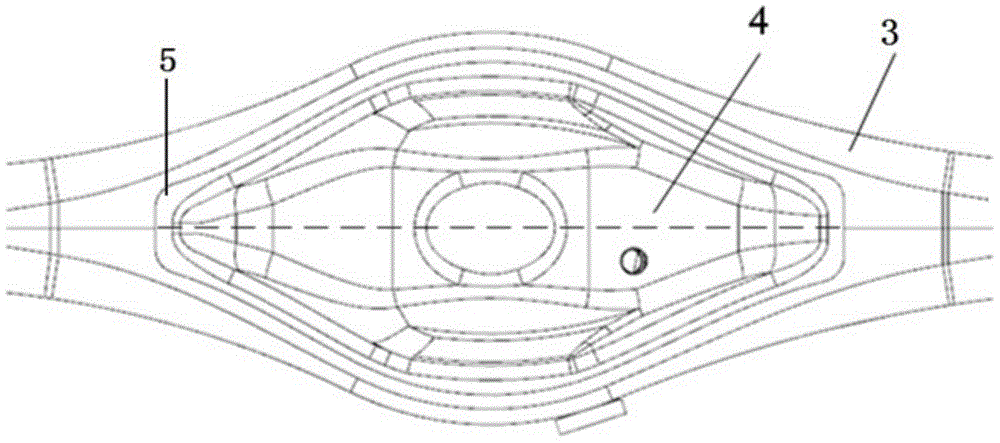

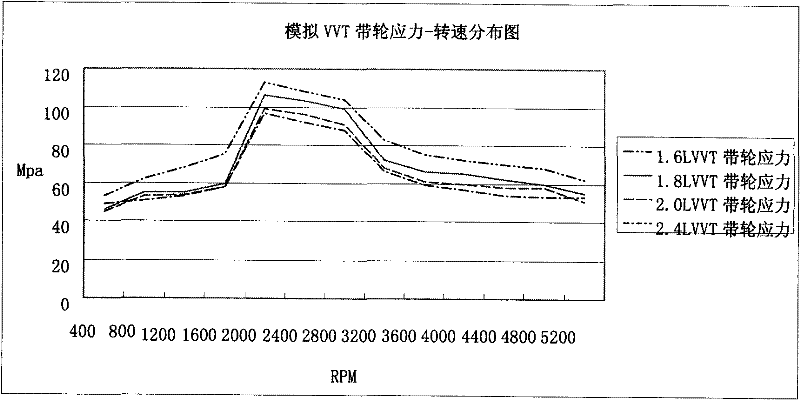

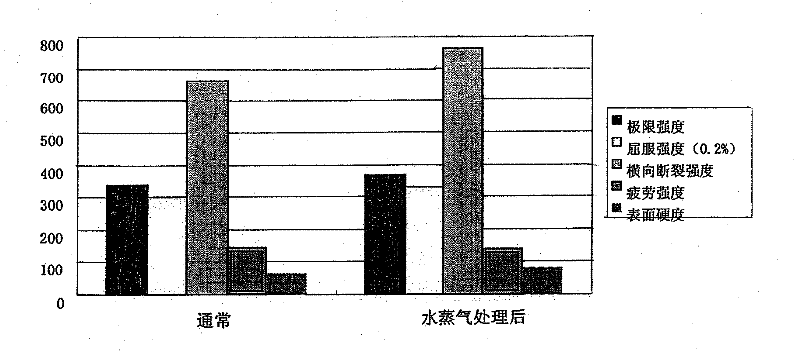

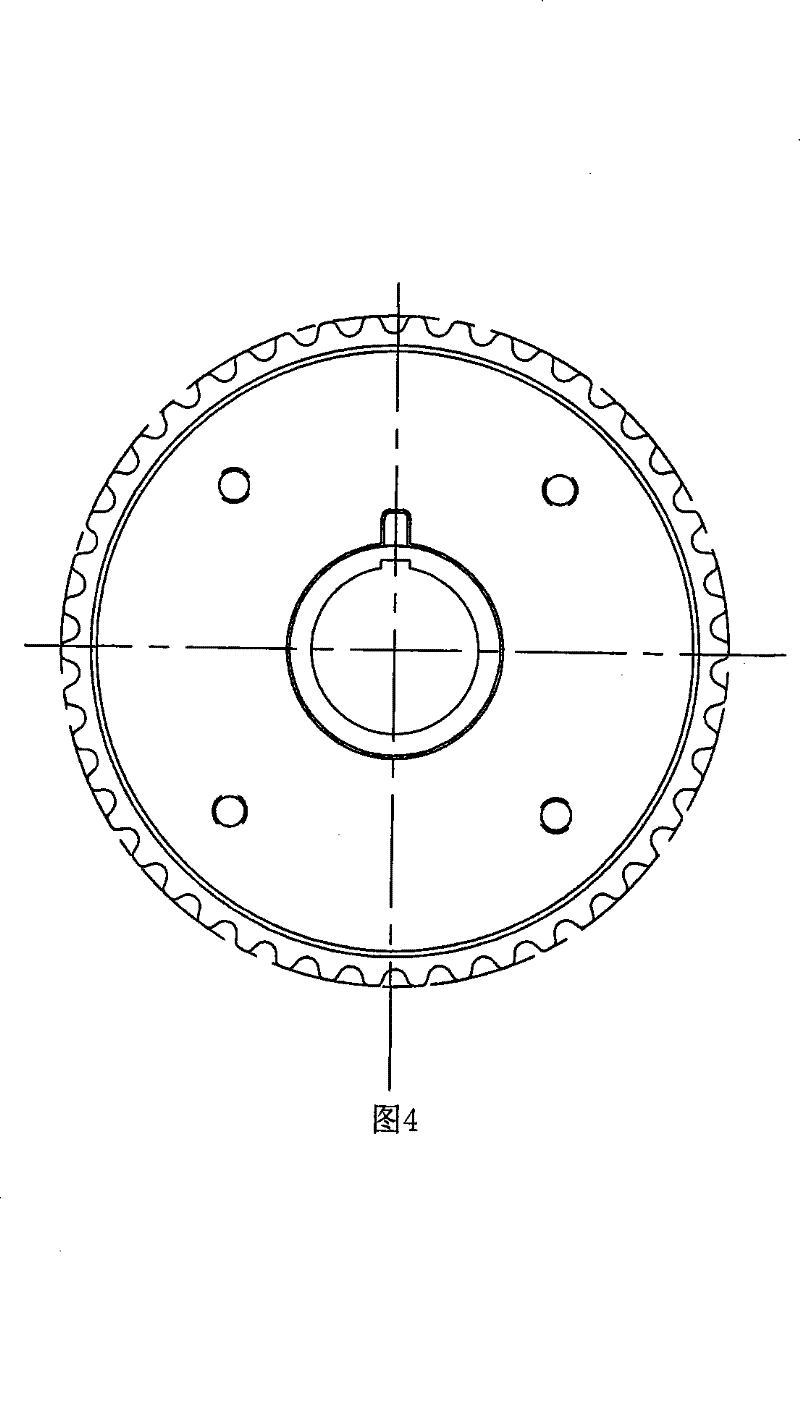

Intelligent variable valve adjustment device pulley and preparation method thereof

