Air cylinder head and engine

A cylinder head and cylinder head technology, applied in the direction of engine components, machines/engines, cylinders, etc., can solve the problems of complex production process, cumbersome assembly, and difficult machining of cylinder heads, etc., to achieve compact structure, simplify assembly process, avoid The effect of oil spill risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

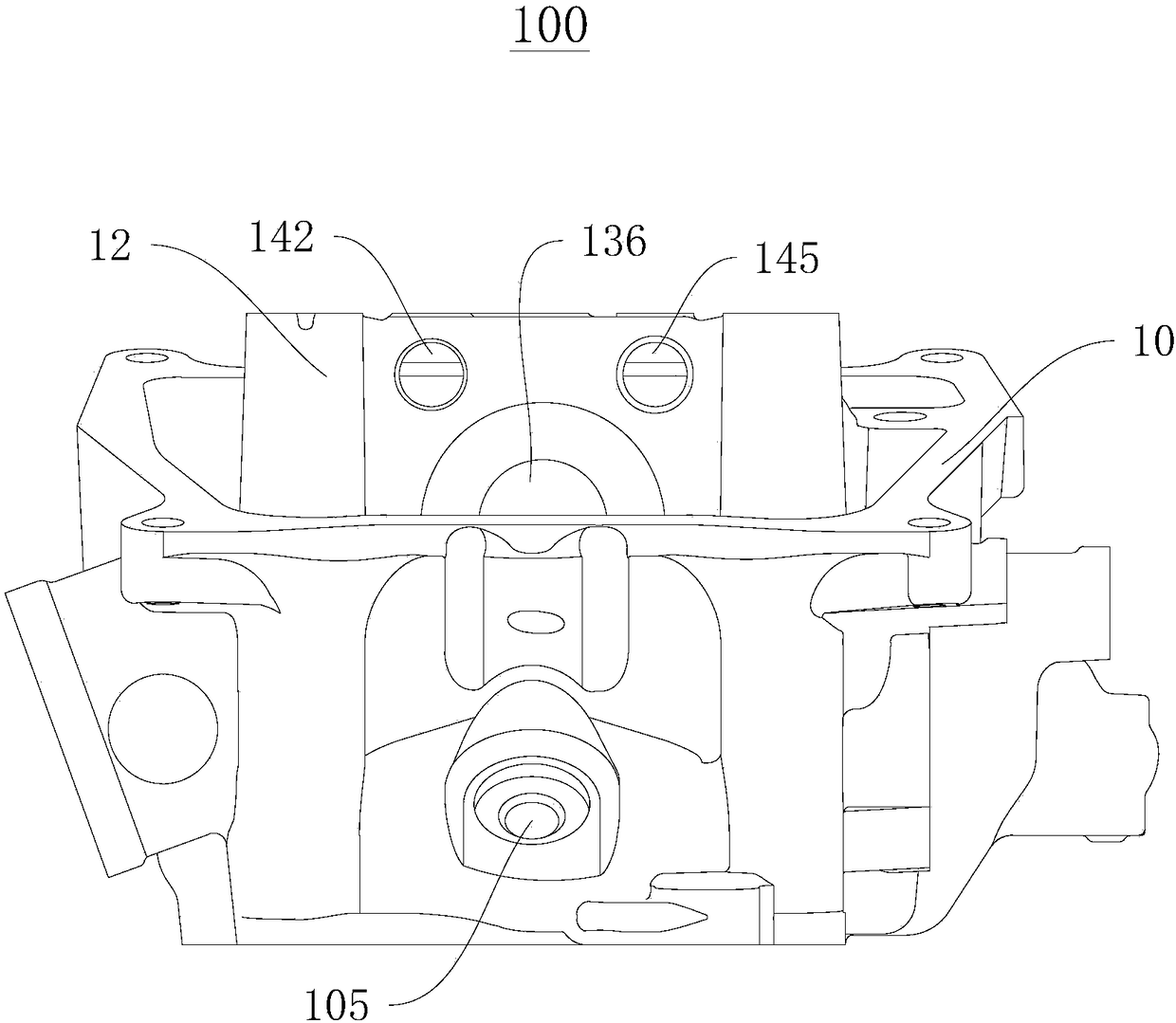

[0046] figure 1 A schematic structural view of the cylinder head 100 provided in this embodiment at a first viewing angle. Please refer to figure 1 shown. The cylinder head 100 includes an integrally formed cylinder head base 10 and a support base 12 , wherein the support base 12 is located inside the cylinder head base 10 , and the support base 12 and the cylinder head base 10 form a cavity.

