Variable stiffness joint hydraulic driving system for exoskeleton robot

An exoskeleton robot and drive system technology, which is applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of non-adjustable hydraulic cylinder stiffness, multiple oil pipe joints, and oil leakage, so as to improve wearing comfort and realize The effect of driving variable stiffness and reducing power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

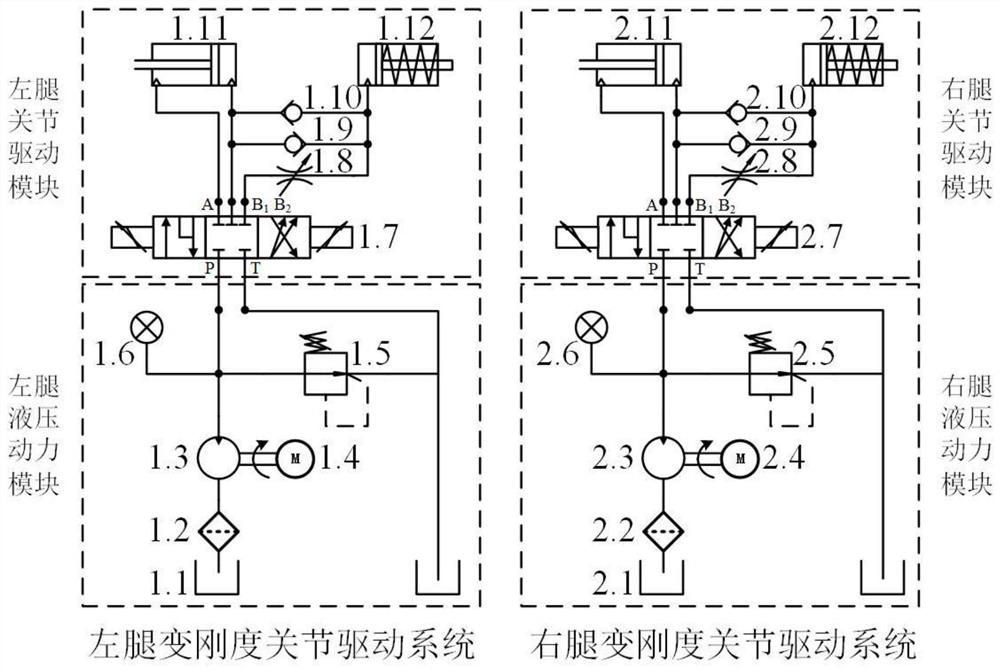

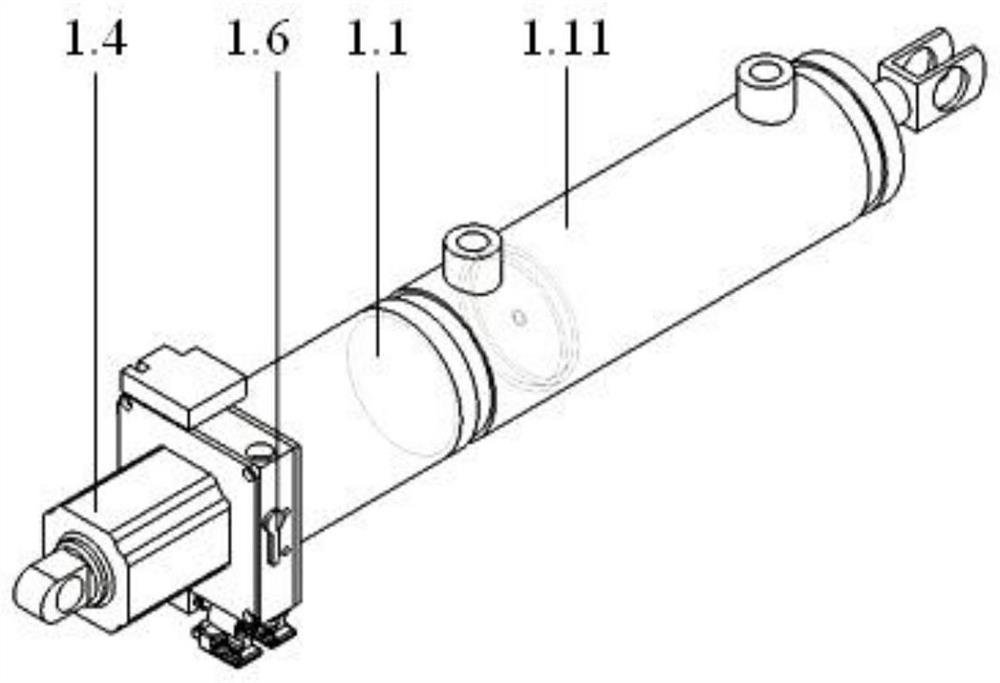

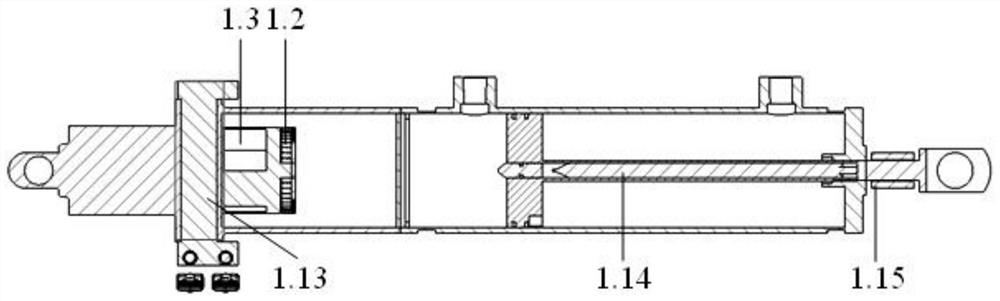

[0022] Such as Figure 1 to Figure 7 As shown, it includes the left leg variable stiffness joint drive system and the right leg variable stiffness joint drive system respectively used to drive the left leg and the right leg with the same internal structure. The drive system includes a hydraulic power module and a joint drive module that assists in driving the human body to walk .

[0023] The present invention uses a distributed power source to replace the centralized hydraulic power source in the exoskeleton backpack, which solves the risk of oil leakage caused by a large number of oil pipes and oil pipe joints in the centralized hydraulic power source, reduces the complexity of system control, and simultaneously integrates the centralized The hydraulic power source is decomposed into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com