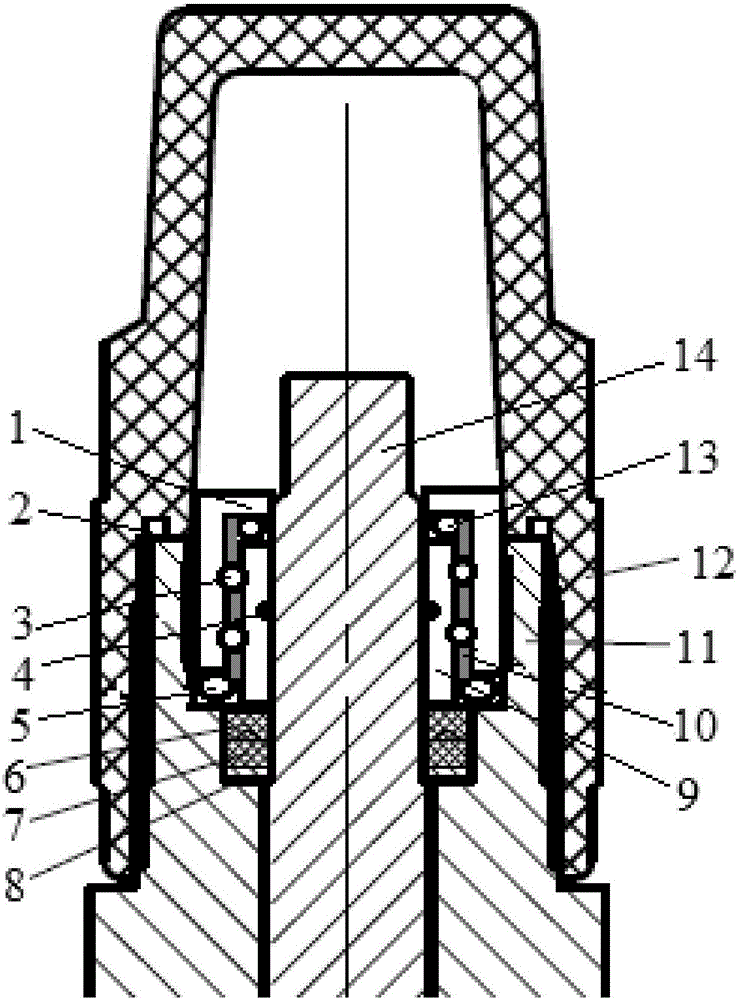

ActiveCN101598044BLow costReduce assembly processValve arrangementsPortable liftingWater vaporEngineering

The invention relates to a pulley of an intelligent variable valve adjusting device and a preparation method thereof, belonging to the field of auto parts. The adjustment device pulley includes a pulley (1), an oil pump base plate (2) and an oil pump body (3), the oil pump base plate (2) and the pulley (1) adopt an integrated design, and the oil pump body (3) It is directly connected with the belt pulley (1) by connecting bolts (4); the powder metallurgy material used for the belt pulley (1), oil pump bottom plate (2) and oil pump pump body (3) is: FC-0205-40. The method is as follows: treating the pulley of the powder metallurgy intelligent variable valve adjusting device with water vapor at 550°C±50°C for 2h±0.5h. The material and manufacturing costs of the invention are relatively low.

Owner:MIANYANG FULIN PRECISION MACHINING

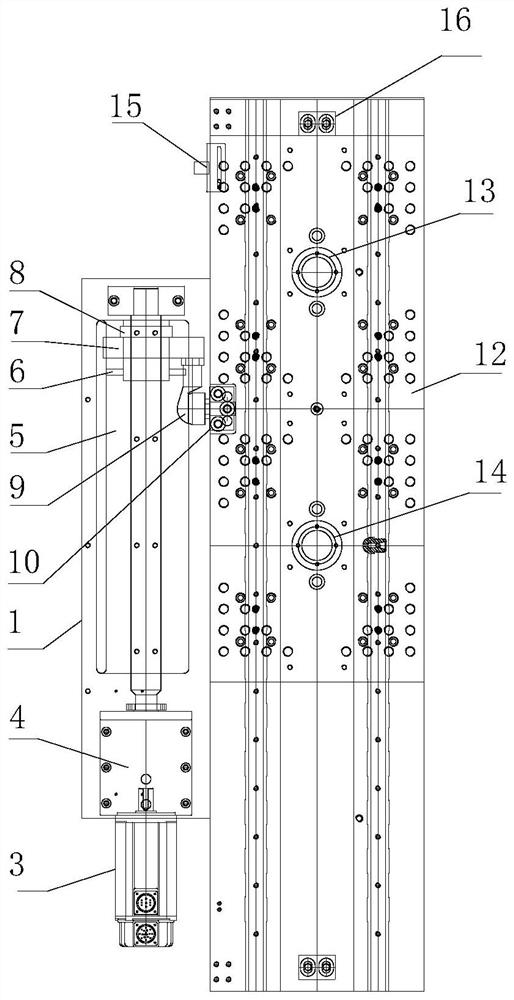

Servo sliding plate mechanism

The invention discloses a servo sliding plate mechanism which comprises a supporting plate, a sliding plate fixing plate is fixedly installed on one side of the top of the supporting plate, a sliding plate is arranged on the top of the sliding plate fixing plate, a servo motor is fixedly installed at one end of the supporting plate, the output end of the servo motor is connected with a rotating shaft, and a connecting block is arranged above the supporting plate. A lead screw nut pair is installed on the connecting block, the other end of the rotating shaft is fixedly connected with one end of the lead screw nut pair, a universal bearing is installed on one side of the lead screw nut pair, a sliding plate pull block is installed at the other end of the universal bearing, and the sliding plate pull block is fixedly connected with a sliding plate; in the technical scheme provided by the invention, the servo motor is used for driving the ball screw of the screw nut pair to rotate in the positive and negative directions, so that the nut pair pulls the sliding plate to complete the reciprocating motion of the sliding plate, the sliding guide of the sliding plate is ensured, and the sliding plate of the sliding plate mechanism is short in sliding time and high in efficiency; and meanwhile, the device has the advantages of high positioning precision, stable operation, no impact and no noise.