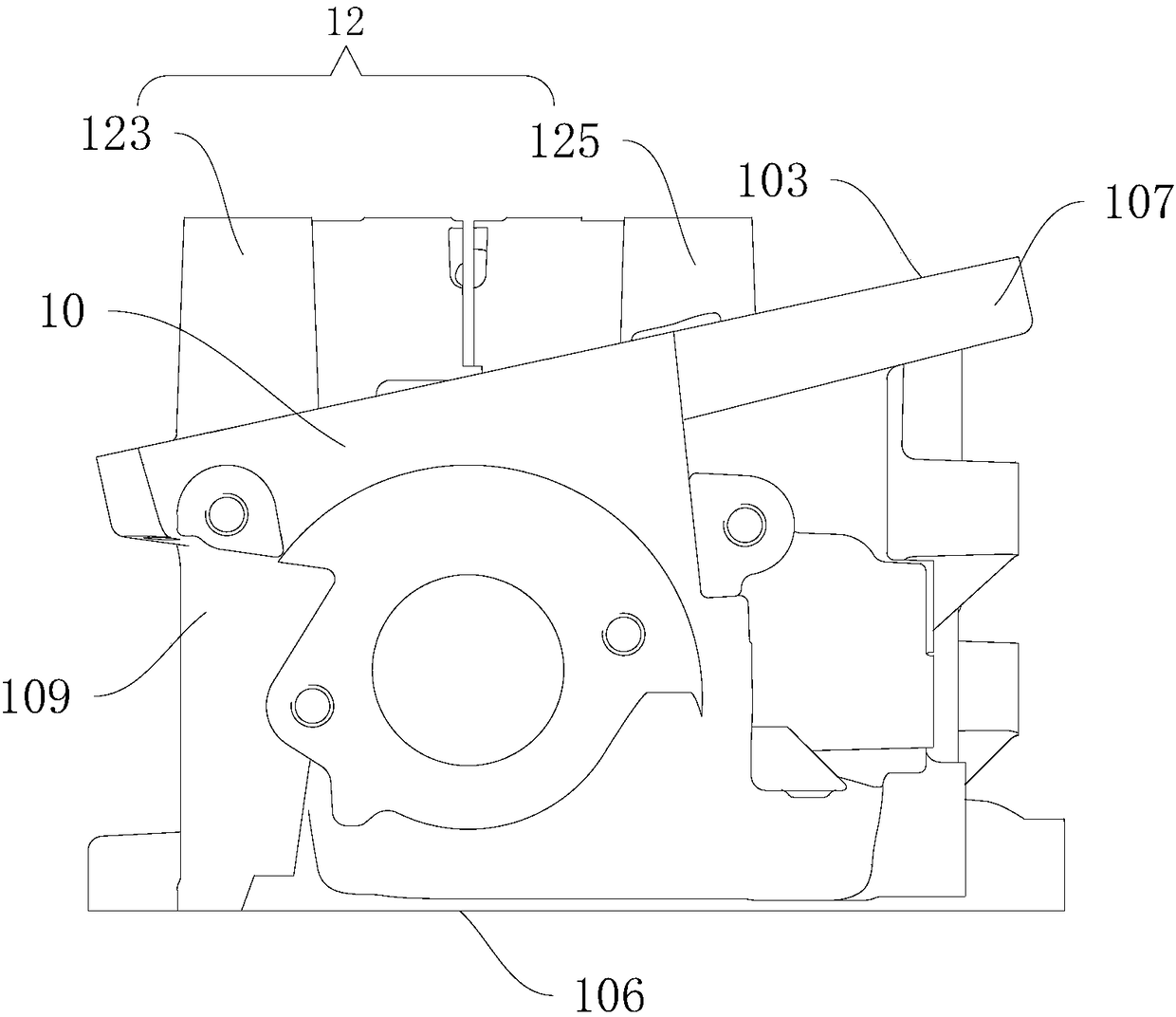

[0047] figure 2 A schematic structural diagram of the cylinder head 100 provided in the second viewing angle for this embodiment. Please refer to figure 2 shown. The cylinder head base 10 includes opposite first installation surfaces 103 and second installation surfaces 106, wherein the first installation surface 103 is located at the top of the cylinder head base 10, the second installation surface 106 is located at the bottom of the cylinder head base 10, and the cylinder head base 10 During installation, the second mounting surface 106 is matched with the cylinder block, the ...

