Return airflow atomizer and electronic cigarette comprising atomizer

A technology of airflow atomization and ventilation holes, which is applied in the field of electronic cigarettes, can solve the problems of oil leakage in electronic cigarette atomizers, and achieve the effect of eliminating oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

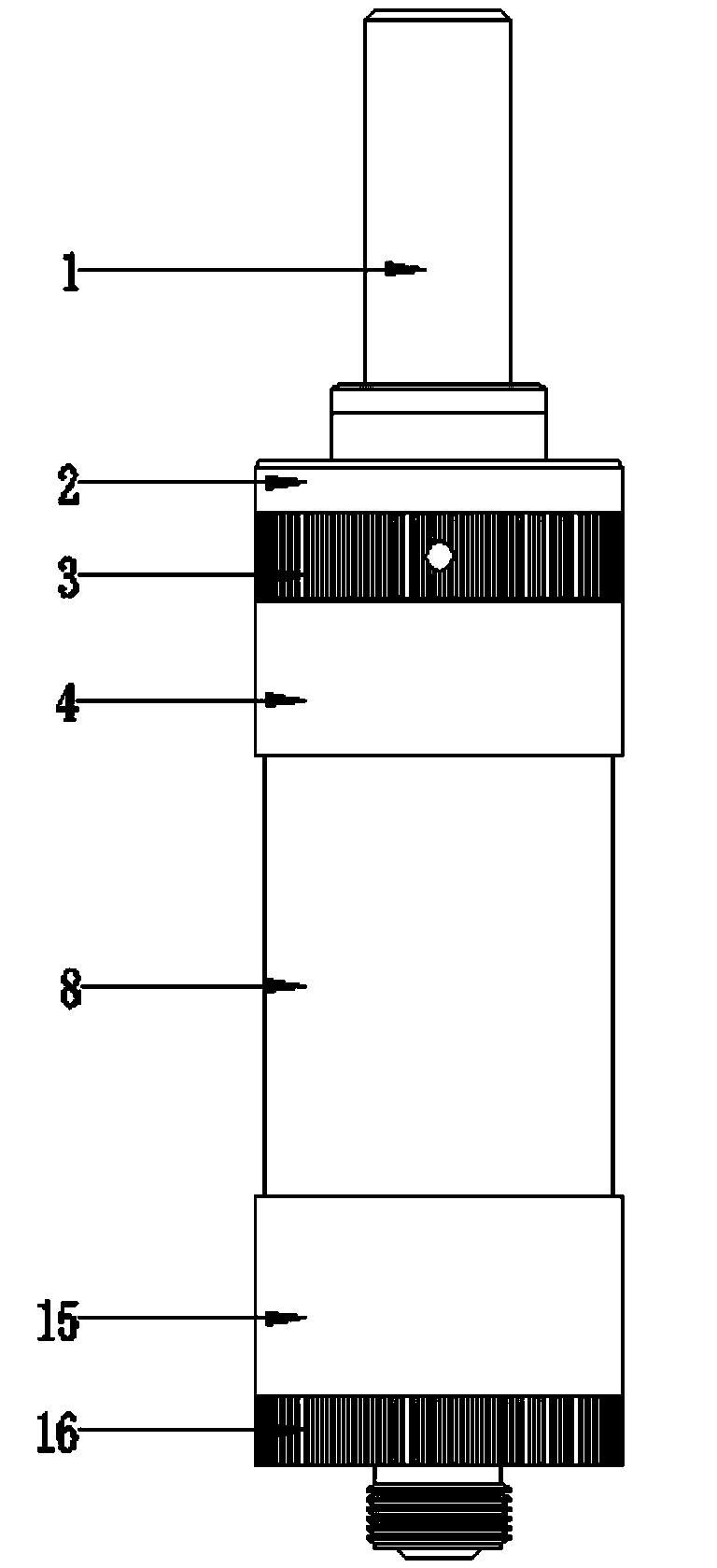

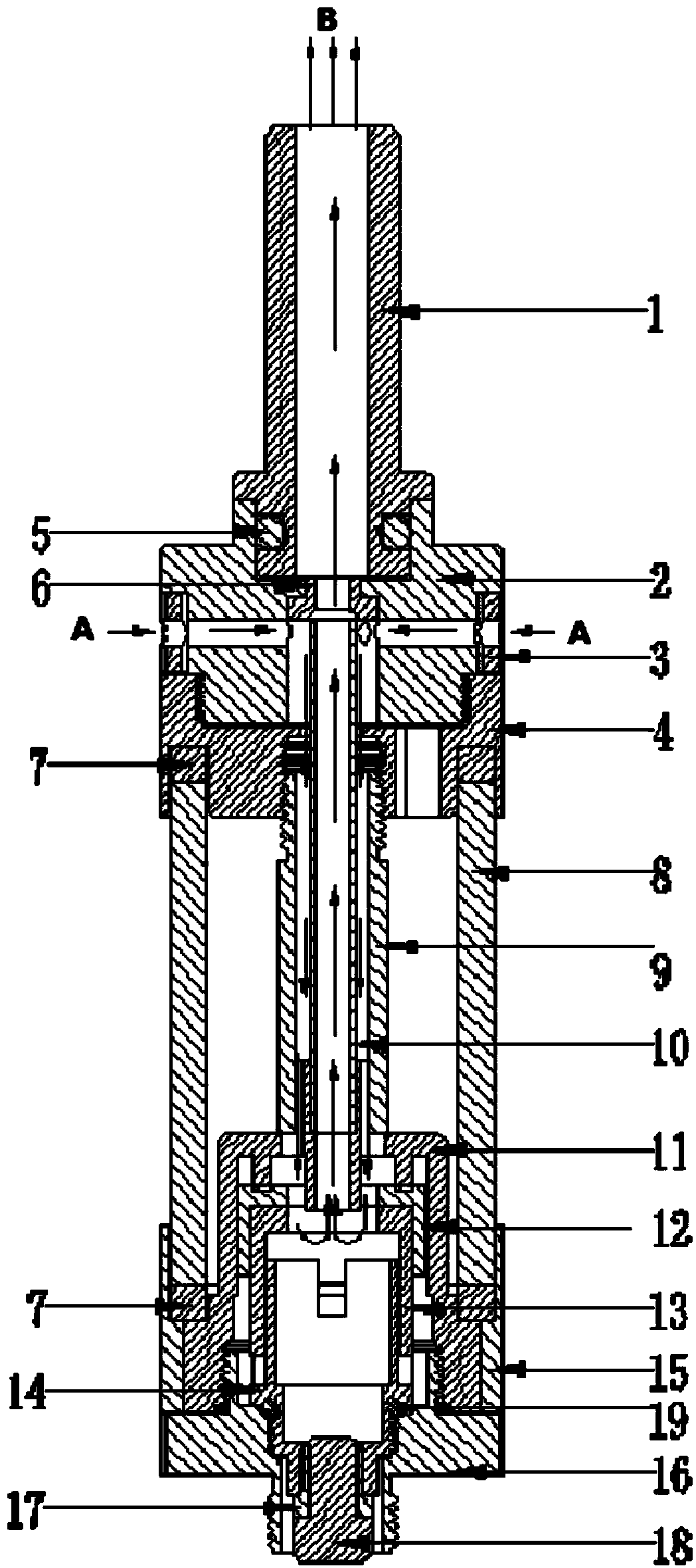

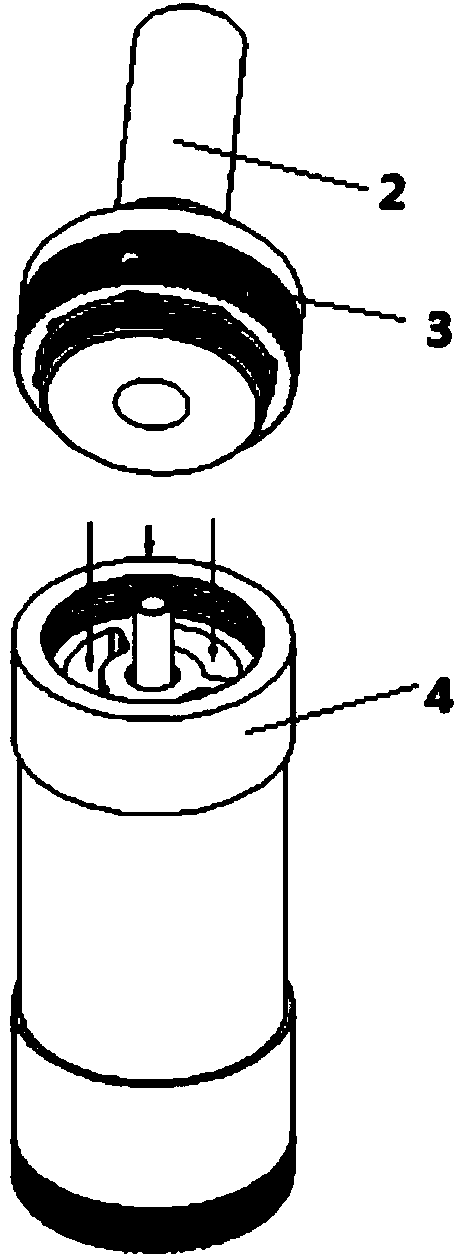

[0024] like figure 2 , Figure 6A , Figure 6B , Figure 6C as shown, figure 2 is a sectional view of the present invention; Figure 6A It is a three-dimensional view of the overall structure of the present invention, Figure 6B Yes Figure 6A Enlarged view of the upper half of the Figure 6C Yes Figure 6A Enlarged view of the lower half of ;

[0025] The atomizer of the present invention comprises: a suction nozzle 1, a top external thread 2, a vent valve 3, a vent thread 4, a first O-ring 5, a damping ring 6, a liquid blocking pad 7, a glass tube 8, an air guide tube 9, a vent Trachea 10, bottom internal thread 11, silicone sheath 12, atomization pressure piece 13, atomization internal thread 14, thread sleeve 15, bottom thread 16, silicone ring 17, contact piece 18, second O-ring 19.

[0026] The bottom of the suction nozzle 1 is installed on the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com