Owner:丰铁塑机(广州)有限公司

Electronic cigarette without oil leakage

The invention discloses an electronic cigarette without oil leakage. The electronic cigarette comprises: a main body, wherein an anti-skid sleeve is arranged on the surface of the main body, and a horizontal electric quantity plate is arranged below the anti-skid sleeve; a panel which is arranged at the upper part of the main body; a base which is arranged above the panel, wherein a glass tube is fixed above the base; and a cigarette holder which is arranged above the glass tube. The panel adjusts the oil supply amount, and then controls the amount of atomized tobacco tar, energization and atomization work, electricity is saved, conditions for long-time endurance of equipment are provided, the anti-skid sleeve can more stably provide the anti-skid effect on the equipment through tight attachment, the anti-skid performance of the equipment is better, the holding feeling of the equipment in the hand is better, and the practicability of the equipment is improved. and the base is detachably arranged above the main body through a connecting mechanism, so that tobacco tar in the glass tube can be directly replaced through the connecting mechanism, the glass tube and the base are sealed, and the risk of oil leakage is avoided.

Owner:洛阳市总深电子科技有限公司

Oil cup anti-leakage structure and electronic cigarette

ActiveCN105595435BAvoid contactQuality is not affectedTobacco devicesEngineeringElectronic cigarette