Embodiment 2

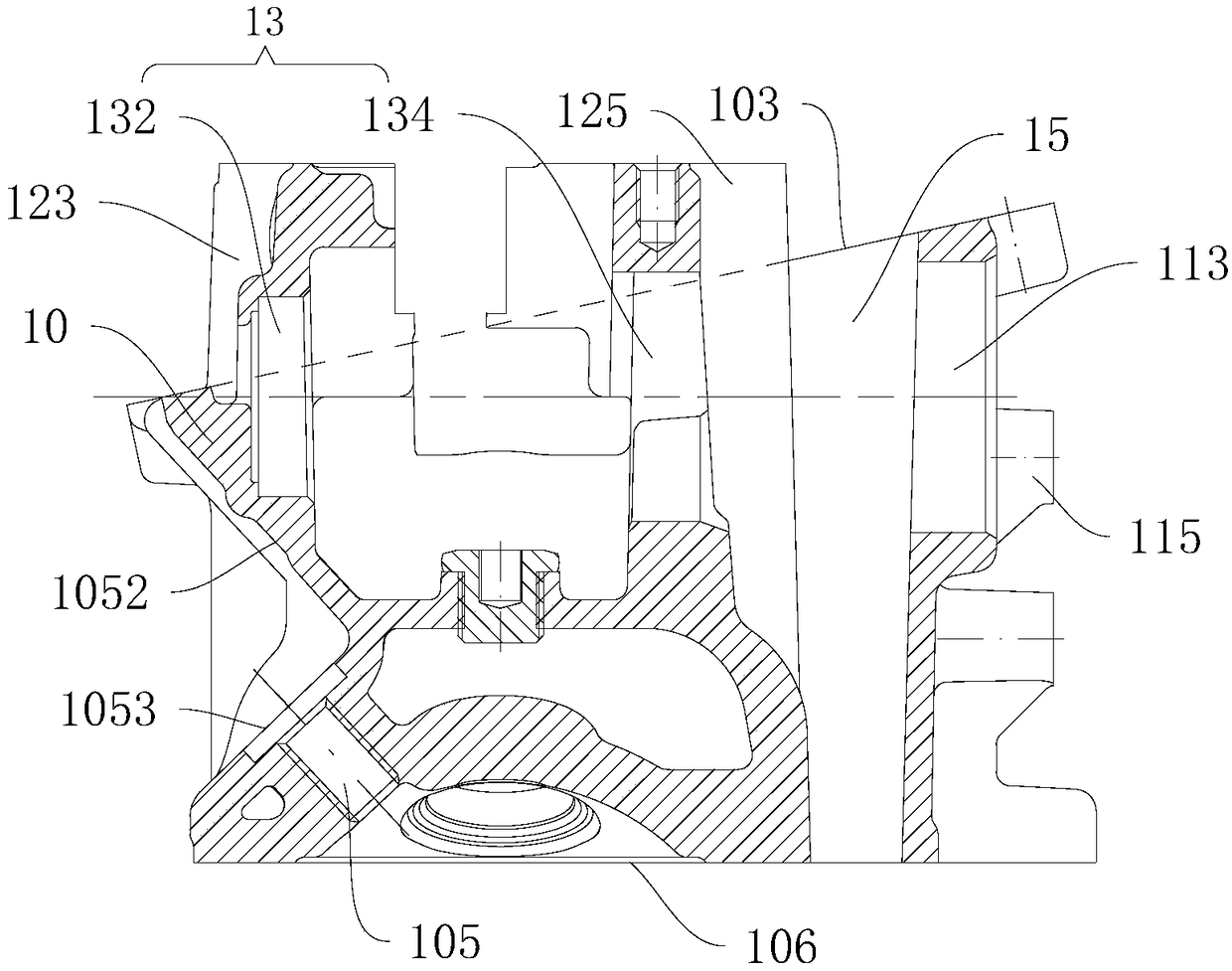

[0071] Embodiment 2 provides an engine, including a camshaft assembly 18, a rocker arm assembly, a water pump assembly 16, a spark plug assembly 17, and the cylinder head 100 provided in Embodiment 1, Image 6 A cross-sectional view of the engine is provided for Example 2. Please refer to Image 6 shown.

[0072] The spark plug assembly 17 is fixedly arranged in the spark plug installation hole 105, and the leaking part of the spark plug assembly 17 is just located in the accommodation space of the lower side 109 of the cylinder head base 10, which is convenient for assembly and does not interfere.

[0073] The camshaft assembly 18 is fixedly arranged on the camshaft mounting portion 13 of the support base 12. Specifically, the first bearing is embedded in the first camshaft mounting hole 132, and the second bearing is embedded in the second camshaft mounting hole 134. The first bearing and the second bearing are coaxially arranged, and the water pump assembly 16 is embedded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com