A positioning device for installing a fuel injector on a diesel engine

A technology for positioning devices and fuel injectors, which is applied to fuel injection devices, machines/engines, and charging systems. It can solve problems such as oil leakage and cylinder head covers that cannot be installed, and achieves convenient manufacturing, fast and convenient fixing and disassembly, and The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

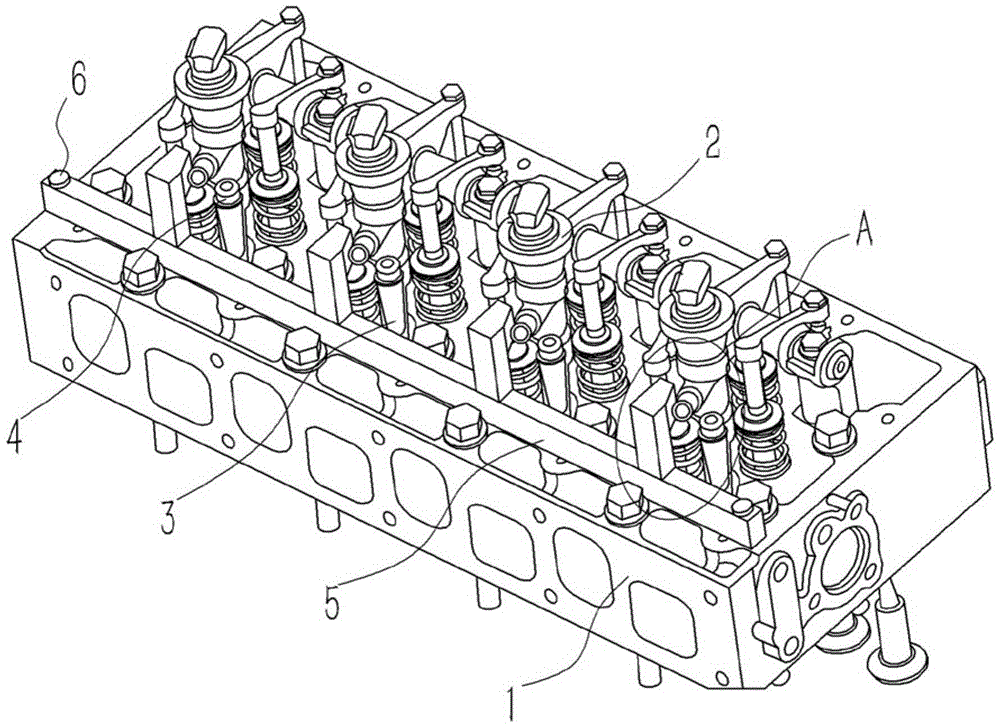

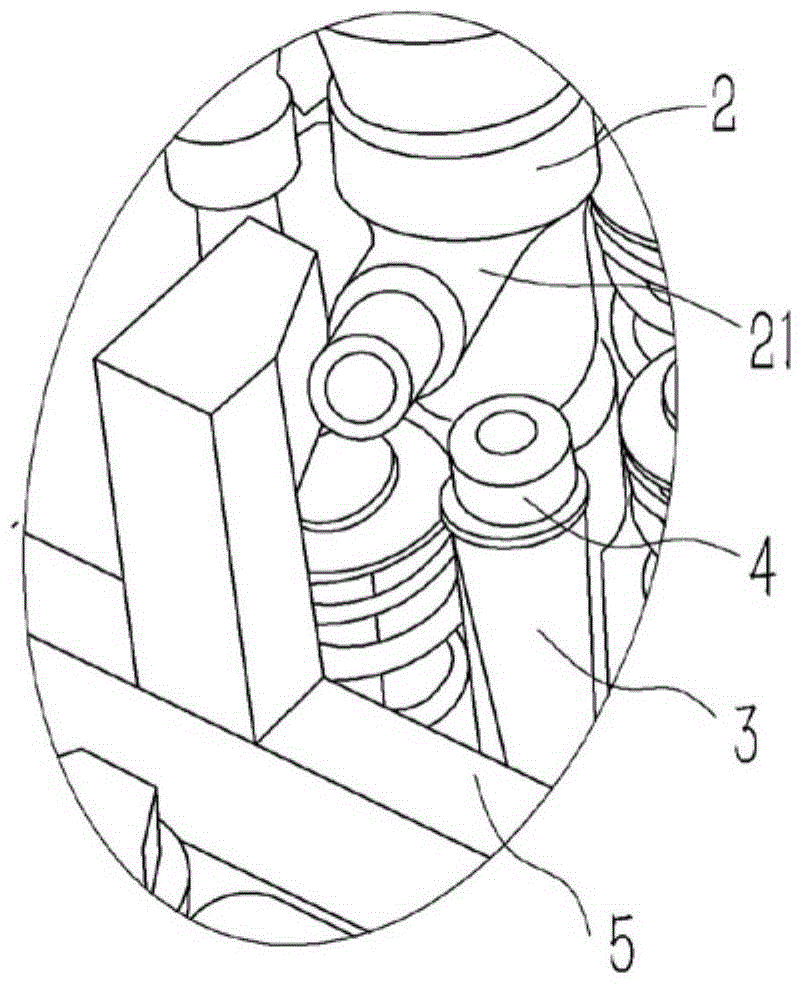

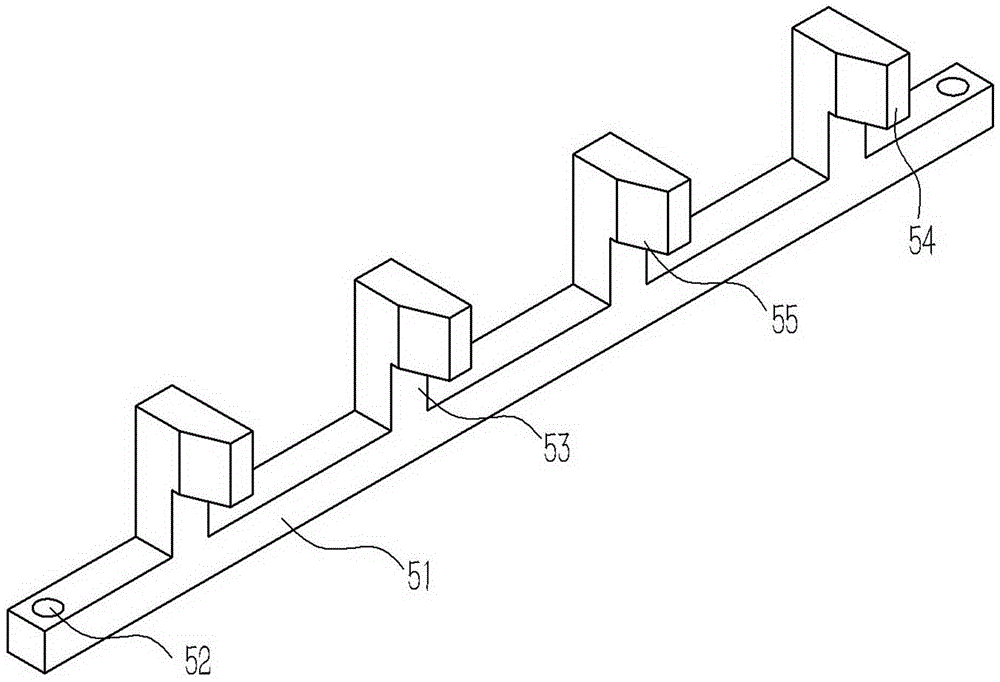

[0021] Example: see Figures 1 to 4 As shown, a positioning device for installing a fuel injector on a diesel engine includes a cylinder head 1 installed on the cylinder, a number of fuel injectors 2 are arranged on the cylinder head 1, and an oil inlet arm 21 is formed on the fuel injector 2. A positioning baffle 5 is installed on the cylinder head 1, and the positioning baffle 5 is composed of a cross bar 51, a vertical bar 53 and a stopper 54. A plurality of vertical bars 53 are formed on the horizontal bar 51, and the top of the vertical bar 53 is formed with a directional horizontal bar. 51 side extension block 54, the side wall of the block 54 is formed with a slope 55, the oil inlet arm 21 of the injector 2 leans against the slope 55 of the positioning baffle 5, and the two sides of the cross bar 51 The end is formed with a pin hole 52, and the positioning pin 6 is inserted into the cylinder head 1 through the pin hole 52 of the cross bar 51; Cover 1.

[0022] The inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com