Owner:CHANGNING DEKANG BIOTECH SHENZHEN CO LTD

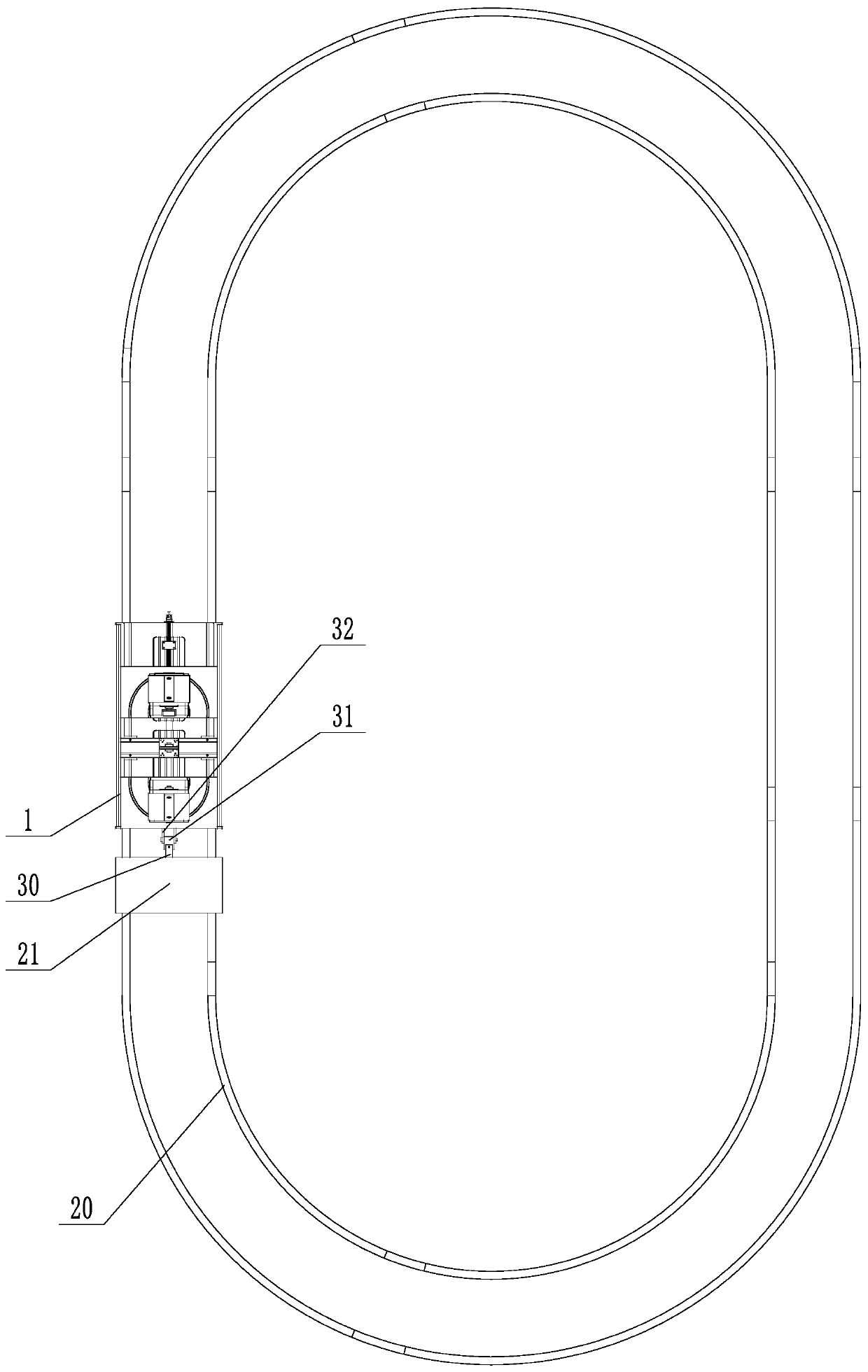

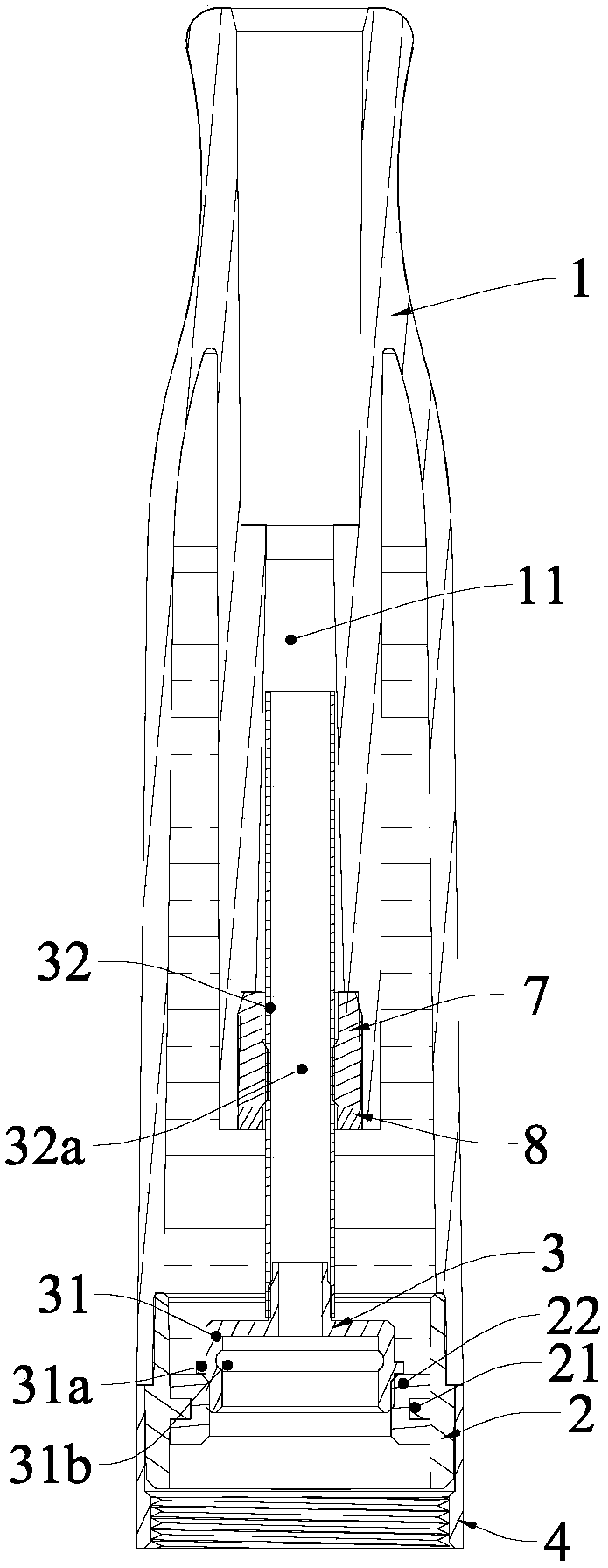

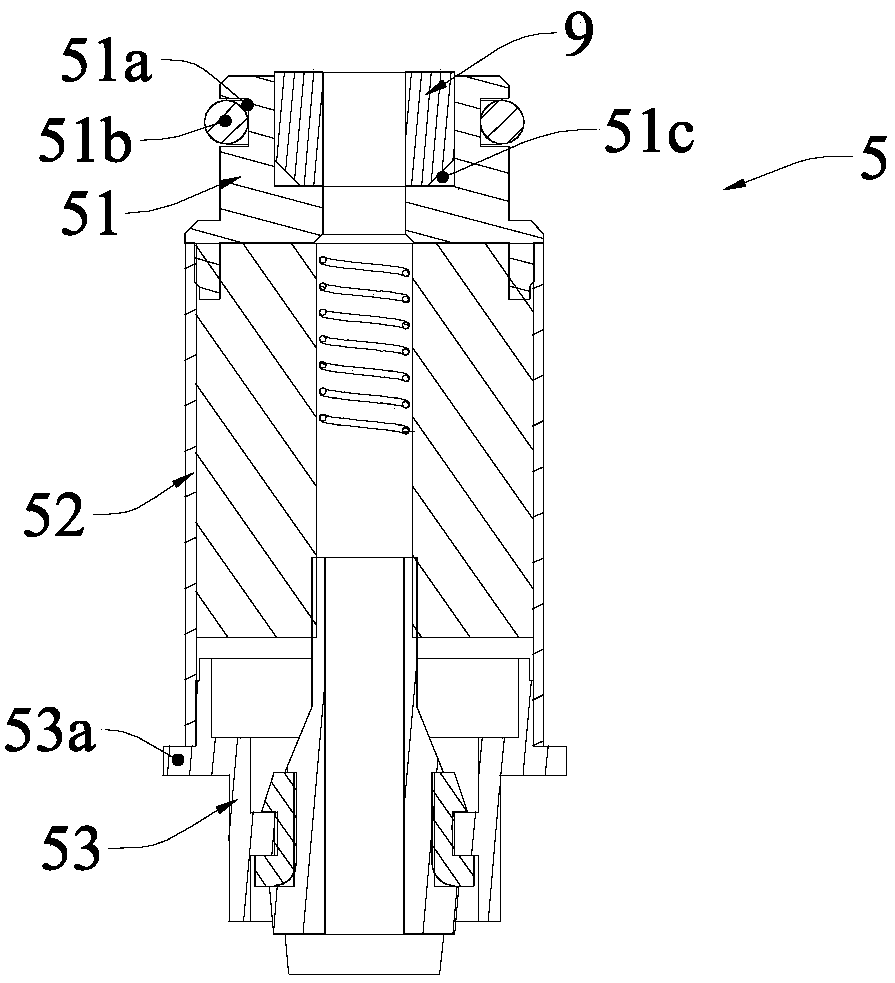

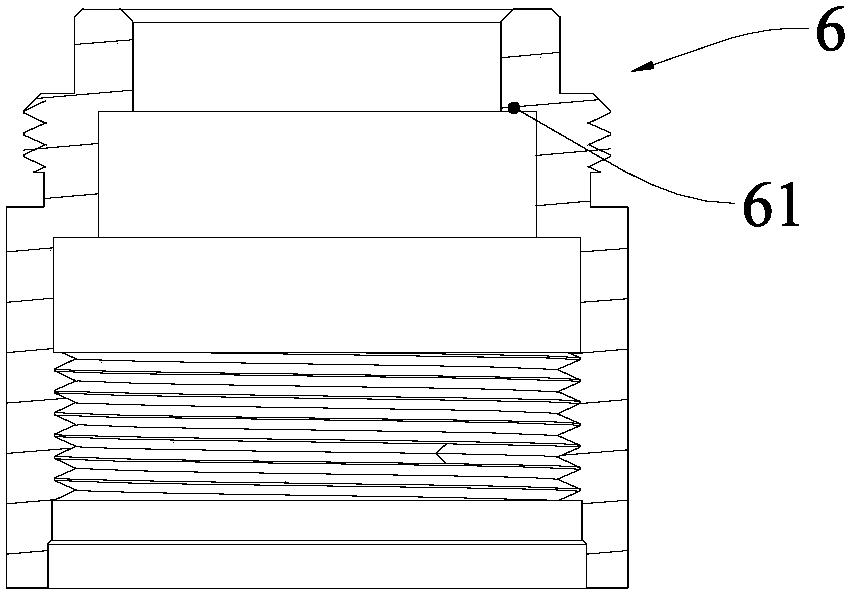

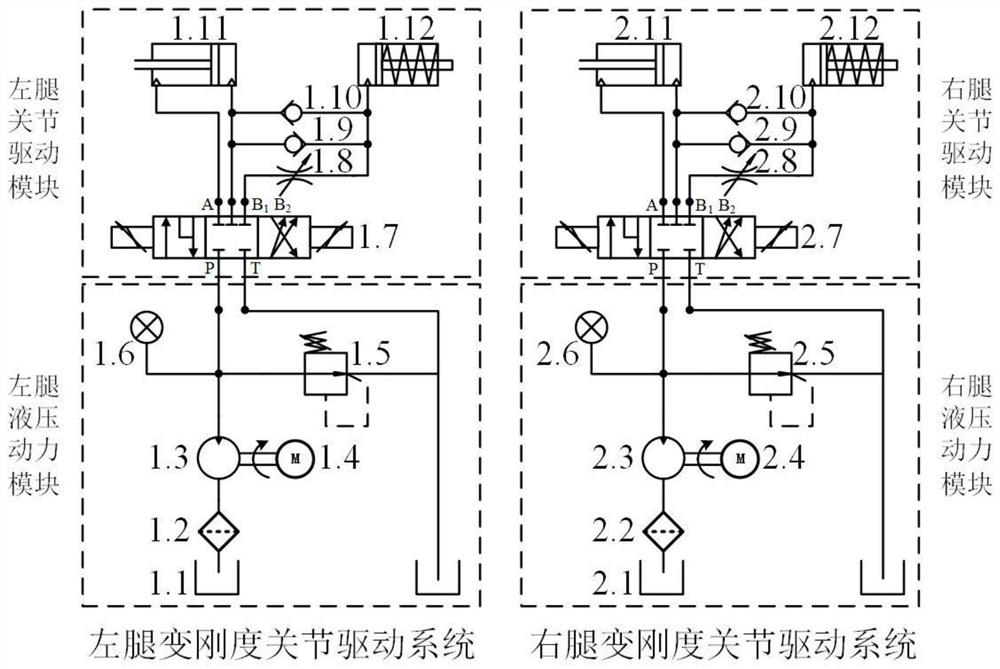

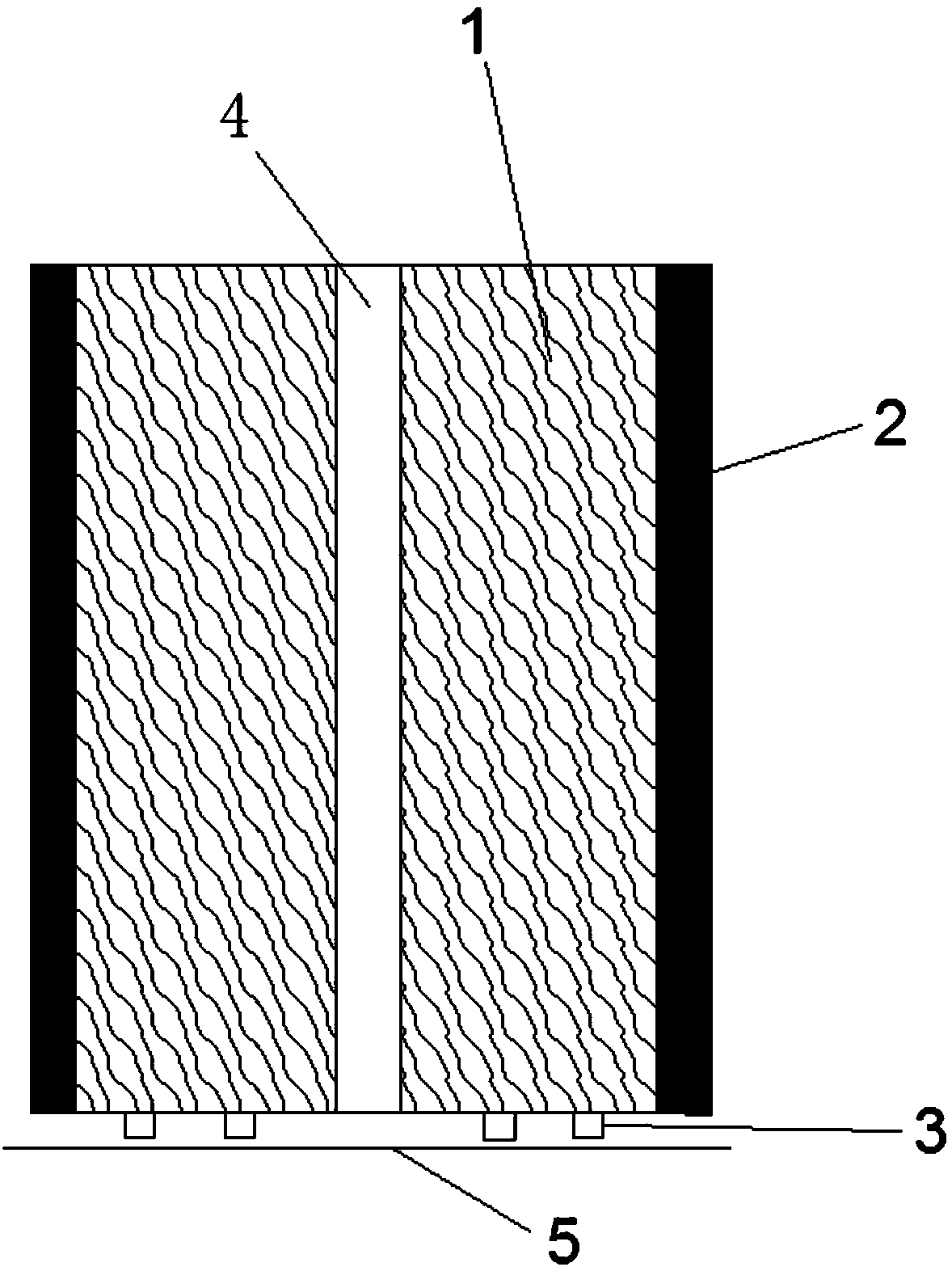

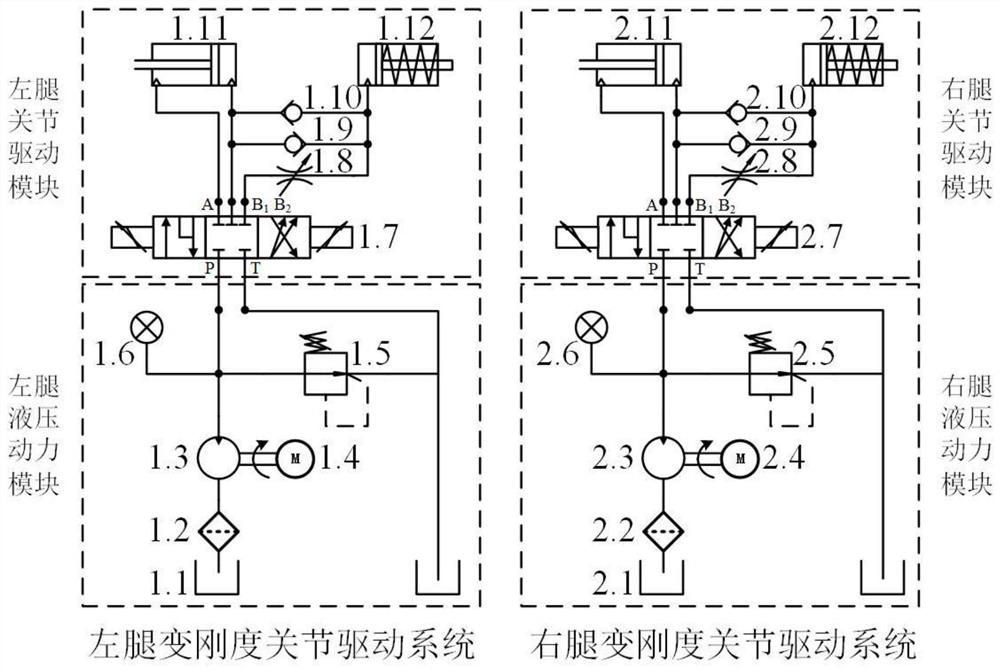

A variable stiffness joint hydraulic drive system for an exoskeleton robot

ActiveCN113232014BAvoid the risk of oil spillsImplement storageProgramme-controlled manipulatorExoskeleton robotControl engineering

The invention relates to the field of hydraulic drive systems, in particular to a variable stiffness joint hydraulic drive system for an exoskeleton robot, comprising a left leg variable stiffness joint drive system and a right leg respectively used to drive a left leg and a right leg and have the same internal structure Variable stiffness joint drive system, the drive system includes a hydraulic power module and a joint drive module that assists driving