Dynamic Demonstration Model of Oil Drilling Well Control Device

An oil drilling and dynamic technology, applied in the field of oil drilling teaching, can solve the problems of potential safety hazards, intuitive inspection of students, poor sealing effect of model equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

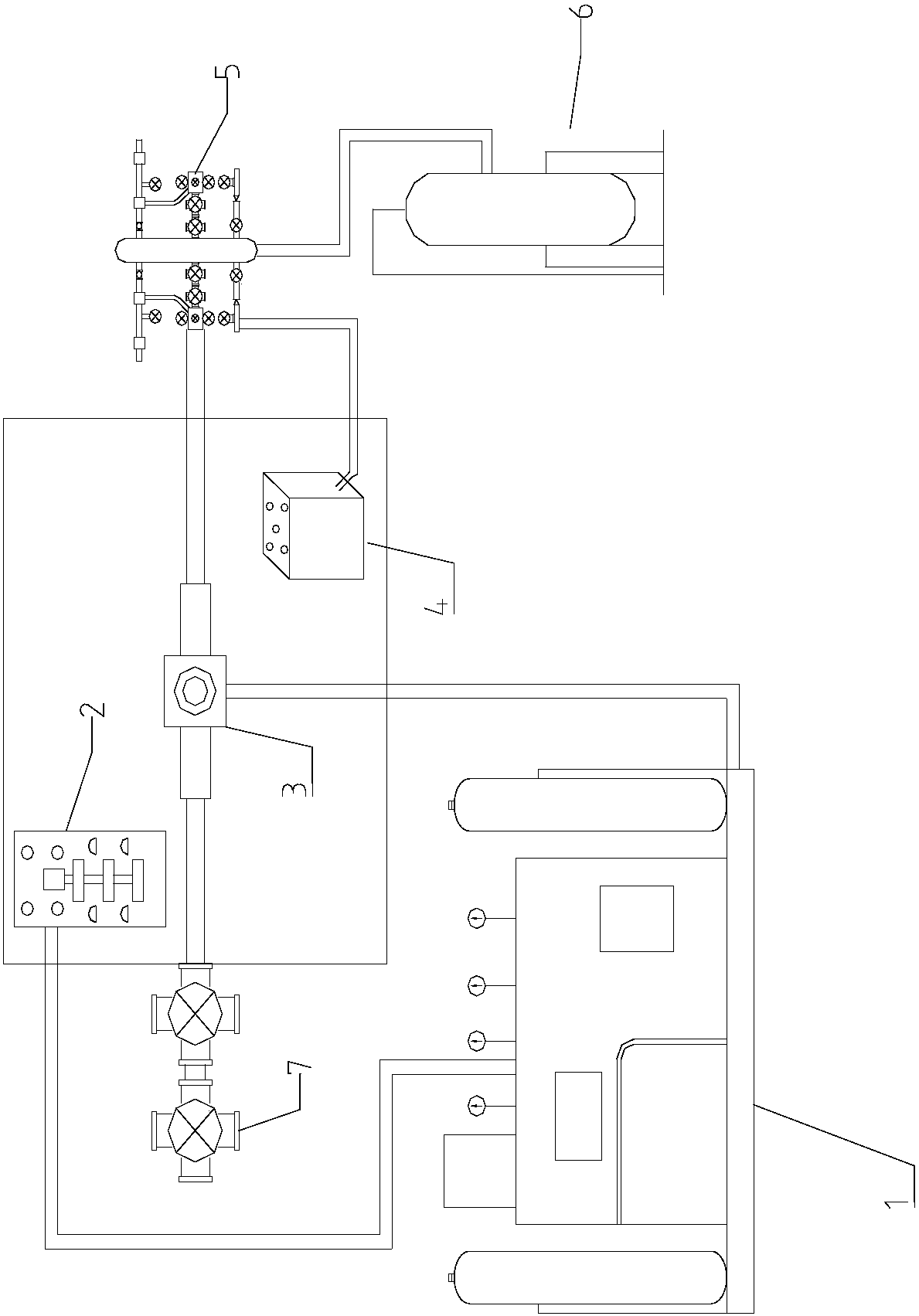

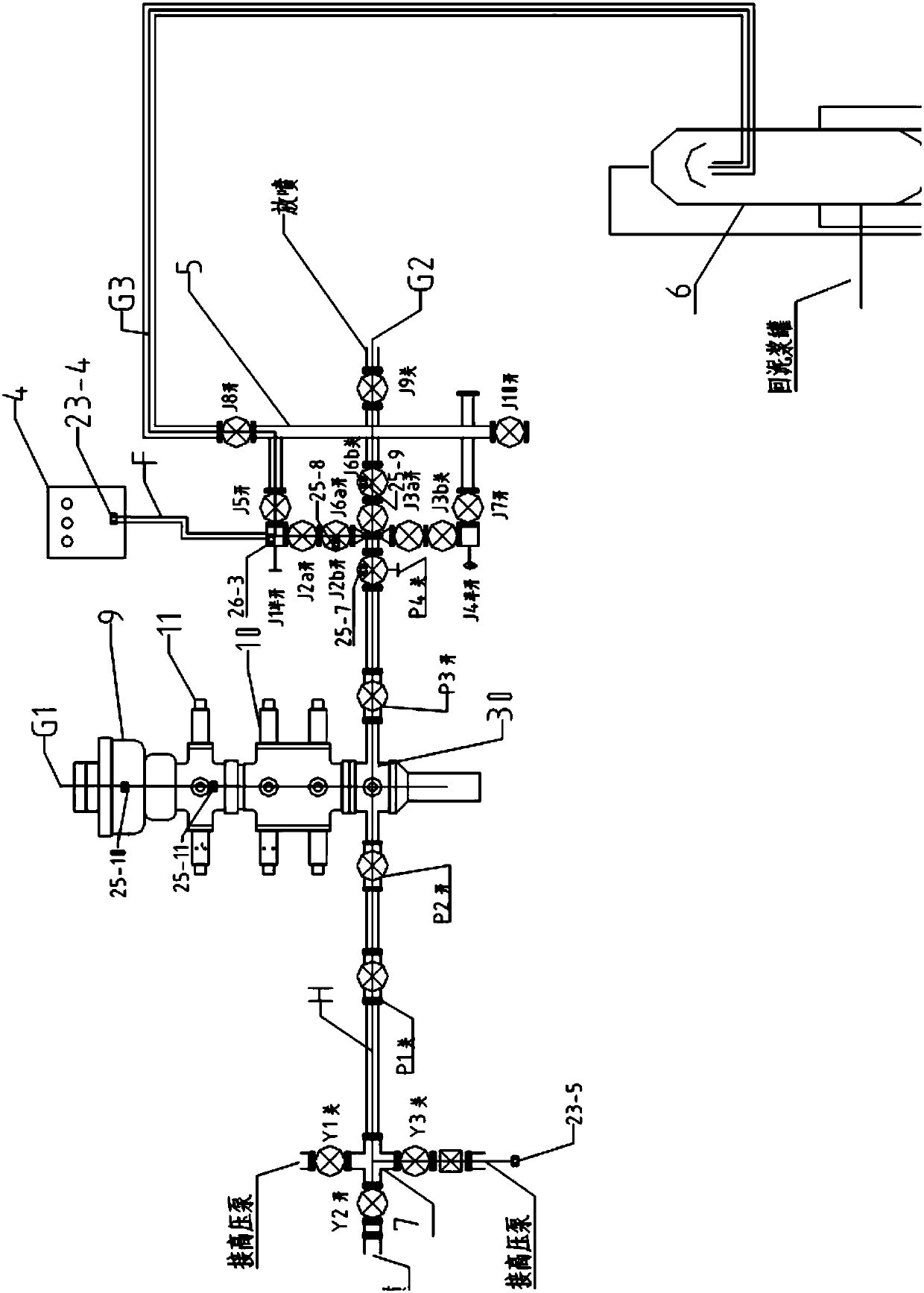

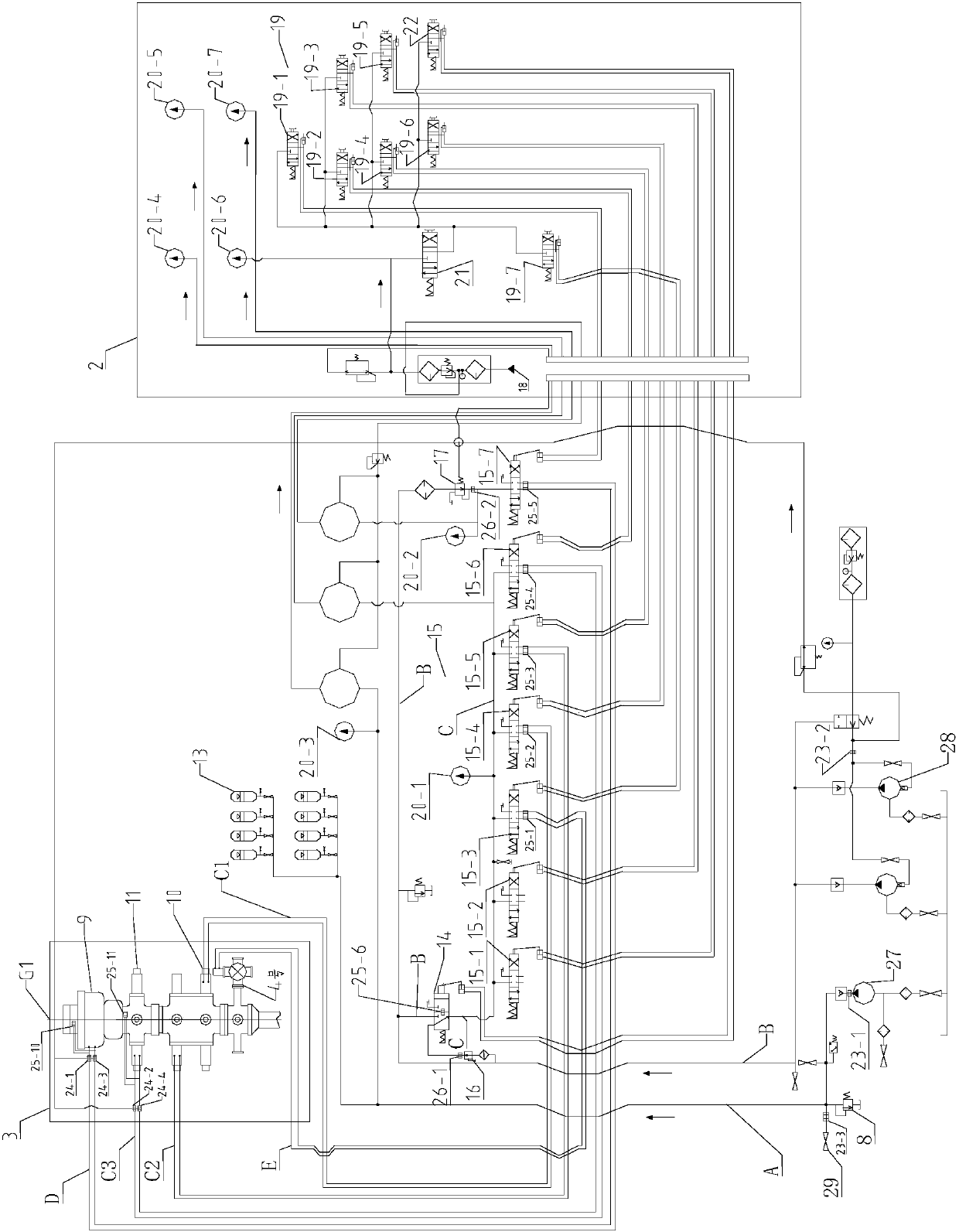

[0027] The following combination Figure 1~3 and specific embodiments describe the technical solution of the present invention in detail.

[0028] A dynamic demonstration model of an oil drilling well control device installed on a simulated rig floor, including a driller's console 2, a remote console 1, a choke manifold control box 4, and a liquid-gas separator 6 connected in sequence, a choke Manifold 5, blowout preventer group 3 and kill manifold 7; and the choke manifold 5, blowout preventer group 3 and kill manifold 7 are respectively installed at different interfaces of the drilling spool 30; The driller console 2 is connected to the remote console 1; the remote console 1 is connected to the blowout preventer group 3; the choke manifold control box 4 is connected to the choke manifold 5; the blowout preventer Group 3 is composed of annular blowout preventer 9, single ram blowout preventer 11 and double ram blowout preventer 10 arranged in sequence from top to bottom, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com