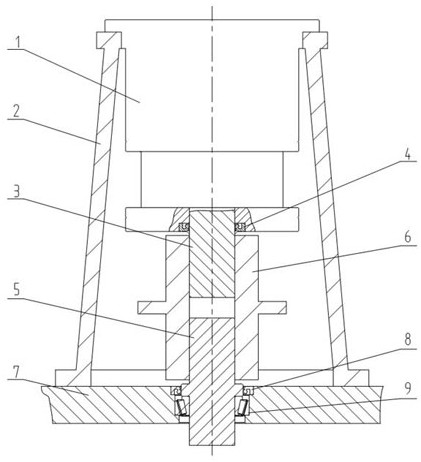

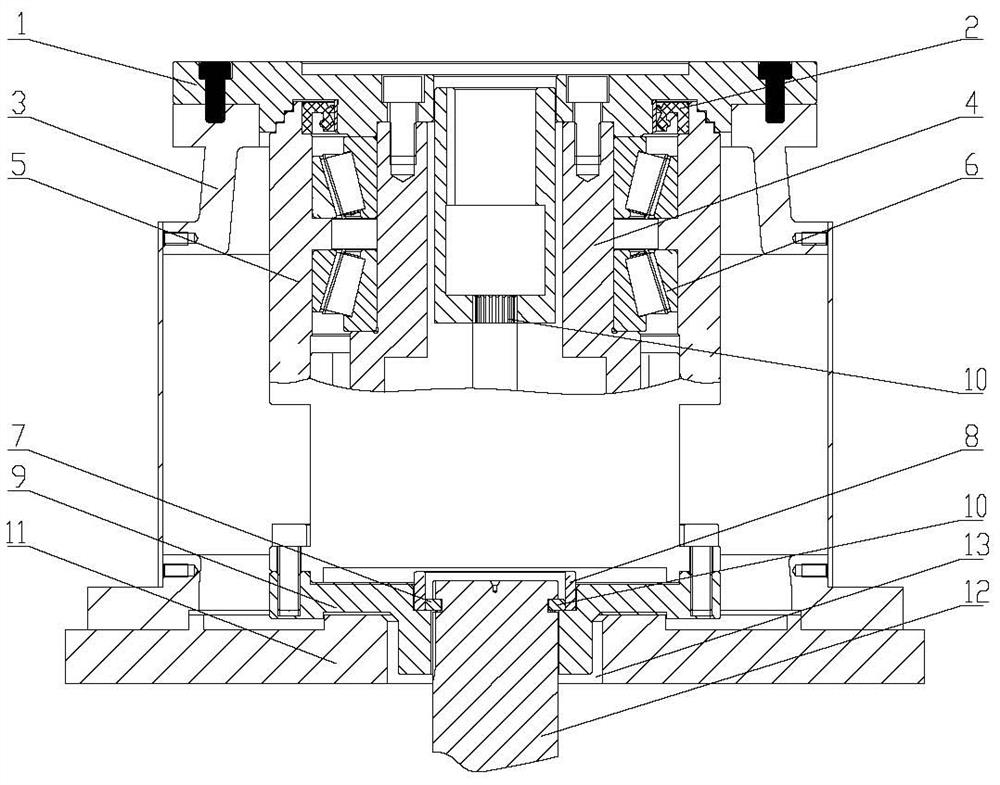

Vertical transmission structure

A transmission structure, vertical technology, applied in mixers, dissolving, chemical instruments and methods, etc., can solve the problems of high axial height, large space occupation, etc., achieve the reduction of length and height of support seat, compact structure, and solve leakage problems. Effects of oil problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] See figure 2 As shown, a vertical transmission structure includes a reducer, the reducer is mounted on a support base 3, the bottom of the reducer is connected to a stirring shaft 12, the reducer includes a reducer intermediate sleeve 4 and a reducer housing 5, and the reducer housing A reducer bearing 6 is arranged between 5 and the intermediate sleeve 4, the bottom of the reducer housing 5 is connected to the lower flange 9 by bolts, a stepped hole is opened in the middle of the upper end face of the lower flange 9, and a collar is arranged on the stepped surface of the stepped hole. 8. The inner side of the collar is provided with a retaining ring 7. The retaining ring 7 is formed by splicing two halves of half-circles together to form a complete retaining ring. The thickness of the retaining ring can be determined according to the axial force of the stirring shaft 12. After calculation, it is determined that the outer diameter of the baffle ring 7 is limited by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com