the human body to walk. The invention uses a distributed power source to replace the centralized hydraulic power source in the exoskeleton backpack, and solves the problem of the centralized hydraulic power source. and the risk of oil leakage caused by many oil pipe joints, reducing the complexity of system control, and decomposing the centralized hydraulic power source into distributed hydraulic power sources, which can replace the load-bearing backpack often found in hydraulically driven lower extremity exoskeletons. Backpacking makes the overall structure more concise.

Owner:芜湖云擎机器人科技有限公司

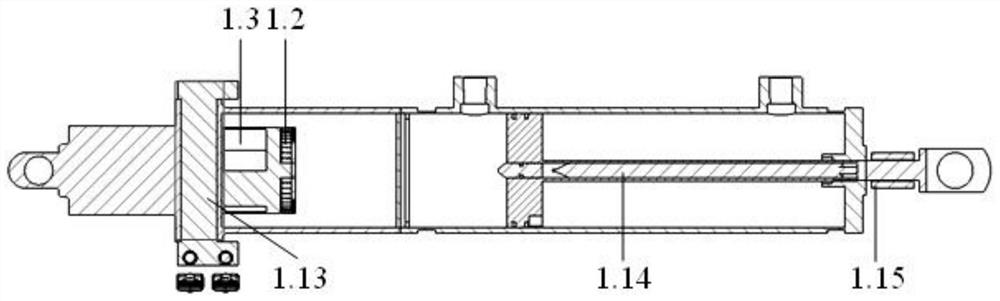

Solid cartridge for ultrasonic atomization electronic cigarette and manufacturing method of solid cartridge

PendingCN109805448ADesign scienceSimple designTobacco devicesElectronic cigaretteUltrasonic atomization

The invention relates to a solid cartridge for an ultrasonic atomization electronic cigarette. The solid cartridge comprises a liquid storage part (1) and an anti-seepage layer (2) surrounding a periphery of the liquid storage part (1), wherein the liquid storage part (1) is made of loose solid materials; the bottom of the liquid storage part (1) is in contact with an ultrasonic atomizing sheet (5) of the ultrasonic atomizing electronic cigarette through protrusions (3); an interval between the protrusions (3) in contact with the ultrasonic atomizing sheet (5) is 0.5-5 mm; and the area of a contact surface of the single protrusion (3) in contact with the ultrasonic atomization sheet (5) does not exceed 30 mm2. The solid cartridge provided by the invention is scientific in design, simple tomanufacture, low in cost, fast in smoke output, high in smoke volume, environment-friendly and safe, and good in user experience; and in addition, the solid cartridge provided by the invention can beused to simplify a structure of ultrasonic smoke forming device and can reduce manufacturing costs and oil leakage risk of the ultrasonic smoke forming device.

Owner:CHINA TOBACCO HUNAN INDAL CORP

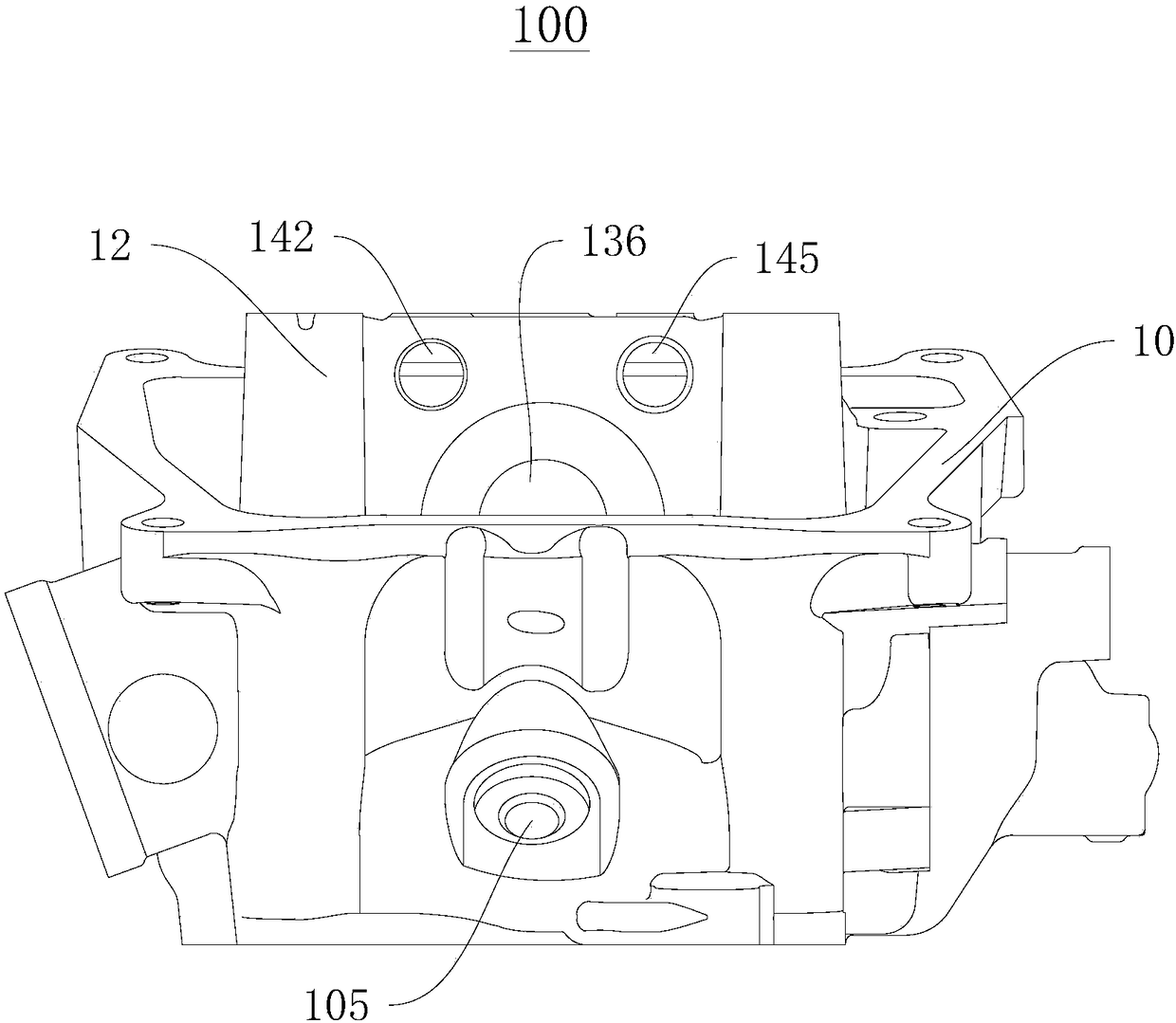

Air cylinder head and engine

PendingCN108131211AReasonable designCompact structureCylinder headsCylindersCylinder headEngineering

The invention discloses an air cylinder head and an engine, relating to the technical field of engines. The air cylinder head comprises a cylinder head matrix and a support seat which are integrally formed, wherein the support seat is located in the cylinder head matrix and forms a mold cavity with the cylinder head matrix; the cylinder head matrix comprises a first mounting surface and a second mounting surface, the first mounting surface is located at the top of the cylinder head matrix and is fixedly connected with an air cylinder cover, the second mounting surface is located at the bottomof the cylinder head matrix and is fixedly connected with an air cylinder body, and the first mounting surface is obliquely arranged relative to the second mounting surface to enable the cylinder headmatrix to form relatively high and low sides; and a perforated chain cavity is formed in the high side and is located between the cylinder head matrix and the support seat, and a sparking plug mounting hole is formed in the lower side, is located on one side, close to the second mounting surface, of the cylinder head matrix and is obliquely formed relative to the second mounting surface. The aircylinder head is reasonable in design and convenient to produce, manufacture and assemble, the production difficulty is greatly reduced, the production and assembling processes are simplified, and theproduction cost is lowered.

Owner:CHONGQING LONCIN ENGINE +1

Dynamic Demonstration Model of Oil Drilling Well Control Device

ActiveCN105632321BAvoid the risk of oil spillsEasy maintenanceEducational modelsLine tubingWell drilling

The present invention discloses a dynamic demonstration model of a petroleum drilling well control device. The dynamic demonstration model of the petroleum drilling well control device comprises a driller's console, a remote console, a throttle manifold control cabinet, and a liquid-gas separator, a throttle manifold, a blowout preventer stack and a kill manifold which are connected in order; the throttle manifold, the blowout preventer stack and the kill manifold are respectively installed at different interfaces of a drilling spool; the driller's console is connected with the remote console; the remote console is connected with the blowout preventer stack through a transparent pipeline, and the blowout preventer stack is internally provided with a light band G1; the throttle manifold control cabinet is connected with the throttle manifold; the three-position four-way air rotary valve and the two-position four-way slide valve of the driller's console are able to pass through the three-position four-way change valves of an air control remote console to control the switch of the blowout preventer stack; the lamp strip is arranged in the associated line of the remote console and the blowout preventer stack; and proximity switches are arranged in the three-position four-way change valves to control the switching of the lamp strip. The dynamic demonstration model of a petroleum drilling well control device is able to visually demonstrate the actual running condition of the device in different work states and improve the operation safety.

Owner:TIANJIN LUYA SCI & TECH CO LTD

Device and method for positioning fault in transformer shell

PendingCN113391174AAchieve positioningReduce security risksSubsonic/sonic/ultrasonic wave measurementTransformers testingTransformerMechanical engineering

The invention provides a device and a method for positioning a fault in a transformer shell. The device comprises a refrigeration sheet, a thermoelectric power generation unit, a plurality of vibration sensors, and an ultrasonic wave transmission module. The refrigeration sheet is installed at the outer side of the shell of a transformer; the thermoelectric power generation unit is mounted on the inner side of the shell of the transformer and is opposite to the refrigeration sheet in position; the plurality of vibration sensors are installed in the transformer, the optimal arrangement scheme of the vibration sensors in insulating oil is determined according to a sensor optimal configuration model, and the vibration sensors are used for detecting and positioning the vibration condition in the transformer in a plurality of different directions in the insulating oil; the plurality of vibration sensors are connected with the thermoelectric power generation unit so as to be powered by the thermoelectric power generation unit; and the ultrasonic wave transmission module is used for sending the vibration condition and the positioning information in the transformer to a terminal outside the transformer. According to the invention, the positioning of a fault source is achieved, the fault measurement precision is higher, and richer information is reflected.

Owner:DALI BUREAU OF ULTRA HIGH VOLTAGE TRANSMISSION CO CHINA SOUTHERN POWER GRID CO LTD

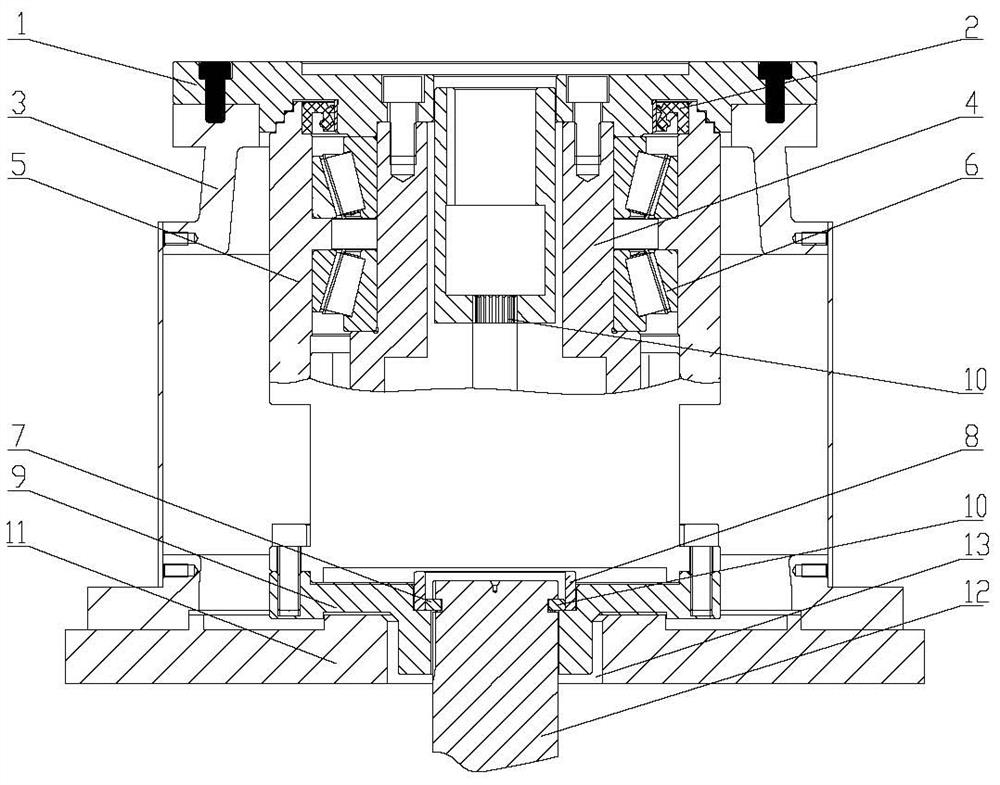

Novel brake caliper body structure

PendingCN114396443APrecise positioningFirmly connectedBrake actuating mechanismsActuatorsInterference fitEngineering

The invention discloses a novel brake caliper body structure which comprises a left caliper body, a right caliper body and a brake disc, matching protruding parts are arranged on the matching faces of the left caliper body and the right caliper body, the brake disc is arranged below the matching protruding parts between the left caliper body and the right caliper body, and a positioning column is arranged between the matching protruding parts. Connecting holes are formed in the two sides of the matched protruding part of the left clamp body and the two sides of the matched protruding part of the right clamp body, the connecting hole in the left clamp body is connected with the connecting hole in the right clamp body through a connecting bolt, a positioning hole is formed in the matched protruding part, and the positioning hole is formed in one side of the connecting hole. The two ends of the positioning column are connected with the positioning holes in an interference fit mode, the positioning column is conveniently connected and positioned through the positioning holes, and the left clamp body and the right clamp body are reliably connected together through the positioning column. The clamp is novel in structural design and convenient to install, matched positioning between the clamp bodies is facilitated, the strength between the clamp body matching faces is improved, and the risk of oil leakage of the clamp bodies is eradicated.

Owner:XINXIANG KEGONG IND

Variable stiffness joint hydraulic driving system for exoskeleton robot

ActiveCN113232014AAvoid the risk of oil spillsImplement storageProgramme-controlled manipulatorExoskeleton robotControl engineering

The invention relates to the field of hydraulic driving systems, in particular to a variable stiffness joint hydraulic driving system for an exoskeleton robot. The variable stiffness joint hydraulic driving system comprises a left leg variable stiffness joint driving system and a right leg variable stiffness joint driving system which are respectively used for driving a left leg and a right leg and have the same internal structure, wherein each driving system comprises a hydraulic power module and a joint driving module for assisting in driving a human body to walk. According to the variable stiffness joint hydraulic driving system, a distributed power source is adopted to replace a centralized hydraulic power source in an exoskeleton backpack, the oil leakage risk caused by more oil pipes and oil pipe joints of the centralized hydraulic power source is solved, the complexity of system control is reduced, meanwhile, the centralized hydraulic power source is decomposed into a distributed hydraulic power source, a common bearing backpack of a hydraulic drive type lower limb exoskeleton can be replaced, the backpack-free mode is achieved, and the overall structure is more concise.

Owner:芜湖云擎机器人科技有限公司

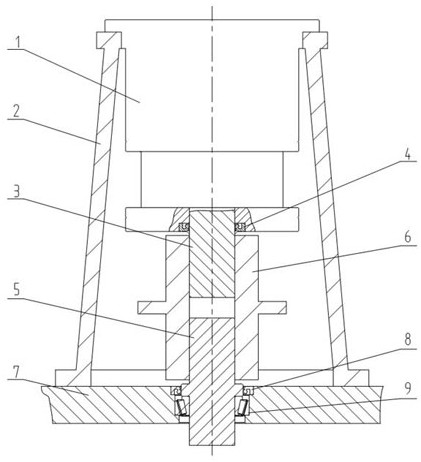

Vertical transmission structure

PendingCN114832715ALower the altitudeAxial space savingTransportation and packagingMixer accessoriesReduction driveEngineering

The invention relates to the technical field of vertical stirring equipment driving devices, in particular to a vertical transmission structure which can reduce axial height, save space and solve the problem of oil leakage, a speed reducer is installed on a supporting seat, the bottom of the speed reducer is connected with a stirring shaft, and the vertical transmission structure is characterized in that the speed reducer comprises a speed reducer middle sleeve and a speed reducer shell; a speed reducer bearing is arranged between the speed reducer shell and the middle sleeve, a lower flange is connected to the bottom of the speed reducer shell, a stepped hole is formed in the middle of the upper end face of the lower flange, a lantern ring is arranged on the stepped face of the stepped hole, and a baffle ring is arranged on the inner side of the lantern ring. The stirring shaft penetrates through the stepped hole and is connected with the lower flange through a key; and an annular groove matched with the baffle ring is formed in the peripheral surface of the stirring shaft.

Owner:南京武岳机械设备有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com